Table of Contents

PNEG-1831 60' Dura-Lok Plank and Support Manual 3

Contents

Chapter 1 Introduction ..........................................................................................................................................4

Chapter 2 Safety .....................................................................................................................................................5

Safety Guidelines .................................................................................................................................. 5

General Safety Statement ..................................................................................................................... 6

Safety Instructions ................................................................................................................................. 7

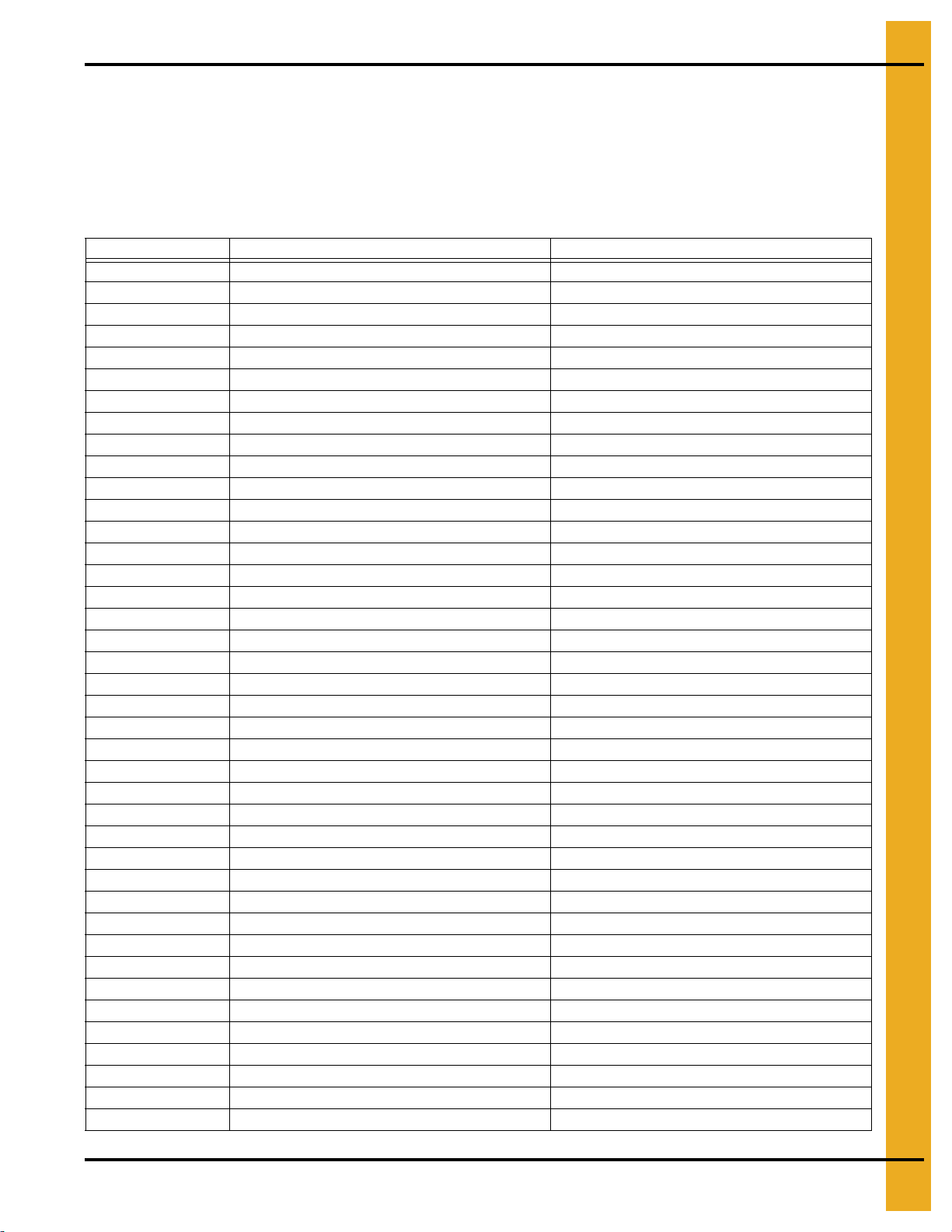

Safety Sign-Off Sheet ........................................................................................................................... 9

Proper Storage of Grain Bin/Silo Materials Prior to Construction ....................................................... 10

Chapter 3 Decals ..................................................................................................................................................11

Roof Damage Warning and Disclaimer ............................................................................................... 11

Chapter 4 Monorail Installation ..........................................................................................................................14

Fan Placement Diagram ..................................................................................................................... 14

Tie Bar Detail ...................................................................................................................................... 15

Tie Strap Detail ................................................................................................................................... 16

Assembling Legs to Rail ...................................................................................................................... 17

Outer Perimeter Rail Details ............................................................................................................... 19

Splicing Rails ....................................................................................................................................... 20

Chapter 5 Flooring - Planks ................................................................................................................................21

Floor Splice Details ............................................................................................................................. 21

Flashing Installation ............................................................................................................................ 22

Center Well Assembly Details ............................................................................................................. 24

Intermediate Well Assembly Details .................................................................................................... 25

Chapter 6 Layouts ................................................................................................................................................26

60'-15" Rail Spacing Layout ................................................................................................................ 26

60'-15" Monorail Spacing Layout ........................................................................................................ 27

60'-16" Monorail Spacing Layout ........................................................................................................ 28

60'-16" Rail Spacing Layout ................................................................................................................ 29

60'-17" Rail Spacing Layout ................................................................................................................ 30

60'-17" Monorail Spacing Layout ........................................................................................................ 31

60'-18" Monorail Spacing Layout ........................................................................................................ 32

60'-18" Rail Spacing Layout ................................................................................................................ 33

60'-20" Rail Spacing Layout ................................................................................................................ 34

60'-20" Monorail Spacing Layout ........................................................................................................ 35

60'-22" Monorail Spacing Layout ........................................................................................................ 36

60'-22" Rail Spacing Layout ................................................................................................................ 37

60'-26" Rail Spacing Layout ................................................................................................................ 38

60'-26" Monorail Spacing Layout ........................................................................................................ 39

60' Floor Bundle Layout ...................................................................................................................... 40

60' Plank Layout .................................................................................................................................. 41

Chapter 7 Warranty ..............................................................................................................................................43