7. TROUBLESHOOTING

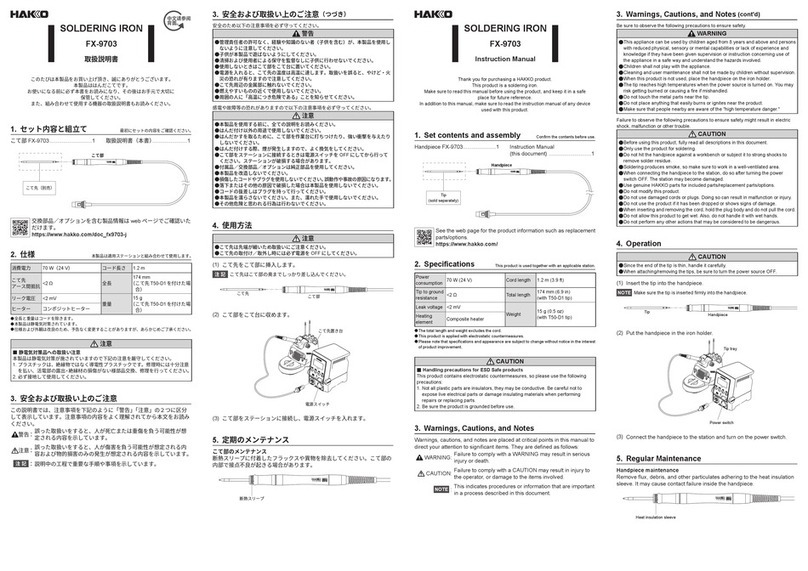

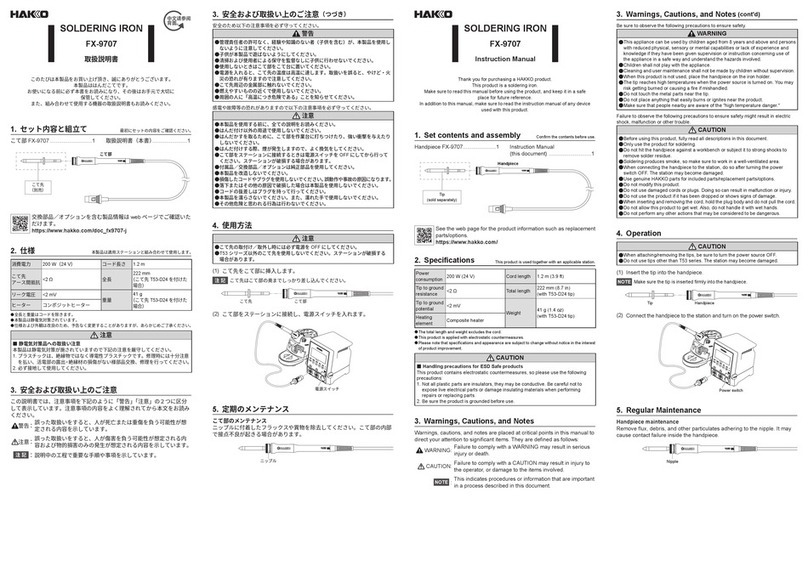

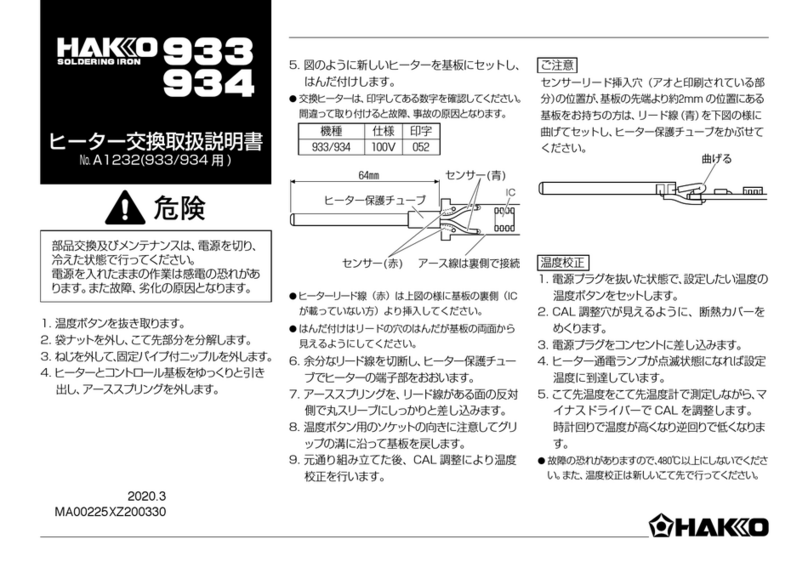

Sensor (White: 100 - 127V)

(Blue: 220 - 240V)

Heater (Red)

