765042196 Rev. 000 3

Contents

Application .................................................................................................................. 4

Safety information ...................................................................................................... 5

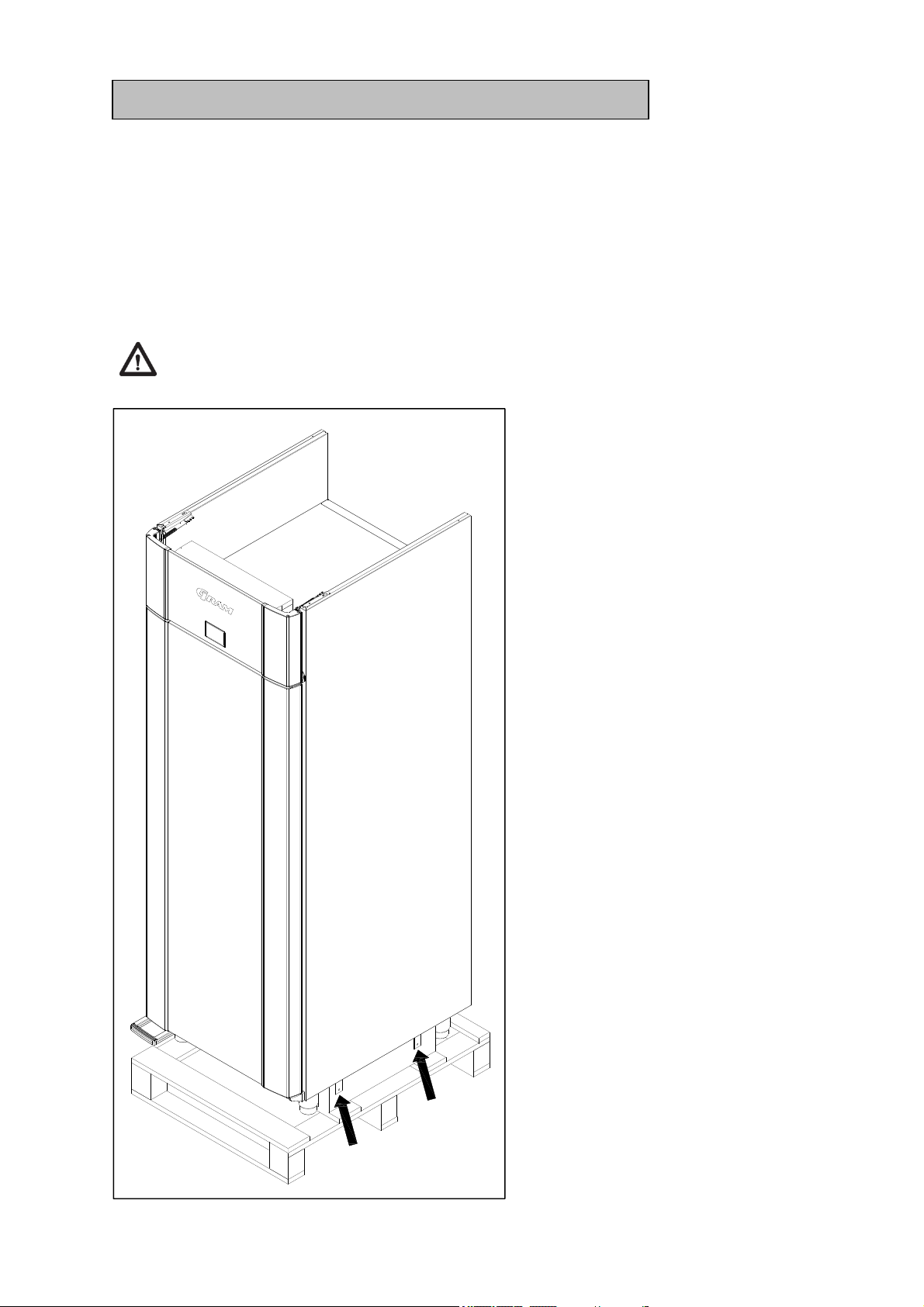

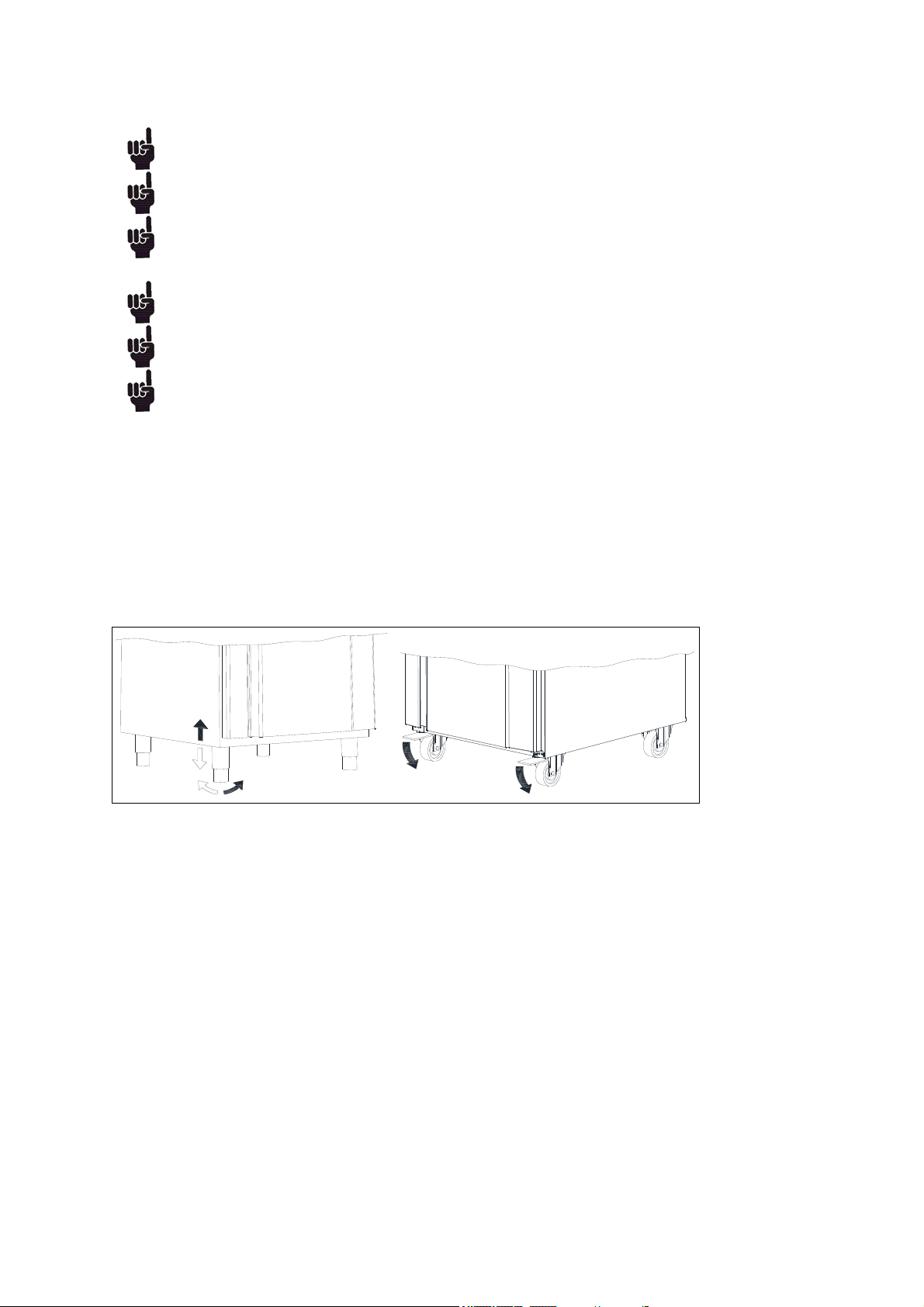

Location ...................................................................................................................... 6

