MOVING PARTS HAZARD

~,~%,~~~-~

Moving parts can pinch or amputate yourfingers or other body

parts. KEEP CLEAR of moving parts when starting or operating

the sprayer. Follow the Pressure Rellet Procedure

on

page

2

before checking or servicing any part of the sprayer, to prevent

it from starting accidentally.

EQUIPMENT MISUSE HAZARD

EE%%

General

Safety

Any misuse of the spray equipment or accessories, such as

calsandfluids,orusingwornordamagedparts,cancausethem

overpressurizing. modifying parts, using incompatible chemi-

toruptureandresultinfluidinjection,splashingintheeyesoron

theskin,orotherseriousbodilyinjury,orfire,explosionorprop-

erty damage.

NEVER alter or modify any part

of

this equipment; doing

so

could cause

it

to malfunction.

CHECKallsprayequipmentregularlyandrepairorreplaceworn

or damaged parts immediately.

Alwayswearprotectiveeyewear,gloves,clothingandrespirator

as recommended by the fluid and solvent manufacturer.

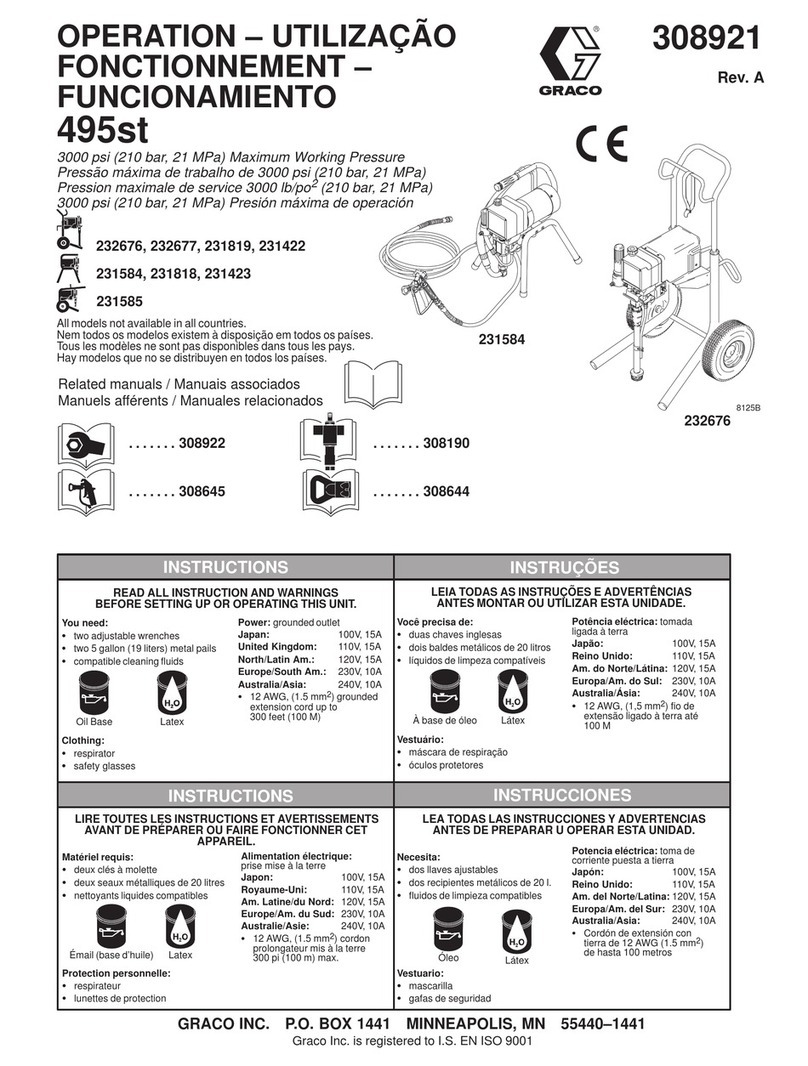

Thissprayercandevelop2750psi(195bar)MAXlMUMWORK-

System Pressure

/NGPRESSURE.Besurethatallsprayequipmentandaccesso-

themaximumworkingpressureofanycomponentoraccessory

lies used are rated to withstand this pressure.

DO

NOT exceed

used in the system.

Fluid

and

Solvent Compatibility

BE SURE that all fluids and solvents used are chemically com-

patiblewiththewettedpartsshownintheTECHNICALDATAon

ture before using them in this sprayer.

page32.Alwaysreadthefluidandsolventmanufacturer'sI~era-

Do

not use l,l,l-trichloroethane, methylenechloride. otherha-

vents in this equipment, which contains aluminum andlor zinc

logenated hydrocarbon solvents or fluids containing such

sol-

parts. Such use could result in a serious chemical reaction, with

the possibility of explosion, which could cause death, serious

bodily injury andlor substantial property damage.

