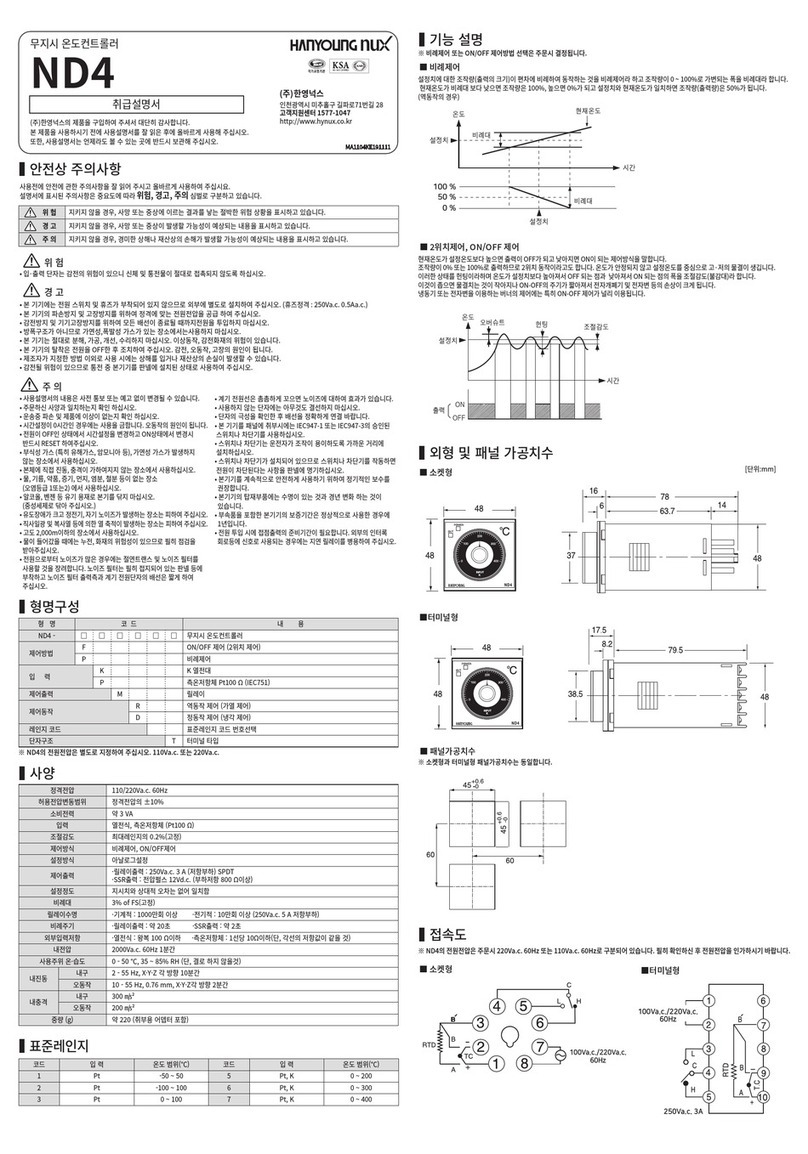

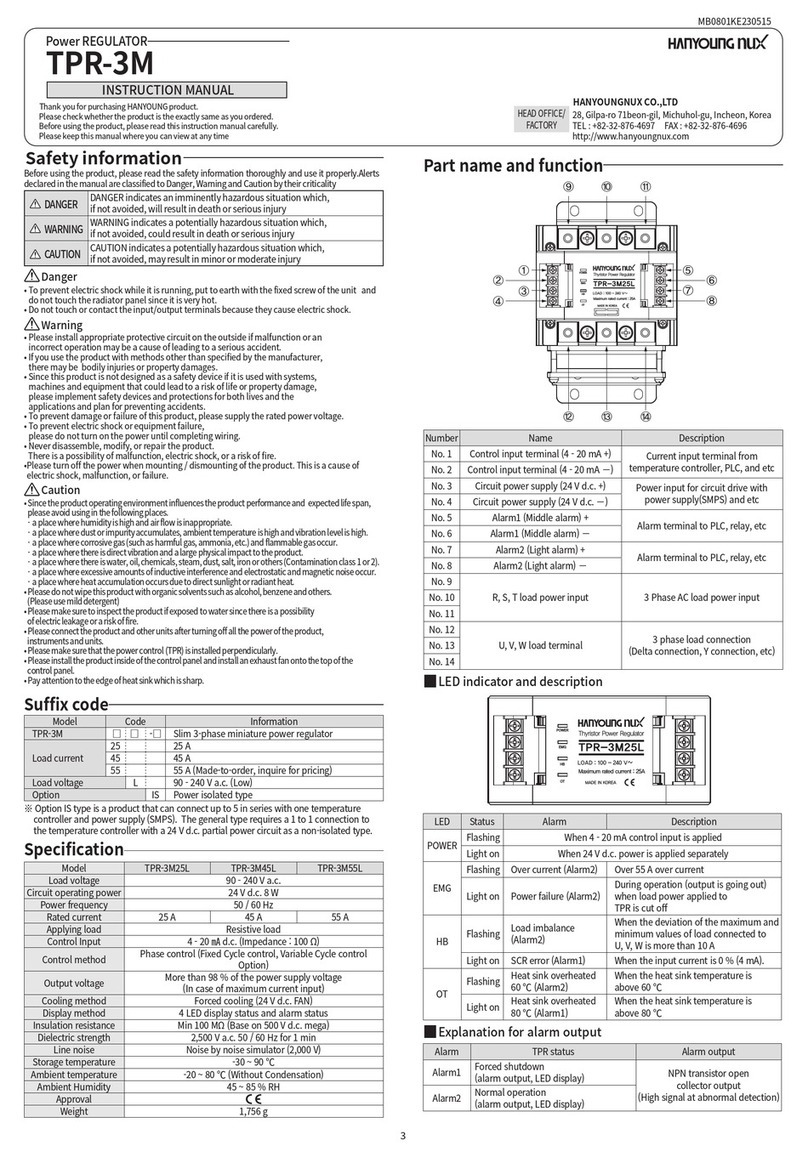

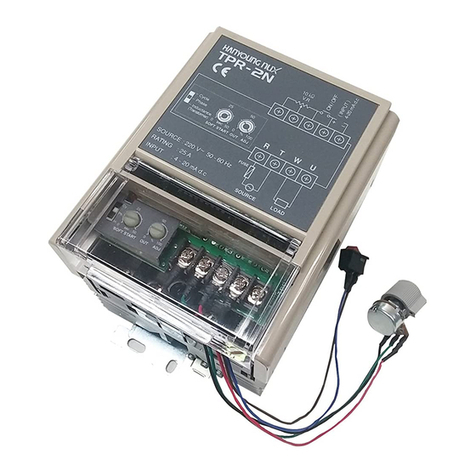

3 4

•

Front volume

Volume / Reset key Information

Output limitation

setting

(PW.MAX)

Function which limits an output amount. Output 0% when volume is

positioned at min and output 100% when it is positioned at max.

•Default setting : 100% (max.)

•No correspondence when performing ON/OFF control

Over current

alarm setting

(O.C)

The current LED becomes ON immediately when input value is more

than the set value and if that value is maintained for more than 0.5

sec then alarm output will become ON.

•Default set value : 100 A

•Set range : 0~rated current (max value)

Soft start setting

ON the switch for the first time when using the inductive or capacitive

load, max value power will be supplied into the load which may

damage the load or destroy the power device. This setting increases

the load voltage gradually.

