260W(29V)

<2Ω

<2mV

1.2m

253mm

(附4BC焊鐵頭)

65g(附4BC焊鐵頭,

排氣鋼管A)

功率消耗

焊鐵頭至接地間電阻

焊鐵頭至接地間電位

電線長度

焊鐵長度

(不包括電線)

重量 (不包括電線)

※規格及外觀有可能改良變更,恕不另行通知。

※本產品施有防靜電措施。

●插入焊鐵頭

➀將焊鐵頭上安裝的護罩取下。

HAKKO FX-8003 不能單獨使用。請將 HAKKO FX-8003 與HAKKO FX-801 維修系統進行

組合使用,並參閱 HAKKO FX-801 之使用說明書。

注意

HAKKO FX-8003 焊鐵

HAKKO FX-8003

焊鐵頭(另售)*排氣鋼管(另售)

護罩(用來防止助焊劑進入)

1. 包裝清單及各部名稱 首先請確認包裝內容。

1使用說明書 1

2. 規格 3. 適用型號

本產品為氮氣焊鐵。 請配合以下產品使用。

・HAKKO FX-801 (電焊臺)

・HAKKO FX-780/781 (氮氣產生裝置)

・HAKKO FX-791 (氮氣流量調節器)

如不與HAKKO FX-780(FX-781)或FX-791 一

起使用時,請參考「5.使用方法」 的連接示例。

注記:

4. 安全及使用上之注意事項

本說明書注意事項區分為如下之「警告」「注意」「注記」三者加以表示。

請充分了解其內容後再閱讀本文。

警告:濫用可能導致使用者死亡或負重傷。

注意:濫用可能導致使用者受傷或對涉及物體造成實質破壞。

注記:表示操作時必須注意之重點。

警 告

當電源接通時,焊鐵頭溫度會達到 50~500℃的高溫。

鑑於濫用可能導致使用者灼傷、火患。請嚴格遵守以下注意事項:

注 意

●為免發生意外或損壞 HAKKO FX-8003,使用時請務必遵守以下事項。

5. 使用方法

將焊鐵長時間放置在焊鐵座時,請務必切斷氮氣供應。

從焊鐵頭附近噴出的氮氣瓦斯是高溫的。請注意不要將焊鐵指向人。

注意

・插拔電線組件時,請務必先關閉電源,以免損壞本產品。

・本產品施有防靜電措施,所以務必請接地之後再使用。

注意

注記:

如果不移除護罩,排氣鋼管將不能被插入。

➁將焊鐵頭插入 HAKKO FX-8003 直到定位。

➂焊鐵頭安裝完成後,(參照"焊鐵頭與排氣鋼管的組合"的"部件清單")將配合

焊鐵頭型號的排氣鋼管插入至底。

注記:

請務必使用 HAKKO FX-8003 專用的 T22 系列銲鐵頭。

5. 使用方法

6. 保養

A. 焊鐵頭和排氣鋼管

B. 連接

C. 設定溫度

➀

1. 將電源線連接到控制臺後面的電源插座。

將焊鐵電線組件連接到控制臺前面的插座。

2. 將焊鐵放置於焊鐵座。

3. 將插頭插入電源插座。

4. 將焊鐵軟管插入HAKKO FX-791*的OUT插孔。

(詳細請閱讀HAKKO FX-791使用說明書。)

