1

Contents

Features

1.0 Recommended Safety Precautions ........................ 2

1.1 Health Hazard Information.................................... 2

1.2 Personal Protection ................................................ 2

1.3 Electric Shock .......................................................... 3

1.4 User Responsibilities .............................................. 3

• AC/DC TIG, MMA

• Single phase input from 230V±10%

• Microprocessor, precise control.

• Anti-sticking, Arc force, Hot start

• Electric HF ignition: Easy arc striking

• Remote control (Optional Feature w/ Torch)

• Foot pedal ready

• AC balance: high quality welds on Aluminum

• Higher AC frequency (50-250Hz), fast travel speed

• Smart-V technology: Better ignition, lower loss

• Soft Switching: low consumption, small but stable

• Intelligent protection: Over-voltage, Low-voltage,

Over-current and Over-heat

• PFC technology (Power Factor Correction)

• TIG Pulse function and all Pulse parameters can be

adjusted

• Complies with EN 60974-1

AC Waveforms

Advanced Square wave

Fast freezing puddle, deep penetration and fast

travel speeds

Soft Square wave

For a soft buttery arc with maximum puddle control

and good wetting action

Sine Wave

For those who prefer traditional arc characteristics.

Quieter welding with good wetting

Triangle Wave

Reduces heat input which is ideal for thin

aluminium welding. Allows for faster travel speeds

2.0 Gas Tungsten Arc Welding (GTAW/TIG) ................ 4

2.1 Introduction ............................................................ 4

2.2 Polarity Variations .................................................. 4

2.3 Shielding Gas Selection .......................................... 6

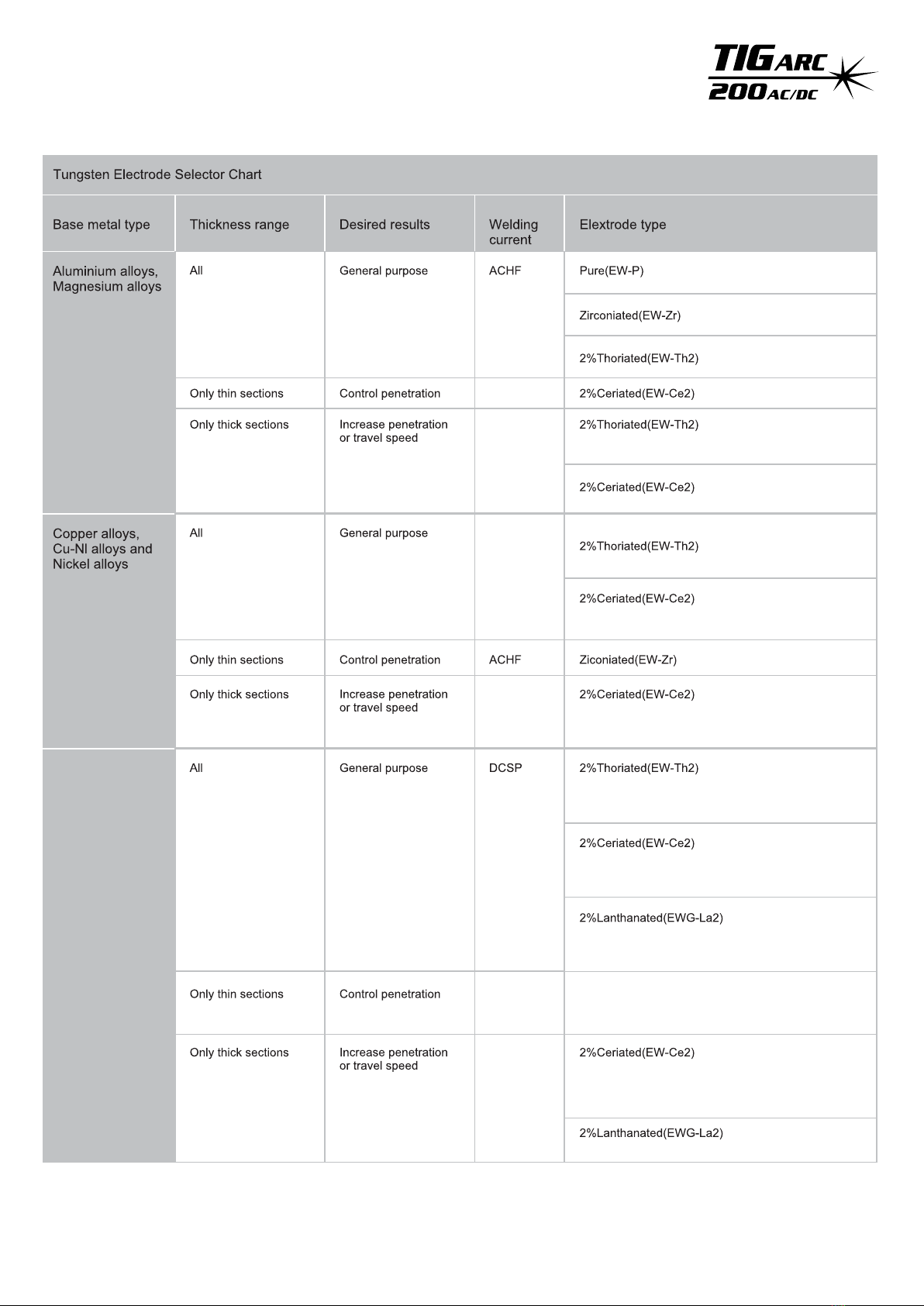

2.4 Consumable Selection ............................................ 7

2.5 Welding Techniques ............................................... 8

2.6 Torch Movement During Welding ......................... 8

2.7 Torch Positioning ................................................... 8

2.8 Non Consumable Tungstens .................................. 9

2.9 Working Principle ................................................. 11

5.0 Troubleshooting.................................................... 25

PLEASE NOTE that under no circumstances should your

TIGARC 200AC/DC be altered or changed in any way from

standard factory configuration. Doing so, will void the

machine warranty.

3.0 Installation and Adjustment ................................ 12

3.1 Parameters.............................................................. 12

3.2 Operation Environment......................................... 12

3.3 Operation Notices .................................................. 12

3.4 Duty Cycle & Over heating .................................... 13

3.5 Polarity Connection (MMA)................................... 13

3.6 Machine layout and components.......................... 14

3.7 Control Panel.......................................................... 15

4.0 Argon Arc Welding Operation ............................. 17

4.1 TIG Welding (4T Operation) ................................. 17

4.2 TIG Welding (2T Operation .................................. 18

4.3 The explanation of welding quality .................... 19

4.4 TIG Parameters...................................................... 19

4.5 Joint Preparation ................................................. 23

6.0 TIG Welding Material Reference ......................... 29

6.1 Application Summary ........................................... 29

6.2 C-Mn Steel ............................................................. 30

6.3 Alloyed Steel ......................................................... 31

6.4 Stainless Steel........................................................ 32

6.5 Aluminium ............................................................ 32

6.6 Balanced Square wave ......................................... 33

6.7 Copper and Copper Alloys ................................... 33

6.8 Direct Current (DC) Tig Welding .......................... 34

6.9 DC Pulse TIG Welding ........................................... 34

8.0 Recommended Safety Guidelines ........................ 36

9.0 Machine Hazards .................................................. 36

7.0 AC TIG Welding ...................................................... 35

10. Warranty Schedule 2021 ...................................... 37