Table of Contents

PNEG-1707 TM-Series Tower Dryer 3

Contents

Chapter 1 Safety ..................................................................................................................................................... 5

Safety Guidelines .................................................................................................................................. 5

Cautionary Symbols Definitions ............................................................................................................ 6

Safety Cautions ..................................................................................................................................... 7

Safety Sign-Off Sheet ......................................................................................................................... 12

Emergency Stop Switch ...................................................................................................................... 13

Operating Precautions ........................................................................................................................ 14

Chapter 2 Safety Decals ...................................................................................................................................... 15

Chapter 3 Specifications ..................................................................................................................................... 17

Modular Tower Dryer Specifications ................................................................................................... 17

Dimensions ......................................................................................................................................... 18

Chapter 4 Dryer Installation ................................................................................................................................ 20

Dryer Layout ........................................................................................................................................ 20

Liquid Propane (LP) Dryers with Internal Vaporizers .......................................................................... 20

Natural Gas (NG) Dryers ..................................................................................................................... 20

Modular Base Layout .......................................................................................................................... 21

Central United States Foundation Plan ............................................................................................... 22

Northern United States Foundation Plan ............................................................................................ 23

Fuel Supply ......................................................................................................................................... 24

Electrical Power Supply ...................................................................................................................... 25

Transformers and Wiring Voltage Drop ............................................................................................... 25

Power Supply Disconnect ................................................................................................................... 26

Machine to Earth Grounding ............................................................................................................... 27

Proper Installation of Ground Rod ....................................................................................................... 27

Connecting Auxiliary Conveyors ......................................................................................................... 27

Chapter 5 Operating Controls ............................................................................................................................. 28

Vision Control Panel Layout ................................................................................................................ 28

Control Power Switch .......................................................................................................................... 28

Fan Switch .......................................................................................................................................... 28

Heater Switch ...................................................................................................................................... 29

Load Auger Switch .............................................................................................................................. 29

Unload Switch ..................................................................................................................................... 29

Outside Light Switch ........................................................................................................................... 29

Start Switch ......................................................................................................................................... 29

Stop Switch ......................................................................................................................................... 29

