EB+ CAN Hub Installation

Guide

4Innovative Vehicle Solutions 2020

EB+ CAN HUB is an ISO 11992 router for 12 / 24 V EB+ EBS systems. It has three EB+ Power A (ISO 7638)

connectors, sharing power and lamp connections but each having a separate ISO 11992 node and an input to

connect an external pressure sensor for a commercial vehicle not equipped with ISO 11992 (i.e. Truck with ABS

system only).

EB+ CAN Hub requires Haldex EBS (Gen3 with E741 or later software) on the same trailer, in order that

configuration and diagnostics is performed correctly. In road trains EB+ CAN Hub works with any EBS meeting the

requirements of ISO 11992, which includes all trailers with UN R13 approval.

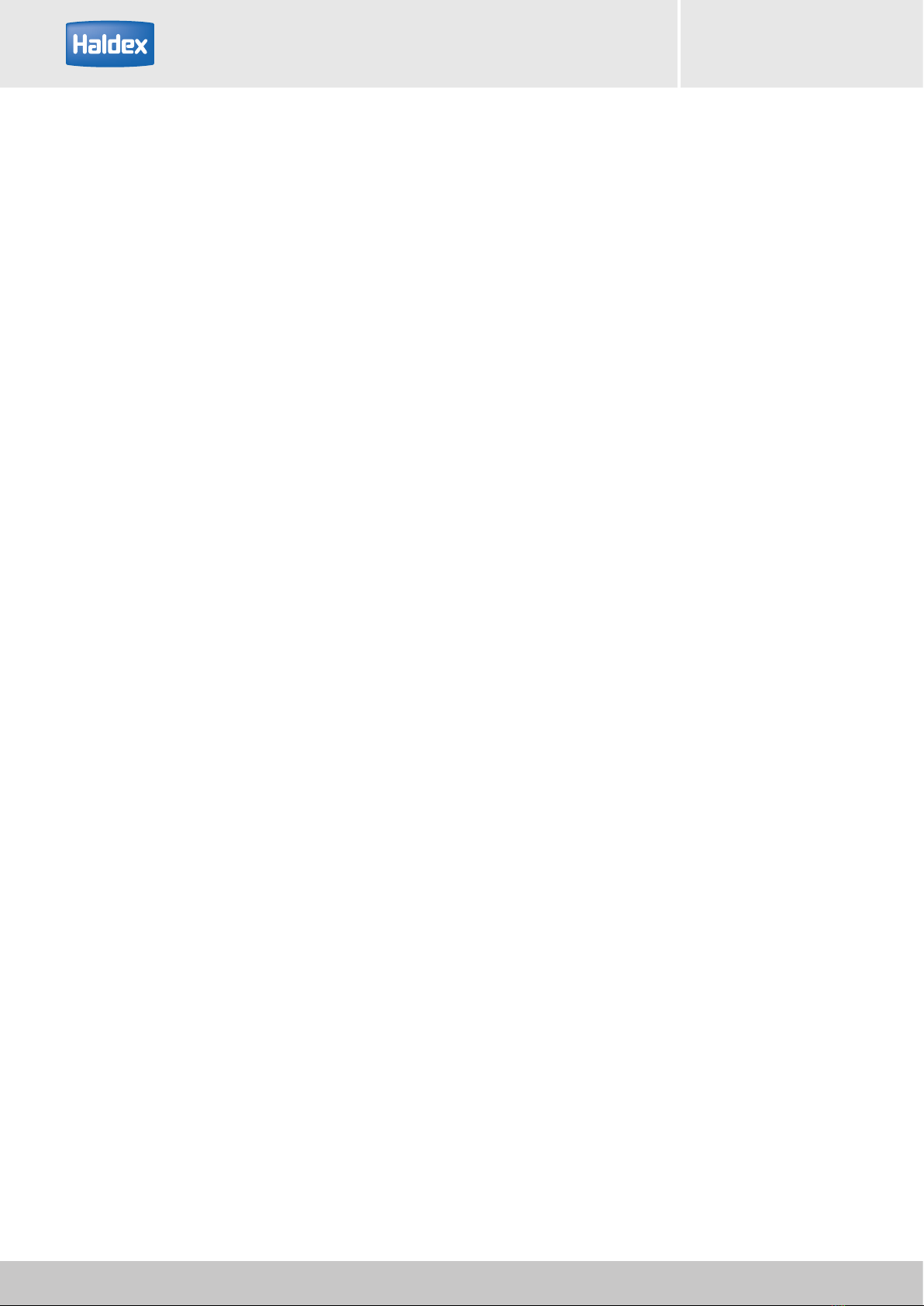

The product is intended to solve three installation problems: -

1. Extend the distance over which EBS can be fitted to certain very long trailers.

2. To connect two EBS together on one trailer, e.g. where there are more than five axles.

3. To provide an ISO 7638 output for a successor trailer in a road train.

Ideally any connector on the EB+ CAN Hub can have any function, with the EB+ CAN Hub self-configuring

according to the messages received. Where two ECU's are attached to the same trailer a configuration step may

be necessary at end-of-line to ensure correct addressing, as defined in ISO 11992-2.

