4

Scorpion 4, 6 and 8

Table of contents

(Letters (x) refer to Machinery Directive 2006/42 / EU, Paragraph 1.7.4.2, sections a - u, Content of the Instruction Book))

IMPORTANT................................................................................................................................................................3

MANUFACTURER –NAME AND ADDRESS (A)..............................................................................................................3

PREFACE........................................................................................................................................................... 8

MODEL NAME (B) AND OTHER USEFUL INFORMATION.................................................................................... 9

GENERAL INFORMATION ............................................................................................................................... 10

HOW TO USE THIS INSTRUCTION MANUAL...........................................................................................................................10

DEFINITIONS OF INFORMATION SIGNS IN THE INSTRUCTION MANUAL........................................................................................10

WHEN USING OTHER MANUFACTURERS'TOOLS WITH THE SCORPION BOOM MOWER ..................................................................10

Manufacturer's plate ......................................................................................................................................11

LOCAL LEGISLATION IN THE COUNTRY WHERE THE MACHINE IS USED.........................................................................................11

WARRANTY ..................................................................................................................................................................11

DECLARATION OF CONFORMITY (C) ............................................................................................................... 12

SAFETY........................................................................................................................................................... 13

WARNINGS,PROHIBITIONS,AND INSTRUCTIONS ..................................................................................................................13

Safety labelling................................................................................................................................................14

Labels ..............................................................................................................................................................14

INFORMATION AND WARNING LABELS................................................................................................................................15

SAFETY INSTRUCTIONS FOR ADJUSTMENT,MAINTENANCE,AND INSPECTION WORK (S).................................................................16

SAFETY INSTRUCTIONS FOR THE OPERATOR /USER................................................................................................................17

HIGH VOLTAGE LINES......................................................................................................................................................17

WORKING IN PUBLIC PLACES ............................................................................................................................................18

WARNING SIGNS IN PUBLIC PLACES....................................................................................................................................18

Suggested signage on public roads.................................................................................................................18

Further use of warning signs...........................................................................................................................18

PERSONAL SAFETY EQUIPMENT.........................................................................................................................................19

RECOMMENDATIONS FOR OPTIMAL SAFETY AND OPERATION (I)..............................................................................................19

INSTRUCTIONS ON NECESSARY PROTECTIVE MEASURES (M) ....................................................................................................20

WARNINGS:HOW NOT TO USE THE MACHINE (H) ................................................................................................................21

MACHINE INFORMATION AND SPECIFICATIONS ............................................................................................ 22

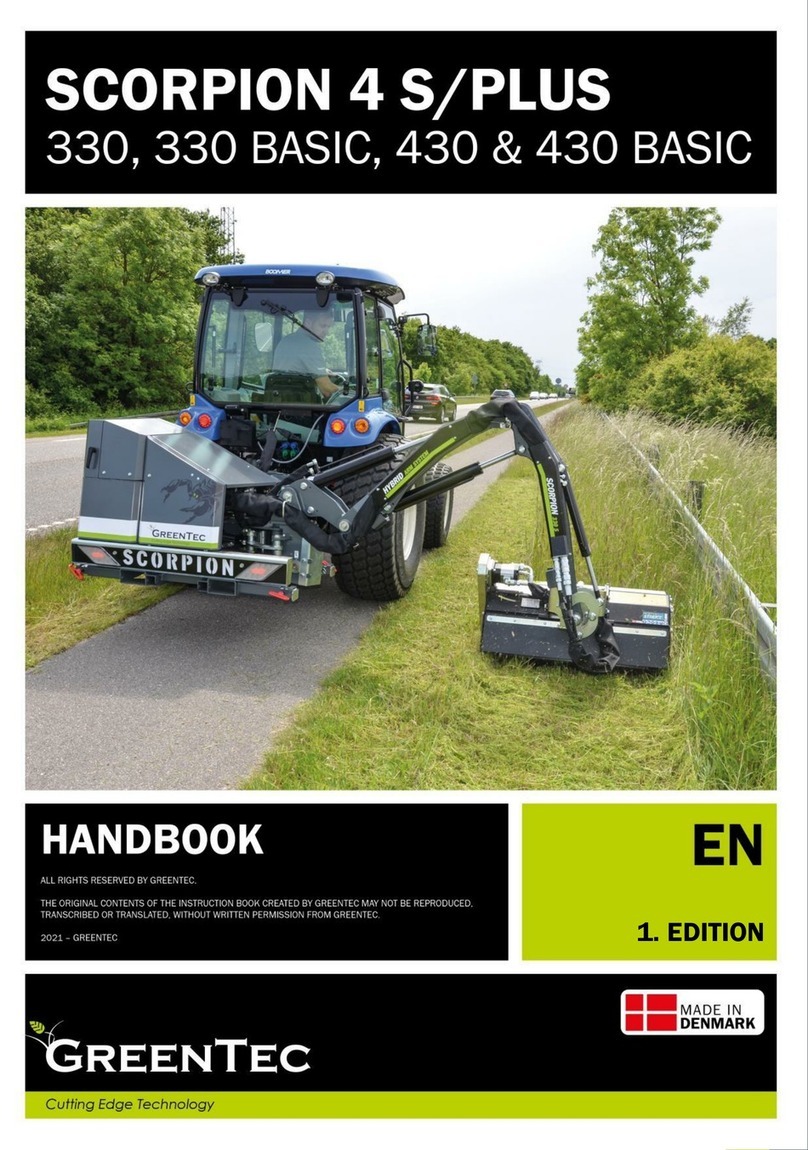

SCORPION BOOM MOWER...............................................................................................................................................22

