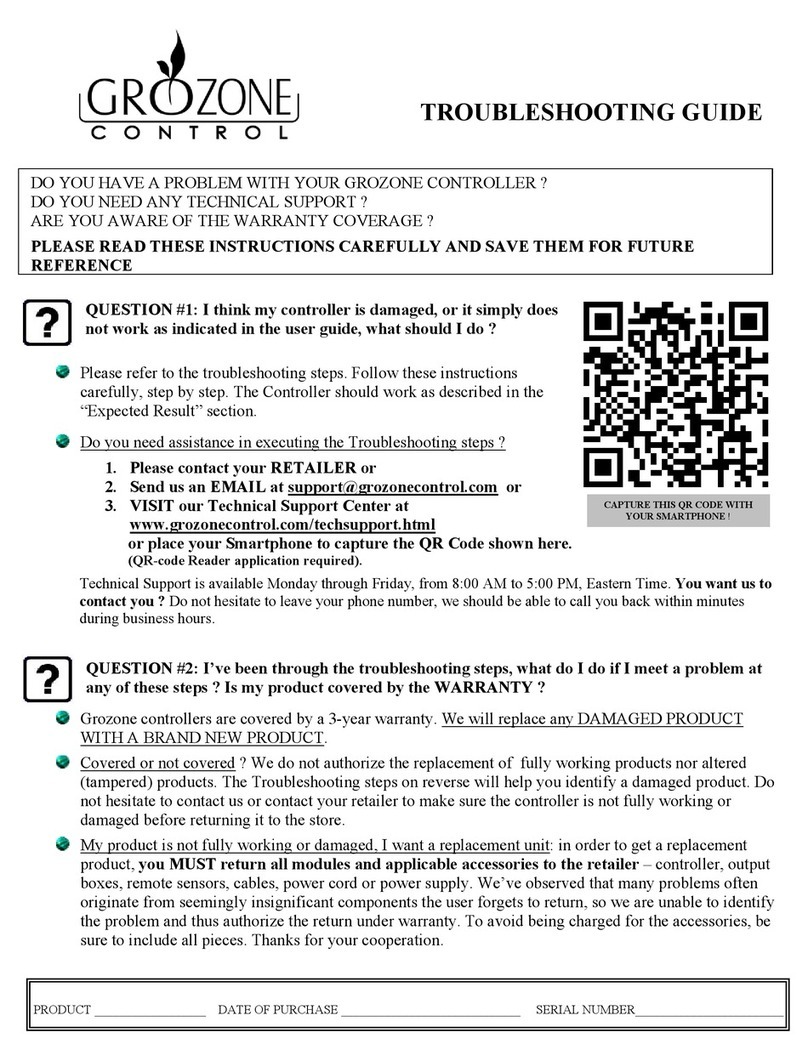

Grozone Control CO2D User manual

Other Grozone Control Controllers manuals

Grozone Control

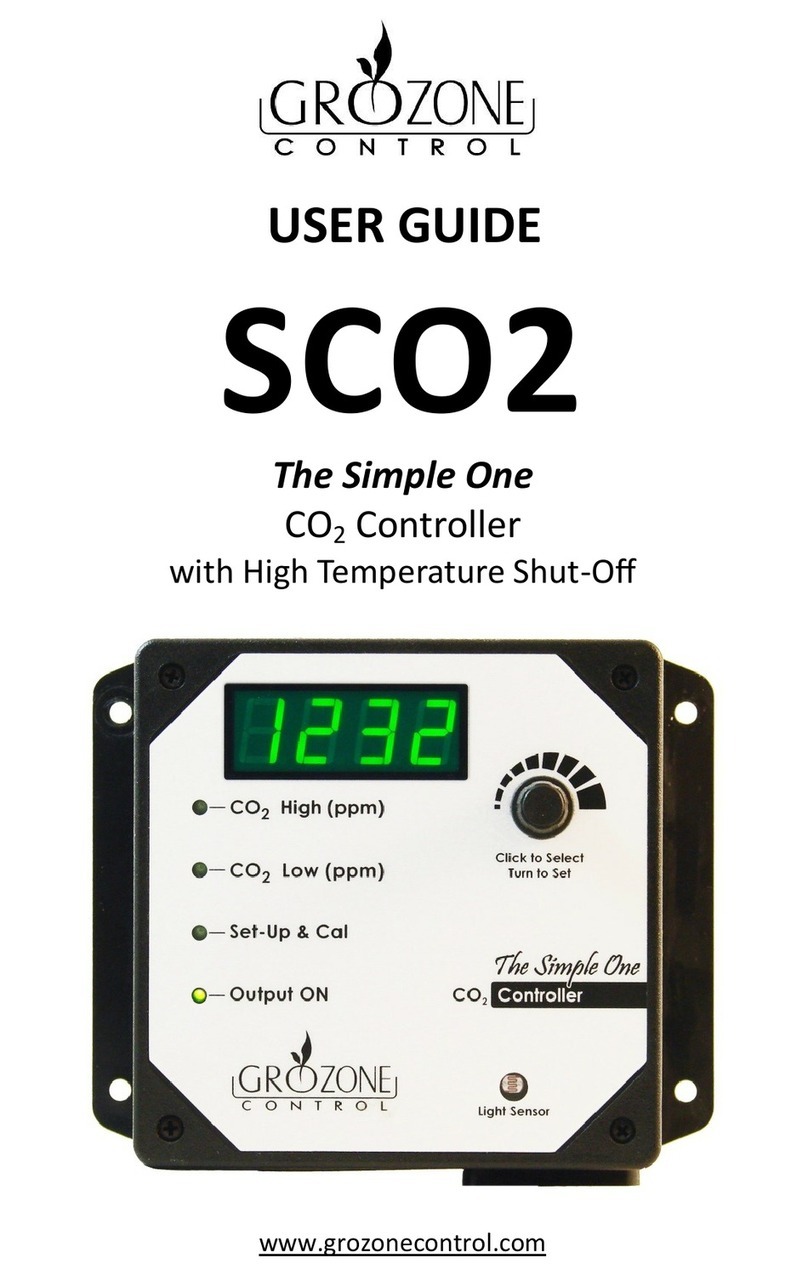

Grozone Control SCO2 User manual

Grozone Control

Grozone Control HT2 User manual

