7

SERVICE MANUAL

SystemRoMedicTM

21

4033

4

131418

1

2

8

2016 10 11 22

756

31

30

3

17

9

2928

27 24

19

23

15

26

25

39 32

12

34

35

37

36

38

REVISION HISTORY

REV.

POS.

DESCRIPTION

DATE

DRAWN BY

ITEM NO.

DOCUMENT NO.

REV.

TITLE

QTY.

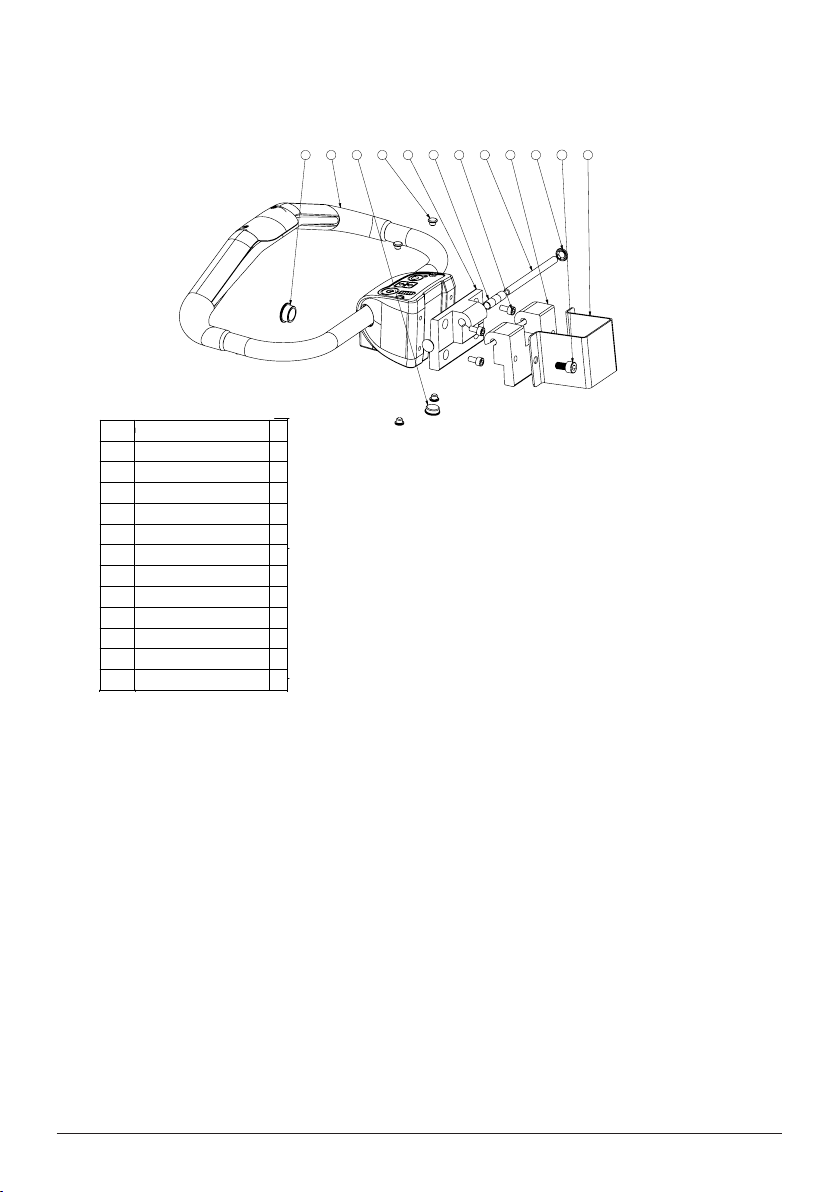

1 90004710

01A+

EvaDrive leg right welded

1

290004711

01A+

EvaDrive leg left welded

1

390000345 04

Washer DIN125 8.4x16x1.6 fzb

4

490004723

01A

Eva drive actuator stearing pin

1

590004718 01

Eva drive wheel bracket left

1

690004466

00B+

Hub motor and wheel left

1

790004737

00A+

Bushing teflon COB010_DB16

4

890004734

00+

Lock nut DIN985 M18 fzb

2

990004720 01

Eva drive wheel distance

2

10 90004719 01

Eva drive wheel bracket right

1

11 90005035

00A+

Parallell key DIN 6885 A RK h9 4x20

2

12 90000026 03

Lock nut DIN985 M8 fzb

10

13 90004735

00A+

Bushing with flange PTFE COB010F 15090 Internordic

4

14 90004722 01

Eva drive sleeve

4

15 90004721 01

Eva drive tension bracket

2

16 90005031

01A+

Eva drive support welded

1

17 90001674 01

Screw MC6S DIN912 8.8 M8x16 fzb

4

18 90004471 01

Screw_MC6S_DIN912_8.8_M8x20_fzb

4

19 90005026 01

Screw K6S DIN7380 10.9 M8x20 fzb

6

20 90005036

00+

Flanged lid Enclosure - Hammond 1591GFLGY

1

21 90005002

00+

Eva Drive cover

1

22 90004467

00+

Hub motor and wheel right

1

23 90003940

00+

Emergeny stop button CE3T-10R-11 (ABB)

