2

The demand pressure is then

modified using data from the air

suspension (Electronic Load

Sensing), and may be further

modified when a wheel speed

sensor detects imminent locking

of the sensed wheels (ABS) .

The output to the brakes is

exercised by the ECU control of

the EPRV's see Fig 2.

TheEB+ECUalsoprovidesupto

5 auxillary functions such as

automaticreset-to-rideheight

(COLAS ), lift axle control

(ILAS -E),retarder and Stability

controlduringABS

EB+incorporatesanodometer

facility which measures total

distance of the trailer and its

read-outisshownonaoptional

EB+INFO CENTRE unit.

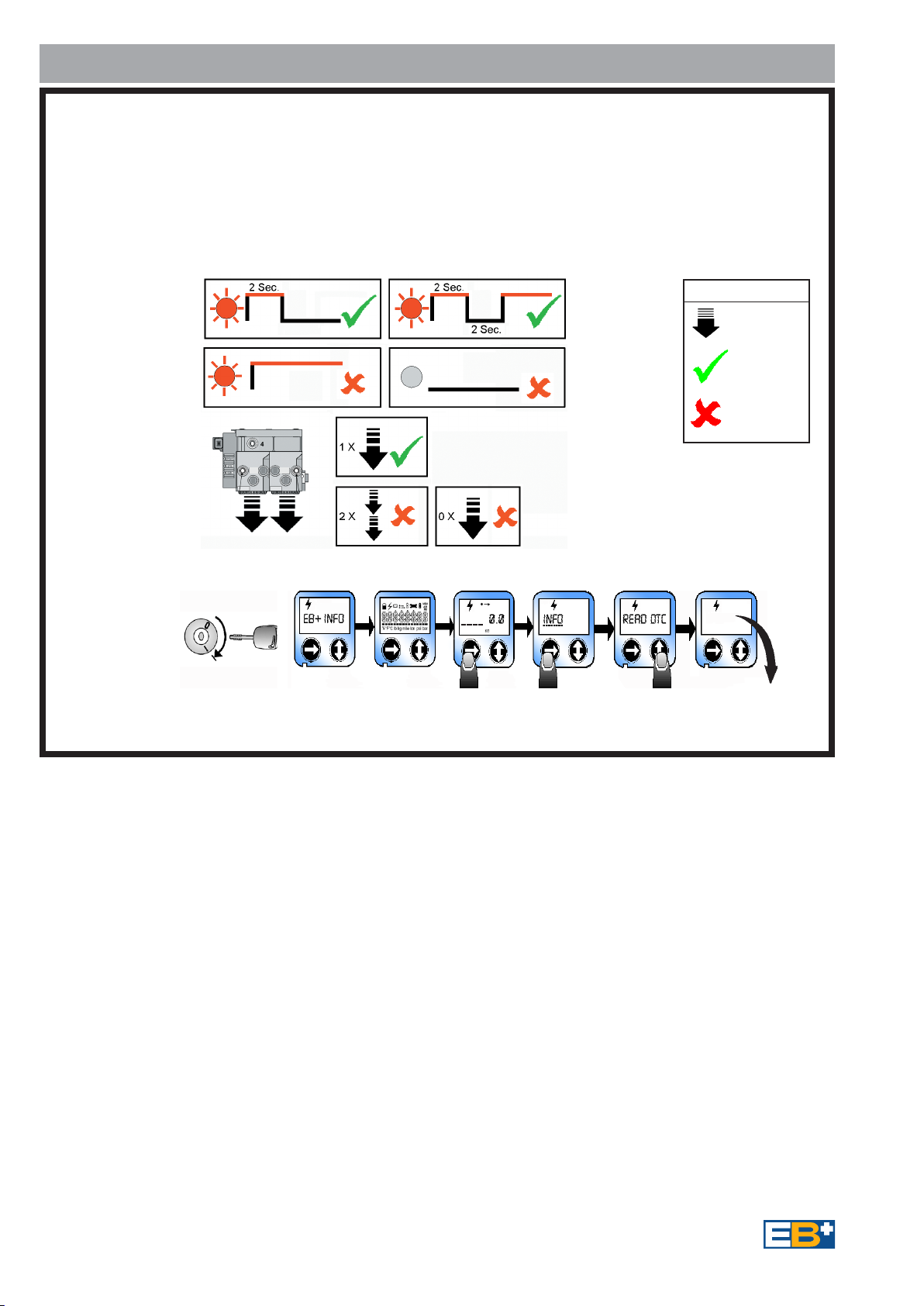

TheEB+INFO CENTRE is a side of

trailermountedunitusedalsofor

read-outofdiagnosticcodesand

otherinformationasavailablefrom

theEB+ECU.

TheEB+also incoporatesa

enhancedinformation storageand

retrievalfacility.

Forthefleetoperator,a 'Fleet Log

Reader'allowsthe compilation of a

full history of each trailer or long

termmonitoring.

Forthetrailer manufacturer,an

'End-of-line'Testing(EOLT)to

confirmcorrect performance ofthe

EB+system.

For semi and centre axle,

Air suspension trailers:-

EB+ (1M and 2M) features

♦Brake application control for all

trailer wheels

♦ABS - 2S/1M or 2S or 4S/2M

2 or 4 Sensors and 1 or 2

Modulators (EPRV's)

♦PneumaticLoadsensingfunction

♦CANinterface

♦'End-of-Line'Test

♦FleetLogReader

♦Odometerfunction

♦Reset-to-RideHeight(COLAS® )

♦LiftAxle (ILAS® -E)

♦Steer axle lock

♦EB+ Stability (2m only)

♦LiningWearIndication

For Full Trailers :-

EB+ 3M (2M +1M)

A 4S/3M system with

featuresas above.

Your trailer has been fitted with the

latest technologyHaldex Electronic

Braking System EB+.This system

has been specifically designed to be

effective,reliableand easy to service.

The purpose of this booklet is to

describethe componentsinvolvedand

giveyousufficient information to make

your use of the system easy.

The use of the diagnostic system is

describedbut when overhaulofthe

componentsisrequired, we advise

you to referto the full SERVICE

MANUAL whichdescribes

replacementprocedures fully.

