9

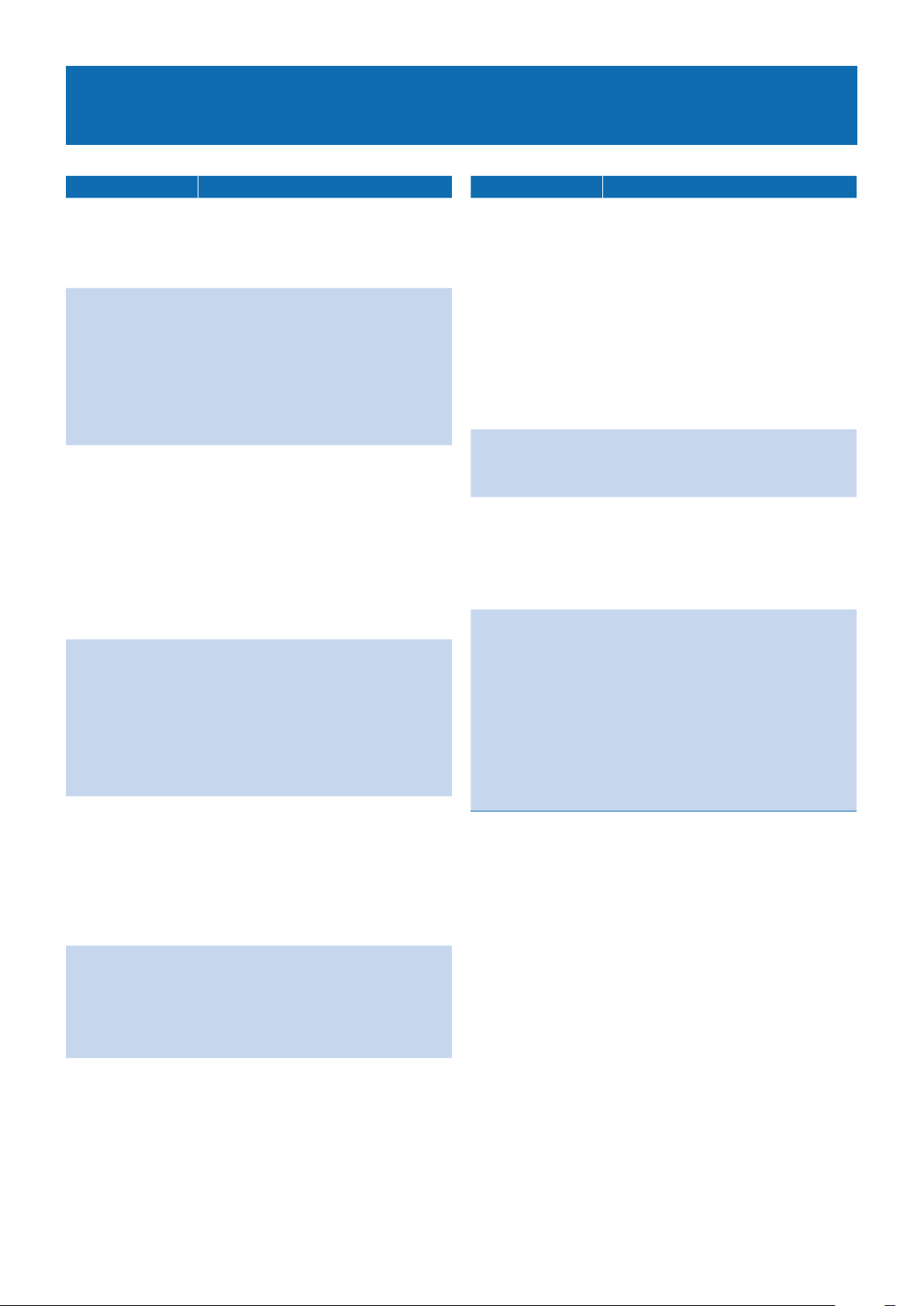

DTC Displayed Possible Causes

ECU TIME OUT

or

NO LINK

No supply on ignition switched line.

Possible causes:

Truck fuse blown

EB+ GEN2 INFO CENTRE or cable fault.