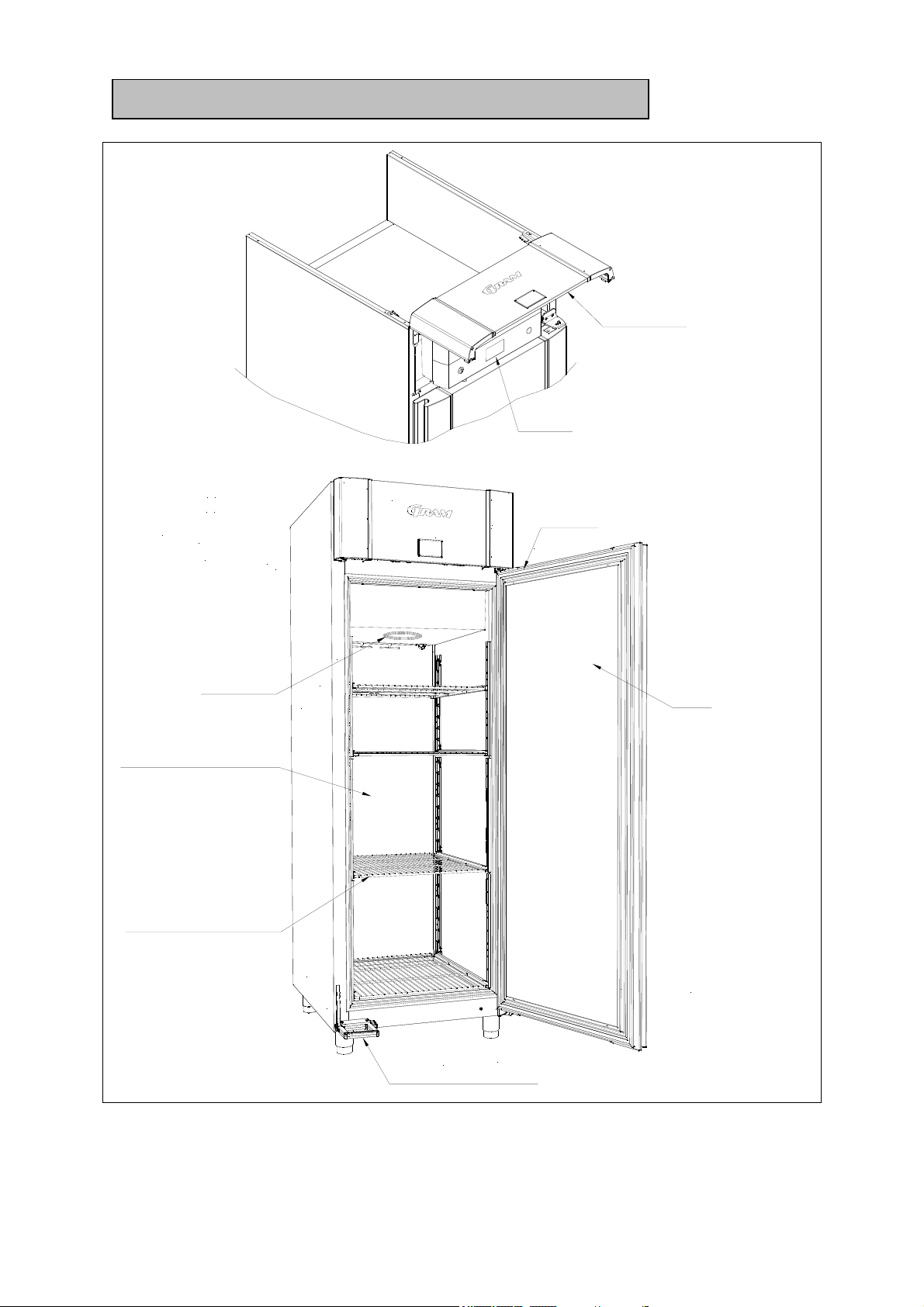

General description .................................................................................................... 9

