Table of Contents

INTRODUCTION ............................................... 2

Foreword ........................................................ 2

Contact Info ................................................... 2

Machine Data Sheet ...................................... 3

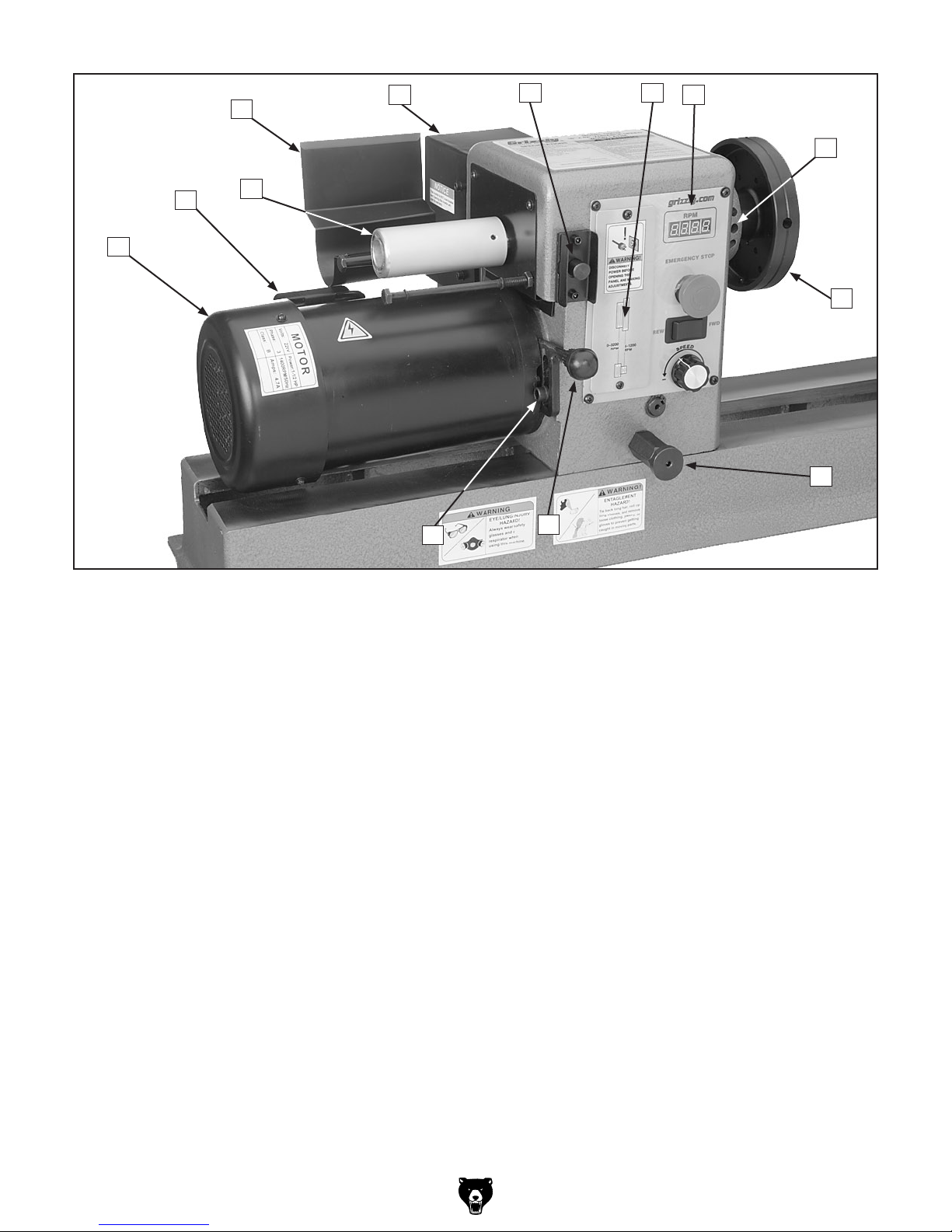

Identification ................................................... 5

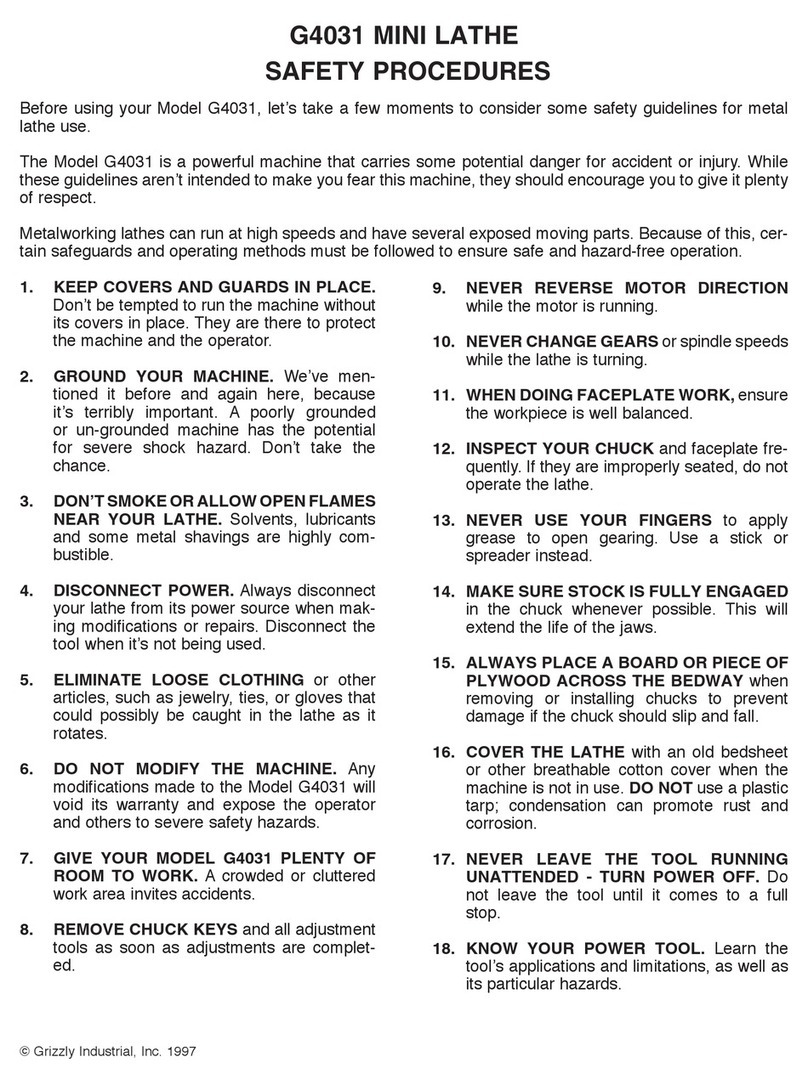

SECTION 1: SAFETY ....................................... 8

Additional Safety Instructions for Wood Lathes

10

SECTION 2: CIRCUIT REQUIREMENTS ...... 11

