Table of Contents

PNEG-012 Vane Axial Heater 3

Contents

Chapter 1 Safety .................................................................................................................................................. 4

Safety Guidelines ............................................................................................................................... 4

Introduction ........................................................................................................................................ 5

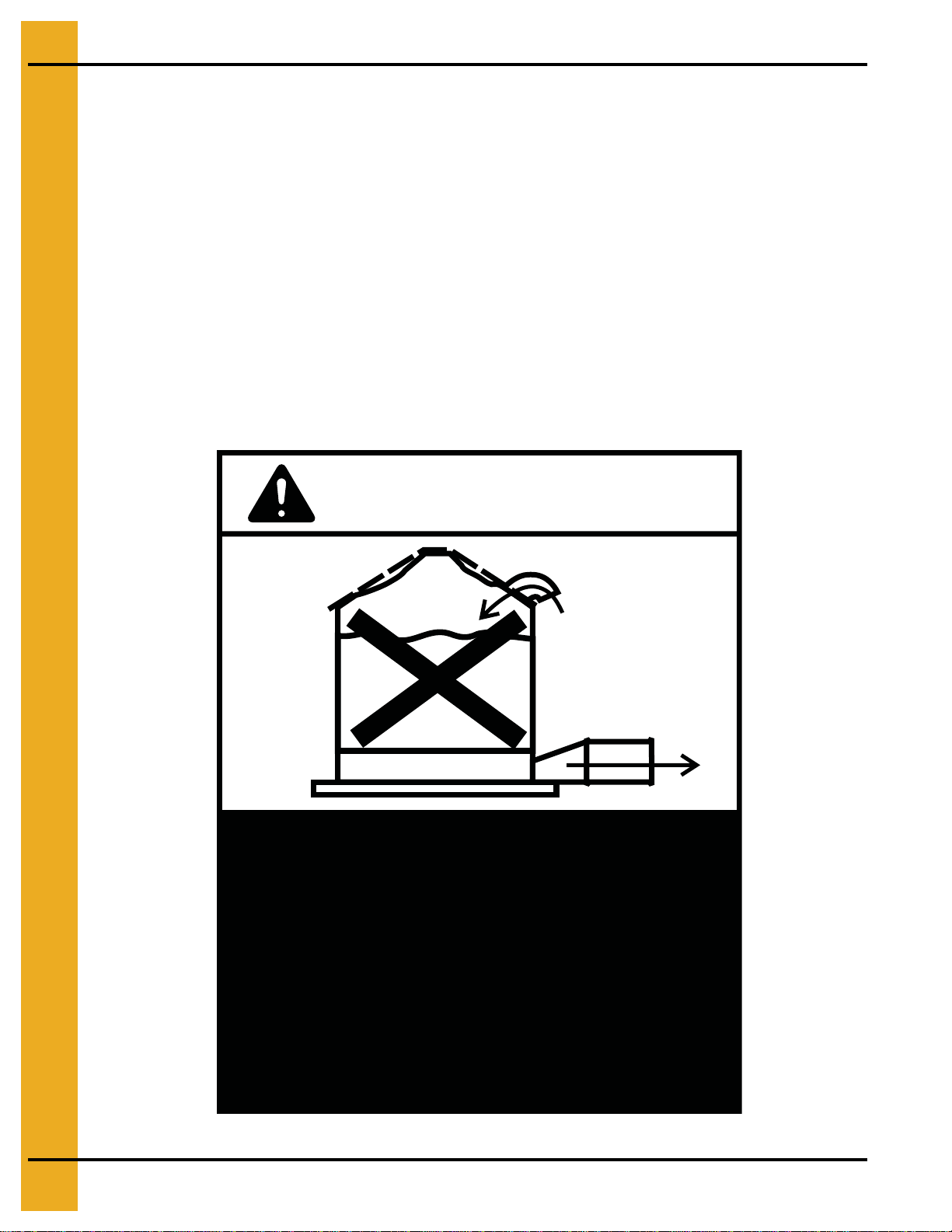

Chapter 2 Safety Decals ..................................................................................................................................... 6

Roof Damage Warning and Disclaimer .............................................................................................. 6

