START

UP

WARNING

Hold the engine starter rope

as

it

recoils to

prevent

lt

hitting someone and causing injury, or

f. Hold the frame of the sprayer with one hand

and pull the starter rope rapidly and firmly.

Continue holding the rope as it returns.

Repeat until the engine starts.

g. Open the choke

as

soon as the engine

starts,

except in cold weather. In cold weather, leave

the choke closed for

10

to

30

seconds before

opening it to keep the engine running.

5.

Prime with texture material

suction strainer.

NOTE

If

the pump does not prime easily, remove the

a.

b.

C.

d.

Reduce the engine speed.

Put the siphon hose (la) in the prepared

texture material.

Set the Easy Spray Control to

PRIME

to load

the pump. Set the control to

SPRAY

when

material appears at the drain hose.

Trigger the gun and direct the solvent into the

solvent container, then when the texture mate-

rial appears, direct the flow into a material

drum.

If

you are ready

to

adjust the spray

pattern, do not release the trigger.

.,

6.

Fill

the pump:

a.

b.

C.

d.

Start the air compressor and adjust the pres-

sure according to the chart on page

9,

or to at

least

30

psi

(2.8

bar)

Set the Easy Spray Control

(75)

to

SPRAY

Trigger the gun for about one minute,

directing the fluid back into the solvent

container. (Air will exit the rear

of

the gun.)

Thls starts the pump and wets the hoses.

Release the trigger. The system pressure

will

be relieved automatically.

7.

