Hakko Electronics FG101-16 User manual

Other Hakko Electronics Test Equipment manuals

Hakko Electronics

Hakko Electronics FR-410 User manual

Hakko Electronics

Hakko Electronics FR-811 User manual

Hakko Electronics

Hakko Electronics FG-470 User manual

Hakko Electronics

Hakko Electronics FG101B-03 User manual

Hakko Electronics

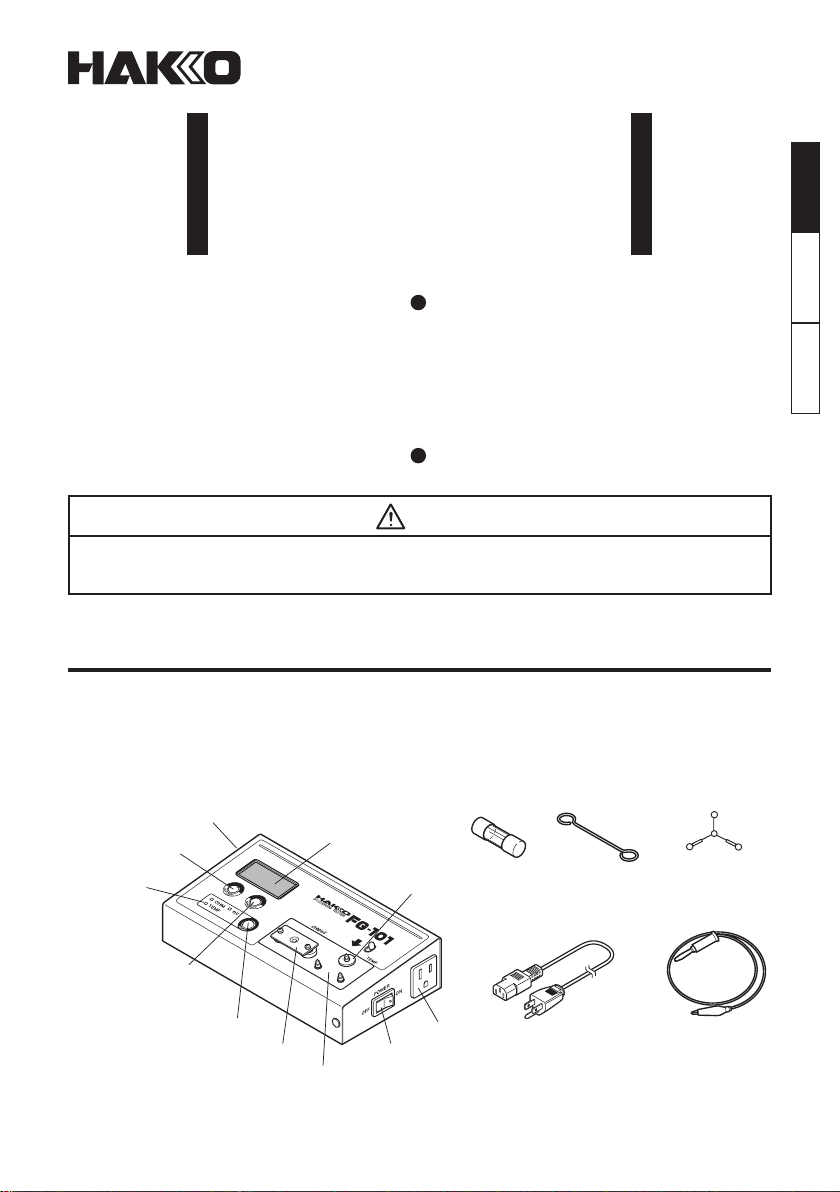

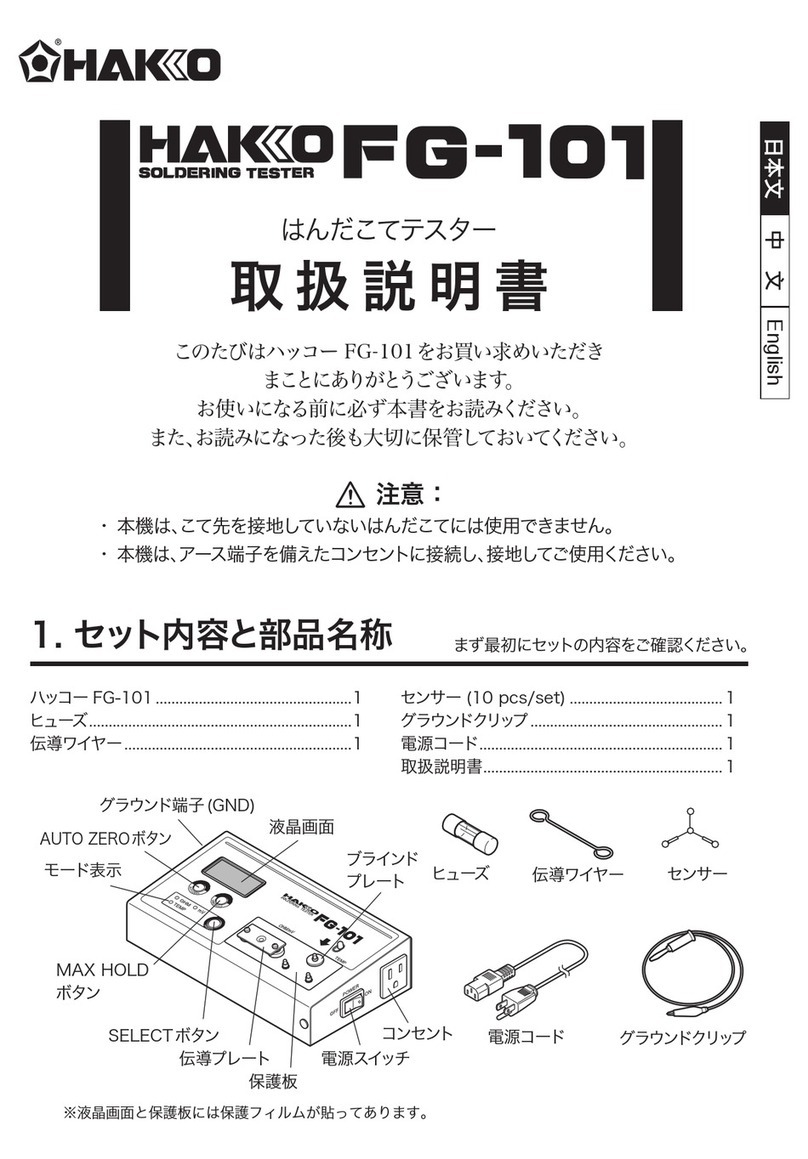

Hakko Electronics FG-101 User manual

Hakko Electronics

Hakko Electronics FG-460 User manual

Hakko Electronics

