Haldex TPMS 2.0 User manual

Innovative Vehicle Solutions

INSTALLATION GUIDE

TPMS 2.0 Installation guide

2Innovative Vehicle Solutions 2023

Notes on the use of this manual

This manual has been designed to assist personnel in

satisfactorily installing Haldex TPMS 2.0 onto trailers.

The intention has been to illustrate the various areas

of installation. It is expected that this manual will be in

possession of the appropriate person throughout their

training and experience and that the manual will be

used for:

› A teaching aid following supervision of a Haldex

engineer.

› A reminder of the correct procedure of Haldex TPMS

2.0 installation.

› Appropriate spare parts documentation when

obtaining spare parts.

› Only genuine Haldex parts in repairs.

› Due to continuous development the right is reserved

to alter the specification without notice.

› No legal rights can be derived from the contents of

the manual.

› Duplication, translation and reprinting are prohibited

without permission from Haldex Brake Products.

Introduction.........................................................................................................................................................4

Specifications.......................................................................................................................................................5

TPMS 2.0 components.........................................................................................................................................6

Mounting the WUS (Belt version) .........................................................................................................................8

Twin wheel mounting ........................................................................................................................................13

Super single rims................................................................................................................................................13

Mounting the tire .............................................................................................................................................. 14

Removing the tire from the rim ..........................................................................................................................15

Receiver Control Unit (RCU) ...............................................................................................................................16

Receiver Control Unit (RCU) mounting ...............................................................................................................22

Receiver Control Unit (RCU) supply cable ...........................................................................................................24

Standard configurations.....................................................................................................................................34

Standard configuration - ADR ............................................................................................................................40

Painting .............................................................................................................................................................41

Enabling and Configuring the TPMS 2.0.............................................................................................................42

TPMS 2.0 Smart DIAG application......................................................................................................................45

TPMS 2.0Installation guide

3

2023 Innovative Vehicle Solutions

Contents

TPMS 2.0 Installation guide

4Innovative Vehicle Solutions 2023

Haldex TPMS 2.0 is a tire pressure and temperature monitoring system for any commercial vehicle trailer equipped

with EB+ 4.0. The EB+ 4.0 shall facilitate the transmission of pressure and temperature for each wheel via

ISO11992 CAN to the towing vehicle and the EB+ Info Centre can be used locally to display the pressure and

temperature on the trailer.

The wheel unit sensor (WUS) measures the pressure and temperature inside the tire and transmits all the

measurements by radio frequency (RF) to the receiver control unit (RCU). The RCU then determines the system

status and sends it to the electronic braking system (EBS) on the trailer CAN bus. The EBS then transmits this

information to the dashboard which can display the required information of pressure, warning, alerts and system

status for the vehicle driver.

The system is configured and diagnosed through CAN communication using Haldex DIAG++ software, and by

using the Haldex TPMS phone application. A trigger is used for low frequency (LF) communication to the wheel

unit sensor (WUS) and is used to force the WUS to send it's unique identification code (ID) to the RCU.

Haldex TPMS 2.0 at a glance

The Haldex TPMS 2.0 monitors both the pressure and the temperature of each individual trailer tire and is

compatible with the Haldex EB+ 4.0 EBS for trailers.

TPMS 2.0 features include:

› Constant measuring of tire pressure and temperature

› Low pressure warning

› Auto-detection

› High Temperature warning

› Over pressure warning

› TPMS Malfunction warning (self-diagnosis)

› WUS low-battery notification

› Compliance with UNECE Regulation 141

Fully compliant

Our improved TPMS 2.0 keeps up the high standards of Haldex, all while being up to industry standards.

The TPMS 2.0 is compatible with the UNECE R141 legislation. Haldex next generation TPMS 2.0 in combination

with EB+ 4.0 is fully compliant with the revised legislation for both OE and aftermarket.