如果不與HAKKO FX-791一起使用時,請參考

右圖之連接方法。

如果不與HAKKO FX-791 一起使用時,請參考下圖的連接方法。

・必須將輸入焊鐵部的瓦斯壓力設定於 0.2MPa(2.0kgf/cm2)以下。

超過 0.2MPa 以上時,有可能損壞焊鐵部元件。

・將瓦斯排出量設定超出建議流量範圍時,焊鐵頭有可能達不到所設定的溫度。

注意

檢查和清理焊鐵頭

1. 將溫度設定為250℃。

2. 溫度穩定後,田清潔海綿清理焊鐵頭,並檢查焊鐵頭狀況。

3. 如果焊鐵頭的鍍錫部份含有黑色氧化物時,可鍍上新錫層,再用清潔海綿抹淨

焊鐵頭。如此重復清理,直到徹底除去氧化物為止,然後再鍍上新錫層。

4. 關掉電源,待冷卻後才將焊鐵頭拆下。其他部分付有氧化物時必須用酒精抹乾淨。

5. 如果焊鐵頭變形或消耗嚴重時,請更換新的焊鐵頭。

注意

切勿用銼刀剔除焊鐵頭上的氧化物。

排氣鋼管組合的保養

使用後噴嘴前端部份會生產氧化物。使用附著氧化物的噴嘴會引起瓦斯難於排出。

請必要定期清除氧化物。

高熱容量N2氮氣焊鐵

使用說明書

* 使用前請先將焊鐵頭上安裝的護罩取下。

●切勿碰觸焊鐵頭或其周圍的金屬部分。

●切勿在易燃物附近使用焊鐵頭。

●通知周圍的人,焊鐵頭極為灼熱,切勿碰觸。

●暫停使用、結束或要離開時關閉電源。

●更換部件或收藏HAKKO FX-8003時,應關掉電源,並待焊鐵冷卻至室溫後進行。

●從焊鐵頭附近噴出的氮氣瓦斯是高溫的。請注意不要將焊鐵指向人。

●在沒有得到相關負責人的許可下,經驗及知識不

足者(包括兒童)請勿使用本產品。

●請注意不要讓兒童碰觸到本產品。

●切勿使用 HAKKO FX-8003 於焊接以外的工作。

●切勿為了弄掉焊鐵上的錫屑而用力敲打。此舉會損及焊鐵。

●切勿改裝本產品。

●更換零件時,使用 HAKKO 原廠部件。

●切勿將 HAKKO FX-8003 泡水或用濕手使用。

●拔出電線時,請抓住插頭,切勿拉住電線。

●焊接時會冒煙,請做好通風。

●請勿進行其他認為危險之行為。

1. 打開 HAKKO FX-801電焊台的電源開關,設定所需要的溫度。

(詳細請參照HAKKO FX-801使用說明書。)

2. 打開氮氣瓦斯供應,調節適當流量。

(HAKKO 建議流量為 0.5L/min.~1.5L/min.)

3. 待溫度穩定後測量焊鐵頭溫度。輸入補正值使焊鐵頭的溫度與設定溫度一致。

(詳細請參照HAKKO FX-801使用說明書。)

焊鐵頭溫度

清理

當不使用時

使用後

溫度過高會使焊鐵頭功能減弱,因此應選擇盡可能低的溫度。

此焊鐵頭的溫度回復力優良,較低的溫度也可充分的焊接,

可保護對於溫度敏感的元件。

焊接前,請先使用HAKKO599B焊鐵頭清潔器或者是清潔濕潤的清潔

海綿將付著在焊鐵頭上的舊銲錫和助焊劑殘渣清除。焊鐵頭上付著的

不純物是導致不良焊接的原因,或使焊鐵頭的傳熱性降低而不得已升

高焊鐵的設定溫度以導致焊鐵頭及電路板的損傷。

不使用焊鐵頭時,不可讓焊鐵長時間處在高溫狀態,會使焊鐵頭上的

焊劑轉化為氧化物,致使焊鐵頭導熱功能大為減退。

使用後,應抹淨焊鐵頭,鍍上新錫層,以防止焊鐵頭引起氧化作用。

260W (29V)

< 2Ω

< 2 mV

1.2 m (4 ft.)

253mm (10.0 in.)

with 4BC tip

65g (0.14lb.) with 4BC tip

and nozzle assembly A

Power Consumption

Tip to Ground Resistance

Tip to Ground Potential

Cord

Length (w/o cord)

Weight (w/o cord)

* Specications and design are subject to

change without notice.

* This product is protected against electrostatic discharge.

2. SPECIFICATIONS 3. COMPATIBLE STATIONS

This N2soldering iron is compatible for

use with the following models:

・HAKKO FX-801 (Soldering station)

・HAKKO FX-780/781 (N2 generator)

・HAKKO FX-791 (N2station)

NOTE:

If you do not connect the product to HAKKO

FX-780 (FX-781) and FX-791, refer to the

connection diagram in "5. OPERATION" as a

guide for using the product.

