CONTENTS

PRODUCT ..................................................................................................................... 2

1 MODELS LIST ............................................................................................................................2

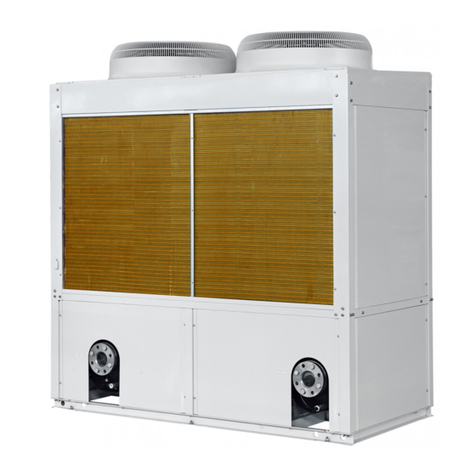

1.1 Outdoor Unit .......................................................................................................................................................2

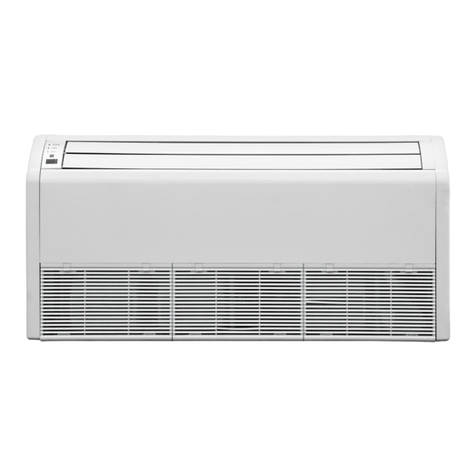

1.2 Indoor Unit...........................................................................................................................................................2

2 NOMENCLATURE .....................................................................................................................4

2.1 Nomenclature of Outdoor Unit ..........................................................................................................................4

2.2 Nomenclature of indoor unit ..............................................................................................................................4

3 FUNCTION ...................................................................................................................................5

4 PRODUCT DATA .......................................................................................................................6

4.1 Product data of outdoor......................................................................................................................................6

4.2 Product data of indoor........................................................................................................................................7

4.3 Working Temperature Range...........................................................................................................................12

5 PIPING DIAGRAM ...................................................................................................................13

CONTROL ................................................................................................................... 15

1 OPERATION FLOWCHART................................................................................................... 15

1.1 Cooling/Dehumidfying Operation ...................................................................................................................16

1.2 Heating Operation.............................................................................................................................................17

2 MAIN LOGIC.............................................................................................................................18

2.1 Control Function of Outdoor Unit...................................................................................................................18

2.2 Protection Function ..........................................................................................................................................19

2.3 other function.....................................................................................................................................................20

2.4 Control Function of Indoor Unit......................................................................................................................20

3 REMOTE CONTROLLER .......................................................................................................23

3.1 Wired Remote Controller ................................................................................................................................23

3.2 Wireless Remote Controller..............................................................................................................................28

INSTALLATION ......................................................................................................... 33

1 PRECAUTIONS FOR INSTALLATION ................................................................................33

1.1 Precautions for Installation ..............................................................................................................................33

1.2 Key Points of Installation .................................................................................................................................34

2 FLOW CHART OF INSTALLATION...................................................................................... 35

3 OUTDOOR UNIT INSTALLATION........................................................................................ 36

3.1 Before Installation .............................................................................................................................................36

3.2 Installation Site..................................................................................................................................................36

3.3 Caution for Installation.....................................................................................................................................36

3.4 Dimension Data ................................................................................................................................................36

3.5 Installation Clearance Data..............................................................................................................................37

4 INDOOR UNIT INSTALLATION............................................................................................ 38

4.1 Installation of Duct Type...................................................................................................................................38