10 OM-TDB/TDBC

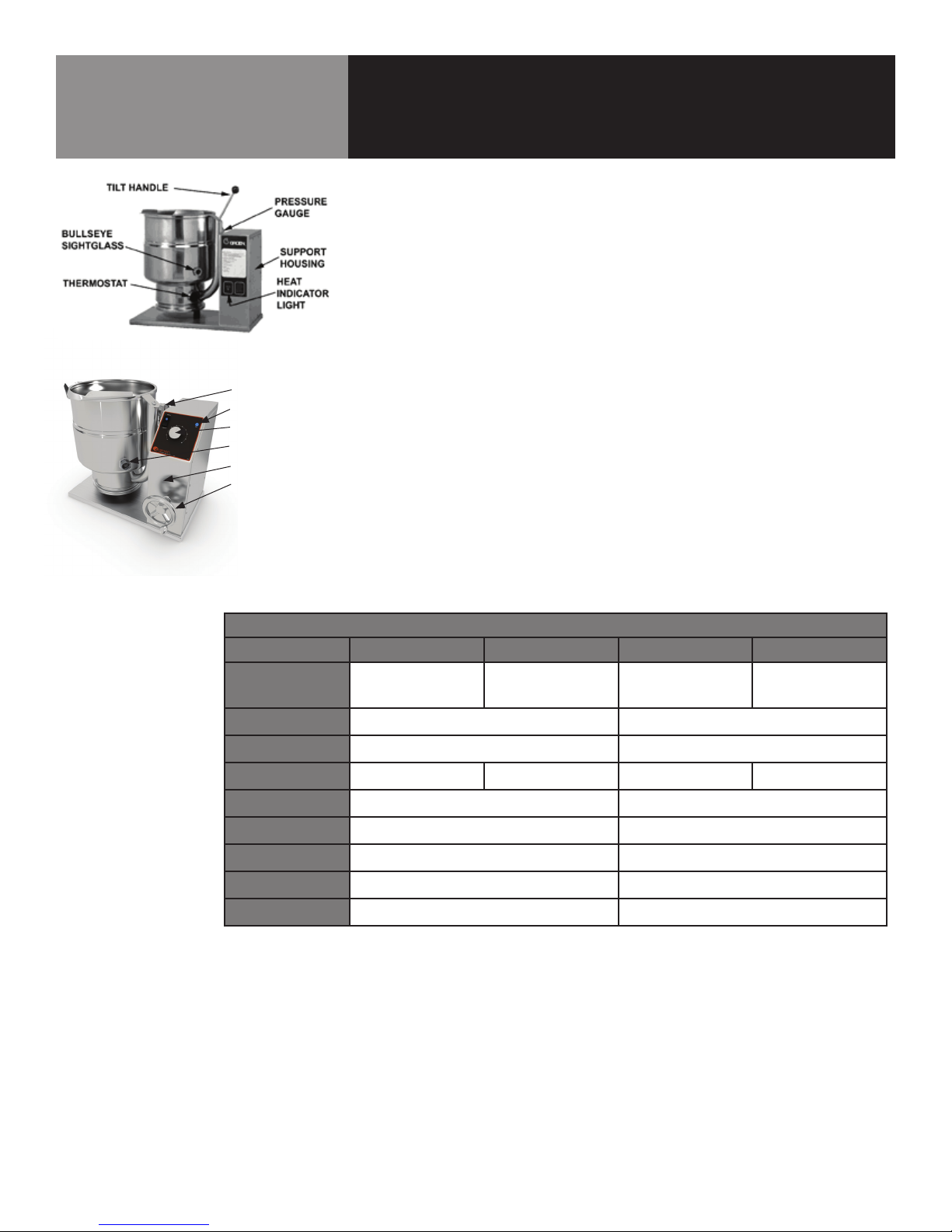

Classic Control

Advanced Control

Operation

A. Controls

1. Classic Control (-XXC) Models

a. Lighted Power ON switch located on the control console.

Controls main power to the unit.

b. The temperature knob, located on the control console, is used

to set the kettle heat values between 1 and 10.

c. Heating indicator light located on the control console, lights

when the controller energizes the heating elements and will

cycle on and off once the unit reaches set temperature. If

the unit is tilted, the heating elements will be disabled and

the light will turn off until the unit is returned to the cooking

position.

d. A LOW WATER indicator light, located on the control console,

illuminates when the jacket water falls below acceptable

levels. When lit, the heating elements are disabled and

will not function until the jacket water is refilled using the

procedure on p. 18 of this manual.

e. Crank tilt - a handle controls the worm and gear mechanism

that smoothly tilts the kettle body and holds it in the desired

position.

2. Advanced Control (-XXA) models

a. i. Lighted Power ON switch located on the control console.

Controls main power to the unit.

b. The temperature knob, located on the control console, is used

to set the kettle heat values between 1 and 10. The current

setting will be reflected on the display.

c. Heating indicator light located on the control console, lights

when the controller energizes the heating elements and will

cycle on and off once the unit reaches set temperature. If

the unit is tilted, the heating elements will be disabled and

the light will turn off until the unit is returned to the cooking

position.

d. A LOW WATER indicator light, located on the control console,

illuminates when the jacket water falls below acceptable

levels. When lit, the heating elements are disabled and

will not function until the jacket water is refilled using the

procedure on p. 18 of this manual.

e. SET TnnP Mode - Allows power to the controller without

the kettle heating; the kettle will heat once the LOW TEMP,

MANUAL or HIGH TEMP button is selected.

f. LOW TEMP Button – Used to set operating temperature of the

kettle at a preset low intensity (default = 2). Can be pressed

at any time during operation of the unit to change the set

temperature to the preset value except when there is an

active TIMER enabled.

g. MANUAL Mode button – Enables the user modify the desired

cooking temperature of the kettle (between 1 and 10)

using the temperature knob and display (default = 4). The

operator will press the MANUAL button and set the desired

temperature using the temperature knob and display. Once

the desired temperature is reached, the user may either

press the MANUAL button again or wait 5 seconds and the