5. OPERATION

Shut off the gas supply when the HAKKO FX-8003 is left unattended for an

extended period. N2gas is hot. Do not direct N2gas toward personnel.

CAUTION

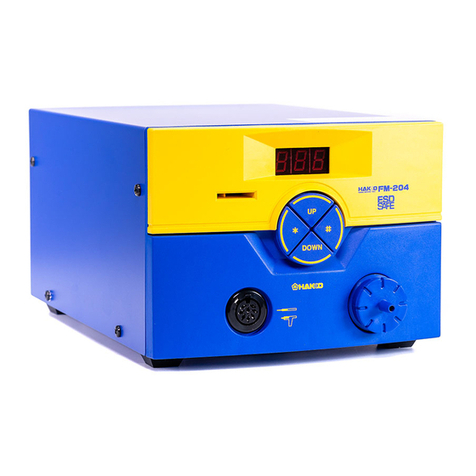

HAKKO FX-8003 soldering iron

HAKKO FX-8003

Tip (not included)

Nozzle assembly

(not included)

Protective cover

1 Instruction Manual 1

* Remove the protective cover before using HAKKO FX-8003

C. Temperature setting

1. Connect the station to the HAKKO FX-801. Set the desired temperature and the

heat control begins. (Please refer to the HAKKO FX-801 instruction manual.)

2. Turn on N2gas and adjust the rate of ow to be appropriate.

Suggested ow rate : 0.5ℓ/min. to 1.5ℓ/min.

3. Measure the tip temperature when it is stabilized. Input the offset value so that

it will become to the measured temperature. (Please refer to the HAKKO FX-801

instruction manual.)

Thank you for purchasing the HAKKO FX-8003 soldering iron.

The HAKKO FX-8003 soldering iron is designed to supply hot gas to the soldering area.

This can increase soldering efficiency, as the gas pre-heats the work area.

When the heated gas is nitrogen (N2), soldering efficiency is further improved as the

nitrogen materially reduces the amount of oxygen in the ambient atmosphere.

Please read this manual before operating the HAKKO FX-8003.

Keep this manual readily accessible for reference.

CAUTION

When you use the HAKKO FX-8003 for the rst time, note that calibration is required

before starting operation. Read the instruction manual for the station used in conjunction

with the HAKKO FX-8003 soldering iron.

Heavy Duty N2Soldering Iron

1. PACKING LIST AND PART NAMES

Instruction Manual

Please check to make sure that all items listed below are included in the package.

Warnings, cautions and notes are placed at critical points in this manual to

direct the operator’s attention to signicant items. They are dened as follows:

WARNING :

Failure to comply with a WARNING may result in serious injury or death.

CAUTION :

Failure to comply with a CAUTION may result in injury to the operator,

or damage to the items involved. Two examples are given below.

NOTE : A NOTE indicates a procedure or point that is important to the

process being described.

4. WARNINGS, CAUTIONS AND NOTES

When power is ON, tip temperature will be between 50°C and 500°C (120 to 940°F).

To avoid injury or damage to personnel and items in the work area, observe the following :

●

To prevent accidents or damage to the HAKKO FX-8003, be sure to observe the followings:

●Do not touch the tip or the metal parts near the tip.

●Do not allow the tip to come close to, or touch, ammable materials.

●Inform others in the area that the unit is hot and should not be touched.

●

urn the power off when not in use, or left unattended.

●Turn the power off when changing parts or storing the HAKKO FX-8003.

●N2 gas is hot. Do not direct N2 gas toward personnel.

●

This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities,

or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance

by a person responsible for their safety.

●Children should be supervised to ensure that

they do not play with the appliance.

●Do not use the HAKKO FX-8003 for applications other than soldering.

●

Do not strike the iron against hard objects to remove excess solder. This will damage the iron.

●Do not modify the unit.

●Use only genuine HAKKO replacement parts.

●

Do not allow the HAKKO FX-8003 to become wet, or use it when hands are wet.

●Be sure to hold the plug when inserting or removing the cord.

●Since smoke is produced when using the HAKKO FX-8003, be sure the work

area is well ventilated.

●While using the HAKKO FX-8003, do not do anything which may cause bodily

harm or physical damage.

