SERIES 2 BUCKET ELEVATOR ASSEMBLY MANUAL

Rev. 3 6/4/01 9

Receiving Inspection

Carefully inspect the shipment for damage as soon as it is received. Verify that the quantity of parts or

packages actually received corresponds to the quantity shown on the packing slip. Any discrepancies should be

clarified immediately. One or more cartons containing the fasteners required for assembly are included with the

shipment. Report any damage or shortage to the delivering carrier as soon as possible. The manufacturer’s

responsibility for damage to the equipment ends with acceptance by the delivering carrier. Refer to the bill of

lading. Save all paperwork and documentation furnished with any of the elevator components.

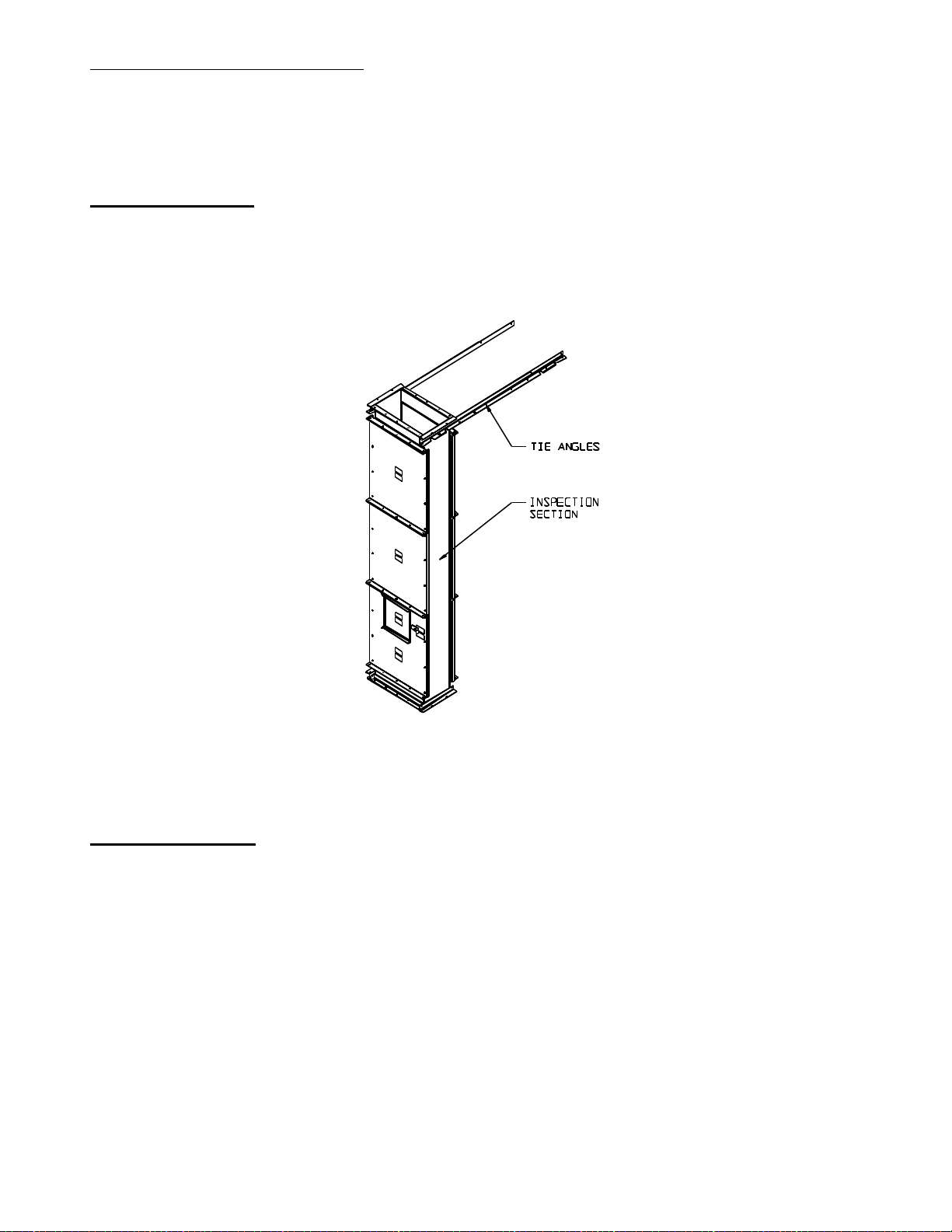

Pre-Installation Preparation

Our Bucket Elevators are designed to be vertically self-supporting when erected but must be supported or

guyed against wind loads.