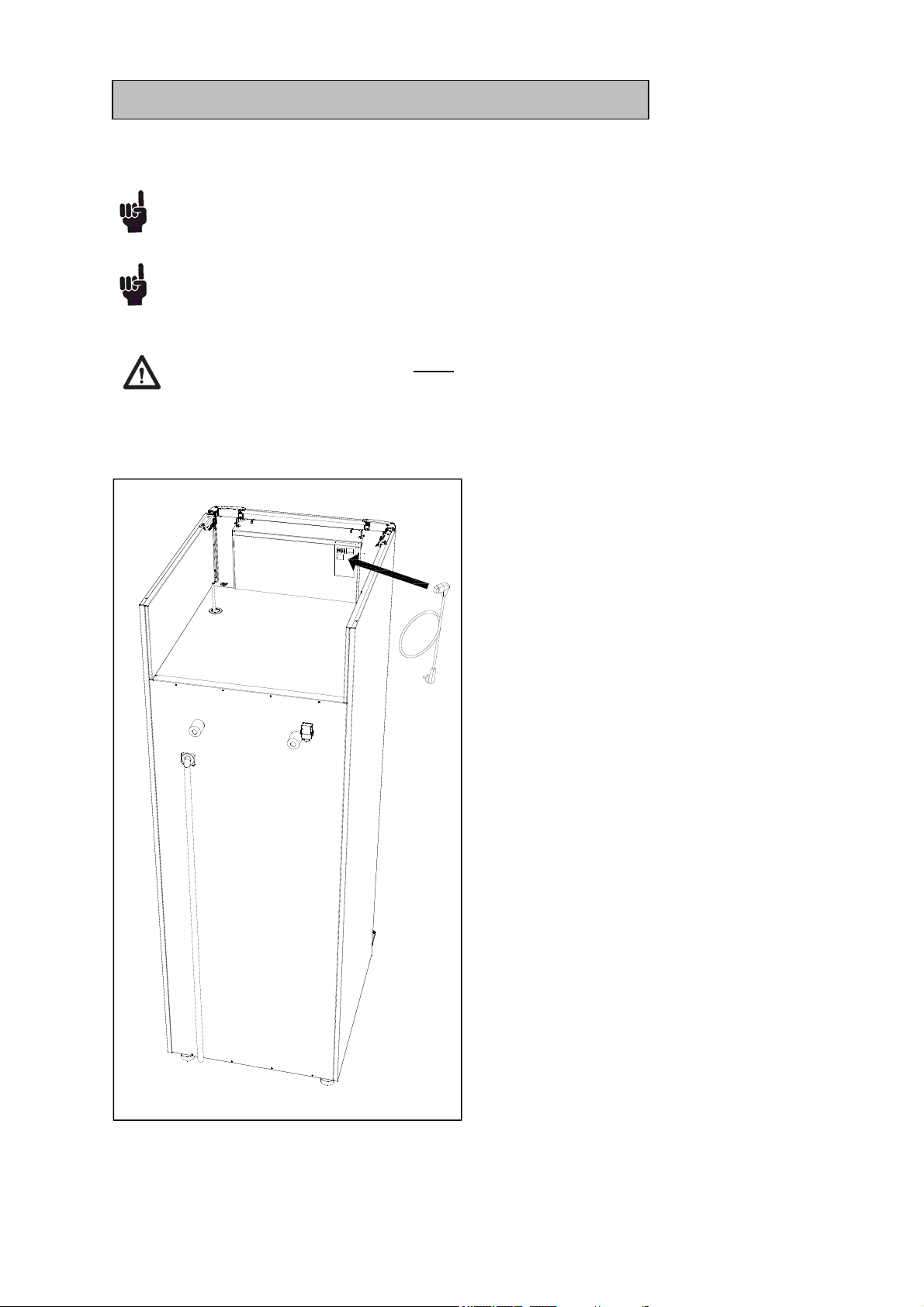

Electrical connection ................................................................................................ 10

General use .............................................................................................................. 11

Operating the product (Danfoss Controller AKCC 550A) ......................................... 13

Errors and alarms...........................................................................................................................16

User menu.......................................................................................................................................16

Operating the product (Carel MPXpro controller) ..................................................... 17

Errors and alarms...........................................................................................................................23

User menu.......................................................................................................................................24

Operating the product (no controller) ........................................................................ 24

Troubleshooting ....................................................................................................... 24

Defrost water ............................................................................................................ 25

Door closing mechanism .......................................................................................... 25

Power failure ............................................................................................................ 26

Cleaning ................................................................................................................... 26

Door gaskets ............................................................................................................ 26

Long term storage .................................................................................................... 26

Service ..................................................................................................................... 27

Disposal ................................................................................................................... 28

Declaration of incorporation of partly completed machinery ..................................... 29

Wiring diagram Danfoss AKCC 550A ....................................................................... 30

Wiring diagram Carel MPXpro .................................................................................. 37

Wiring diagram - no controller .................................................................................. 44

Piping diagram ......................................................................................................... 51