SystemDescription Page2

SystemLayout Page4

SystemDiagnostics Page6

Warningdeviceand Page7

SystemCheck

Procedure

DiagnosticSystem Page9

Codes

ECUConnection Page12

Identification

WiringDiagram

Semi,CentreaxleTrailers Page13

FullTrailers Page14

PipingDiagram

Semi,CentreaxleTrailers Page15

FullTrailers Page 18

Multimeterreadings Page 19

Recommended Page 20

Maintenance

Schedules

ServiceParts Page 21

GeneralInformation Page 24

UserNotes Page 25

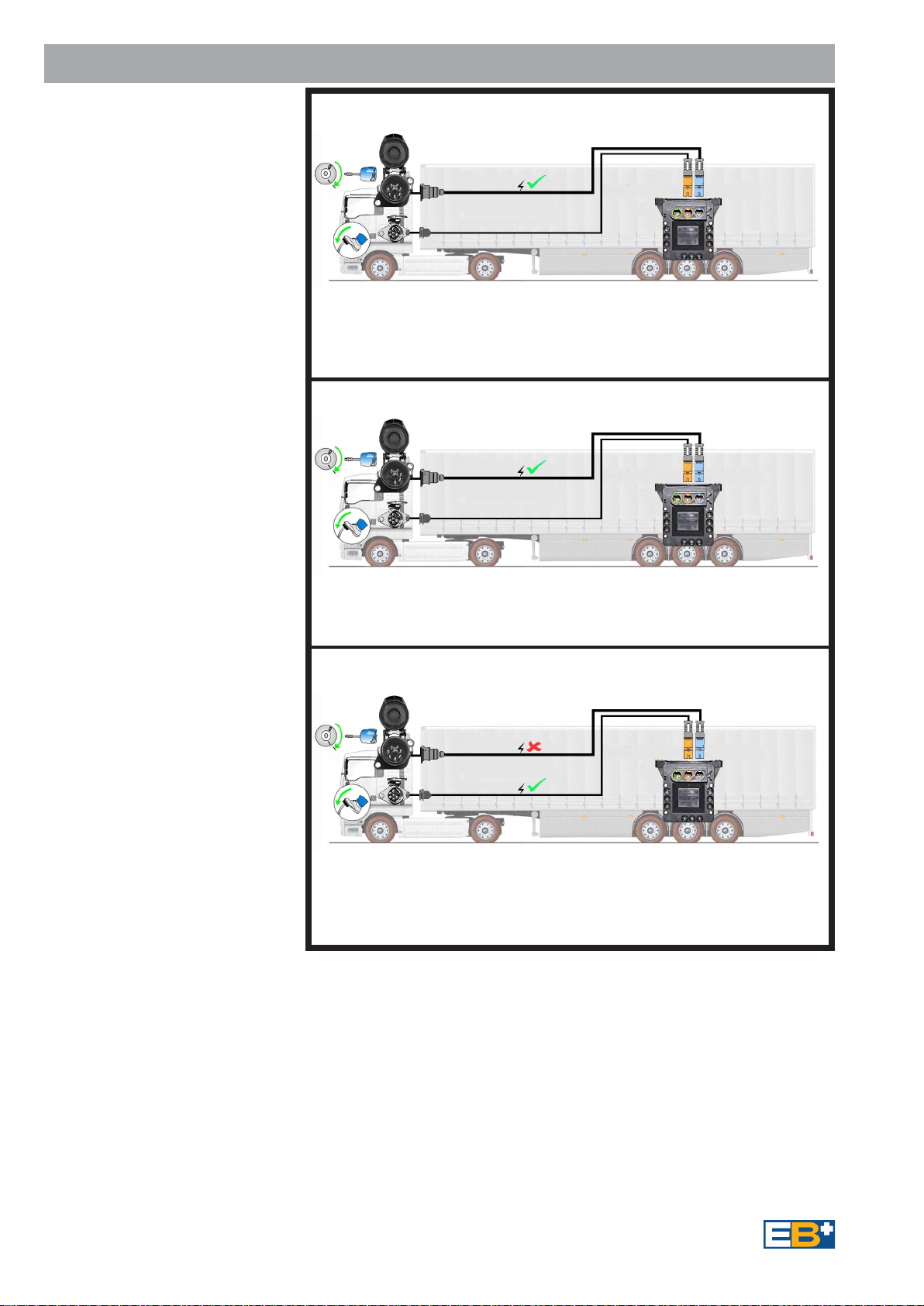

The position of the various

components is shown in Tri-axle

layout, Fig 1. The system is equally

compatible with single and tandem

axles.The EB+systemfeaturesare,

amodularintegrated construction,

anencapsulatedElectronic Control

unit(ECU)andElectro pneumatic

relayvalve/s(EPRV's),over-moulded

connectors,integratedpressure

transducers and a flash up-gradable

program memory.