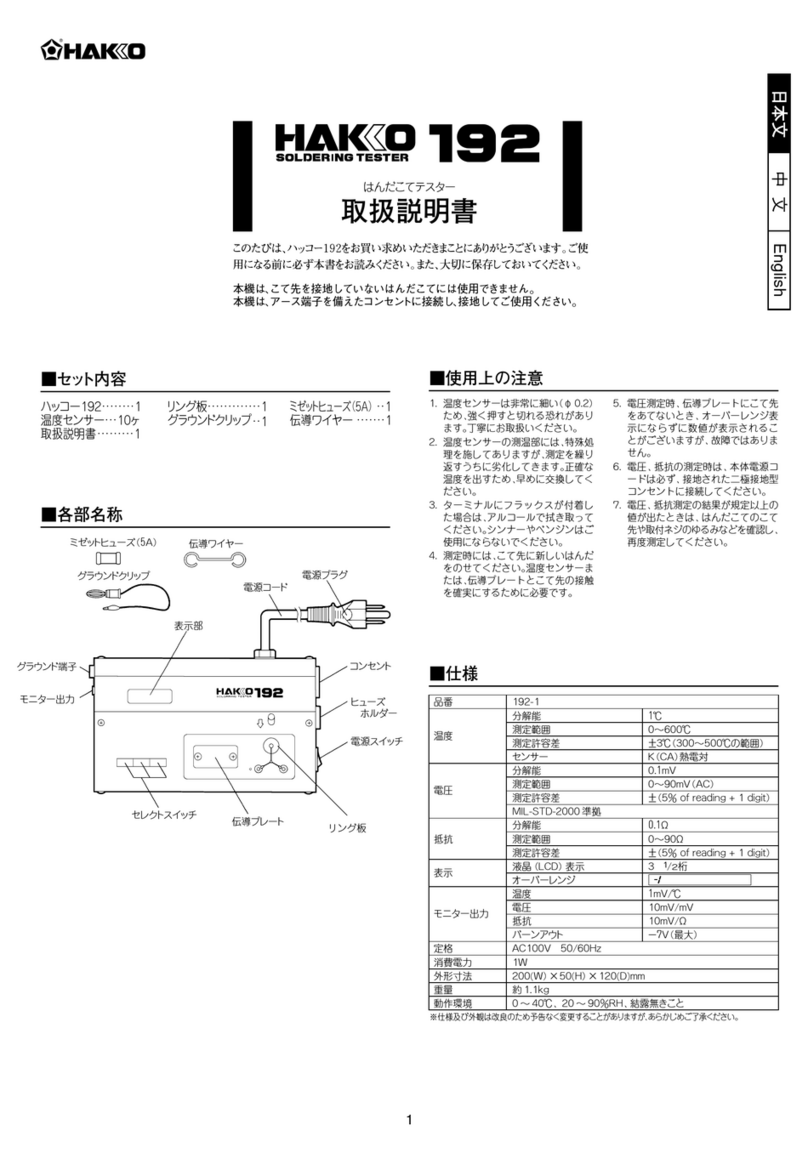

Hakko Electronics 192 User manual

Hakko Electronics

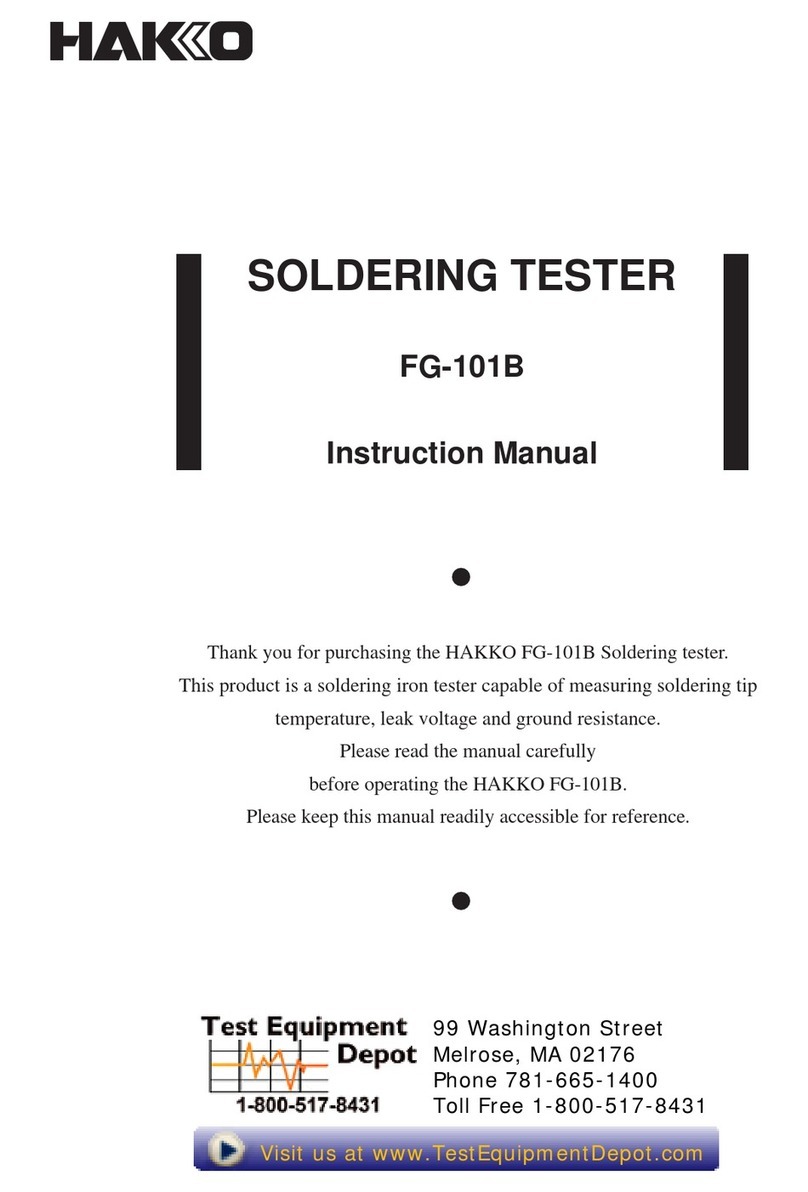

Hakko Electronics FG-101B User manual

Hakko Electronics

Hakko Electronics FG-465 User manual

Hakko Electronics

Hakko Electronics FG-470 User manual