220V Single-Phase ...................................... 11

SECTION 3: SETUP ....................................... 12

Setup Safety ................................................ 12

Items Needed for Setup ............................... 12

Unpacking .................................................... 12

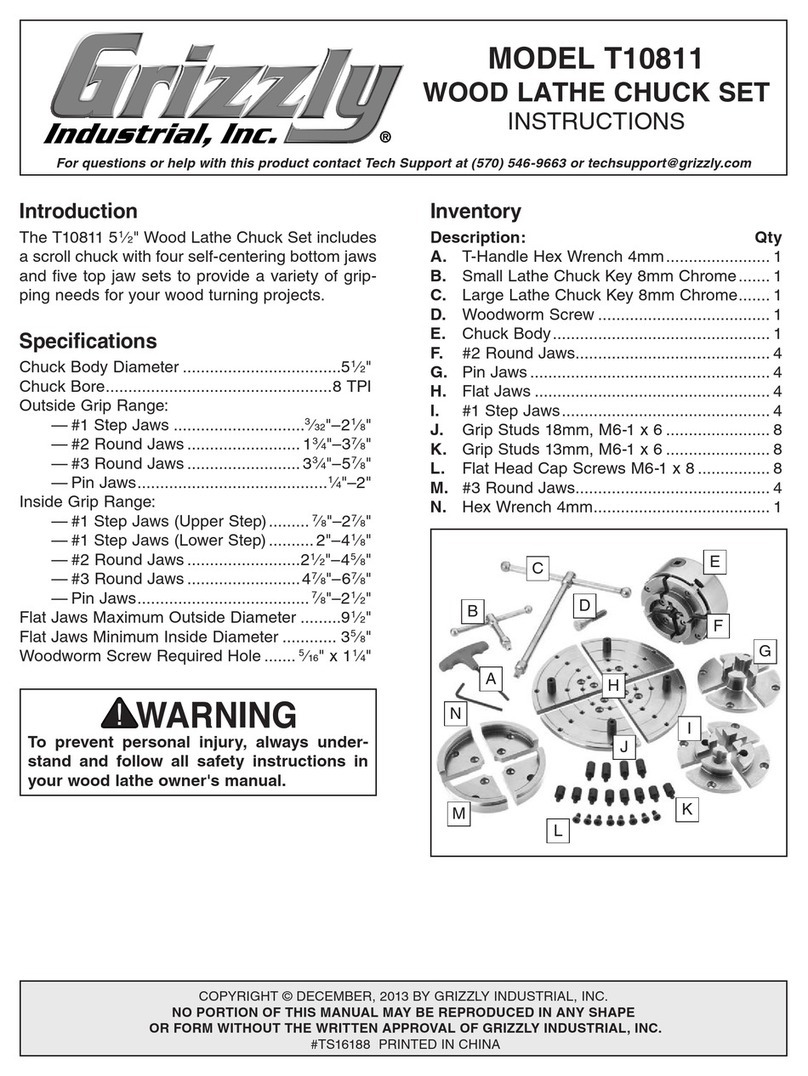

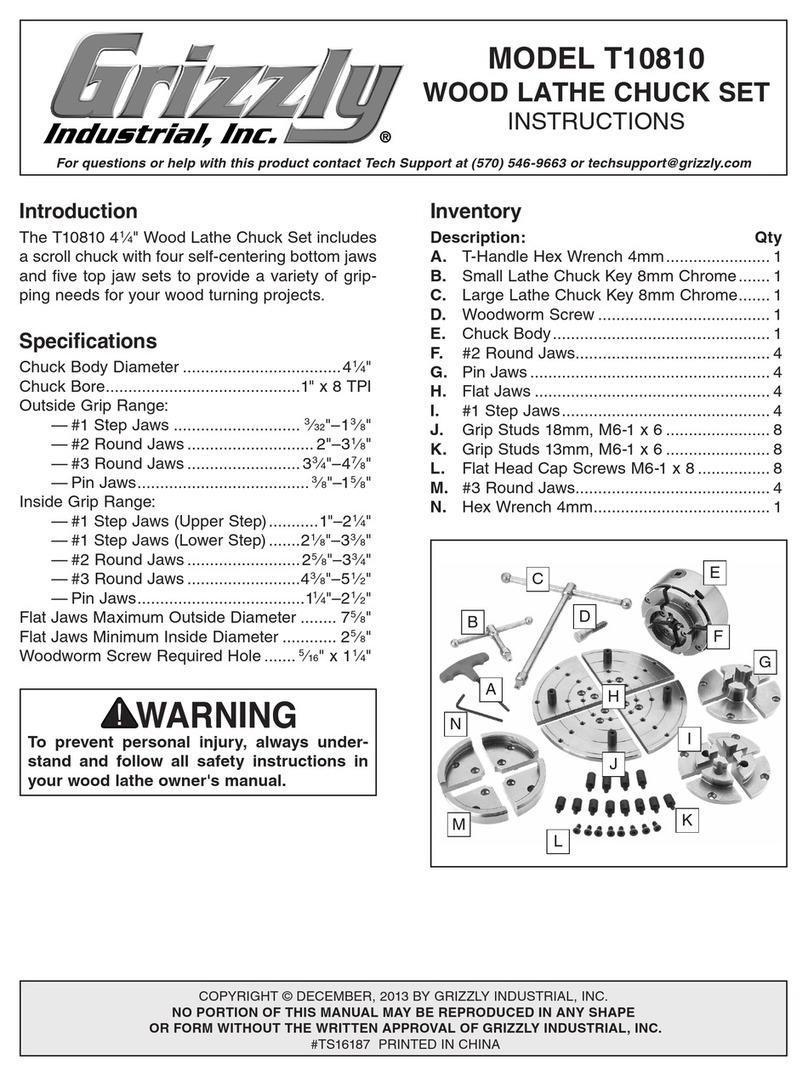

Inventory ...................................................... 13

Hardware Recognition Chart ....................... 14

Site Considerations ...................................... 15

