56

2.5 Electrical Connection Warnings

2.6 Operation Warnings

Ø

Ø

Ø

Ø

Prior to installation, inspect the unit to ensure absence of any

transport or handling damage, which could affect insulation

integrity or safety clearances; failure to do so could result in

safety hazards.

Assemble the inverter per the instructions in this manual. Use care

when choosing installation location and adhere to specified

cooling requirements.

Unauthorized removal of necessary protections, improper use,

incorrect installation and operation may lead to serious safety

and shock hazards and/or equipment damage.

In order to minimize the potential of a shock hazard due to

hazardous voltages, cover the entire solar array with dark

material prior to connecting the array to any equipment.

ØGrounding the PV modules:The MIN TL-X is a transformerless

inverter. That is why it has no galvanic separation. Do not ground

the DC circuits of the PV modules connected to the MIN TL-X.

Only ground the mounting frame of the PV modules.If you

connect grounded PV modules to the MIN TL-X, the error

message "PV ISO Low".

Comply with the local requirements for grounding the PV

modules and the PV generator. GROWATT recommends

connecting the generator frame and other electrically conductive

surfaces in a manner which ensures continuous conduction with

ground in order to have optimal protection of the system and

personnel.

Ø

WARNING

CAUTION

CAUTION

Do not open the inverter except the wire box by qualified persons.

Electrical installation, repairs and conversions may only be carried

out by electrically qualified persons.

Do not touch damaged inverters.

ØDanger to life due to high voltages in the inverter

ØPersons with limited physical or mental abilities may only work

with the Growatt inverter following proper instruction and under

constant supervision. Children are forbidden to play with the

Growatt inverter. Must keep the Growatt inverter away from

children.

There is residual voltage in the inverter. The inverter takes 20

minutes to ischarge.

ØThe components in the inverter are live. Touching live components

can result in serious injury or death.

DANGER

WARNING

Ø

Ø

Ø

Ensure all connectors are sealed and secure during operation.

Although designed to meet all safety requirements, some parts

and surfaces of Inverter are still hot during operation. To reduce

the risk of injury, do not touch the heat sink at the back of the PV-

Inverter or nearby surfaces while Inverter is operating.

Incorrect sizing of the PV plant may result in voltages being

present which could destroy the inverter. The inverter display will

read the error message “PV voltage High!”

Turn the rotary switch of the DC Disconnect to the Off

position immediately.

Contact installer.

Ø

Ø

Ø

Ø

All operations regarding transport, installation and start-up,

including maintenance must be operated by qualified, trained

personnel and in compliance with all prevailing codes and

regulations.

Anytime the inverter has been disconnected from the power

network, use extreme caution as some components can retain

charge sufficient to create a shock hazard; to minimize

occurrence of such conditions, comply with all corresponding

safety symbols and markings present on the unit and in this

manual.

In special cases, there may still be interference for the specified

application area despite maintaining standardized emission limit

values (e.g. when sensitive equipment is located at the setup

location or when the setup location is near radio or television

receivers).In this case, the operator is obliged to take proper

action to rectify the situation.

Do not stay closer than 20 cm to the inverter for any length of

time.

2.4 Assembly Warnings Ø

Ø

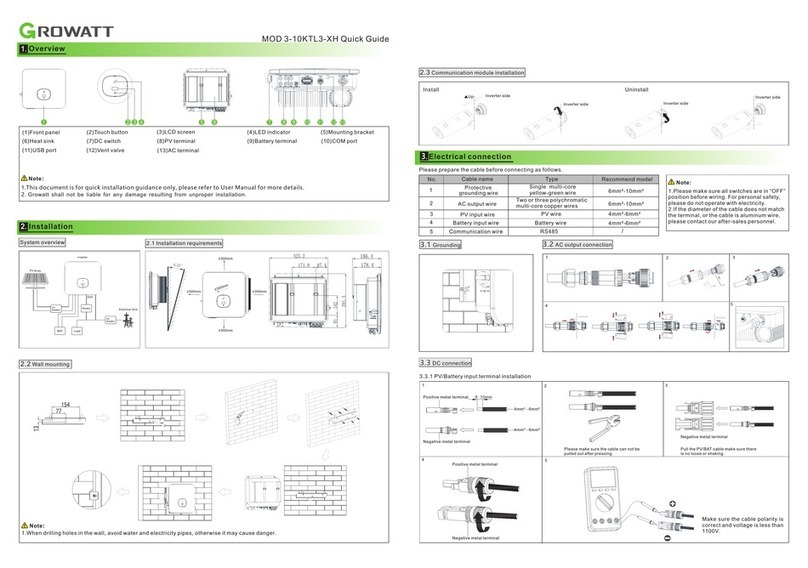

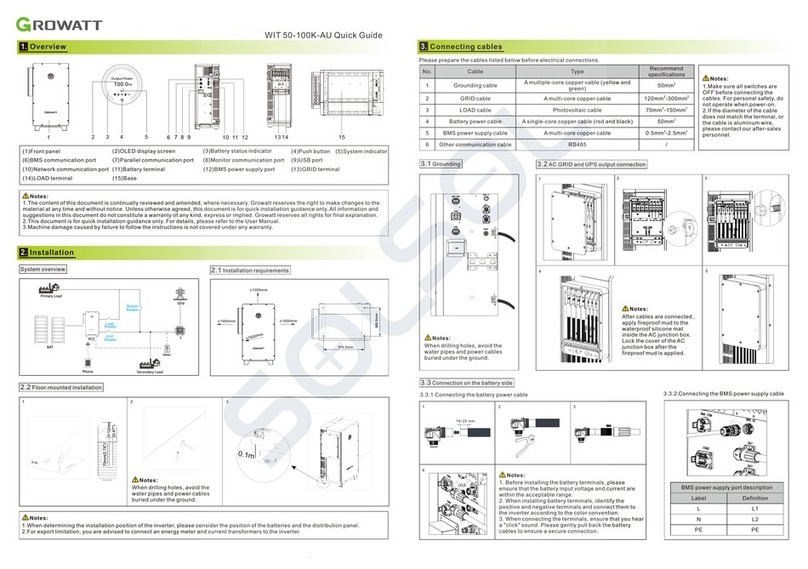

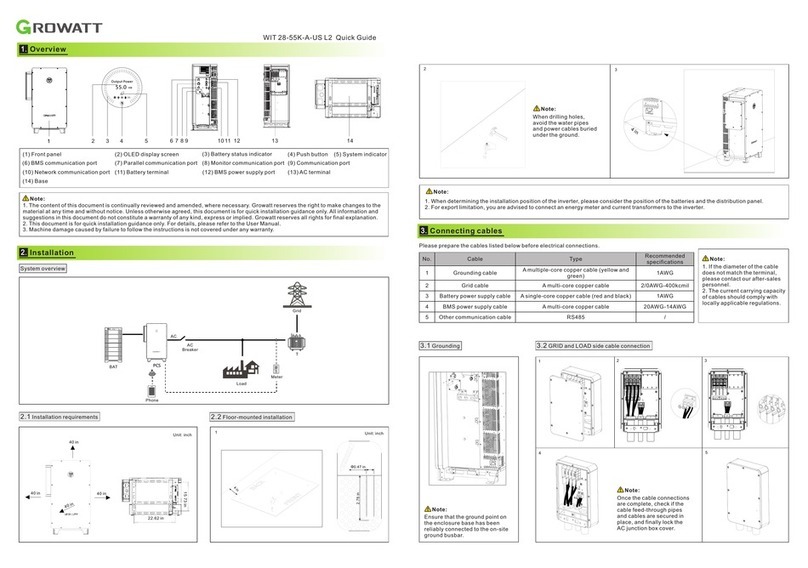

Make all electrical connections (e.g. conductor termination,

fuses, PE connection, etc.) in accordance with prevailing

regulations. When working with the inverter powered on, adhere

to all prevailing safety regulations to minimize risk of accidents.

Systems with inverters typically require additional control (e.g.,

switches, disconnects) or protective devices (e.g., fusing circuit

breakers) depending upon the prevailing safety rules.

WARNING