1

24 90005023 00

Screw K6S DIN7380 10.9 M8x40 fzb

2

25 90001200 01

Washer DIN125 4,3x9x0,8 fzb

2

26 90005025 01

Screw MC6S DIN912 8.8 M4x30 fzb

2

27 90004920 01

Spacer 6,2x10x5 PA-66 Skiffy 005 4900 000 02

4

28 90005028 01

Washer DIN 7349 4,3x12x1,6 fzb

4

29 90005027 01

Lock nut DIN985 M4 fzb

4

30 90005029 01

Screw MF6S DIN7991 8.8 M4x20 fzb

4

31 90003696 01

Shoulder bolt ISO7379 12.9 10xM8x40

2

32 90001716 01

Plug Ackurat IKPT 13x9 G

2

33 90003706 01

Flange bushing COB010f - 10120 (Internordic)

1

34 90005060 00

Nut ML6M DIN439 ISO4035 M10 fzb

1

35 90000732 01

Bushing teflon C0B010-1012

1

36 90005086

00+

Eva Drive Cable entry top

1

37 90005085

00+

Eva Drive Cable entry front

1

38 90005087

00+

Screw for thermoplastic TPPT 2,5x12 fzb (BUFAB)

2

39 90003273

00+

Control box VR2

1

40 90003945

00+ Actuator LA30 2-way 335mm

1

B

C

D

1

2

A

3

2

1

4

B

A

5

6

C

3

1:5

CREATED

STATUS

TITLE

MATERIAL:

SIZE

In work

Eva Drive 450 base assy

90005037

00D+

2015-11-18

A4

This drawing and any information or descriptive matter set out hereon are the confidential and copyright property of Handicare

and must not be disclosed, loaned, copied or used for manufacturing, tendering or any other purpose without their written permission.

MATERIAL SPECIFICATION:

PROJECTION

SCALE

21

4033 4

131418 1

2

82016 10 11 22756

31

30

3

17

92928

27 24

19

23

15

26

25

39 32

12

34

35

37

36

38

REVISION HISTORY

REV.

POS.

DESCRIPTION

DATE

DRAWN BY

ITEM NO.

DOCUMENT NO.

REV.

TITLE

QTY.

1

90004710

01A+

EvaDrive leg right welded

1

2

90004711

01A+

EvaDrive leg left welded

1

3

90000345 04

Washer DIN125 8.4x16x1.6 fzb

4

4

90004723

01A

Eva drive actuator stearing pin

1

5

90004718 01

Eva drive wheel bracket left

1

6

90004466

00B+

Hub motor and wheel left

1

7

90004737

00A+

Bushing teflon COB010_DB16

4

8

90004734

00+

Lock nut DIN985 M18 fzb

2

9

90004720 01

Eva drive wheel distance

2

10

90004719 01

Eva drive wheel bracket right

1

11

90005035

00A+

Parallell key DIN 6885 A RK h9 4x20

2

12

90000026 03

Lock nut DIN985 M8 fzb

10

13

90004735

00A+

Bushing with flange PTFE COB010F 15090 Internordic

4

14

90004722 01

Eva drive sleeve

4

15

90004721 01

Eva drive tension bracket

2

16

90005031

01A+

Eva drive support welded

1

17

90001674 01

Screw MC6S DIN912 8.8 M8x16 fzb

4

18

90004471 01

Screw_MC6S_DIN912_8.8_M8x20_fzb

4

19

90005026 01

Screw K6S DIN7380 10.9 M8x20 fzb

6

20

90005036

00+

Flanged lid Enclosure - Hammond 1591GFLGY

1

21

90005002

00+

Eva Drive cover

1

22

90004467

00+

Hub motor and wheel right

1

23

90003940

00+

Emergeny stop button CE3T-10R-11 (ABB)

