4Specications are subject to change without prior notication

From serial number 6714

Including 6586, 6666, 6703

CompanyProle

Australia’s largest manufacturer and exporter

of Disc ploughs, Grizzly Engineering Pty

Ltd is an Australian owned and operated

manufacturing company based at Swan Hill in

Victoria.

Like many other Australian icons of ingenuity,

the Grizzly plough was founded on need.

The Grizzly name was established in the

early 1980’s by country people with the will to

construct a better oset disc plough.

In 1983, a unique three gang, tandem oset

disc design was patented and released. This

innovative Grizzly plough provided complete

ploughing out (no unworked ridges), less

working draught, elimination of side draught

and longer disc life. Other new features, at

that time, included self phasing wheel lift and

improved scrapers.

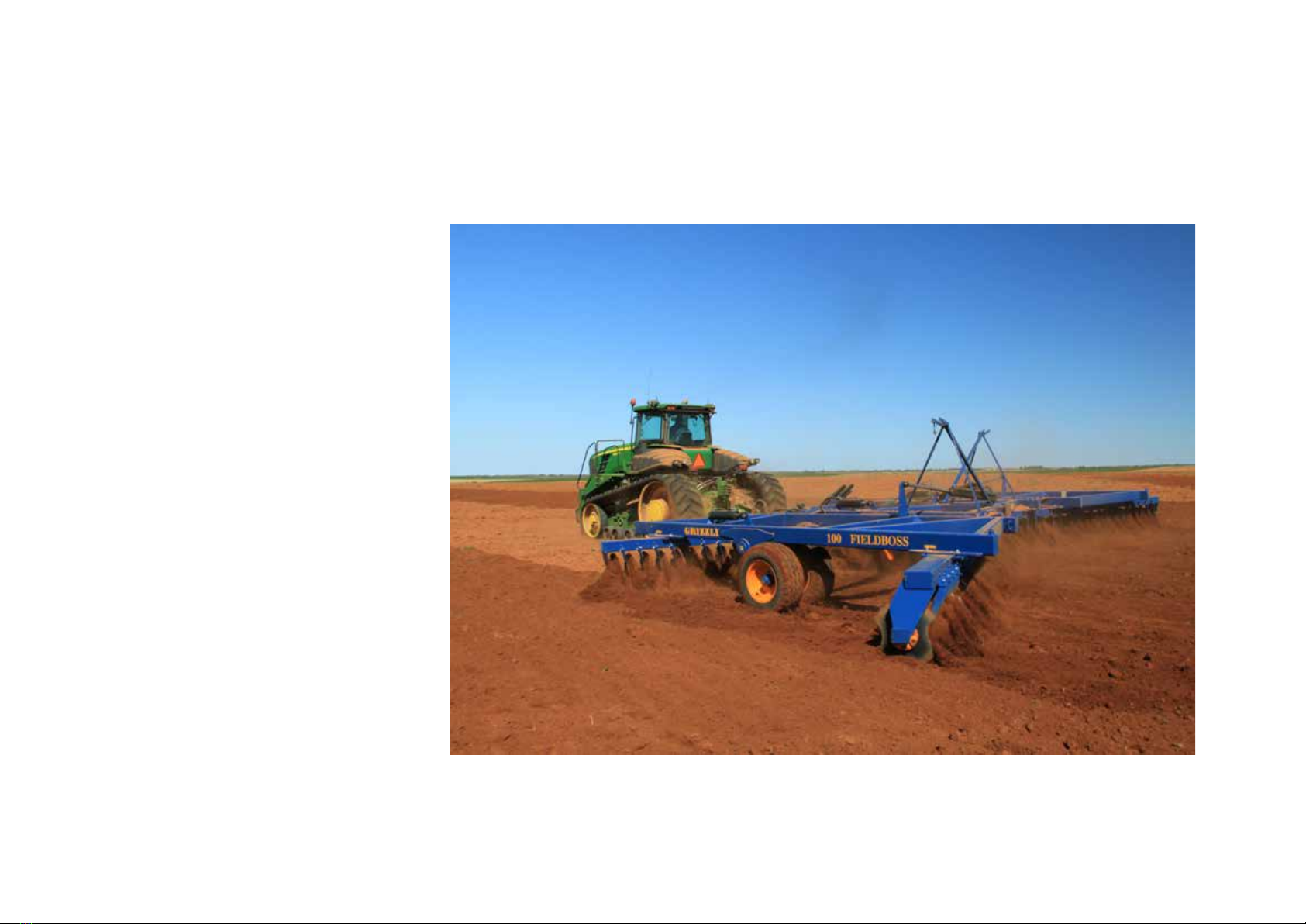

Grizzly’s broad range of versatile ploughs

suit a wide variety of agricultural applications.

Sizes vary from 1.4 metres to 15.6 metres

working width.

Grizzly also manufacture Bankers,

Renovators, and a large range of subsoil and

row crop Rippers from 1 tine.

Advantages of Grizzly technology include

lower power requirements, signicant fuel

savings, reduced stress on components,

reduced maintenance costs, and greater

operator control allowing eortless

adjustments for better performance.

The Grizzly product has earned a reputation

of uncompromising strength, performance and

reliability.

Factory and Head Oce located in Swan Hill Victoria Australia

2 Welcome to Grizzly

This manual includes safety, assembly,

setting up and operating instructions, as well

as lubrication, maintenance and problem

solving instructions, warranty guidelines and

assembly drawing and parts for the Field Boss

range of machines.

Some components explained in this manual

may not be installed on your machine.

Replacement manuals are obtainable from

your Grizzly dealer.

Each model is designed with inbuilt durability,

and accuracy, Eciency and easy operation

for sustainable farming practices.

Continued investment into research and

development plays a key role in the success

of the company’s product range

The company has a very successful and

loyal dealer network throughout Australia.

All dealers are backed by Grizzly training,

technical support and rapid delivery parts

replacement anywhere in Australia.