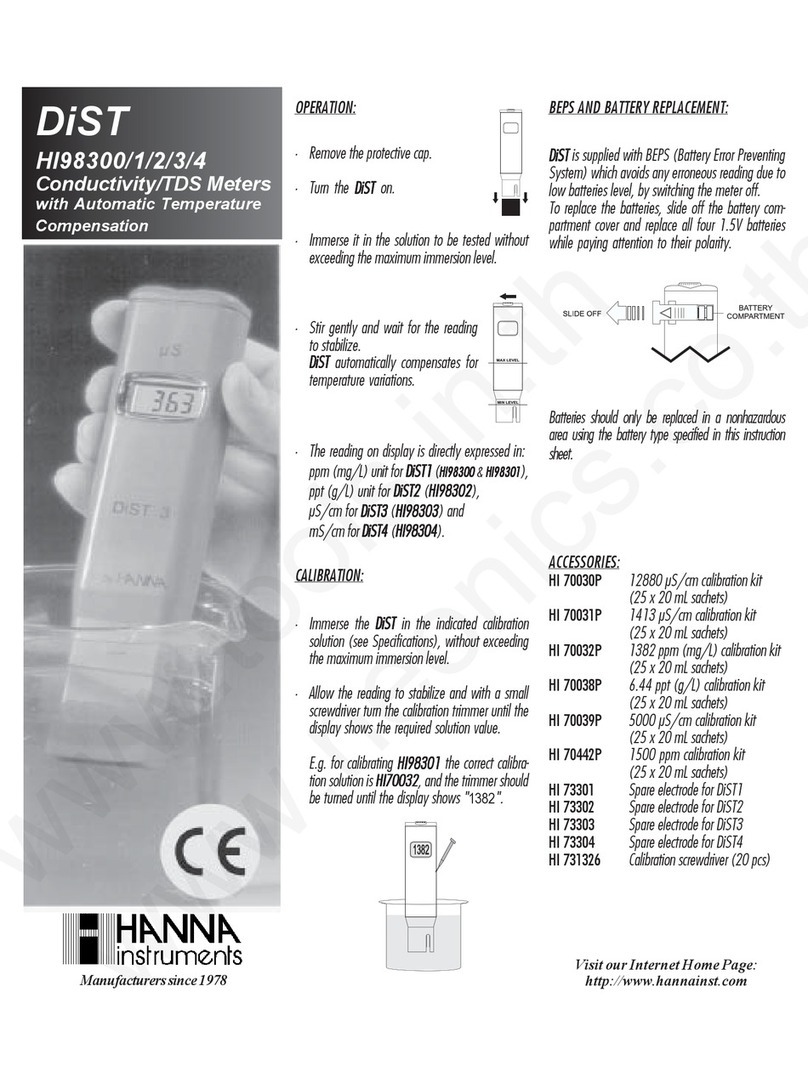

First time you use the instrument open the battery compartment

and put the batteries inside observing the polarity.

To connect the probe

With the meter turned off, connect the HI 1297D probe to the

DIN socket on the bottom of the meter by aligning the pins and

pushing in the plug. Tighten the nut to ensure a good connection.

Remove the protective cap from the probe before taking any

measurements.

