6 6LE001152A.f

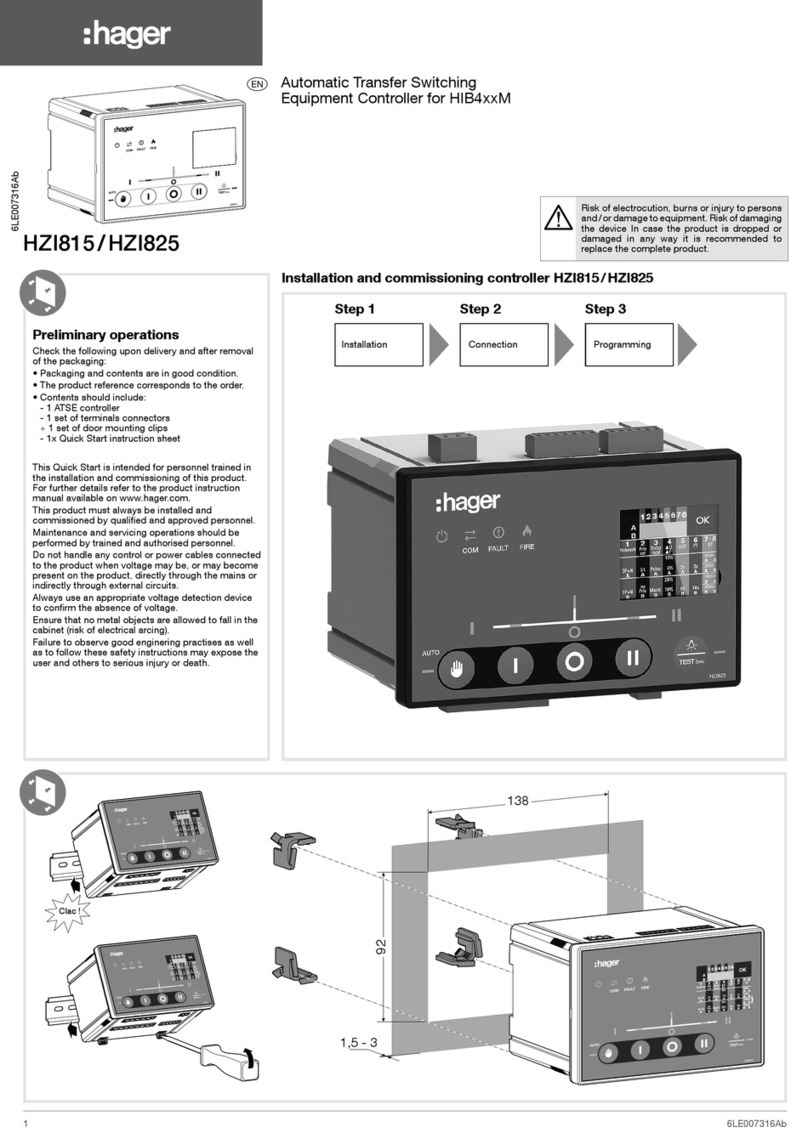

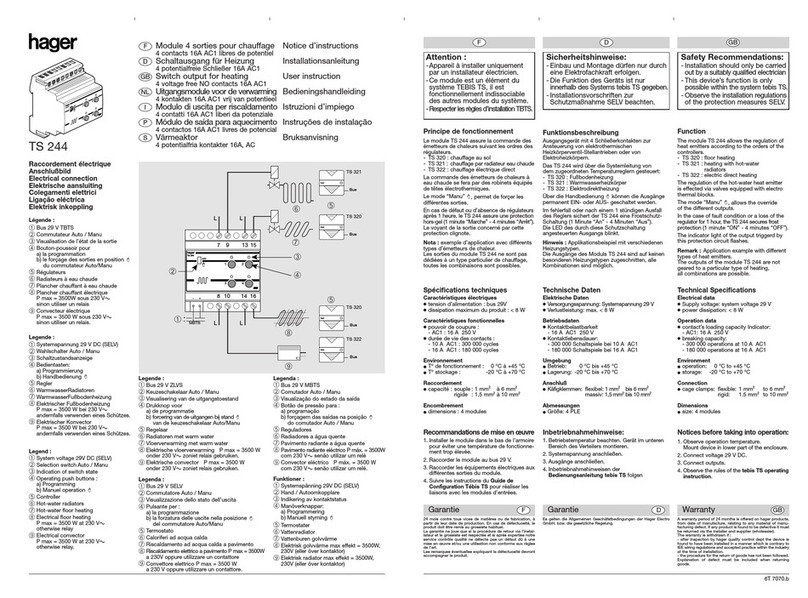

&MANUAL Mode LED indication.

(yellow steady light when in Maual Mode).

éAUTO Mode LED indication

(green steady light when in Auto mode

with no timers running, green fl ashing light

when in Auto with timers running in the

background).

"REMOTE CONTROL Mode LED indication.

Yellow steady light when in remote control

mode.

Remote control mode is achieved with the

Auto/Manu selector switched to Auto and

terminals 312 closed with terminal 317.

Remote control orders are received through

closing 314 to 316 with 317.

' TEST ON LOAD CONTROL Mode LED

indication (yellow steady light when in TON

mode)

(TEST OFF LOAD CONTROL Mode LED

indication (yellow steady light when in TOF

mode).

§ Switch 1 LED position indication.

(green when in position 1).

èSource supply I availability LED indication

(green when supply I voltage is within the

set limits).

!Zero position LED indication

(yellow when in position 0).

çSwitch 2 LED position indication.

(green when in position 2)

a Source supply II availability LED indication

(green when supply II voltage is within the

set limits).

zSealing screw location 1 for use with

sealing cover (available as an accessory

e Potentiometer 1: Network Confi guration.

