Graco 231-830 Operation manual

Other Graco Paint Sprayer manuals

Graco

Graco MAGNUM 309225W User manual

Graco

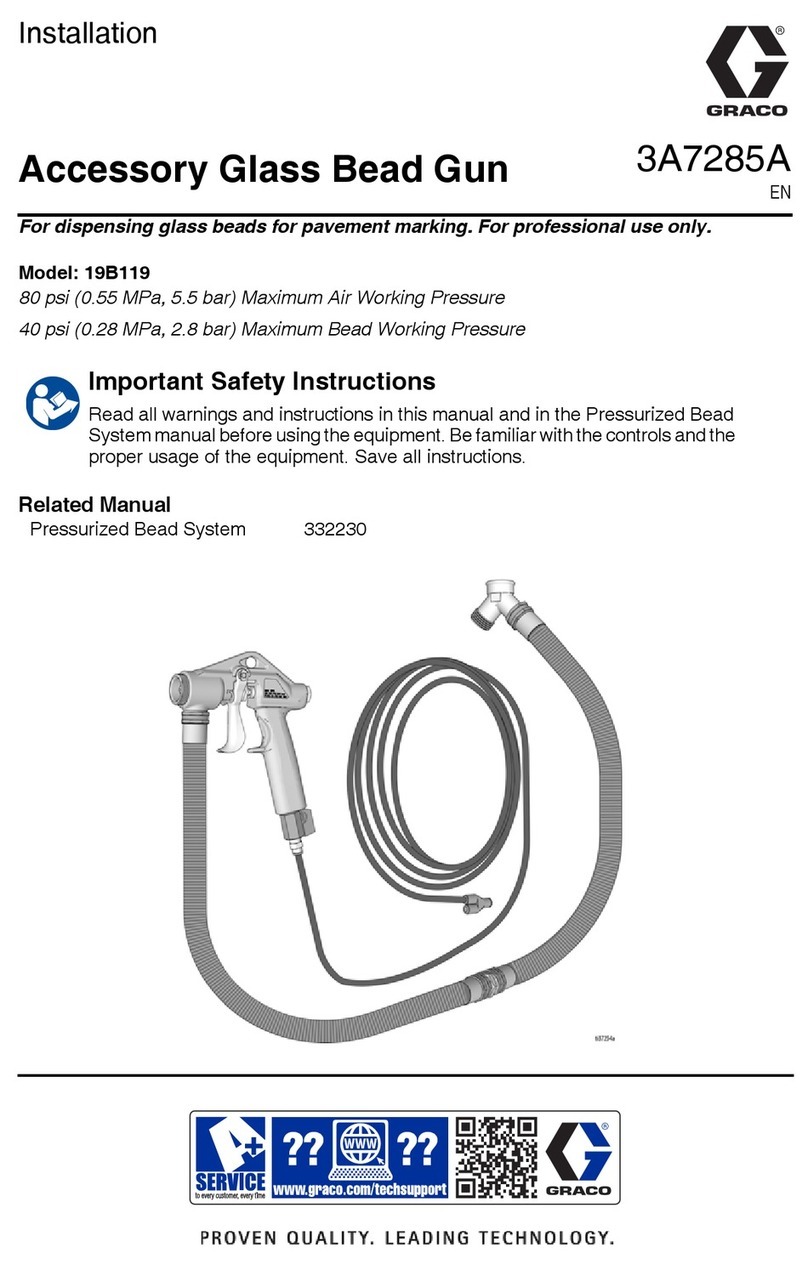

Graco 19B119 User manual

Graco

Graco Magnum User manual

Graco

Graco 3A1698F User manual

Graco

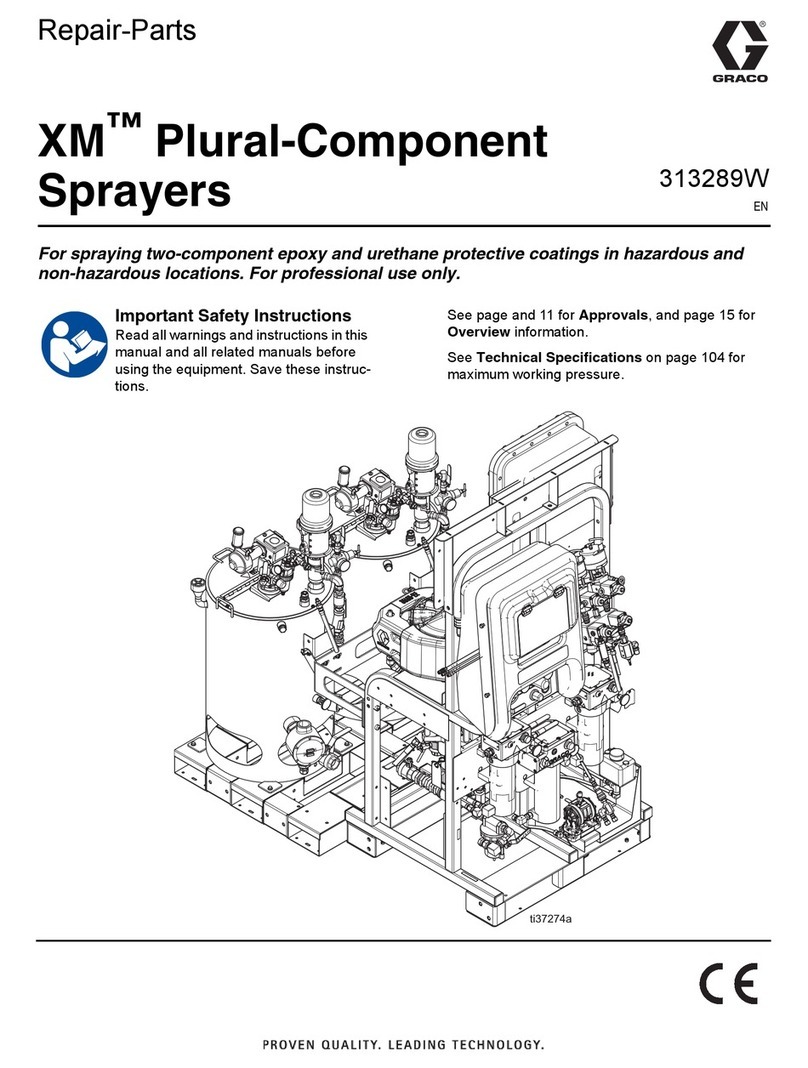

Graco XM Series Use and care manual

Graco

Graco ProComp HVLP 3800 User manual

Graco

