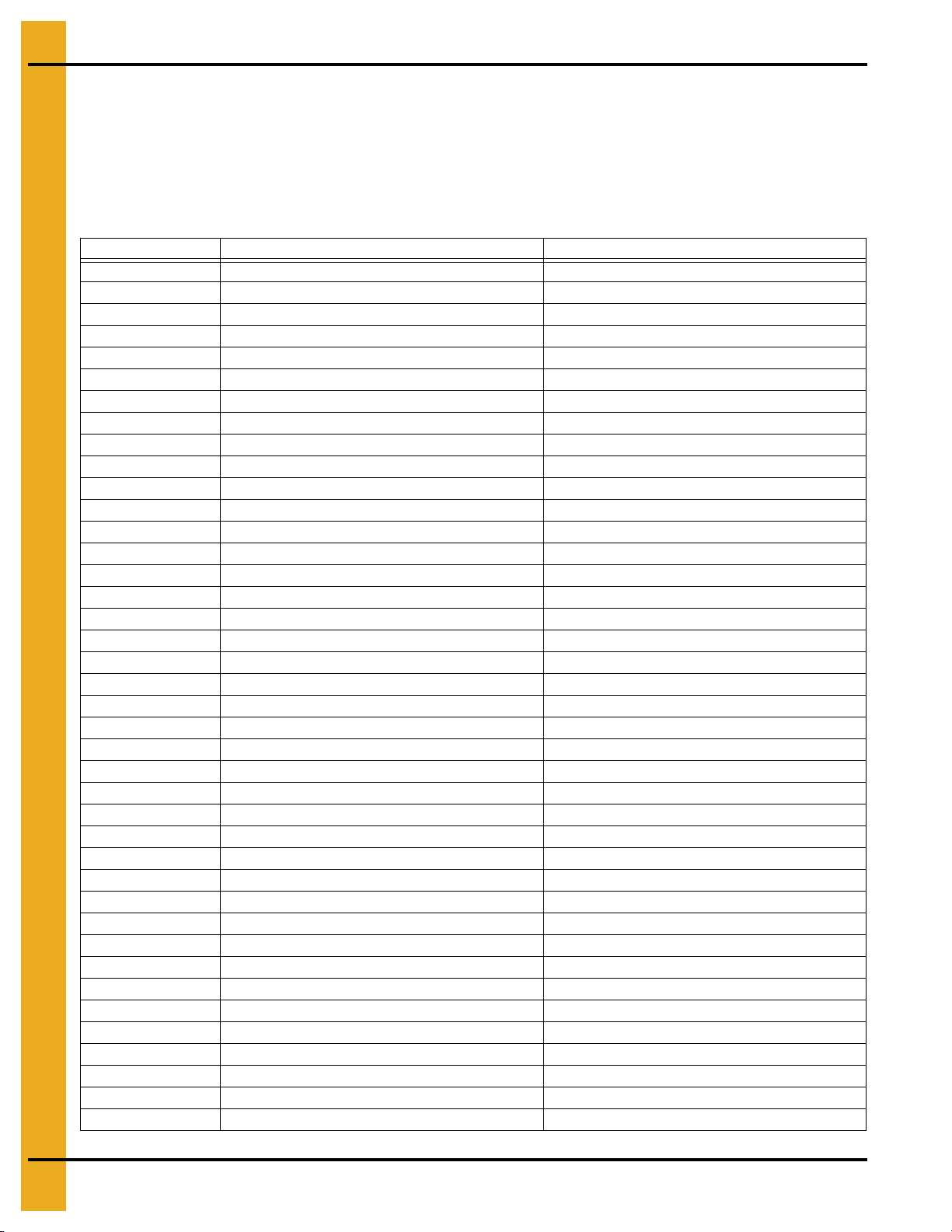

Table of Contents

4PNEG-696 TopDry Series 2000 Autoflow

Chapter 7 Error Messages ..................................................................................................................................22

Burner 1 Loss Flame ........................................................................................................................... 22

Burner 2 Loss Flame ........................................................................................................................... 22

Fan 1 Vapor High-Limit ....................................................................................................................... 22

Fan 2 Vapor High-Limit ....................................................................................................................... 22

Fan 1 Housing High-Limit .................................................................................................................... 22

Fan 2 Housing High-Limit .................................................................................................................... 22

Plenum High-Limit ............................................................................................................................... 23

Fan 1 Motor Overload ......................................................................................................................... 23

Fan 2 Motor Overload ......................................................................................................................... 23

Fan 1 Loss of Airflow ........................................................................................................................... 23

Fan 2 Loss of Airflow ........................................................................................................................... 23

Drying Chamber Overflow ................................................................................................................... 23

Bin Grain High-Limit Full ..................................................................................................................... 23

Bin High-Limit Switch Bad ................................................................................................................... 23

Out of Grain ......................................................................................................................................... 23

Fill 1 Motor Overload ........................................................................................................................... 24

Fill 2 Motor Overload ........................................................................................................................... 24

Aeration Overload ............................................................................................................................... 24

Grain High-Limit .................................................................................................................................. 24

Chapter 8 Pre-Season Checks ............................................................................................................................25

Set Control Switches ........................................................................................................................... 25

Control Power Switch.......................................................................................................................... 25

Drying Chamber.................................................................................................................................. 25

Rotary Switches .................................................................................................................................. 25

Dump Chutes ...................................................................................................................................... 25

Linear Actuator .................................................................................................................................... 26

Power Start Button .............................................................................................................................. 26

Fuel Check .......................................................................................................................................... 26

Fan ...................................................................................................................................................... 26

Aeration Fan ........................................................................................................................................ 26

Fill System ........................................................................................................................................... 27

Air Switch ............................................................................................................................................ 27

Burner Test Fire .................................................................................................................................. 27

Dryer Shut Down ................................................................................................................................. 27

Emergency .......................................................................................................................................... 27

Chapter 9 Autoflow Theory .................................................................................................................................28

TopDry Autoflow Theory of Operation ................................................................................................. 28

Chapter 10 Start-Up Procedure ..........................................................................................................................30

Initial Dryer Start-Up .......................................................................................................................... 30

Normal Start-Up ................................................................................................................................. 32

Last Fill .............................................................................................................................................. 32

Chapter 11 Drying Rates .....................................................................................................................................33

Chapter 12 Autoflow Series Drying Rates .........................................................................................................35

Chapter 13 Warranty ............................................................................................................................................37