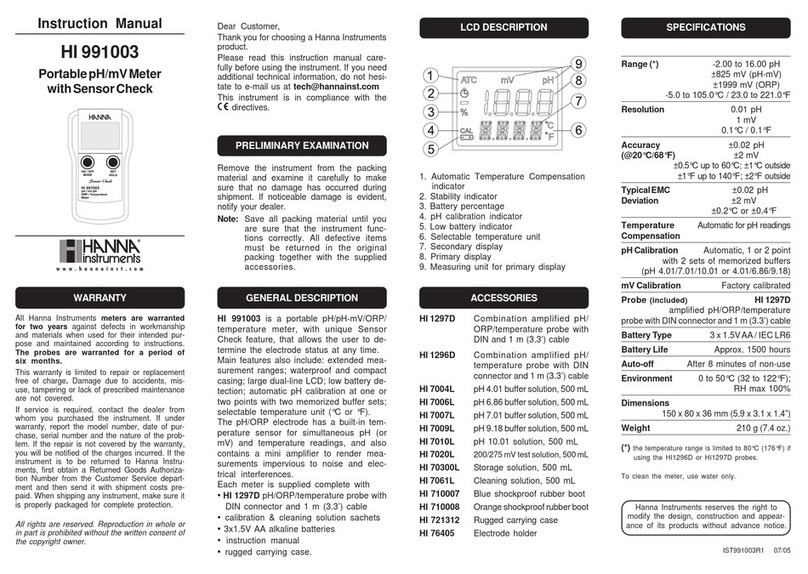

To turn the meter ON and check the battery status

Press the ON/OFF/MODE button until the display lights up. At

start-up, all the LCD segments are displayed for 1 second, then

the percent indication of the remaining battery life is displayed for

another second (E.g. “100 % BATT“). The meter then enters the

normal measuring mode.

Note:If the display needs to be checked, keep the ON button

pressed while turning the meter on. The meter will display

all segments as long as the button is pressed.

To select the measurement range

While in measurement mode, press the SET/HOLD button to

select pH or mV (pH-mV or ORP, depending on probe) measure-

ment range.

To freeze the display

While in measurement mode, press and hold the SET/HOLD

button until “HOLD“ appears on the secondary display and the

reading will be frozen on the LCD (E.g. “pH 5.73 HOLD“). Press

any button to return to normal mode.

To turn the meter OFF

While in normal measurement mode, press the ON/OFF/MODE

button. “OFF“ will appear on the secondary display. Release the

button.

The meter is provided with an acoustic signal active when a key is

pressed.

Note:When the meter detects the absence of probe at its input,

the message “Probe not connected“ appears on LCD and

“---“blinking on LCD lines. When a probe is connected, the

“Probe not connected“ tag is turned off, and the readings

are displayed on LCD lines.

•Make sure the meter has been calibrated before use.

•If the probe is dry, soak it in HI 70300 storage solution for

30 minutes to reactivate it.

•Submerge the probe in the sample to be tested while stirring it

gently. Wait until the “Not Stable“ tag on the LCD is turned off.

•The pH value automatically compensated for temperature is

displayed on the primary LCD, while the secondary LCD displays

the sample temperature.

•If measurements are taken in different samples successively,

rinse the probe tip thoroughly to eliminate cross-contamination.

After cleaning, rinse the probe tip with some deionized water

and some of the sample to be measured.

pH calibration

For better accuracy, frequent calibration of the pH sensor with

the meter is recommended. In addition, the meter must be

recalibrated whenever:

a) The pH electrode is replaced.

b) After testing aggressive chemicals.

c) Where high accuracy is required.

d) At least once a month.

•While in pH measurement mode, press and hold the

ON/OFF/MODE button until “OFF“ on the secondary display

is replaced by “CAL“. Release the button. Place the sensor

into the first calibration buffer.

•The meter enters the calibration mode, displaying “pH 7.01

USE” (or “pH 6.86 USE” if the NIST buffer set was selected).

•For a

single-point calibration

place the probe in any buffer from

the selected buffer set (E.g. pH 4.01, 9.18 or 10.01). The meter

will automatically recognize the buffer value.

•If the buffer is not recognized or the calibration offset is out of

the accepted range ''---WRONG'' is displayed.

•If the buffer is recognised ''REC" is displayed until the reading is

stable and the calibration is accepted.

•If using pH 7.01 (or pH 6.86 from NIST buffer set), after

acceptance of the buffer press any key to exit. ''OK1'' message is

displayed and meter returns to pH measurment mode.

•If using 4.01 or 10.01 (9.18) buffer the ''OK1'' message is

displayed and meter returns to pH measurment mode.

•For a

two-point calibration

, proceed as for the single point

calibration selecting 7.01/6.86 pH buffer.

•The ''pH 4.01 USE'' message is displayed.