Introduction

Wheel unit sensor (WUS) Belt WUS

Rim diameter range 17.5'' <> 24.5 ''

Tire inflating Air ; Azote (Nitrogen)

TPMS 2.0: Electronic features Data

Power supply 12-24 V

Temperature range -20°C to +85°C

Storage range temperature 0°C to +40°C

RCU nominal current 30 mA (max)

System maximum current (i.e. 2 x RCU) 600 mA (peak)

Antennas (GSM, RF and LF) Internal

Type of signal Analogue

TPMS 2.0: Mechanical features Data

Total mass 143g

Dimensions (L x W x H) 118 x 98 x 57 mm

Female connector TE 1-1418469-1

Ingress protection rating IPx9K

Mounting Bracket

Wiring Haldex harness

TPMS 2.0Installation guide

5

2023 Innovative Vehicle Solutions

Specications

TPMS 2.0 Installation guide

6Innovative Vehicle Solutions 2023

P/N 815 058 001

P/N 042 7272 19

P/N H144896

P/N H144897

TPMS 2.0 components

Receiver control unit (RCU)

The RCU receives sensor information, determines the system status, and

sends it to the EBS via the trailer CAN.

Wheel unit sensor (WUS)

The TPMS 2.0 wheel unit sensor (WUS) is a pressure sensor which is

clamped inside the tire using a velcro belt. It measures the pressure and

temperature inside the tire and transmits all the measurements by radio

frequency (RF) to the RCU.

Belt assembly

A velcro belt is used to attach the WUS (042727219) to the tire rim. One

belt part number covers all rim sizes from 17.5'' to 24.5''

WUS Sole (optional)

The sole should be used / clipped onto the WUS for smaller diameter rims,

which have a small drop centre width from 25 mm to 40 mm.

TPMS 2.0Installation guide

7

2023 Innovative Vehicle Solutions

P/N 815 063 001

TPMS 2.0 Smart DIAG Tool

The TPMS Smart diagnostic tool is a tool used to send

a low frequency (LF) trigger to the WUS. This tool is

operated by an Android mobile phone application.

It is used to configure the system for the first time,

writing the trailer configuration (number of wheels

and axles), recommended pressure per axle, warning

thresholds and WUS positions into the RCU.