(Auto Confi guration

or

refer to the confi guration guide sticker on

the front of the product when using the

predefi ned setting positions 1 to 13).

rPotentiometer 2 : Voltage and Frequency

threshold settings. (Refer to the

confi guration guide sticker on the front of

the product to set the V / Hz threshold.

Positions 1 to 14).

tPotentiometer 3: Supply FAILURE Time (FT)

Adjustable from 0 to 60 seconds

yPotentiometer 4: Supply RETURN Time (RT)

Adjustable from 0 to 60 minutes.

uREADY LED indication (green steady light:

product in AUTO, Watchdog OK, Product

Available to changeover; green fl ashing:

settings displayed not saved or have been

changed since last saved. Press PROG OK

button in manual mode to save or revert to

last saved settings).

iSealing screw location 2 for use with the

sealing cover.

oFAULT LED indication (red steady light in

case of an ATS controller internal fault).

p Confi guration dip switches:

(4 dip switches with 2 positions in each A

to H).

q PROG OK: confi guration save push button

(ATTN: active in Manual Mode ONLY).

Press briefl y to confi rm and save all set

confi guration settings.

Hold pressed for 2 seconds to set the

network supply voltage and frequency by

Auto Confi guration.

This is to be followed by pressing briefl y to

save the set value confi gured.

