6

ROOF WARNING, OPERATION & SAFETY

ROOF DAMAGE WARNING AND DISCLAIMER

WARNING! BE ALERT!

Personnel operating or working around

electric fans should read this manual.

This manual must be delivered with the

equipment to its owner. Failure to read

this manual and its safety instructions is

a misuse of the equipment.

The symbol shown is used to call

your attention to instructions con-

cerning your personal safety. Watch

for this symbol; it points out impor-

tant safety precautions. It means

"ATTENTION", "WARNING", "CAU-

TION", and "DANGER". Read the

message and be cautious to the

possibility of personal injury or

death.

SAFETY ALERT SYMBOL

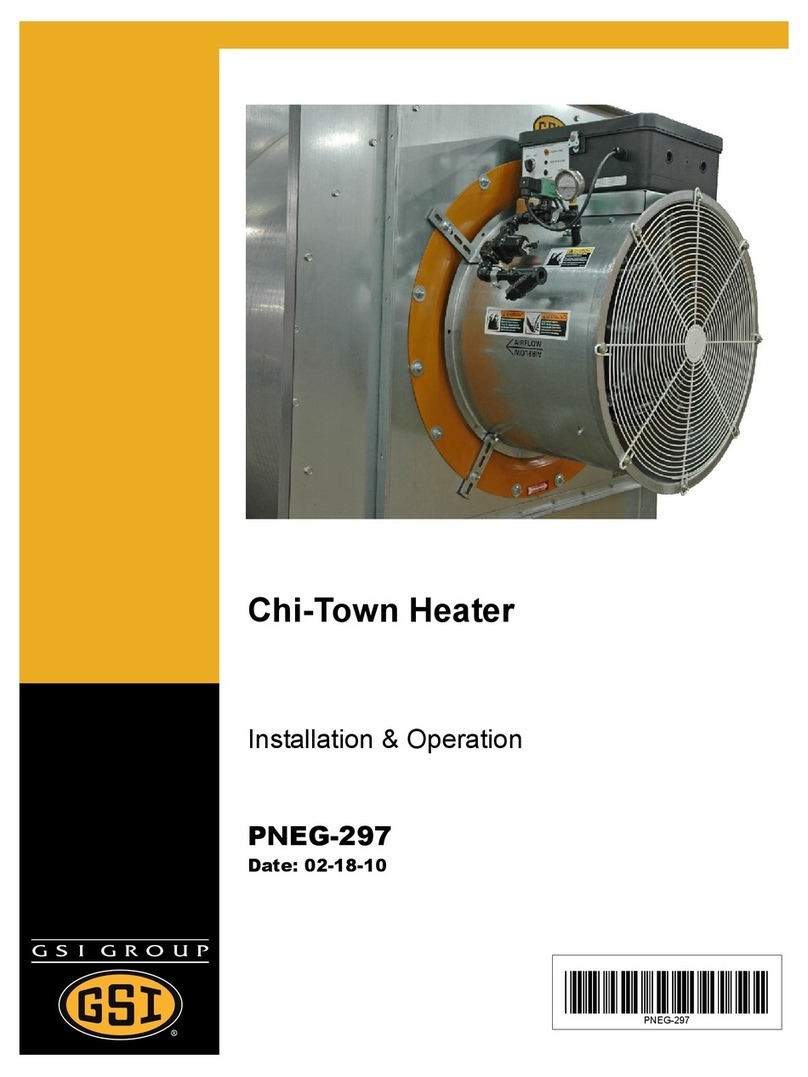

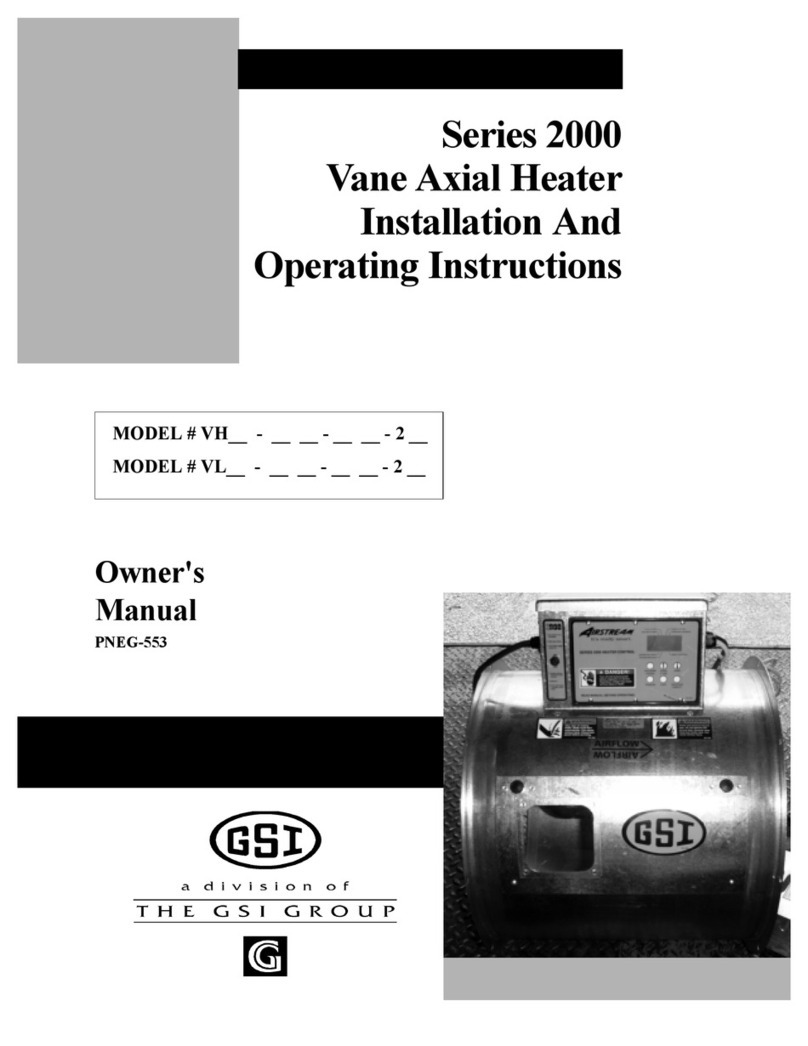

Thank you for choosing a GSI/Air-

stream product. It is designed to

give excellent performance and

service for many years.

This manual describes the op-

eration of the Airstream Chi-town

Heater. It is designed for low to me-

dium temperature grain condi-

tioning, and is ideal for the aera-

tion of rice, popcorn or other se-

lect grains. It is available in both

propane vapor and natural gas

models.