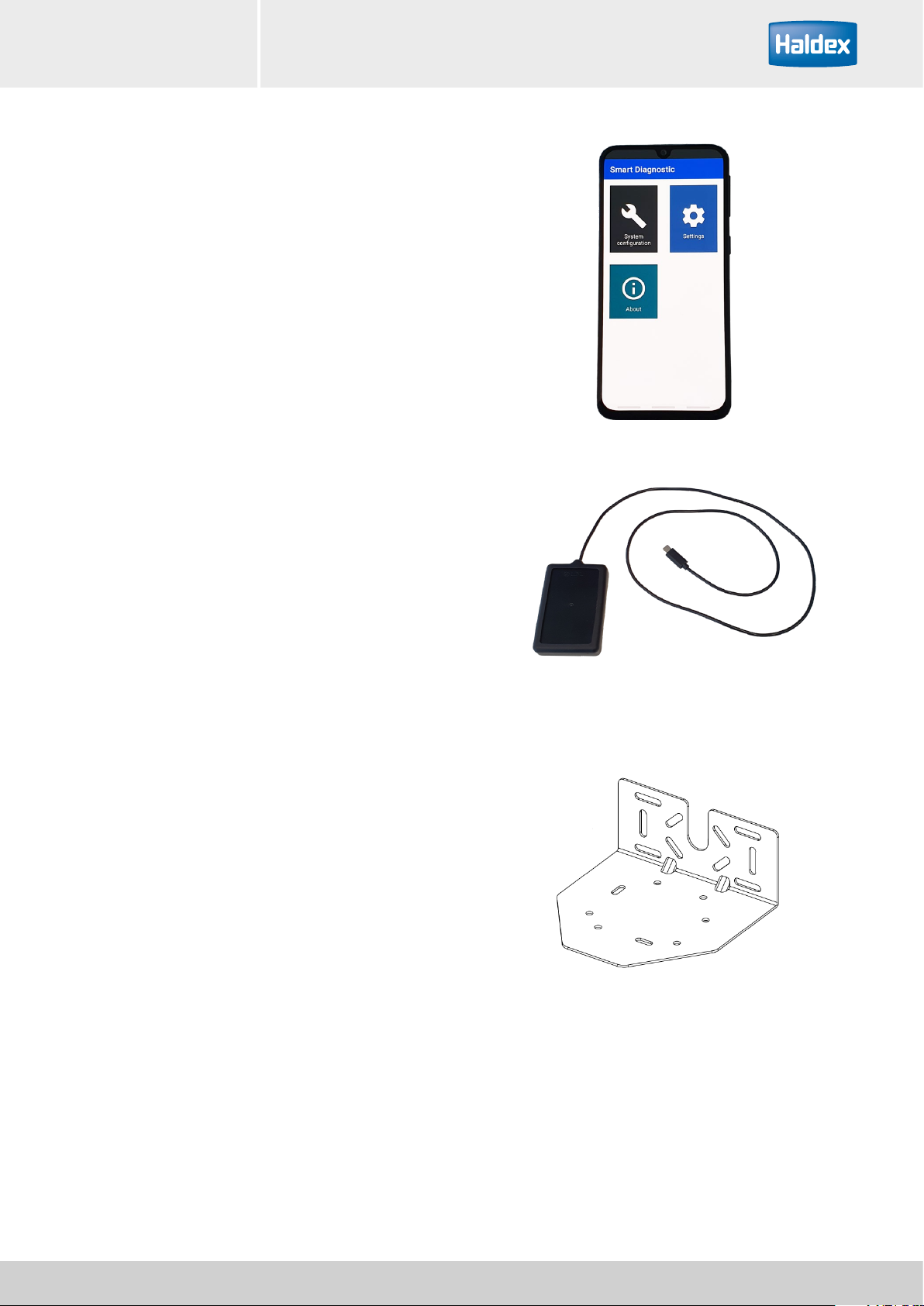

TPMS 2.0 Smart Box

The TPMS 2.0 Smart Box is connected to the mobile

phone and used to read the TPMS wheel sensor ID's.

Bracket

Bracket as per "Bracket specifications" on page 22

TPMS 2.0 Installation guide

8Innovative Vehicle Solutions 2023

TPMS 2.0 label

Indicate the presence of a WUS in the wheel by

sticking the TPMS label onto the wheel rim next to the

valve. The WUS must be located by eye before the tire

is removed from the rim.

Valve indication

Indicate the presence of a WUS in the wheel by fixing

a plastic colored tube (blue or other) onto the wheel

valve nose.

P/N 006700021_M

The TPMS 2.0 wheel unit sensor (WUS) can be mounted on all tire rims compliant to national and international

tire standards from 17.5 up to 24 inches diameter.

Tire standards:

› European tire and rim technical organisation (ETRTO)

› Tire and rim association (TRA)

› Japan automobile tire manufacturers association (JATMA)

For all rims which do not respect these specifications, customer must send all rims drawings for Haldex Brake

Products for approval.

Mounting the WUS (Belt version)

TPMS 2.0 indicator

TPMS 2.0Installation guide

9

2023 Innovative Vehicle Solutions

Examples of major mounting

problems

Example 1

There is a limitation of the mounting of the WUS on

small width drop centre tire rims.

Do not mount the WUS, if the flat width available in

the drop centre is below 25 mm.

Mount the WUS with the sole, if the flat width

available in the drop centre is between 25 mm to 40

mm.

Mount the WUS without the sole, if the flat width

available in the drop centre is larger than 40 mm.

Larger than 40 mm = OK to mount the WUS without the sole

OK

Larger than 25 mm = OK to mount the WUS with the sole

OK

OK

Flat width 25 - 40 mm = Not OK to mount the WUS without the sole

TPMS 2.0 Installation guide

10 Innovative Vehicle Solutions 2023

Example 2

Mounting with a wrong position on a conical rim profile.

Note: The angle between the sensor and the wheel axis must stay below 15° in order to avoid bad acquisition of

the acceleration level by the sensor. Also the more the sensor is raised from the rim, the greater the tire can catch

it during mounting / dismounting phase.

On a conical rim

profile, always locate

the TPMS 2.0 WUS on

the lower perimeter to

avoid sliding

Sliding under vibration

Attaching the sole adaptor (optional)

For small diameter rim with small drop centre width (25 mm minimum): => clip the sole onto the housing of the

WUS before introducing the belt in windows.

Table of contents

Other Haldex Diagnostic Equipment manuals