HOSE SAFETY

:::~~.r

~~,~,~,,,,,~~~,~~.....;..-..."",r~,~

.~i~,~.~~",~.~l;i",~

.

-"-e

High pressure fluid in the hoses can be very dangerous.

If

the

hose develops a leak, split or rupture due to any kind of wear,

damage or misuse, the high pressure spray emitted from

it

can

cause a fluid injection injuty or other serious bodily injuty or

property damage.

ALLFLUIDHOSESMUSTHAVESPRINGGUARDSONBOTH

at or close

to

the coupling which can result in hose rupture.

ENDSlSpringguardshelpprotectthehosefromkinksorbends

TIGHTEN all fluid connections securely before each use. High

pressurefluidcan dislodgea loose coupling orallow high pres-

sure spray to be emitted from the coupling.

NNERuseadamagedhose.Beforeeachuse,checktheentire

hose for cuts, leaks, abrasion, bulging cover, or damage or

movementofthehosecouplings.Ifanyoftheseconditionsexist,

sure hose or mend it with tape or any other device.

A

repaired

replacethehoseimmediately.DON0Ttrytorecouplehighpres-

hose cannot contain the high pressure fluid.

HANDLE AND ROUTE HOSES CAREFULLY

Do

not puli

on

and hot surfaces ofthe pump and

gas engine.

Do

not use fluids

hoses to move equipment. Keep

hoses clear

of moving parts

or solvents which are not compatible with the inner tube and

coverofthe hose. DONOTexposeGraco hosetotemperatures

above 180° F

(82"

C) or below

-40"

F

(-40'

C).

Hose

Grounding Continuity

Proper hose grounding continuity is essential to maintaining a

fluidhosesatleastonceaweek.1fyourhosedoesnothaveatag

groundedspraysystem. Checktheelectrical resistanceof your

on

itwhich specifiesthemaximum electrical resistance, contact

the hose supplier or manufacturer for the maximum resistance

limits. Use a resistance meter in the appropriate range for your

ommended limits. reolace it immediatelv. An unarounded or

hose to check the resistance.

If

the resistance exceeds the rec-

,,*,

:,,.*...

poorly grounded

hose

can make your syetem haz;?rdous.

Also

read

FIRE

OR

EXPLOSION

HAZARD.

Staticelectricityiscreatedbytheflowoffiuidthroughthepump

and hose.

If

every part of the spray equipment is not properly

grounded, sparking may occur, and the system may become

hazardous. Sparking may also occur when plugging in or un-

pluggingapowersupplycord.Sparkscanignitefumesfromso1-

vents and the fluid being sprayed, dust particles and otherflam-

mable substances, whether you are spraying indoors

or

outdoors, and can cause afire or explosion and serious bodily

injury and property damage. Plug the sprayer into

a

grounded

outlet at least

20

n.

(6

m) from the sprayer.

Ifyouexperienceanystaticsparkingorevenaslightshockwhile

the entire system for proper grounding.

Do

not use the system

usingthisequipment,STOPSPRAYlNGIMMEDIATELY.Check

again until the problem has been identified and corrected.

To reduce the risk of static sparking, ground the sprayer and all

Grounding

other spray equipment used or located in the spray area.

tionsfor your area and

type

of

equipment.

BE

SURE to ground

CHECKyourlocaleiectricalcodefordetailedgroundinginstruc-

ail

of

this spray equipment:

1.

Sprayer:plugintoaproperlygroundedoutlet.Donotusean

for at

least

15

amps.

adapter.Exiensioncordsmusthavethreewiresandberated

2

Fluid

hoses: use only grounded hoses with a maximum of

150mcombinedhoselengthtoensuregroundingcontinu-

ily.

See Hose Groundlng Contlnulty.

3.

Spraygun: obtain grounding through connection to a prop-

erly grounded fluid hose and sprayer.

4.

Object being sprayed: according to local code

5.

Fluid

supply container: according

to

local code.

6.

Allsolventpailsusedwhenflushing,

accordingtolocalcode.

Useonlymetalpails,whichareconduciive.Donotplacethe

pail

on

a

non-conductive surface, such as paper or card-

board, which interrupts the grounding continuity.

7.

To

maintain grounding continuity when flushing orrelieving

pressure, always hold a metal part

of

the gun firmly to the

side of

a

grounded metal pail, then trigger the gun.

Flushing Safety

Reducetheriskoffluidinjectioninjuty,staticsparking,orsplash-

ing by following the flushing procedure given

on

page

13

ofthis

manual. Follow the Pressure Relief Procedure

on

page

2,

and

firmly to the side of a grounded metal pail and use the lowest

removethespraytipbeforefiushing.Ho1dametaipartofthegun

possible fluid pressure during flushing.

IMPORTANT

United States Government safety standards have been adopted under the Occupational Safety and Health Act. These standards

-

particularly the General Standards, Part

1910,

and the Construction Standards, Part 1926

-

should be consulted.

308-248

3