Mounting to Shop Floor ............................... 15

Clean Up ...................................................... 16

Assembly ..................................................... 16

Test Run ...................................................... 18

SECTION 4: OPERATIONS ........................... 19

Operation Safety .......................................... 19

Adjusting Headstock .................................... 19

Adjusting Tailstock ....................................... 20

Adjusting Tool Rest ...................................... 21

Installing/Removing Headstock Center ........ 22

Installing/Removing Tailstock Center .......... 23

Headstock Faceplate ................................... 24

Changing Speed Ranges ............................. 25

Indexing ....................................................... 27

Selecting Turning Tools ............................... 28

Spindle Turning ............................................ 29

Faceplate Turning ........................................ 32

Outboard Turning ......................................... 33

Sanding/Finishing ........................................ 33

SECTION 5: ACCESSORIES ......................... 34

SECTION 6: MAINTENANCE ......................... 36

Schedule ...................................................... 36

Cleaning ....................................................... 36

Lathe Bed .................................................... 36

Lubrication ................................................... 36

SECTION 7: SERVICE ................................... 37

Troubleshooting ........................................... 37

Service Log .................................................. 39

Aligning Centers .......................................... 40

Changing Belt .............................................. 40

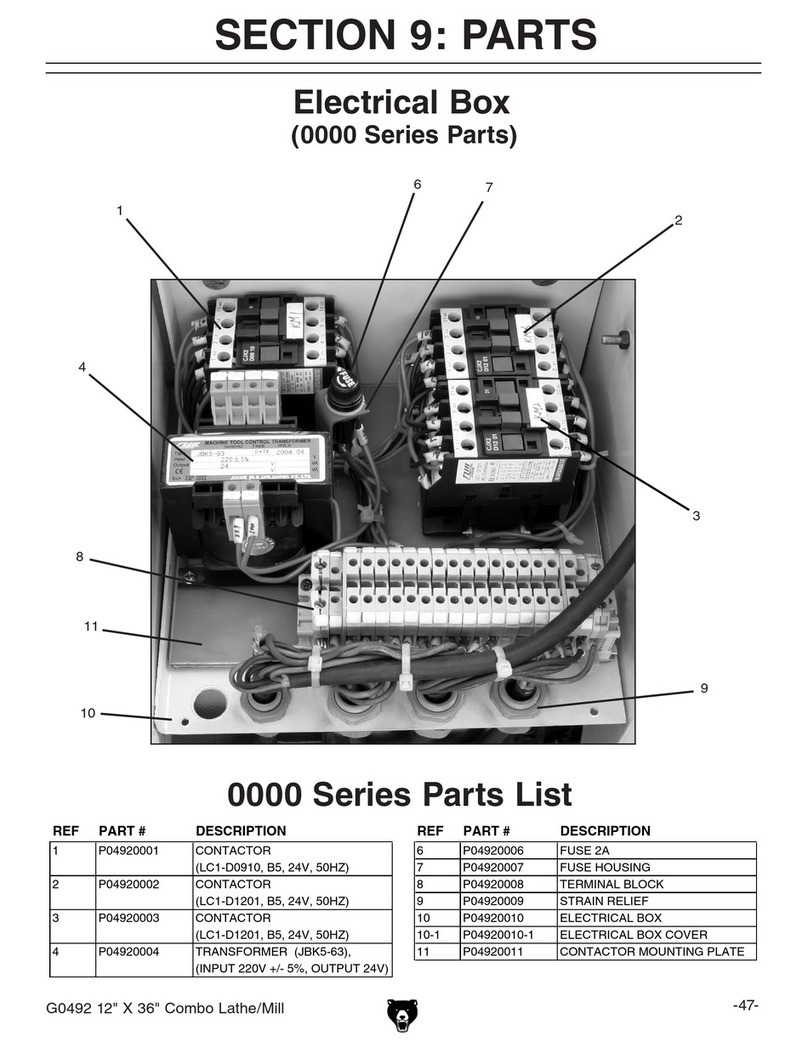

Electrical Components ................................. 41

Wiring Diagram Overview ............................ 42

Frequency Inverter Wiring Diagram ............. 43

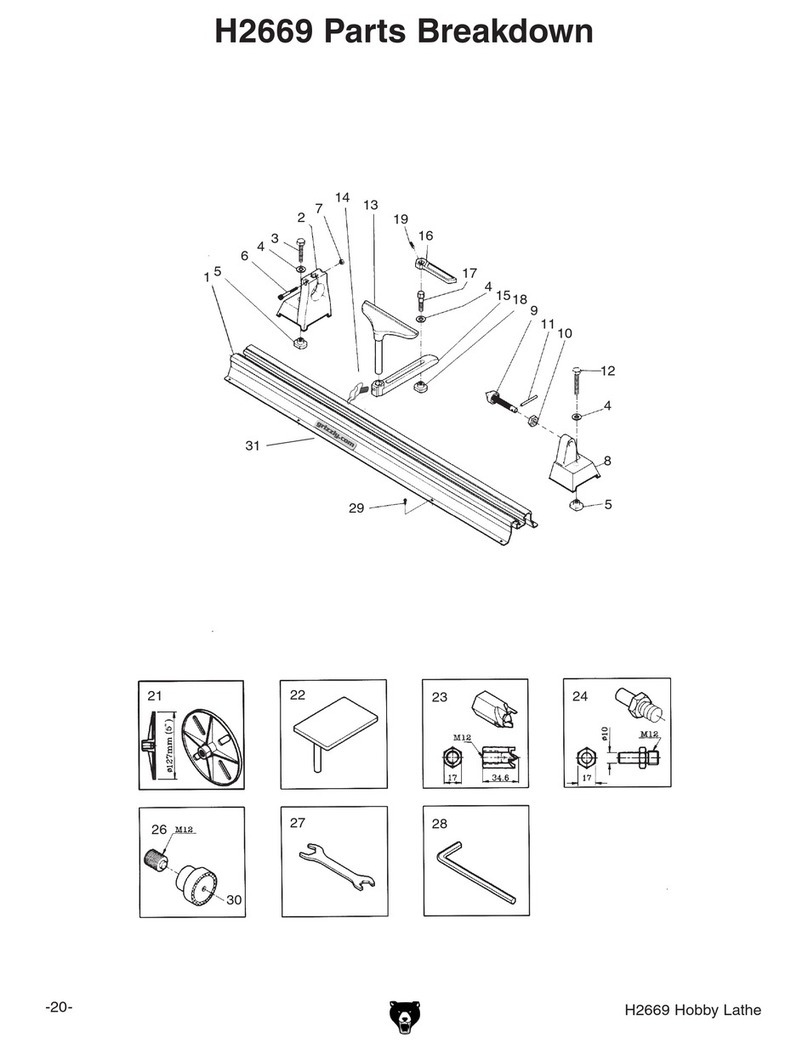

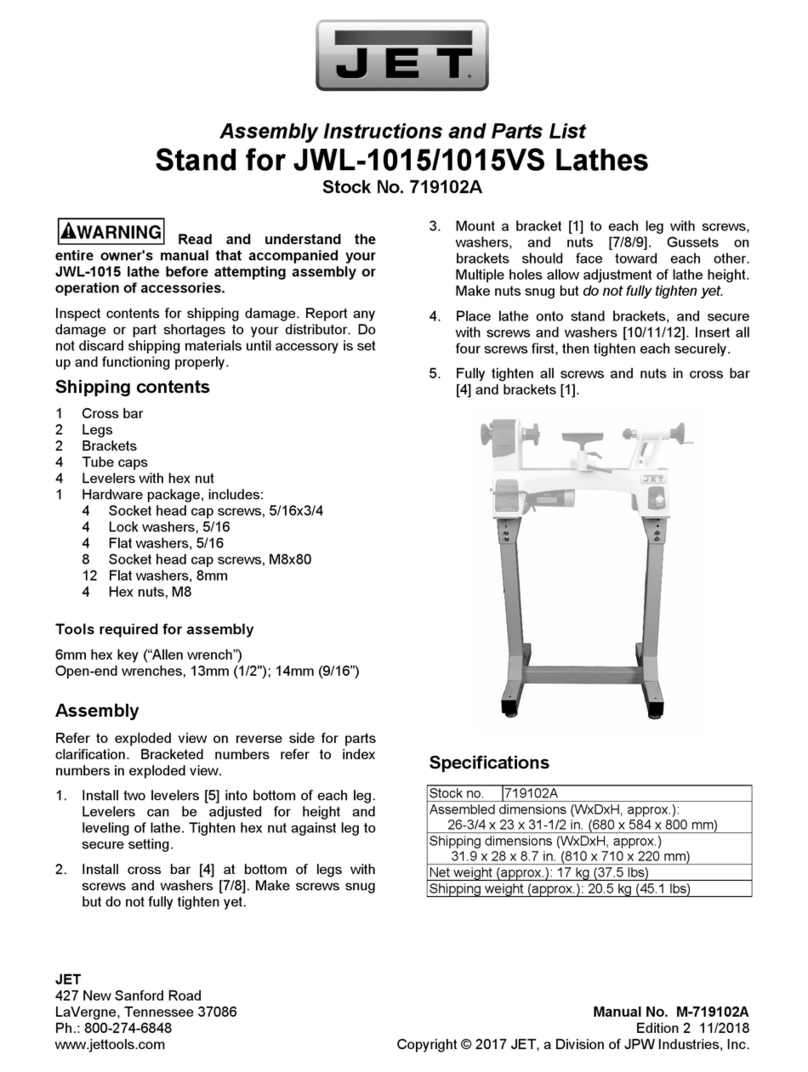

Stand & Bed Parts Breakdown .................... 44

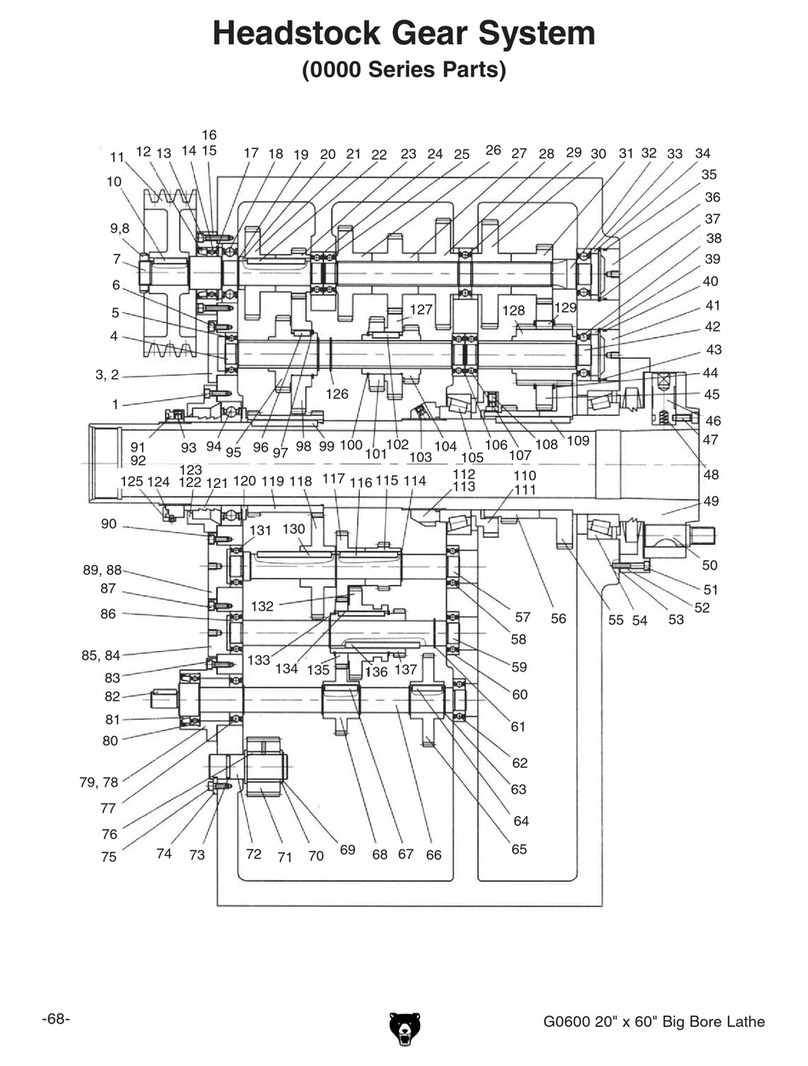

Headstock Parts Breakdown ....................... 46

Label Placement .......................................... 48

WARRANTY AND RETURNS ........................ 49