Greenlee SITE-RITE 840A User manual

Other Greenlee Power Tools manuals

Greenlee

Greenlee RK1550 User manual

Greenlee

Greenlee CLS 60 plus User manual

Greenlee

Greenlee CTR100 User manual

Greenlee

Greenlee 1981 User manual

Greenlee

Greenlee F09 User manual

Greenlee

Greenlee Gator LS60 User manual

Greenlee

Greenlee GATOR EK410L User manual

Greenlee

Greenlee Fairmont F20 User manual

Greenlee

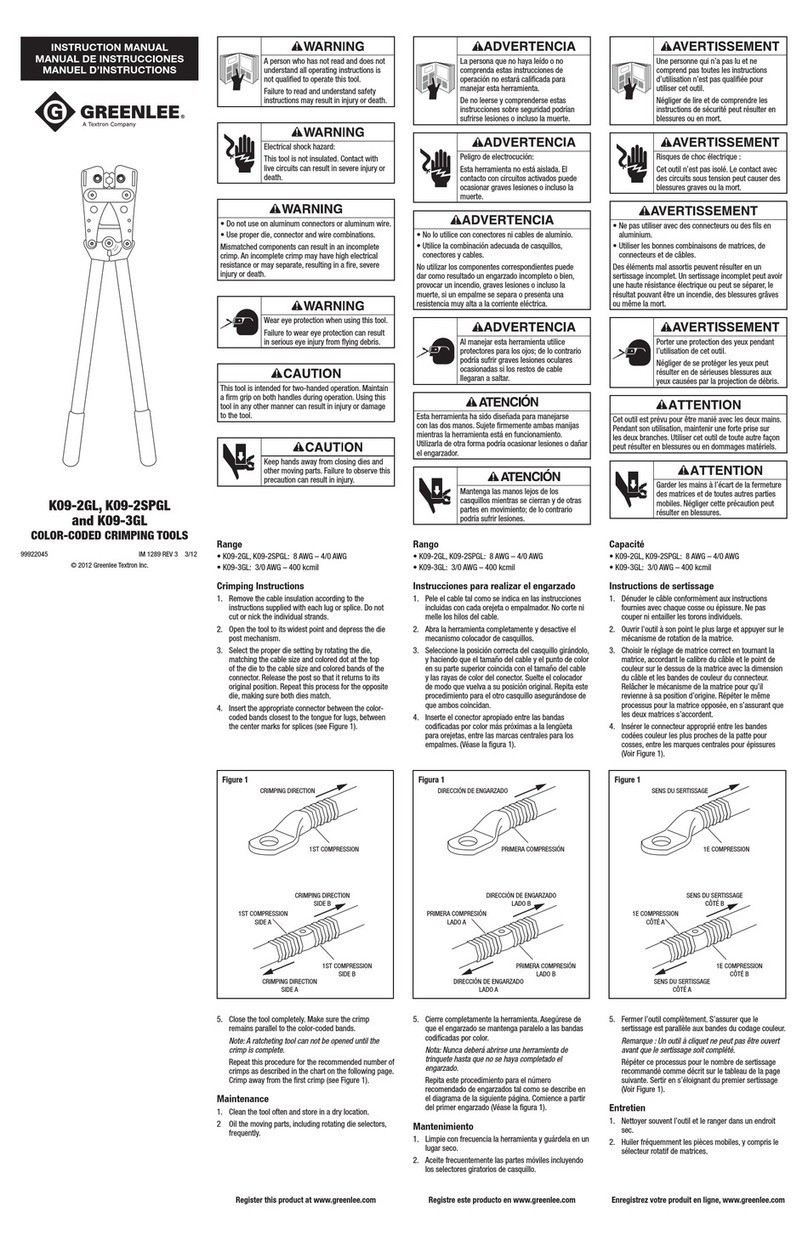

Greenlee K09-2GL User manual

Greenlee

Greenlee 1400 User manual

Greenlee

Greenlee GATOR RK12CX User manual

Greenlee

Greenlee GATOR EK6IDLX User manual

Greenlee

Greenlee 36587 User manual

Greenlee

Greenlee Fairmont F07 User manual

Greenlee

Greenlee Fairmont RK6040 User manual

Greenlee

Greenlee CTR200 User manual

Greenlee

Greenlee 724 User manual

Greenlee

Greenlee F05 User manual

Greenlee

Greenlee Gator LS-60-ULTRA User manual

Greenlee

Greenlee GATOR ES20L User manual