NOTE: The elevator has not been designed to support other equipment such as cleaners, distributors

or spouting. Separate structures must be provided for any accessory equipment.

The manufacturer is the vendor of the elevator and certain of its optional accessories only and does not assume

responsibility for the installation recommendations contained within this manual. The installation

recommendations contained within this manual are for consideration only. The user or installer must consult a

civil or structural engineer regarding the design, construction and supervision of the entire installation, including

the elevator foundation and the guying cable and/or bracing system.

The MOST IMPORTANT preparations are retaining a licensed engineer to plan the installation and a qualified

millwright or contractor to erect the elevator and the accompanying equipment and structures.

Bucket Elevator Foundation

The bucket elevator foundation must be designed by a qualified civil engineer and installed by a qualified

contractor. Consideration should be given to live loads, dead loads, wind loads, and soil bearing loads.

Attention should also be given to ensure proper moisture run-off on the top of the base

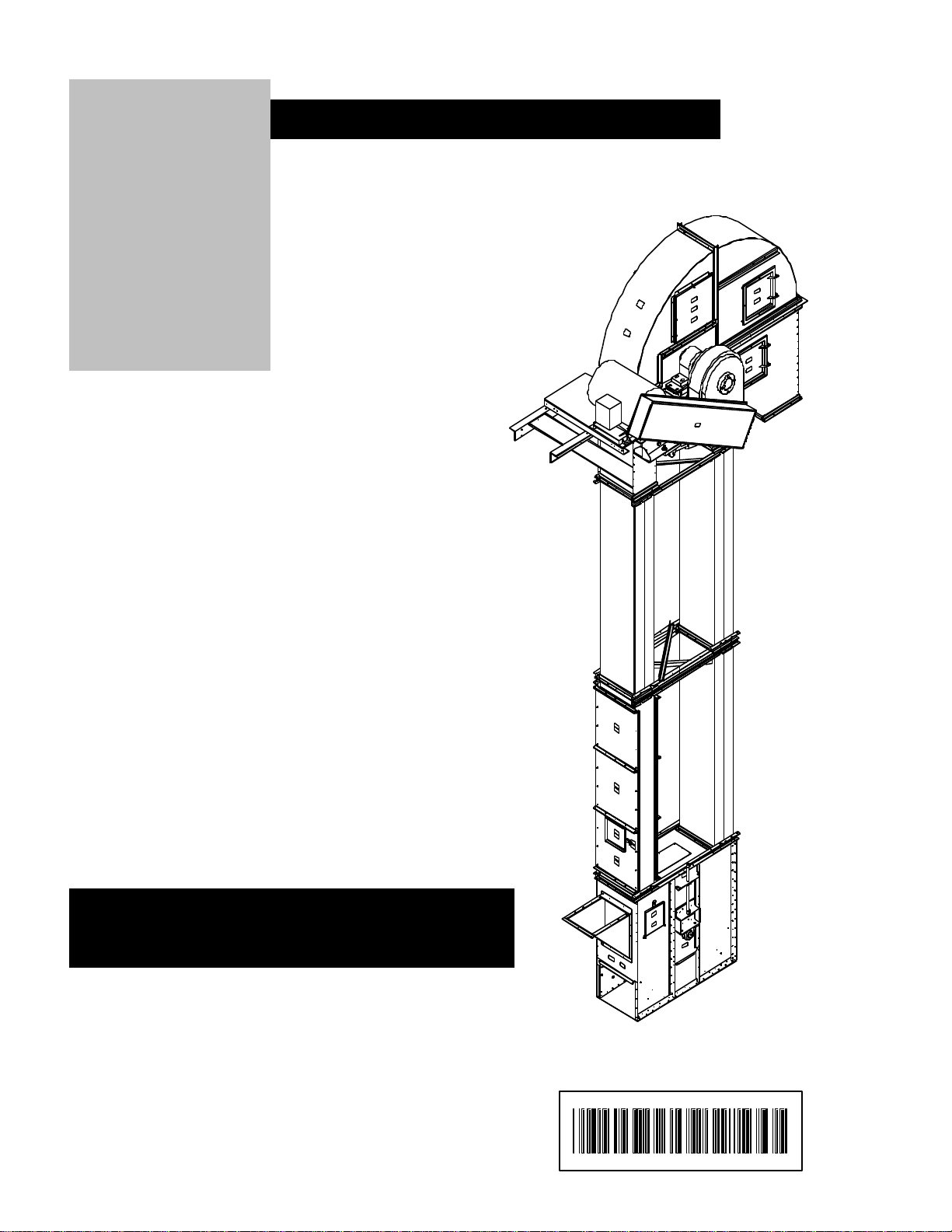

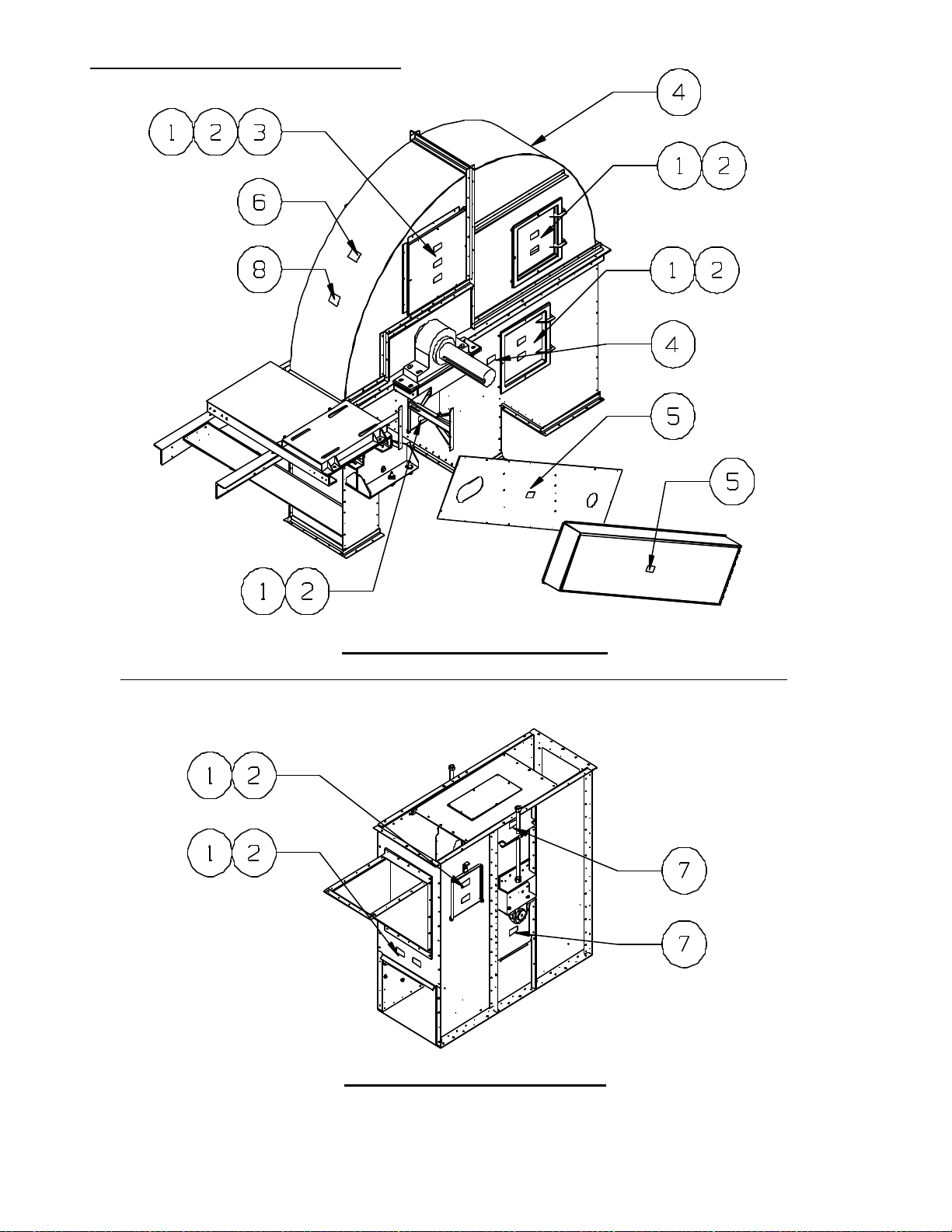

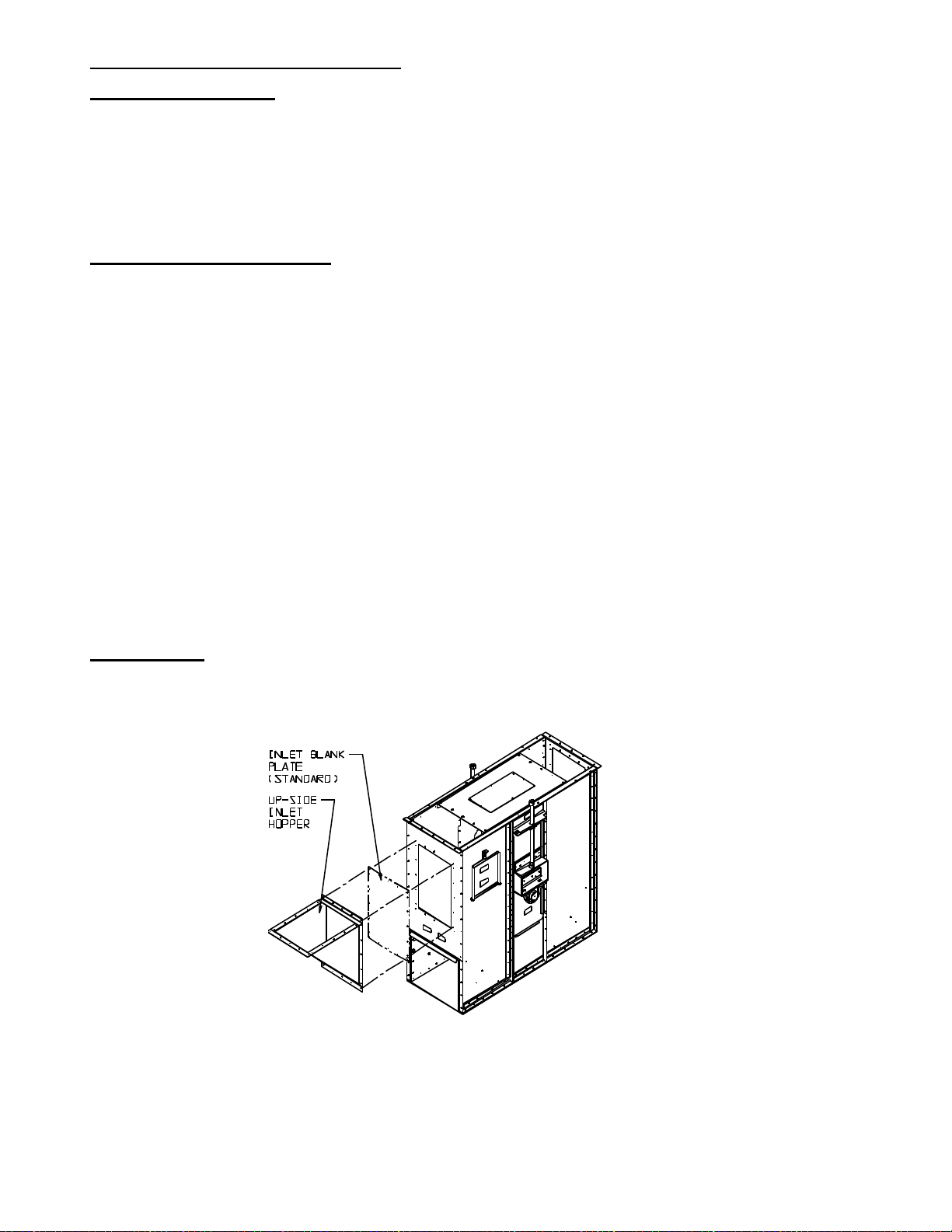

Boot Section

Prior to boot installation on the foundation, examine entire boot for any damage or loose hardware. Do not

attempt to install if parts are damaged.

Boot sections are pre-assembled at the factory, however Boot Inlet Hoppers are typically shipped separately.

Take time now to identify the up and down side of the boot, as proper positioning is critical. The boot inlet

section can be installed either as an up-leg or a down-leg inlet. You will note that the up-leg inlet position is

approximately six (6”) inches higher than the down-leg side. By removing the nuts and blank-off plates from the

studs, the boot inlet hopper can be attached.