WARNING

CAUTION

•

Be sure to turn off the power switch before connecting or disconnecting the cord assembly

for the soldering iron to and from the receptacle to avoid damaging the unit.

• The HAKKO FX-8003 is protected against electrostatic discharge and must be

grounded for full efciency.

CAUTION

➁Insert the tip into the HAKKO FX-8003 until it stops.

➂Insert a compatible nozzle

assembly into the tip until it

stops after tting the tip.

(See “Cross reference guide for tip and nozzle” of “PARTS LIST”.)

NOTE:

Please use only T33 Series Tips. The attempted use of other tips may damage

the product and/or station.

➁➂

6. MAINTENANCE

●Inserting the tip

➀Remove the protective cover

NOTE:

If you do not remove the protective cover, nozzle assembly can not be inserted.

5. OPERATION

A. Insert the tip and nozzle assembly

B. Connection

➀

1. Connect the power cord to the power receptacle at

the back of the station. Connect the connector cord

to the receptacle at the front of the station.

2. Place the FX-8003 soldering iron on the iron holder.

3. Plug the power cord into a grounded wall socket.

4. Insert the tube of the HAKKO FX-8003 to the terminal

marked ‘OUT’ of the HAKKO FX-791*. (Refer to the

instruction manual for the HAKKO FX-791.) If HAKKO FX-791 is not used, refer

to the diagram on the right for connection and use without HAKKO FX-791.

Insert the plug into

the receptacle until

it seats.

To disconnect, pull the

plug from the receptacle

whilst pressing down the

tab on the plug.

Receptacle

Typical interconnection

adjust the value between 0.5ℓ/min ~ 1.5ℓ/min

CAUTION

• Ensure that the gas pressure to the HAKKO FX-8003 is less than 0.2MPa

(2.0kgf/cm2). If the pressure exceeds 0.2MPa, damage may occur.

•

Tip temperature may not reach the set value if the gas ow rate exceeds

the specied limit.

Tip

temperature

Cleaning

Interruption

After us

High temperatures shorten tip life. Always use the soldering iron

at the lowest possible temperature. The excellent thermal recovery

characteristics of the HAKKO FX-8003 ensures effective soldering

at low temperature, protecting sensitive components easily

damaged by thermal shock.

Always clean the soldering tip before use to remove any residual

solder or ux adhering to it. Use the 599B tip cleaner or a clean

moist cleaning sponge. Contaminants on the tip have many

deleterious effects, including reduced heat conductivity, which

contribute to poor soldering performance.

Do not allow the unit to idle at high temperature for extended

periods. A heavy oxide layer on the tip will reduce the heat transfer

from the tip.

Whenever you nish soldering work, always clean the tip and coat

it with fresh solder. This guards against oxidation.

Tip maintenance

1. Set the temperature to 250°C/482°F.

2. When the temperature stabilizes, clean the tip and check its condition.

3.

If the solder plated part of the tip is covered with black oxide, apply fresh solder

containing ux and clean the tip again. Repeat until all the oxide is removed, then

coat the tip with fresh solder.

4.

Turn the power OFF and remove the tip after it cools off. Remaining oxides, such

as the yellow discoloration on the tip shaft, can be removed with isopropyl alcohol.

5. Replace the tip with a new one if it is badly deformed or corroded.

CAUTION

NEVER le the tip to remove oxides!

Maintenance of nozzle assembly

As the unit is used, oxidation will accumulate on the nozzle tip.

Remove it periodically by cleaning so that the gas will ow freely.

日本白光牌

當要拆下時,

一邊按下突出

部分,一邊拆下。

一直插到底,

聼到喀嚓聲為止 插座

連接圖 調節於0.5ℓ/min~1.5ℓ/min

氮氣產生裝置

空氣過濾器把

塵埃、油份及水份過濾

壓力調節器

調節於0.2MPa以下

空氣過濾器

流量控制閥

焊鐵軟管

流量調節器

壓力器

Flow meter to remove dust, oil

and moisture

Pressure

gauge

To the tube

Flow controI valve

Regulator Gas

generator

Adjust to less

than 0.2MPa

Air lter

FX-8003_JEC_MAC_201006_2校.indd 2 2020/10/06 9:17