Open circuit B -. ISO7638 not connected

Sensor Group

S1A CONT 1A Sensor1/wiring open or short circuit

S1B CONT 1B Sensor/wiring open or short circuit

S2A CONT 2A Sensor/wiring open or short circuit

S2B CONT 2B Sensor/wiring open or short circuit

Intermittent Low Sensor Output Group

S1A SIGNAL 1A Sensor signal fault

S1B SIGNAL 1B Sensor signal fault

S2A SIGNAL 2A Sensor signal fault

S2B SIGNAL 2B Sensor signal fault

Possible causes:

Loose sensor, connection, bracket or

exciter. Damaged exciter.

Maladjusted sensor or worn sensor cable

insulation.

Low Sensor Output Group

S1A OUTPUT 1A Sensor system fault

S1B OUTPUT 1B Sensor system fault

S2A OUTPUT 2A Sensor system fault

S2B OUTPUT 2B Sensor system fault

Possible causes:

Sensor worn, maladjusted sensor, wiring

open or short circuit

Brake Apply Solenoid Group

BRK APPLY SC Brake apply solenoid short circuit

BRK APPLY OC Brake apply solenoid short circuit

BRK APPLY SC DRIVE Brake apply solenoid short circuit

permanently energised

BRK APPLY UNSPEC Brake apply solenoid short circuit

EPRV 21 Hold and Dump Solenoid Group

EPRV 21 HOLD SC Modulator 21 hold solenoid short circuit

EPRV 21 DUMP SC Modulator 21 dump solenoid short circuit

EPRV 21 HOLD OC Modulator 21 hold solenoid open circuit

EPRV 21 DUMP OC Modulator 21 dump solenoid open circuit

EPRV 21 HOLD SC

DRIVE

Modulator 21 hold solenoid short circuit

permanently energised

If a Diagnostic Trouble Code displayed is not listed here, check for intermittent sensor and wiring faults.

DTC Displayed Possible Causes

EPRV 21 DUMP SC

DRIVE

Modulator 21 dump solenoid short circuit

permanently energised

EPRV 21 HOLD

UNSPEC

Modulator 21 hold solenoid control

circuit fault

EPRV 21 DUMP

UNSPEC

Modulator 21 dump solenoid control

circuit fault

EPRV 22 Hold and Dump Solenoid Group

EPRV 22 HOLD SC Modulator 22 hold solenoid short circuit

EPRV 22 DUMP SC Modulator 22 dump solenoid short circuit

EPRV 22 HOLD OC Modulator 22 hold solenoid open circuit

EPRV 22 DUMP OC Modulator 22 dump solenoid open circuit

EPRV 22 HOLD SC

DRIVE

Modulator 22 hold solenoid short circuit

permanently energised

EPRV 22 DUMP SC

DRIVE

Modulator 22 dump solenoid short

circuit permanently energised

EPRV 22 HOLD

UNSPEC

Modulator 22 hold solenoid control

circuit fault

EPRV 22 DUMP

UNSPEC

Modulator 22 dump solenoid control

circuit fault

Demand Pressure Transducer Group

DEMAND SC Service line pressure transducer

short circuit

DEMAND OC Service line pressure transducer

open circuit

Delivery Pressure Transducer Group

EPRV 21 DEL SC Modulator 21 delivery pressure transducer

short circuit

EPRV 21 DEL OC Modulator 21 delivery pressure transducer

open circuit

EPRV 22 DEL SC Modulator 22 delivery pressure transducer

short circuit

EPRV 22 DEL OC Modulator 22 delivery pressure transducer

open circuit

One Wheel with Slow Recovery Group

EPRV 21 SLOW REC Slow recovery of one wheel of

modulator 21

EPRV 22 SLOW REC Slow recovery of one wheel of

modulator 22

Possible causes:

Slow brake release, foundation brake

mechanical faults, dry bearings, broken

spring, restricted piping

Check for kinks and blockages etc. Incorrect

piping, Wiring.

Modulator fault. Sensor wiring crossed

across an axle

Diagnostic Trouble Codes (DTC)