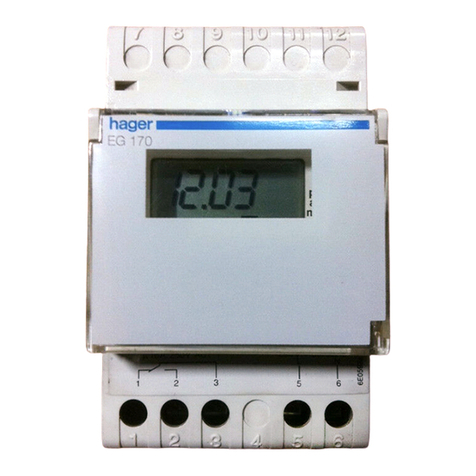

sGreen LED Indication: power

dRed LED Indication: Product Unavailable /

Manual Mode / Fault Condition

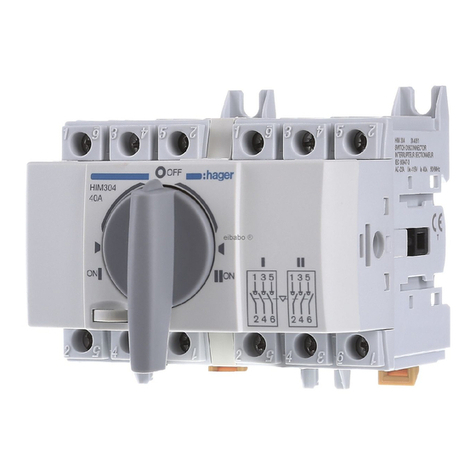

fAuto / Manual mode selector switch (Kky

version available as an option)

gPadlocking facility (up to 3 padlocks of dia.

4 – 8mm)

hEmergency manual operation shaft location

(accessible only in manual mode)

jSwitch position indication window:

I (On switch I)

O (Off)

II (On switch II.)