MACHINE DESCRIPTION (D) .............................................................................................................................................22

Right/left turning models ..................................................................................................................................23

Basic version, Scorpion 4 ...................................................................................................................................23

Plus versions Scorpion 6 and 8 ..........................................................................................................................23

Strenx steel......................................................................................................................................................23

Hybrid Arm System (patent pending)..............................................................................................................23

Scorpion PLUS, RotorFlex, forward reach........................................................................................................24

4-Point mounting system (patent pending) ....................................................................................................24

Auto Hight Control (AHC) ................................................................................................................................24

Break-back ......................................................................................................................................................25

Description of the hydraulic system ................................................................................................................25

Hydraulic diagram Scorpion 4 (e)..............................................................................................................................26

Hydraulic diagram Scorpion 6 + 8 Plus (e).................................................................................................................27

CYLINDERS ON THE SCORPION....................................................................................................................... 28

The intended use of the machine (g)...............................................................................................................29

THE SCOPE OF APPLICATION AND LIMITATIONS OF THE BOOM MOWER......................................................................................30

THE ATTACHMENT TOOLS OF THE BOOM MOWER (N)............................................................................................................30

SPECIFICATIONS.............................................................................................................................................................31

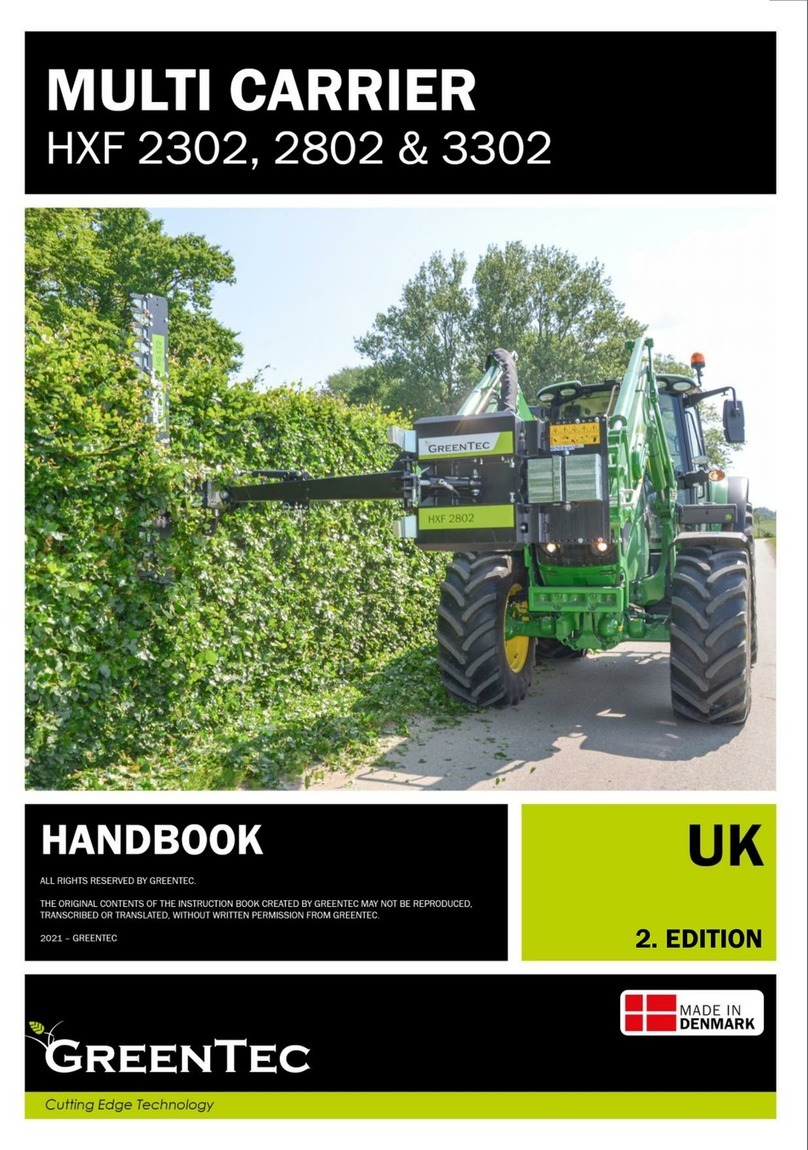

SPECIFICATIONS:SCORPION 4................................................................................................................................31