Grozone Control

Grozone Control SCC1 User manual

Grozone Control

Grozone Control TV2 User manual

Grozone Control

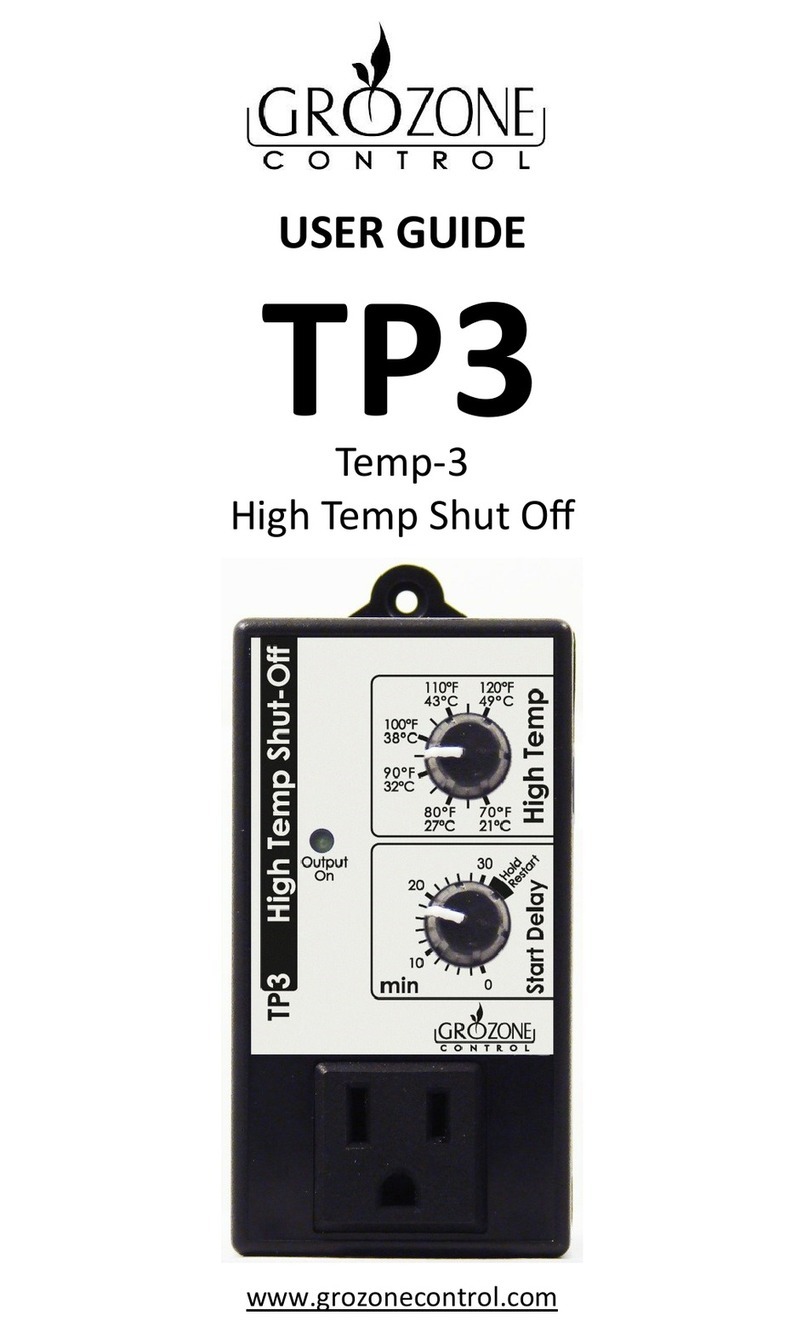

Grozone Control Temp-3 User manual

Grozone Control

Grozone Control TV2 User manual

Grozone Control