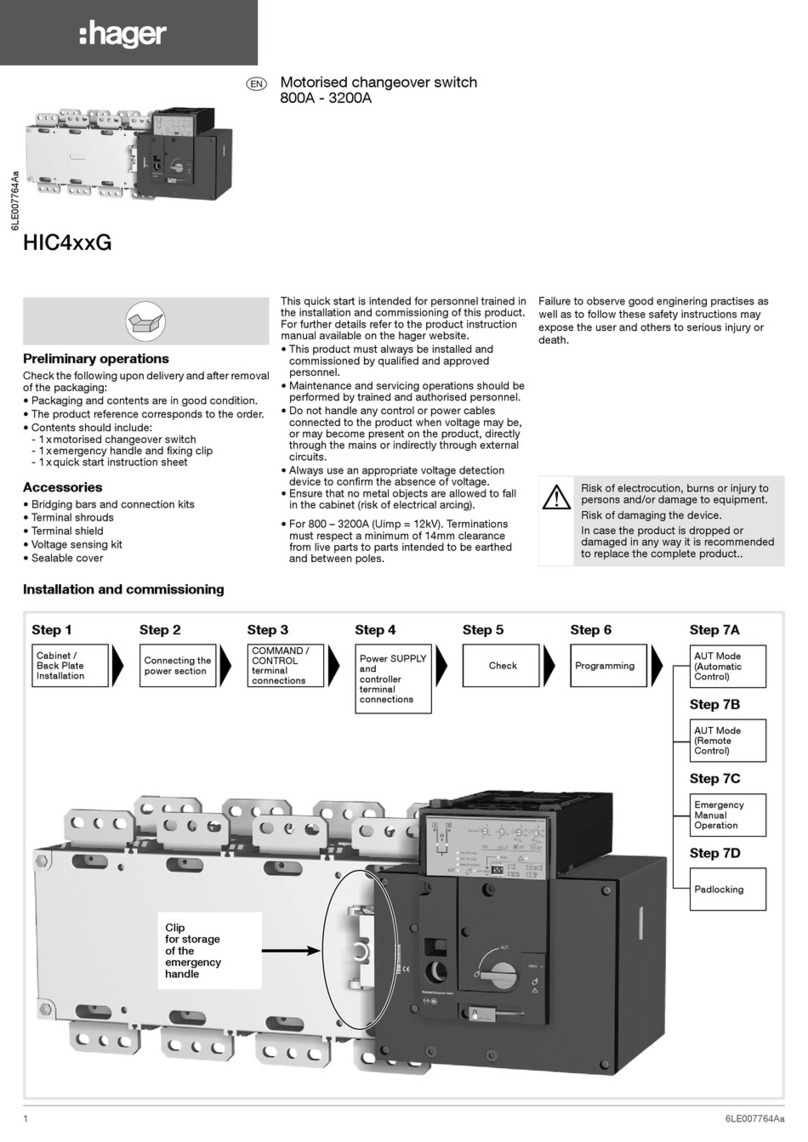

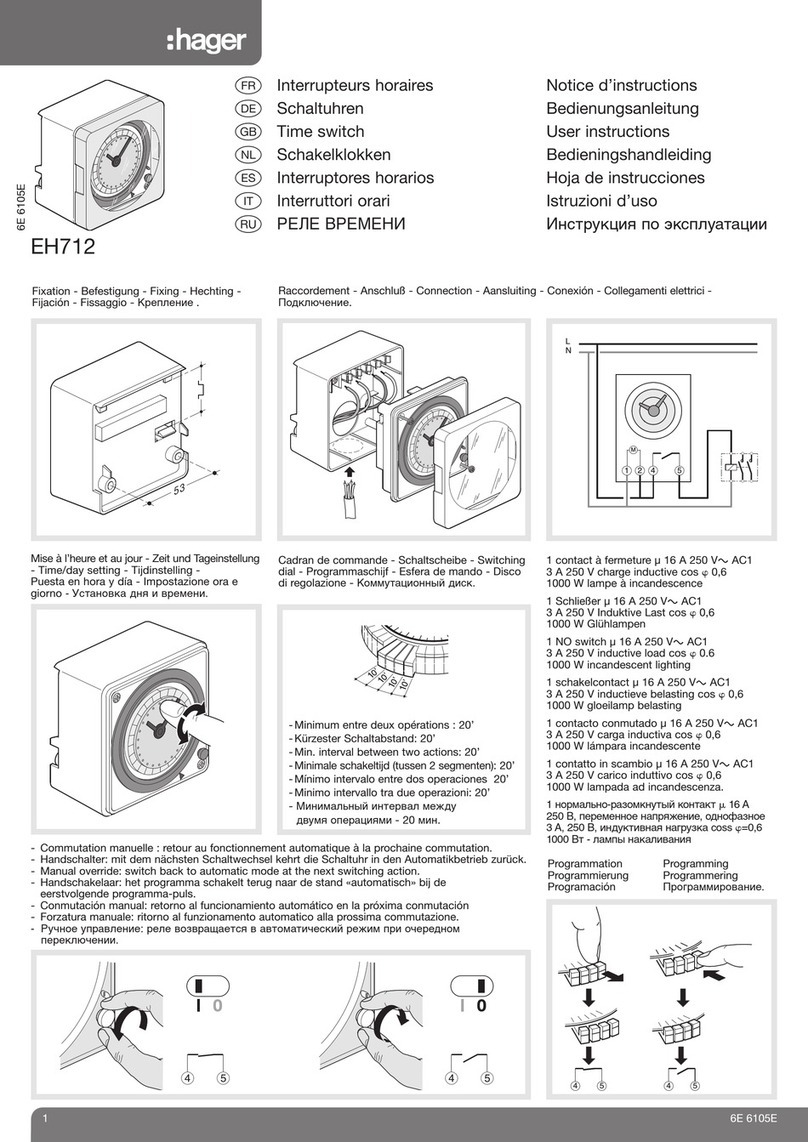

7A. Automatic operation

Ensure that the

emergency handle

is not inserted in the

product and turn

the mode selector

to the AUT position.

LED green = “Power”:

ON

LED Manuel/Default :

OFF

LED green "AUT": ON

7B. Automatic operation:

remote control

Impulse 60 ms

Impulse

maintened

To enable control,

close contact 312 with

317.

For contactor logic

bridge contact 316

with 317.

To operate: close the

contact corresponding

to the desired position.

To force the product to 0 position “OFF” bridge

contact 313 with 317.

7C. Manual operation

90°

90°

I II

0

7D. Padlocking mode

(Standard: in position O)

Foreseen for max. 3 padlocks Ø 4-8mm

Impulse logic Contactor logic

Order I

Order O

Order II

Position I

Position O

Position II

AUT

AUT

fg

h

j

è

§

é

&

"

'

i

s

d

o

p

u

q

a z! ç te yr

(