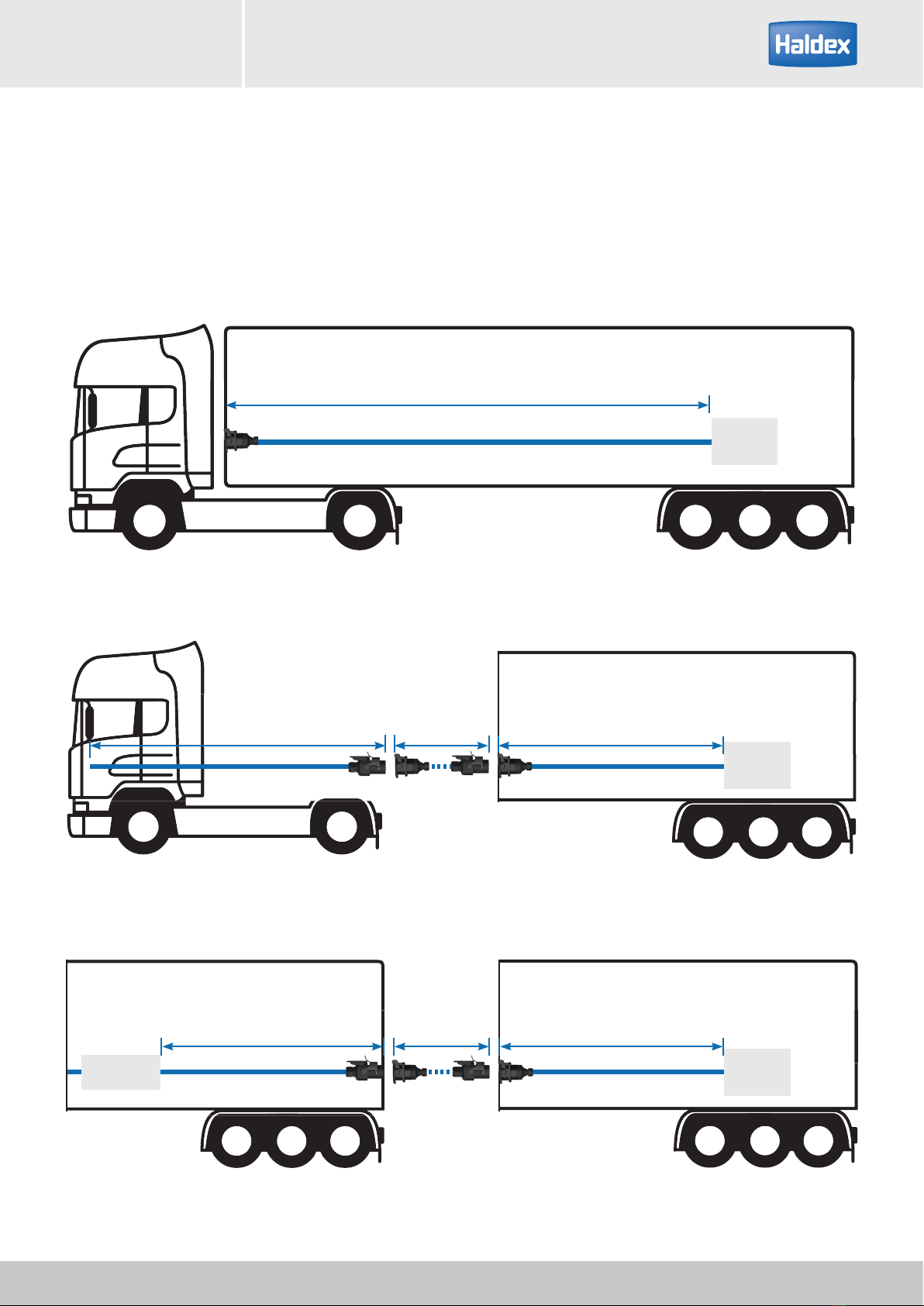

A road train consists of one truck (commercial vehicle) and one or more trailer(s) (towed vehicles). Dollies within

the road train shall be treated as additional towed vehicles.

1 2 3 4

Key

1 Truck (commercial vehicle)

2 Semi-Trailer (towed vehicle)

3 Converter dolly (towed vehicle)

4 Semi-Trailer (towed vehicle)

Introduction