To

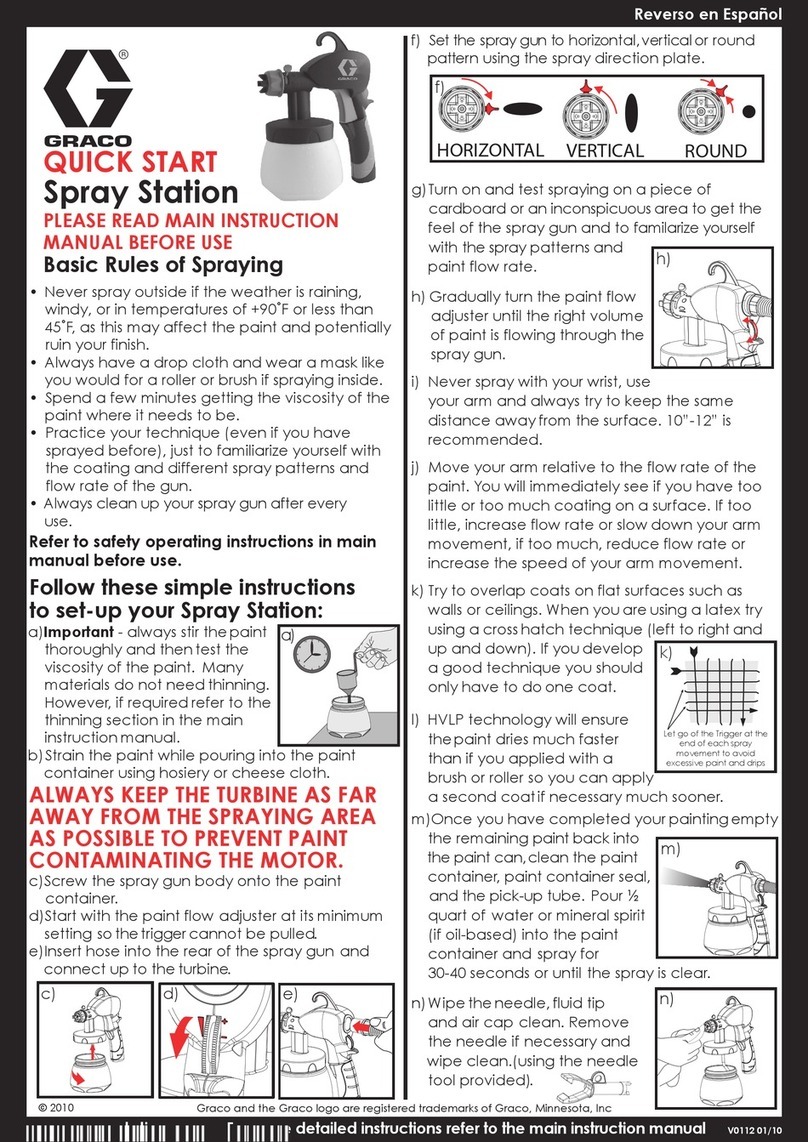

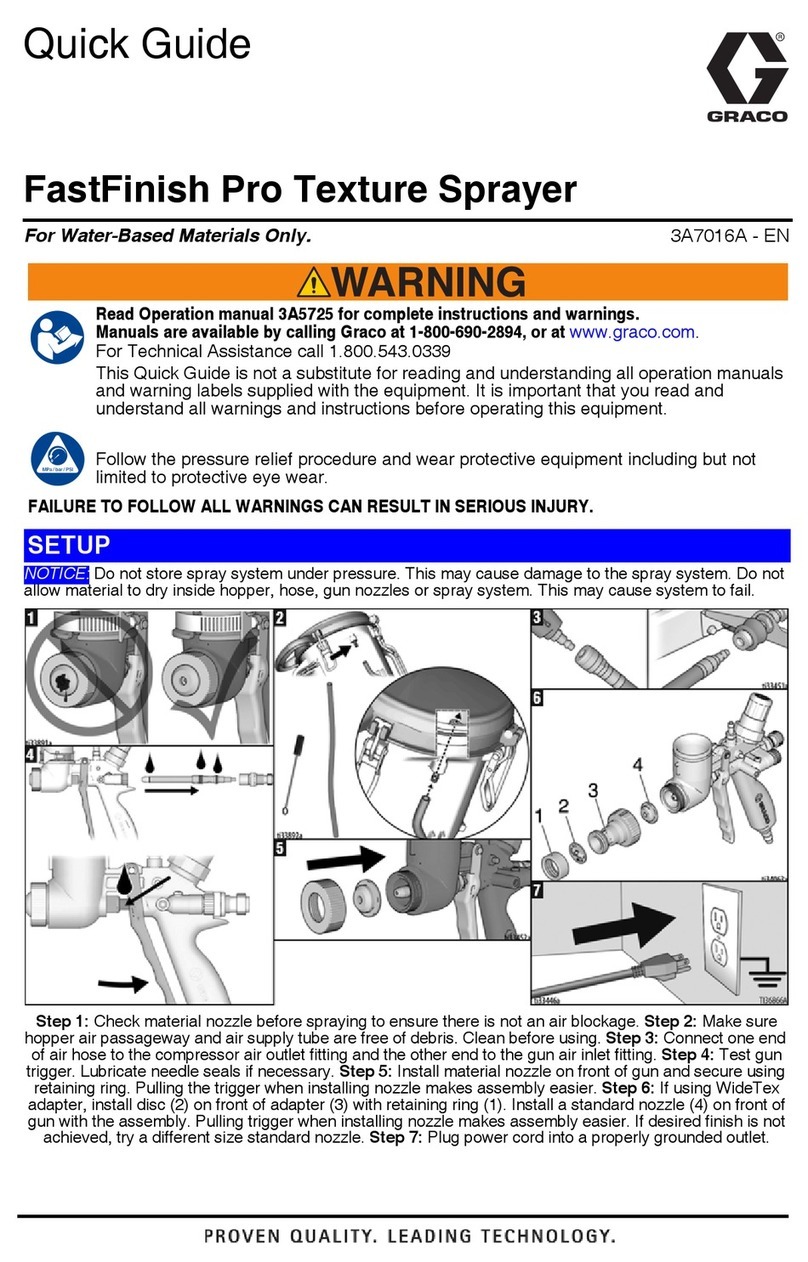

adjust the spray pattern:

a.

b.

While triggering the gun, adjust the engine

good starting point

is

to adjust the fluid flow

RPM

to determine fluid flow and pressure.

A

until you have an

8

in

(20

cm) stream.

Holding the gun

18

to

30

in

(0.5

to

1.0

m)

from a test surface, test the spray pattern

while backing out the gun's Air Control Valve

(G)

which allows the air to atomize the fluid.

Adjust the Air Control Valve to obtain.the

desired spray pattern.

TIP

More fluid flow

=

more air,

and less fluid flow

=

less air.

c.

If

you cannot get a good spray pattern, try

adjusting the air compressor pressure or try

another spray disc and nozzle combination.

8. To prevent material

surge

at the beginning

of

a

spray pattern

a.

