795-93850 4of 41 12/15/21

SAFETY WARNINGS / CAUTIONS

Read all the SAFETY INSTRUCTIONS on the machine and those in the manual BEFORE installing

or using this equipment. Keep this manual handy for reference/training.

You will find various types of safety information on the following pages and on the labels attached to

Graymills equipment. The following Safety Statements explain their meaning.

Read and understand the user manual before operating this unit.

Do not operate above 100°F (38°C) maximum ambient temperature, near open flames, sparks, or

smoking materials. Keep cover closed when unattended.

To provide continued protection against risk of electrical shock, fire, and explosion, connect to

properly grounded supply or outlets only.

Risk of explosion. This equipment has internal arcing and sparking parts, which shall not be

exposed to flammable vapors. This equipment shall not be located in a recessed floor area or

below grade.

Only cleaning fluids with a flash point at or above 104°F (40°C) shall beused. Referto user manual

for a list of solvents which have been evaluated for use.

Do NOT contaminate cleaning solution with fluids below 104°F (40°C) flash point including

gasoline, alcohol, or other flammable liquids. Even small amounts will create a hazardous

condition.

Ensure fusible link and closing device are in proper working order. Fusible link melts at

165°F(74°C) causing lid to close. When open the lid must lean forward so it will close automatically

when link melts. Do NOT tamper with or remove the fusible safety link. If the safety link breaks or

is lost, do NOT use the unit. Replace the safety link immediately.

Hazardous voltage present. Disconnect power before repairing or cleaning. Unit must be properly

grounded toprevent electricshock, fire, and explosion hazard.Connect only tothree prong outlets.

Should cord become cracked, frayed, or damaged in any way, it should be repaired immediately

by a qualified electrician. Never use an extension cord. Since operator safety at all times is a

priority, we strongly recommend that, whether or not required by local code, this equipment be

connected only into a power supply equipped with a “Ground Fault Interrupter” (GFI). All electrical

connections should conform to national/local codes and be made by qualified personnel.

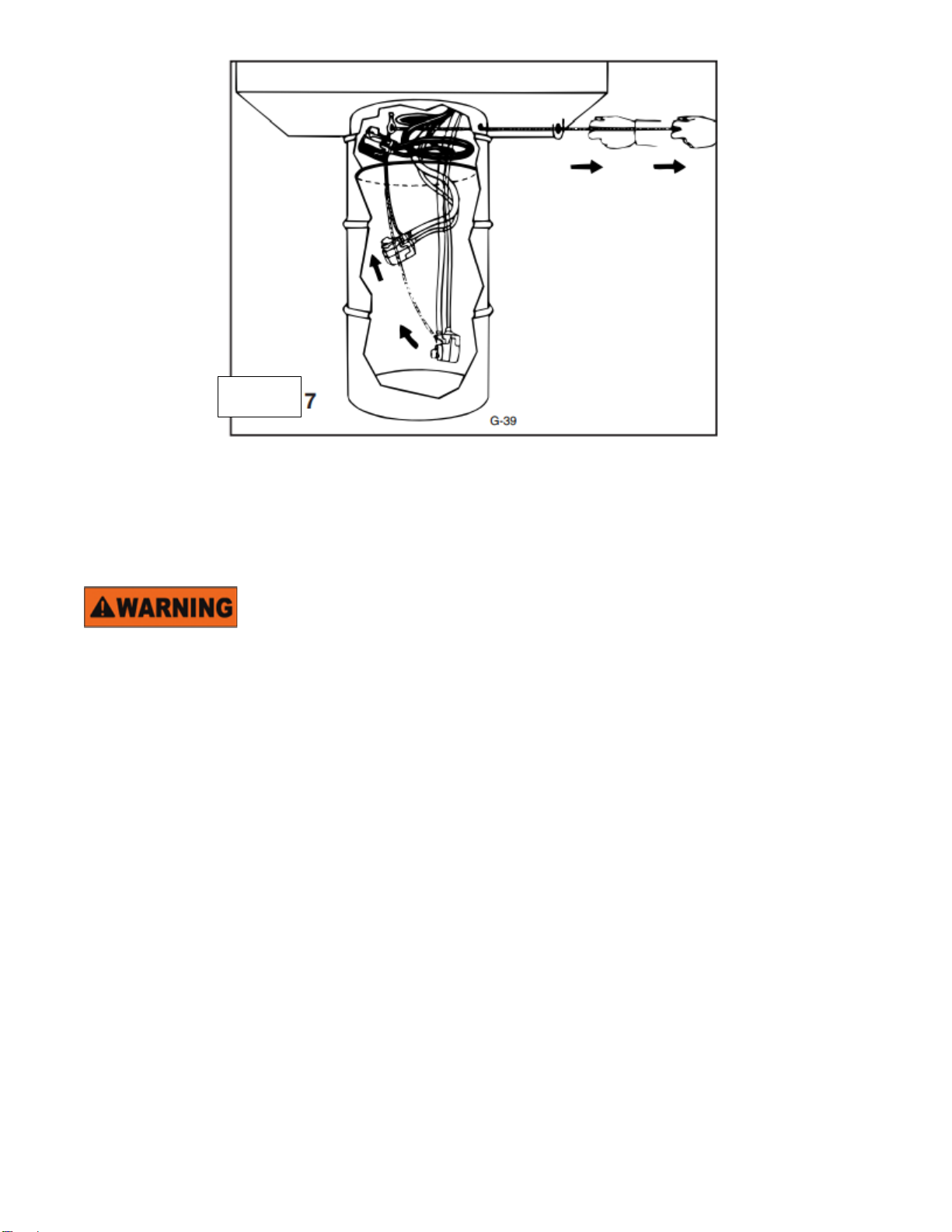

Do not leave objects inthe tank or let hose attachments exitthe tank which prevent lid from closing

completely in the event of fire.