•Place the probe in the second calibration buffer (pH 4.01 or

10.01, or, if using NIST, pH 4.01 or 9.18). When the second

buffer is accepted, the LCD will display “OK2” for 1 second and

the meter will return to the normal measurement mode.

•If the buffer is not recognised or the slope is out of accepted

range ''---WRONG'' is displayed. Change the buffer, clean the

electrode or press any key to exit calibration.

Note:When the calibration procedure is completed, the “Calibrated“

tag is turned on.

It is always recommended to carry out a two-point calibration

for better accuracy.

To exit calibration and reset default values

•After entering the calibration mode and before the point is

accepted, it is possible to quit the procedure and return to the

last calibration data by pressing the ON/OFF/MODE button.

The LCD displays “---ESC“ for 1 second and the meter returns to

normal mode.

•To reset the default values and clear a previous calibration,

press the SET/HOLD button after entering the calibration

mode, before the first point is accepted.

The LCD displays “---CLR“ for 1 second, the meter resets to the

default calibration and the “Calibrated” tag on the LCD disap-

pears.

Setup mode allows the selection of the temperature unit and the

type of pH buffer set.

To enter the Setup mode, press and hold the ON/OFF/MODE

button until “CAL“ on the secondary display is replaced by “TEMP“

and the current temperature unit (E.g. “TEMP °C“). Then:

•

for °C/°F selection

, use the SET/HOLD button. After the

temperature unit has been selected, press ON/OFF/MODE to

enter the buffer set selection mode; press ON/OFF/MODE

twice to return to the normal measuring mode.

•

to change the type of calibration buffer set

, after setting the

temperature unit, the meter will show the current buffer set:

“pH 7.01 BUFF” (for standard buffer set: 4.01/7.01/10.01) or

“pH 6.86 BUFF” (for NIST buffer set: 4.01/6.86/9.18). Change

the set with the SET/HOLD button, then press ON/OFF/MODE

to return to normal mode.

ORP MEASUREMENT

pH MEASUREMENT & CALIBRATIONOPERATIONAL GUIDE

METER SETUP

BATTERY REPLACEMENT

The meter is supplied with batteries.

The meter displays the remaining battery percentage when turned

on. When the level is below 5%, the “

“ symbol on the LCD

blinks to indicate a low battery condition. If the battery level is low

enough to cause erroneous readings, the Battery Error Prevention

System (BEPS) turns the meter

off. It is recommended to replace

the batteries as soon as the display will flash the battery symbol.

To replace the batteries, follow the next steps:

•Open the battery compartment cap (on the bottom of the

instrument).

•Remove old batteries.

•Replace new batteries observing the polarity on the rear of

the instrument.

•Close the battery compartment cap.

•Make sure the probe is connected.

•Set the meter to mV range.

•Place the probe into the sample to be tested.

•Stir briefly and wait until the “Not Stable“ tag on the LCD is

turned off.

•If using the supplied HI 1297D probe, the meter will show the

ORP (mV) value and the temperature of the sample; if using

optional HI 1296D probe, the meter will show the mV value

equivalent to the pH and the temperature of the sample.

Notes:•The ORP range is factory calibrated and cannot be

calibrated by the user. HI 7020L ORP solution can be

used to validate ORP sensor is reading correctly.

•“ATC“ tag turns off because the mV readings are

not temperature compensated.

The Sensor Check feature allows the user to check the electrode status

at any time. This is possible by setting the meter to pH-mV range.

The offset value is the reading of the electrode immersed in pH7

buffer (@25°C/77°F). If this reading is outside the range

±40 mV, the electrode is considered "poor" and it is recommended

to replace it with a new one.

The slope value of the electrode is the difference between readings

in pH7 and in pH4 buffers. For a new electrode this is about 174 mV

(@25°C/77°F). With time, the slope value decreases. When it

reaches the value of about 150 mV, the electrode is considered

“poor“, and it is recommended to replace it with a new one.

Note:Always recalibrate the meter after replacing the electrode.

To ensure reliable readings, the electrode must be cleaned with

cleaning solution before measuring the offset and the slope.

SENSOR CHECK