The principal concern of the GSI

Group, Inc. ("GSI") is your safety and

the safety of others associated with

grain handling equipment. This

manual is written to help you under-

stand safe operating procedures,

and some of the problems that may

be encountered by the operator or

other personnel.

As owner and/or operator, it is

your responsibility to know what

requirements, hazards and pre-

cautions exist, and to inform all

personnel associated with the

equipment, or who are in the dryer

area. Avoid any alterations to the

equipment. Such alterations may

produce a very dangerous situa-

tion, where serious injury or death

may occur.

GSI DOES NOT WARRANT ANY ROOF DAMAGE CAUSED

BY EXCESSIVE VACUUM OR INTERNAL PRESSURE FROM

FANS OR OTHER AIR MOVING SYSTEMS. ADEQUATE

VENTILATION AND/OR "MAKEUP AIR" DEVICES SHOULD

BE PROVIDED FOR ALL POWERED AIR HANDLING SYS-

TEMS. GSI DOES NOT RECOMMEND THE USE OF DOWN-

WARD FLOW SYSTEMS (SUCTION). SEVERE ROOF DAM-

AGE CAN RESULT FROM ANY BLOCKAGE OF AIR PAS-

SAGES. RUNNING FANS DURING HIGH HUMIDITY/COLD

WEATHER CONDITIONS CAN CAUSE AIR EXHAUST OR

INTAKE PORTS TO FREEZE.

HEATER OPERATION