1

24

90005023 00

Screw K6S DIN7380 10.9 M8x40 fzb

2

25

90001200 01

Washer DIN125 4,3x9x0,8 fzb

2

26

90005025 01

Screw MC6S DIN912 8.8 M4x30 fzb

2

27

90004920 01

Spacer 6,2x10x5 PA-66 Skiffy 005 4900 000 02

4

28

90005028 01

Washer DIN 7349 4,3x12x1,6 fzb

4

29

90005027 01

Lock nut DIN985 M4 fzb

4

30

90005029 01

Screw MF6S DIN7991 8.8 M4x20 fzb

4

31

90003696 01

Shoulder bolt ISO7379 12.9 10xM8x40

2

32

90001716 01

Plug Ackurat IKPT 13x9 G

2

33

90003706 01

Flange bushing COB010f - 10120 (Internordic)

1

34

90005060 00

Nut ML6M DIN439 ISO4035 M10 fzb

1

35

90000732 01

Bushing teflon C0B010-1012

1

36

90005086

00+

Eva Drive Cable entry top

1

37

90005085

00+

Eva Drive Cable entry front

1

38

90005087

00+

Screw for thermoplastic TPPT 2,5x12 fzb (BUFAB)

2

39

90003273

00+

Control box VR2

1

40

90003945

00+

Actuator LA30 2-way 335mm

1

B

C

D

1

2

A

3

2

1

4

B

A

5

6

C

3

1:5

DWG. NO.

REV.

NAME

DATE

CREATED

SHEET 1 OF 1

WEIGHT:

STATUS

TITLE

MATERIAL:

SIZE

In work

Eva Drive 450 base assy

90005037

00D+

2015-11-18

A4

This drawing and any information or descriptive matter set out hereon are the confidential and copyright property of Handicare

and must not be disclosed, loaned, copied or used for manufacturing, tendering or any other purpose without their written permission.

MATERIAL SPECIFICATION:

PROJECTION

SCALE

hc-matfre

21

4033 4

131418 1

2

82016 10 11 22756

31

30

3

17

92928

27 24

19

23

15

26

25

39 32

12

34

35

37

36

38

REVISION HISTORY

REV.

POS.

DESCRIPTION

DATE

DRAWN BY

ITEM NO.

DOCUMENT NO.

REV.

TITLE

QTY.

EvaDrive leg right welded

1

EvaDrive leg left welded

1

Washer DIN125 8.4x16x1.6 fzb

4

Eva drive actuator stearing pin

1

Eva drive wheel bracket left

1

Hub motor and wheel left

1

Bushing teflon COB010_DB16

4

Lock nut DIN985 M18 fzb

2

Eva drive wheel distance

2

Eva drive wheel bracket right

1

Parallell key DIN 6885 A RK h9 4x20

2

Lock nut DIN985 M8 fzb

10

Bushing with flange PTFE COB010F 15090 Internordic

4

Eva drive sleeve

4

Eva drive tension bracket

2

Eva drive support welded

1

Screw MC6S DIN912 8.8 M8x16 fzb

4

Screw_MC6S_DIN912_8.8_M8x20_fzb

4

Screw K6S DIN7380 10.9 M8x20 fzb

6

Flanged lid Enclosure - Hammond 1591GFLGY

1

Eva Drive cover

1

Hub motor and wheel right

1

Emergeny stop button CE3T-10R-11 (ABB)

1

Screw K6S DIN7380 10.9 M8x40 fzb

2

Washer DIN125 4,3x9x0,8 fzb

2

Screw MC6S DIN912 8.8 M4x30 fzb

2

Spacer 6,2x10x5 PA-66 Skiffy 005 4900 000 02

4

Washer DIN 7349 4,3x12x1,6 fzb

4

Lock nut DIN985 M4 fzb

4

Screw MF6S DIN7991 8.8 M4x20 fzb

4

Shoulder bolt ISO7379 12.9 10xM8x40

2

Plug Ackurat IKPT 13x9 G

2

Flange bushing COB010f - 10120 (Internordic)

1

Nut ML6M DIN439 ISO4035 M10 fzb

1

Bushing teflon C0B010-1012

1

Eva Drive Cable entry top

1

Eva Drive Cable entry front

1

Screw for thermoplastic TPPT 2,5x12 fzb (BUFAB)

2

Control box VR2

1

Actuator LA30 2-way 335mm

1

B

C

D

1

2

A

3

2

1

4

B

A

5

6

C

3

1:5

DWG. NO.

REV.

NAME

DATE

CREATED

SHEET 1 OF 1

WEIGHT:

STATUS

TITLE

MATERIAL:

SIZE

In work

Eva Drive 450 base assy

90005037

00D+

2015-11-18

A4

This drawing and any information or descriptive matter set out hereon are the confidential and copyright property of Handicare

and must not be disclosed, loaned, copied or used for manufacturing, tendering or any other purpose without their written permission.

MATERIAL SPECIFICATION:

PROJECTION

SCALE

hc-matfre

Exploded view and components - EvaDrive, base