Always trigger the gun

fuilF

If

triggered partially, which only triggers the air

portion of the system, the pump will start and

complete the triggering action you will get a

pressurize the hoses. Then when you

blast of unatomized material.

b.

When

you

release the

gun

trigger, allow the

materlal

to

completely depressurize before

trlggerlng the gun agaln.

Failure to do this will result in spraying some

to back up into the gun air passages and

unatomized material, and may cause material

block air flow. Longer hoses and heavier

material may take several seconds longer to

depressurize.

As

you test the spray pattern, also time how

long

it

determine to depressurize the system

and keep that

in

mind

as

you are working.

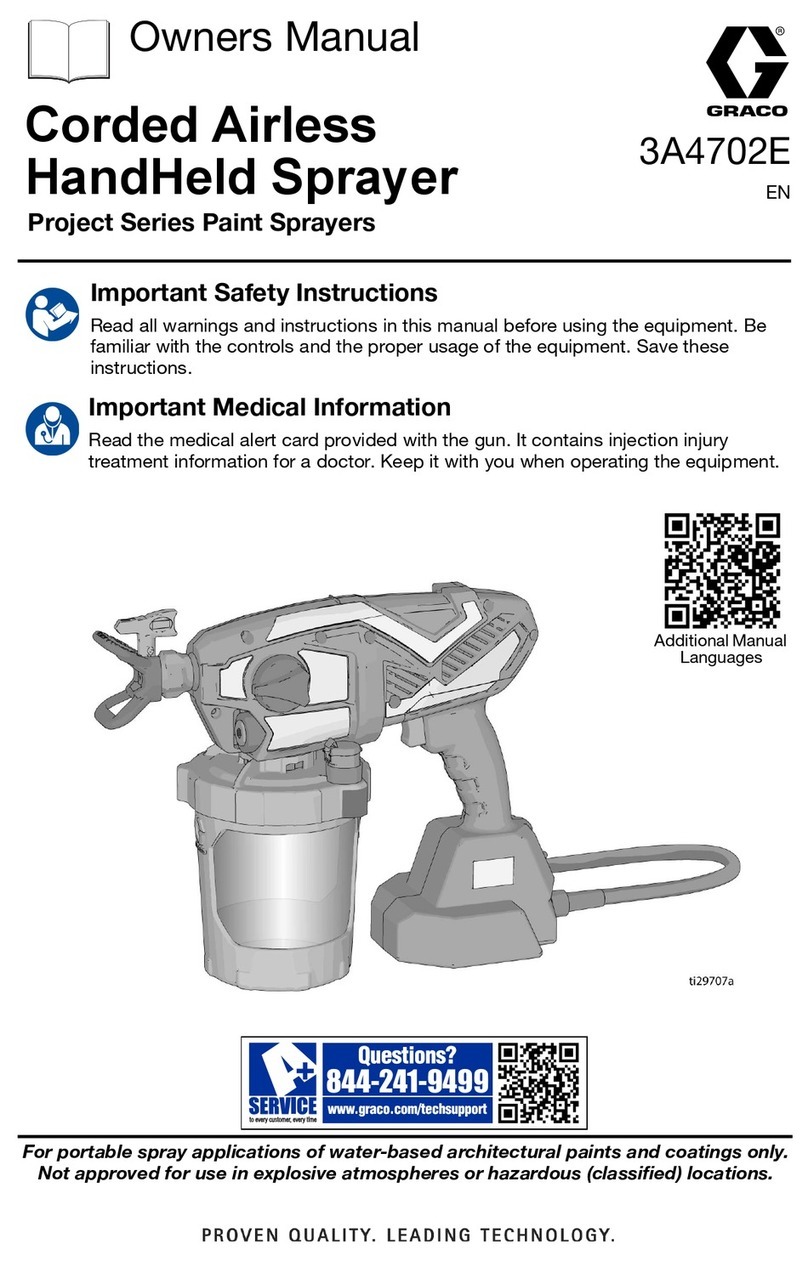

/G

Fig

7

OIBOB

Use the lowest fluid pressure and the lowest

throttle setting needed. Higher settings cause

excessive drain time from the dump valve and

premature seal wear.

9.

When you stop spraying

release the gun trigger

to relieve pressure. Shut

off

the sprayer.

308-269

9

~~~