Graco 238338 Operation manual

Graco

Graco RTX 1500 Use and care manual

Graco

Graco LineDriver Use and care manual

Graco

Graco 309489 User manual

Graco

Graco 313483A Use and care manual

Graco

Graco Reactor 3 E-XP1 Standard Instruction Manual

Graco

Graco SaniSpray HP ProPack 25T780 Use and care manual

Graco

Graco Sharpe Finex FX1000 Operation manual

Graco

Graco RTX-650 Operating instructions

Graco

Graco Reactor A-25 Use and care manual

Graco

Graco 308972R Operation manual

Graco

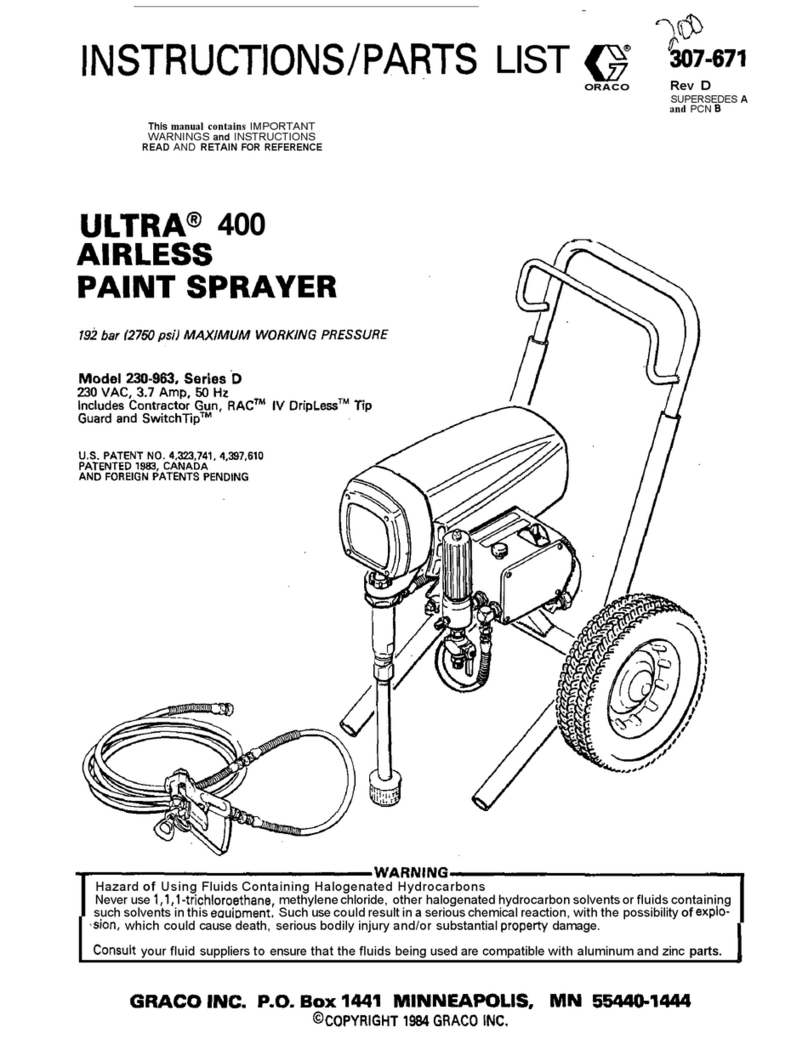

Graco ULTRA AIRLESS 230-963 Datasheet

Graco

Graco Fusion CS Series User manual

Graco

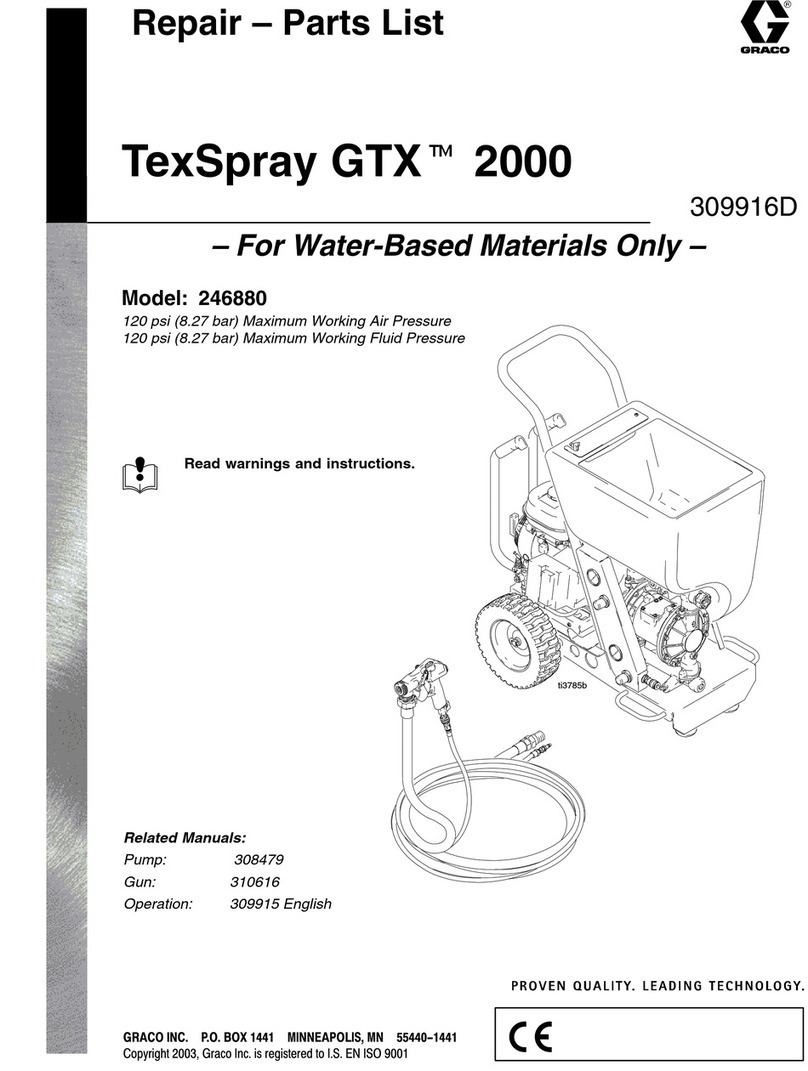

Graco TexSpray GTX 2000 Operation Manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual