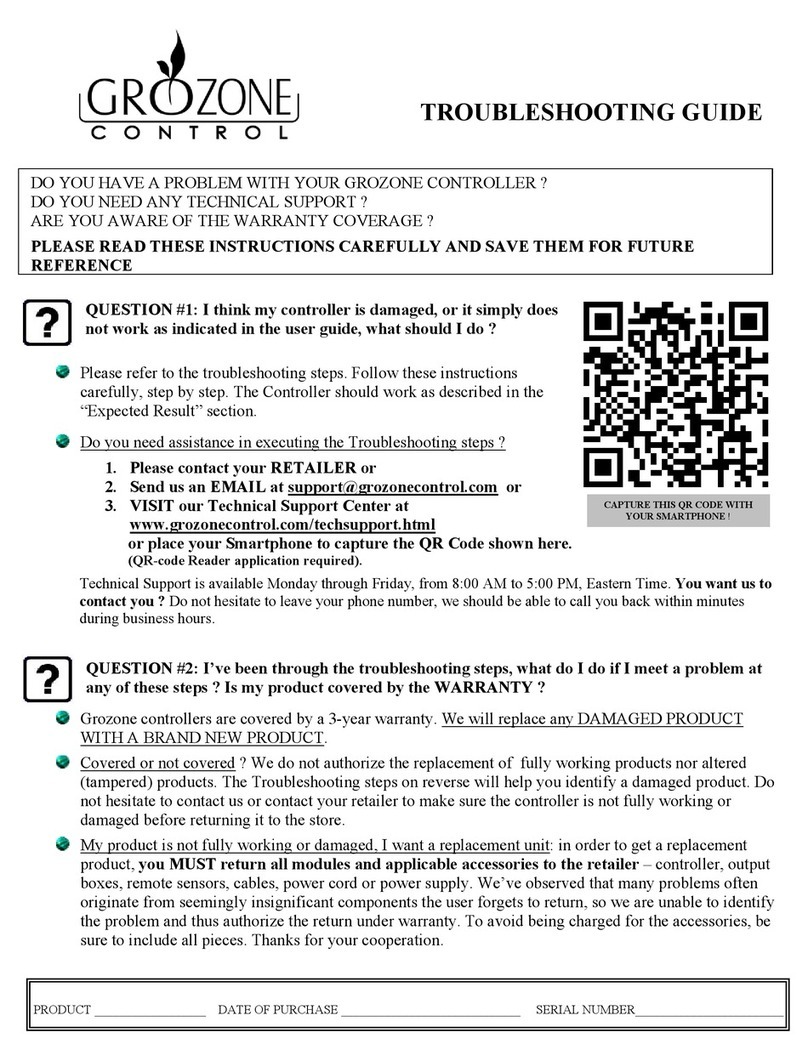

Step 6

Setting high temperature limit

Click knob and rotate to set high temperature limit from 21°C to 49°

C (70°F to 120°F). Default is 35°C (95°F) displayed as H 35 (H 95).

To disable the high temperature shut-off function turn knob clock-

wise beyond 49°C (120°F) until « OFF » appears on screen.

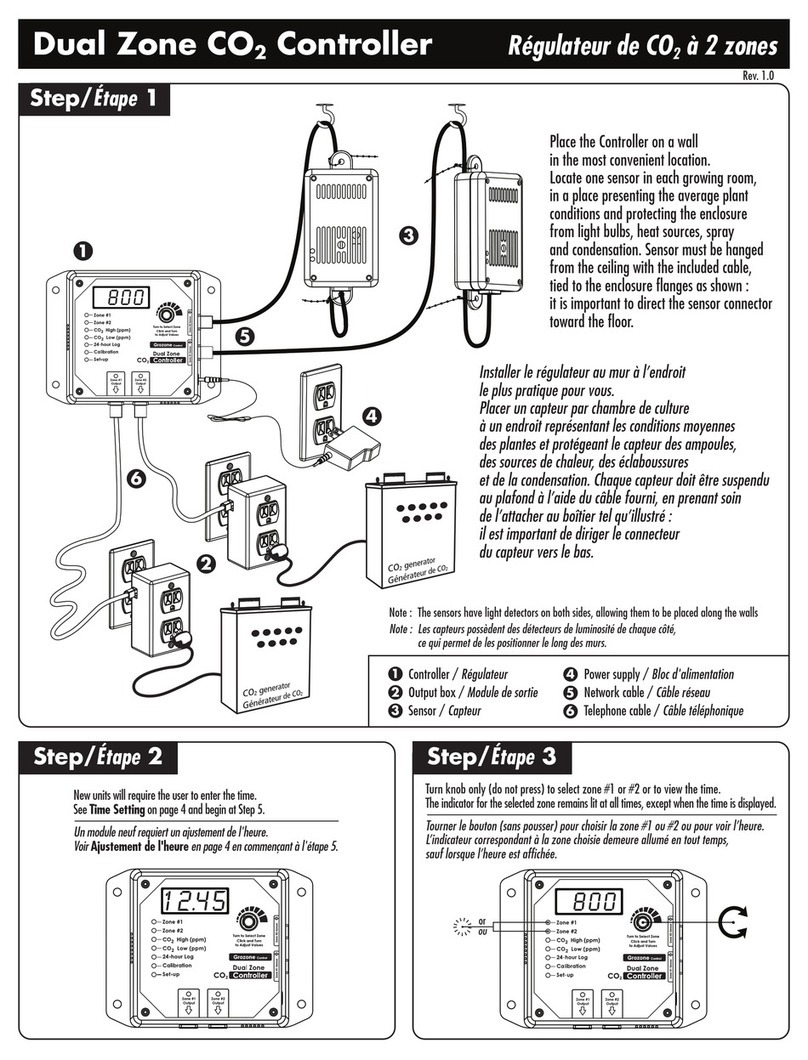

INSTALLATION & OPERATION

End of settings

TO EXIT and RETURN TO NORMAL OPERATION click knob TWICE.

TO CALIBRATE THE CO2 SENSOR click knob only ONCE and refer to the

instructions on next pages.

Controller Operation

Your controller is set and ready to operate when the top 3 light indicators

are off. According to selected operation mode the controller will either

exhaust CO2 from or inject CO2 into your grow room and maintain the CO2

level between the user defined high and low limits (steps 2 and 3).

When using a gas burner as CO2 generator you are likely to experience high

temperature conditions that can damage your crop. With high temp shut-

off function enabled the controller will defeat the burner if room tempera-

ture reaches the high temperature limit (step 6). CO2 Operation resumes

automatically when room temperature cools down by 3°C (5°F).

Displaying actual CO2 and temperature: in order to switch between

actual CO2 and temperature values on screen rotate knob clockwise

for temperature or counter clockwise for CO2.

7