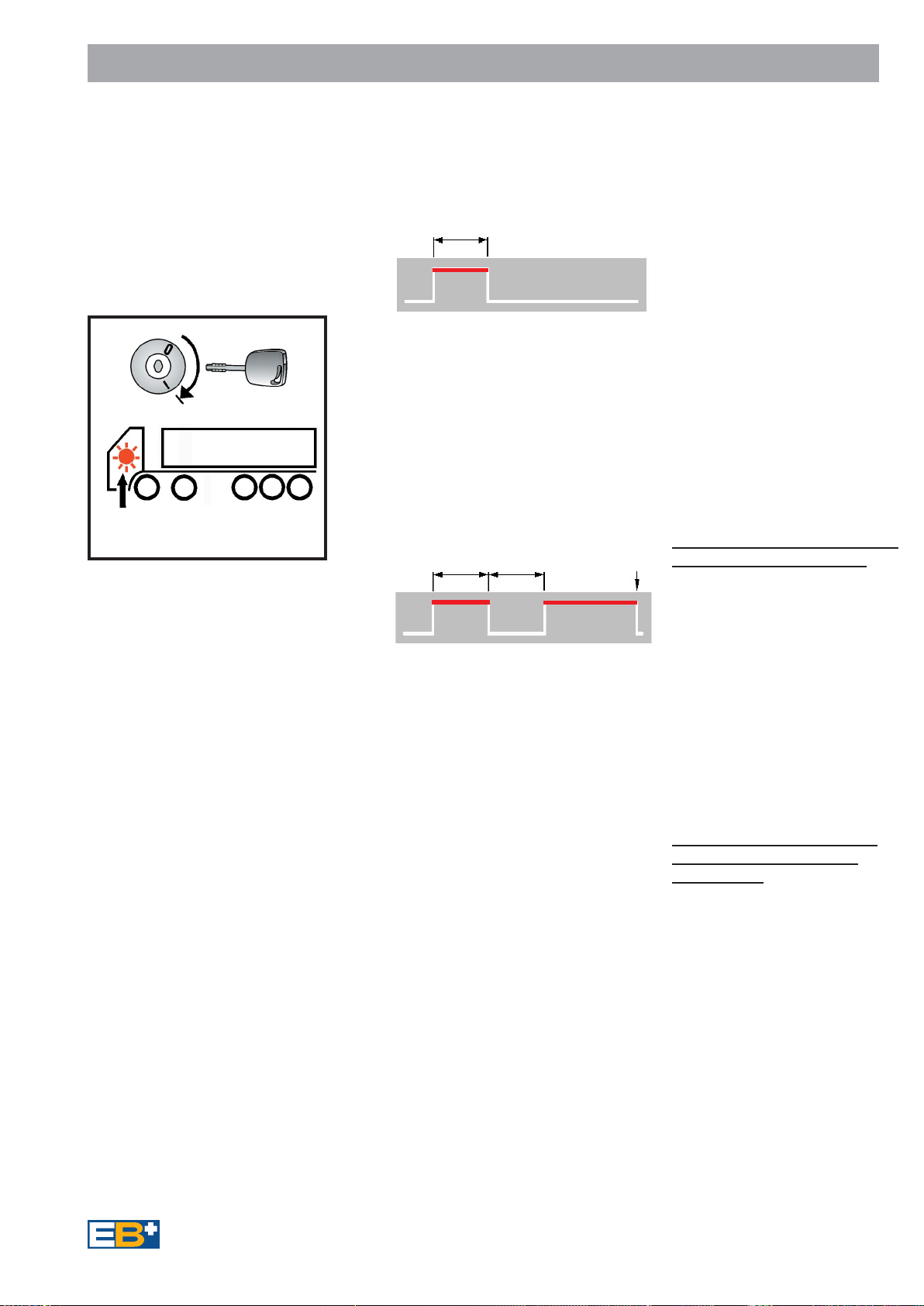

Onset of braking is denoted by

either the presence of a demand on

the ISO11992 data link (CAN) via

the ISO7638 connector and/or by

the operation of the pressure switch

in the pneumatic control line.

Driver demand pressure is then

determined electronically either by

the data link or control line pressure

transducer within the EPRV's

assembly.

EB+=A nt i lock Brake System

+ Electronic Load Sensing

+ CAN (Controller area network

ISO11992 data link-

computer data from and to

the towing vehicle)

The system reacts to electrical or

pneumatic signal from the towing

vehicle. It electronically processes

those signals plus signals received

from other sensors on the trailer.

In response to those signals the

EB+

regulatespressureto the brake

chambers.

Operators Guide

Concept

System Description

®

®

Contents