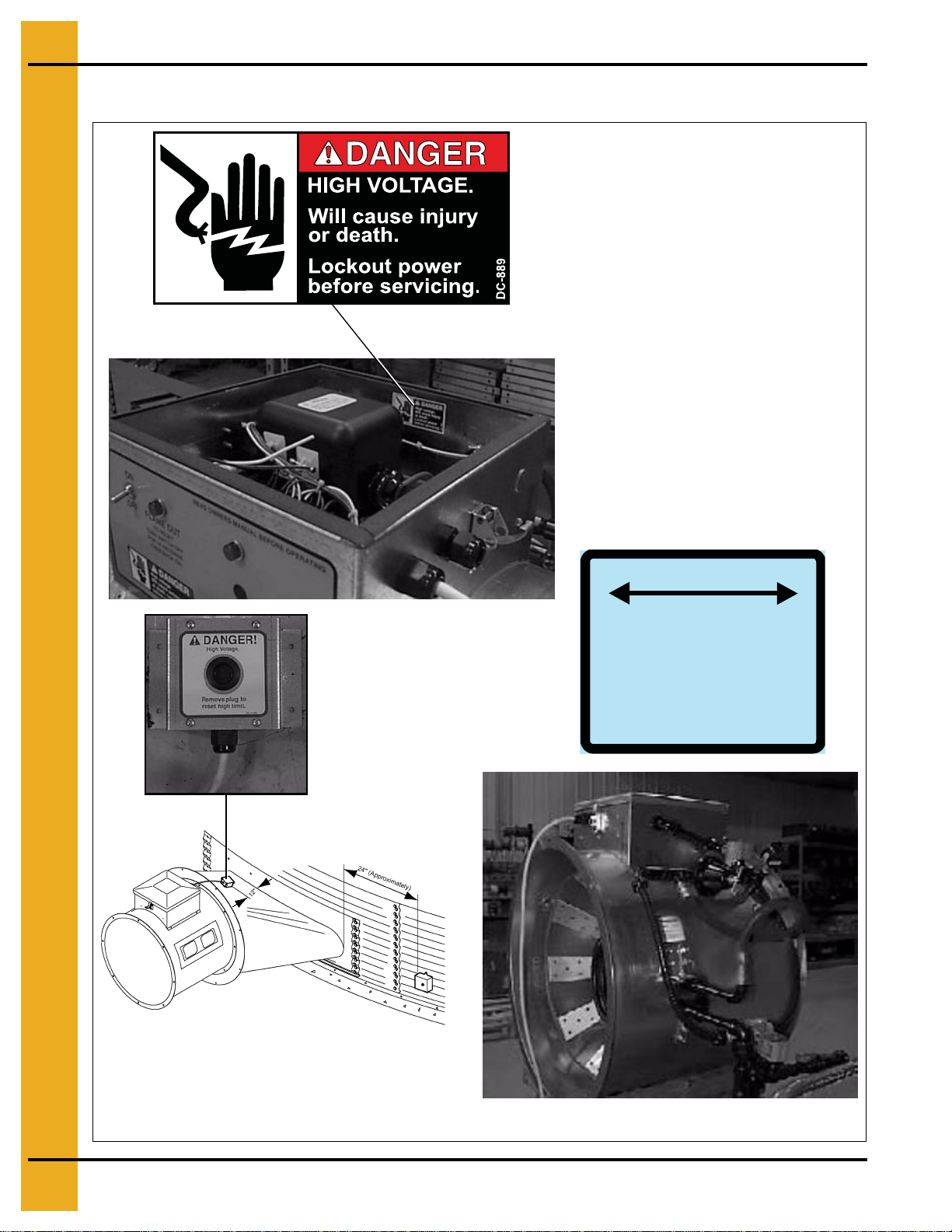

Heater Access Door Decals ............................................................................................................... 7

Control Box Decals ............................................................................................................................ 8

Chapter 3 Specifications .................................................................................................................................... 9

Heater Specifications ......................................................................................................................... 9

Chapter 4 Installation ....................................................................................................................................... 10

Fuel Connection ............................................................................................................................... 10

Liquid Propane Models .................................................................................................................... 10

Propane Vapor Models .................................................................................................................... 10

Natural Gas Models ......................................................................................................................... 10

Standard Heater Electrical Installation ............................................................................................. 10

Standard Heater - Second Heater Installation ................................................................................. 12

Deluxe Heater Electrical Installation ................................................................................................ 13

Deluxe Heater - Second Heater Installation ..................................................................................... 14

Bin Configuration .............................................................................................................................. 15

Transition High-Limit Installation ...................................................................................................... 15

Plenum Thermostat Mounting .......................................................................................................... 16

Heater Setup .................................................................................................................................... 17

Chapter 5 Operation ......................................................................................................................................... 18

Operating Temperature Table .......................................................................................................... 18

Cycling Heater Operation ................................................................................................................. 18

Time Delay Operation - Standard Heater.......................................................................................... 19

High-Low Heater Operation ............................................................................................................. 20

Modulating Valve Operation ............................................................................................................. 21

Adjusting the Vaporizer .................................................................................................................... 22

BTUs per Gauge Pressure (PSI) - Propane Models (Approximate) ................................................. 23

BTUs per Gauge Pressure (PSI) - Natural Gas Models (Approximate) ........................................... 24

Chapter 6 Service .............................................................................................................................................. 25

Chapter 7 Troubleshooting - Standard Heater................................................................................................ 26

Chapter 8 Wiring Diagrams .............................................................................................................................. 27

Standard Heater Wiring .................................................................................................................... 27

Standard Heater Schematic ............................................................................................................. 28

Deluxe Heater .................................................................................................................................. 29

Chapter 9 Parts List .......................................................................................................................................... 30

Standard Heater Control Box Parts .................................................................................................. 30

Deluxe Heater Control Box Parts ..................................................................................................... 32

18" Gas Heater Parts ....................................................................................................................... 33

24", 26" and 28" Gas Heater Parts ................................................................................................... 34

18" Vapor/NG Pipe Train Assembly ................................................................................................. 36

24", 26" and 28" LP Pipe Train Assembly ........................................................................................ 37

24", 26" and 28" LP High-Low Pipe Train Assembly ........................................................................ 38

24", 26" and 28" LP Modulating Pipe Train Assembly ..................................................................... 39

24", 26" and 28" Vapor/NG Pipe Train Assembly ............................................................................ 40

24", 26" and 28" Vapor/NG High-Low Pipe Train Assembly ............................................................ 41

24", 26" and 28" Vapor/NG Modulating Pipe Train Assembly .......................................................... 42

LP Supply Pipe Train Assembly ....................................................................................................... 43

Chapter 10 Warranty ......................................................................................................................................... 45