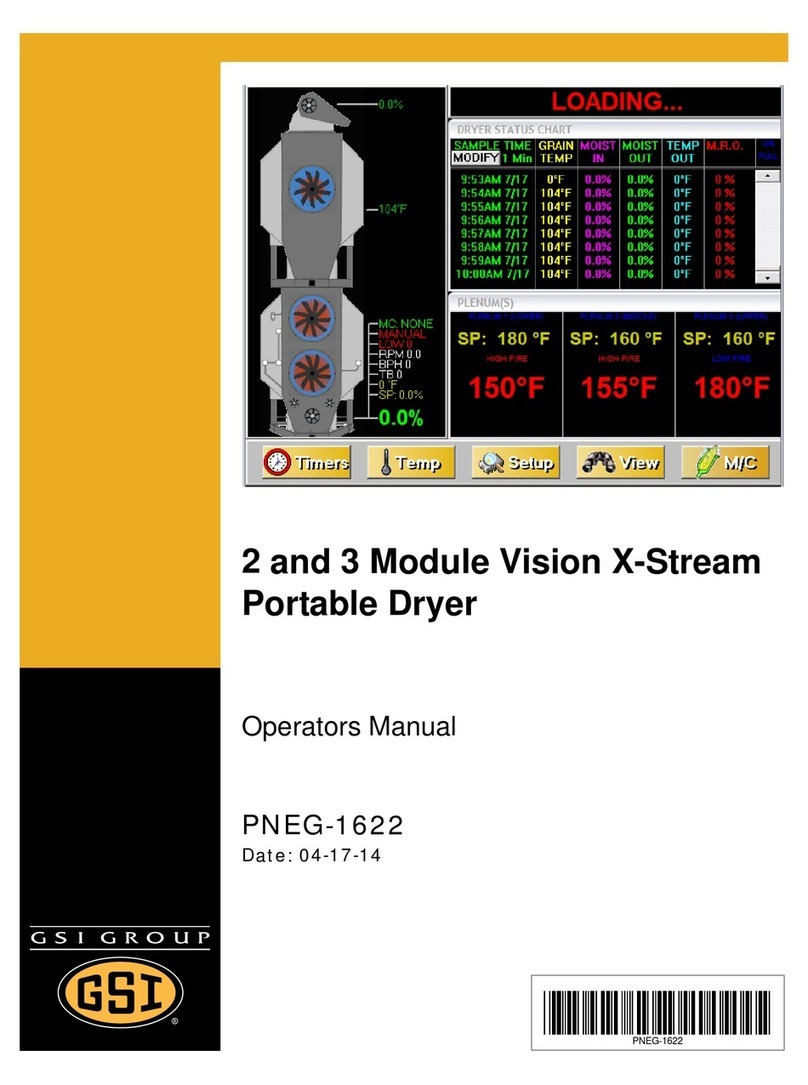

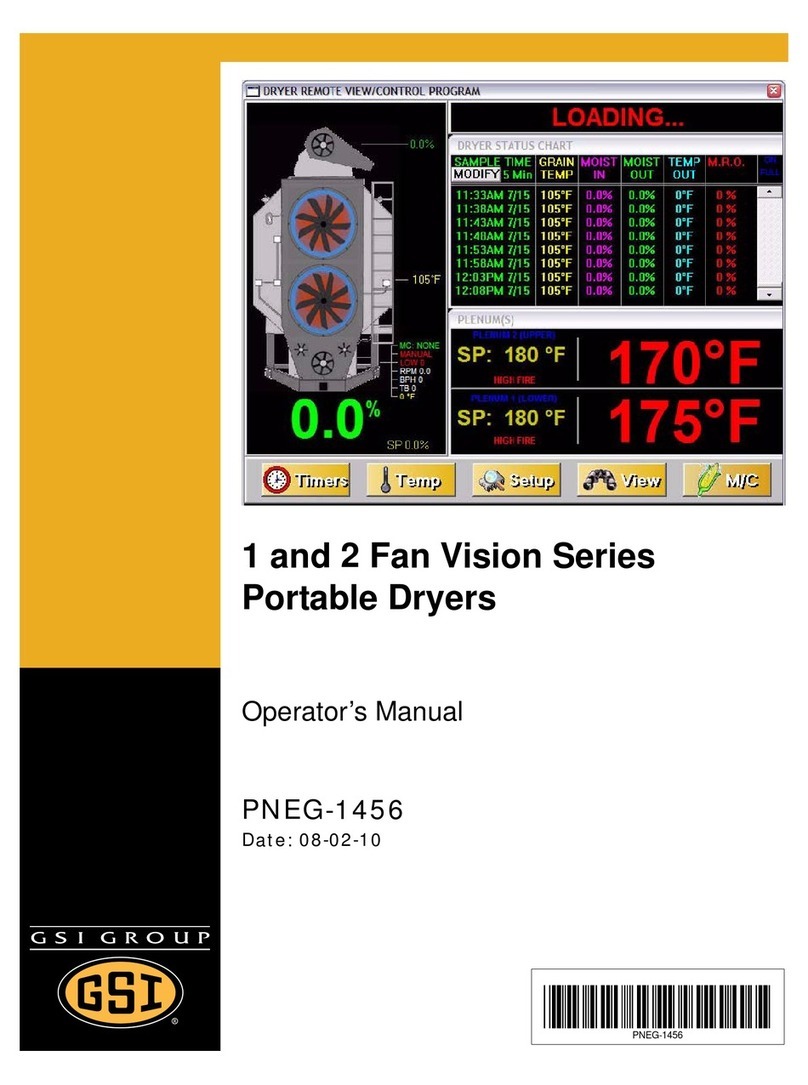

Chapter 6 Vision Touch Screen Display ............................................................................................................ 30

Boot Screen ........................................................................................................................................ 30

Default Operation Screen .................................................................................................................... 30

Setting the Timers ............................................................................................................................... 31

Setting the Temperatures .................................................................................................................... 32

The Setup Screen ............................................................................................................................... 34