Grozone Control The Simple One CLIMATE CONTROLLER Assembly instructions

Grozone Control

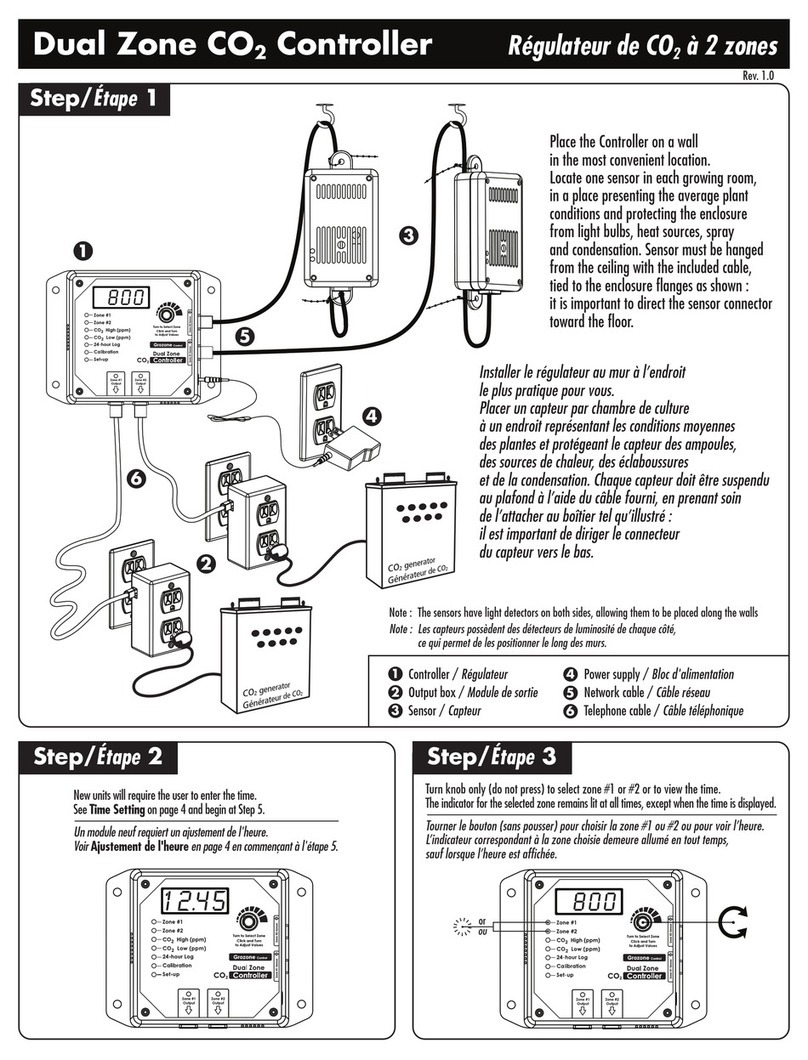

Grozone Control Dual Zone CO2 Controller User manual

Grozone Control

Grozone Control TV12 User manual

Grozone Control

Grozone Control SCO2 User manual