*At 23℃/73°F,

Normal heater resistance value: 35 Ω (100 - 127 V models) 160 Ω (220 - 240 V models)

Normal sensor resistance value: 50 Ω (100 - 127 V, 220 - 240 V models)

NOTE:

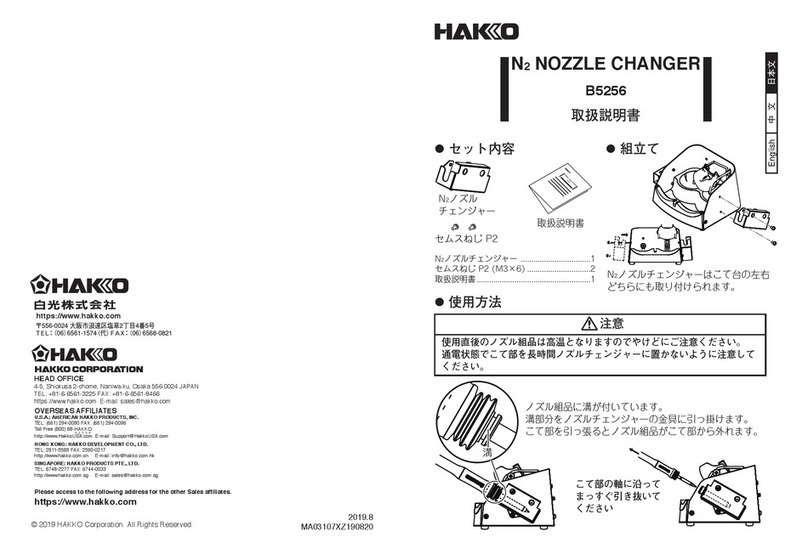

Use of the tool when the nozzle, heating core, or lter is clogged may cause the pump to

lock up and render operation impossible. Clean or otherwise eliminate the blockage before

attempting to use the tool.

Repairs

When repair becomes necessary, check the following and then bring the desoldering tool

to a HAKKO sales outlet or HAKKO dealer.

1. Is the nozzle or heating core clogged?

2. Is the valve plate cracked or missing?

3. Is the front holder or lter holder warped or cracked?

4. Is the pre-lter or ceramic paper lter dirty or warped?

Detailed information can be found in manuals available

at the HAKKO Document Portal.

Please download and make use of them.

https://doc.hakko.com

Calibrating the temperature

1. Install a new nozzle. The nozzle being used may have already

started to wear, so use a new nozzle.

2. Insert the power plug into the outlet.

3. Set the temperature to 400 °C/750 °F.

4. Wait for about 1 minute until the nozzle will melt solder, then

apply a generous coating of your solder to the end of the nozzle.

When the iron temperature reaches the set temperature, the

LED lamp will ash.

5. Use a soldering iron tip thermometer (optional accessory) to

measure the temperature at the tip of the nozzle. Do not apply

suction, as this will cause the temperature to drop.

6. Adjust CAL until the temperature is 400 °C/750 °F. Turn CAL

clockwise to increase the temperature.

• It may take several minutes for the nozzle temperature to

stabilize after CAL is adjusted.

• During CAL adjustment, make sure the set temperature does not go above 500℃/930°F,

as this may damage the desoldering tool.

Problem cause Procedure

Tool does not

heat up

Tool is not connected properly

to power outlet Connect properly

Heating element burnout* Replace heating element

Sensor is broken*

Temperature is

low

Temperature is set too low Reset

Temperature has not been

calibrated properly Calibrate properly

Nozzle is worn out Replace nozzle

Pump does not

operate

Nozzle or heating core (in heating

element) is clogged Clean

Too much solder or ux has

collected in the lter Replace lter

Suction force is

weak

Too much solder or ux has

collected in the lter or inner hose Replace lter or inner hose

Vacuum leakage Inspect nozzle, area around lter

and pump hose

Pump valve or diaphragm is broken Replace valve or diaphragm

*Heater lead (Sensor lead)

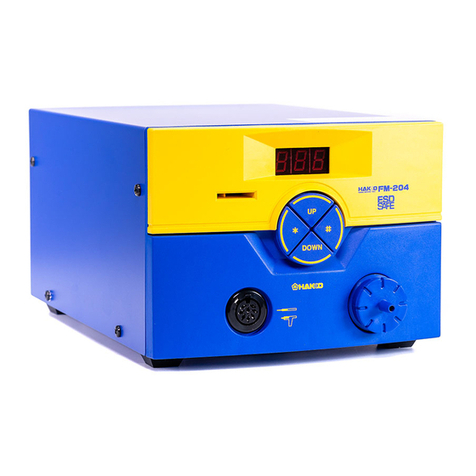

Low High

Use a athead screwdriver

to adjust