•Default setting: 0 (Set range: 0~50 sec)

•It is not operated with “0” setting

•No correspondence when performing ON/OFF control

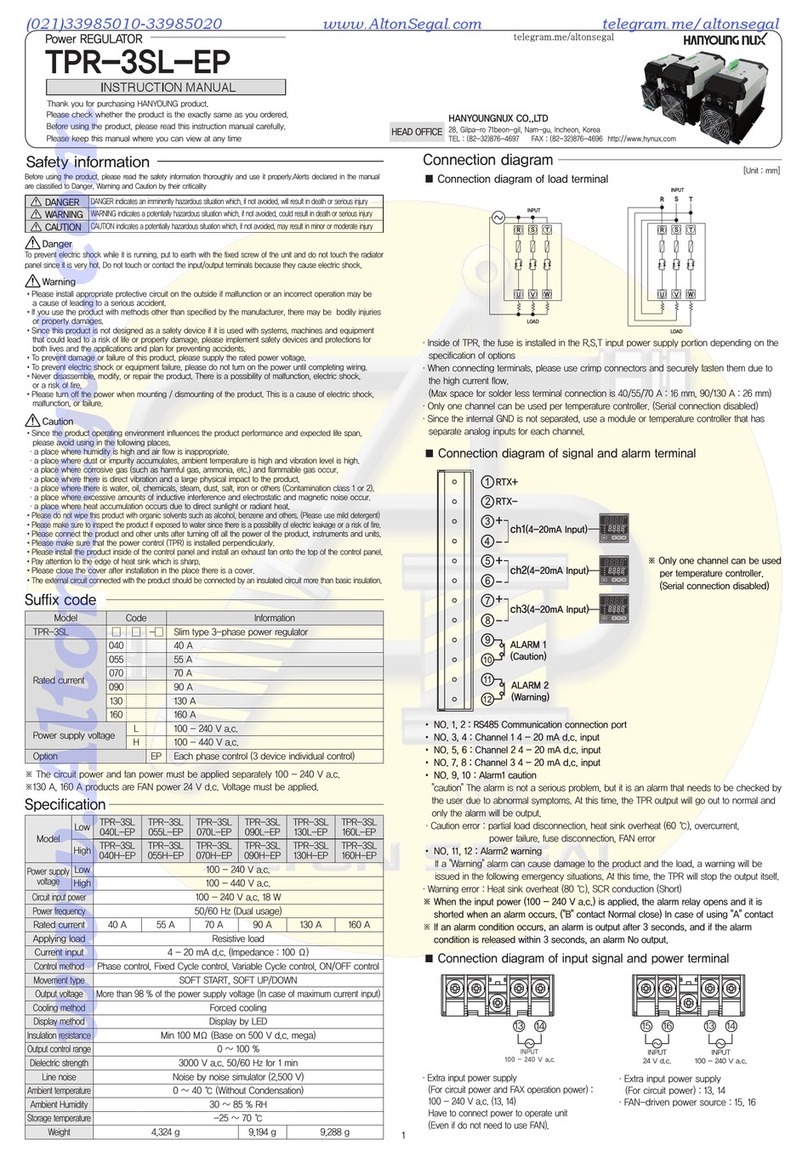

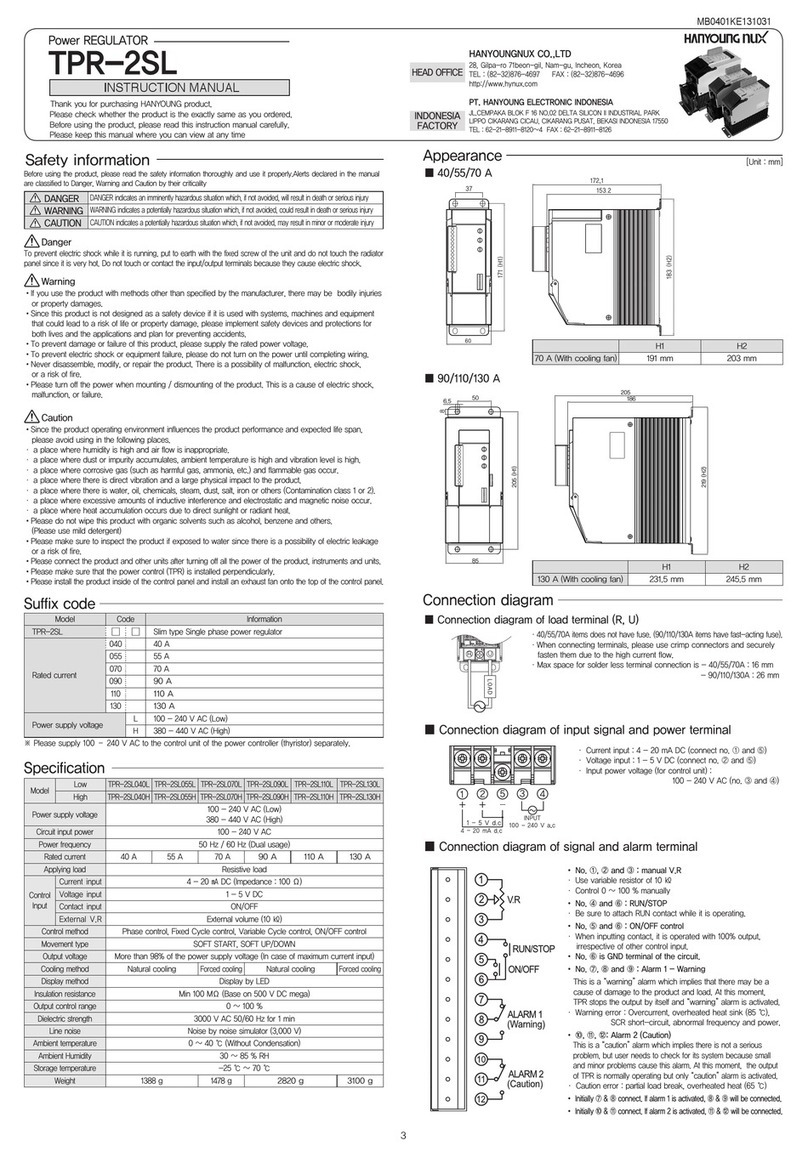

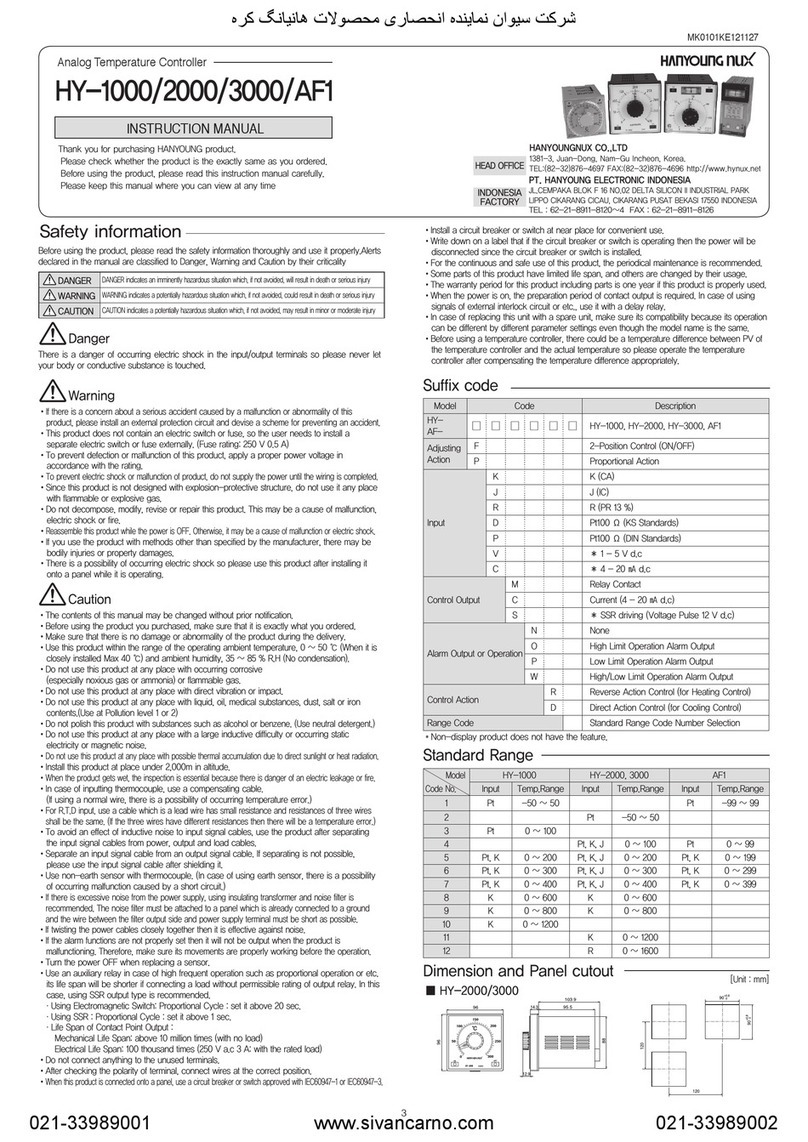

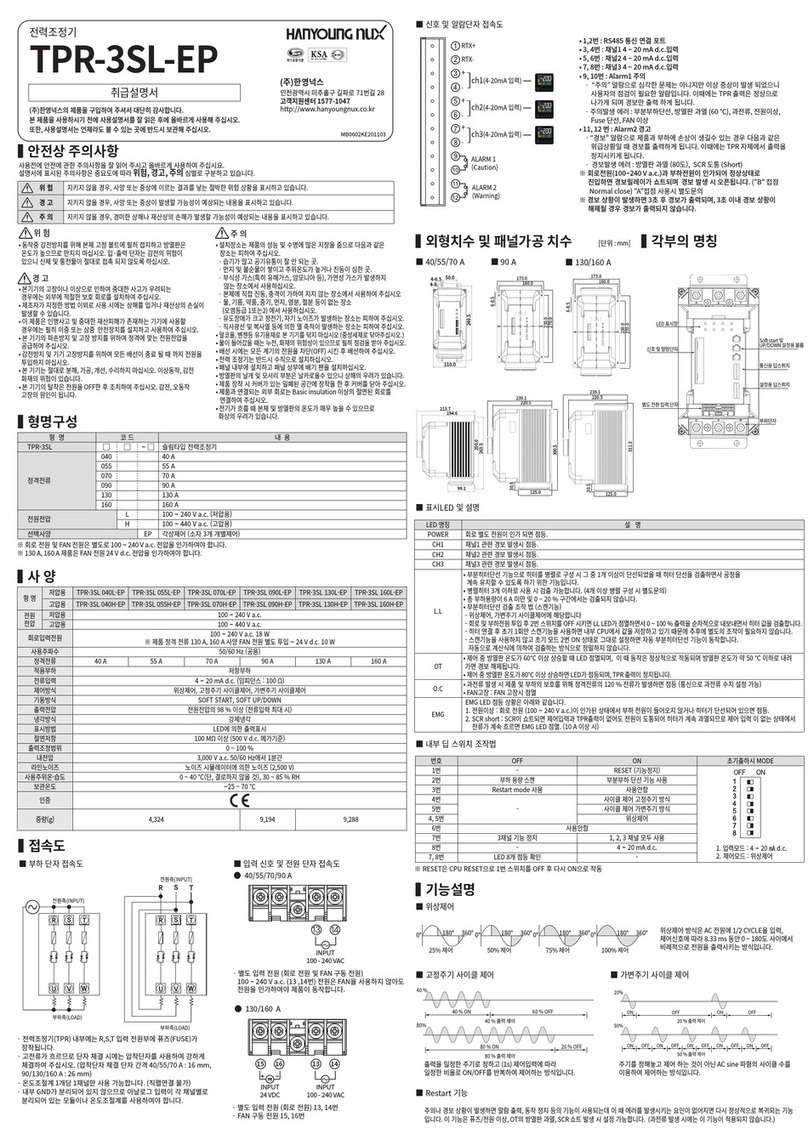

▒ Phase control

AC power source has 50/60 ㎐ frequency and 1/2 cycle of 60 ㎐ frequency appears a value of 0 ~180 degree

in about 8.33 ㎳. Phase Control is a method that after inputting 1/2 cycle into AC power source, it proportionally

generates power between 0 ~ 180 degree in 8.33 ㎳ according to the control signal. Also, this method can be

fully adjusted according to the wave form of AC so that AC motors and other variety of electronic devices are

controlled easily.

This is a mode that is used when load contains a lot of inductance components such as coil. Max output

value is limited to 50 %.

•

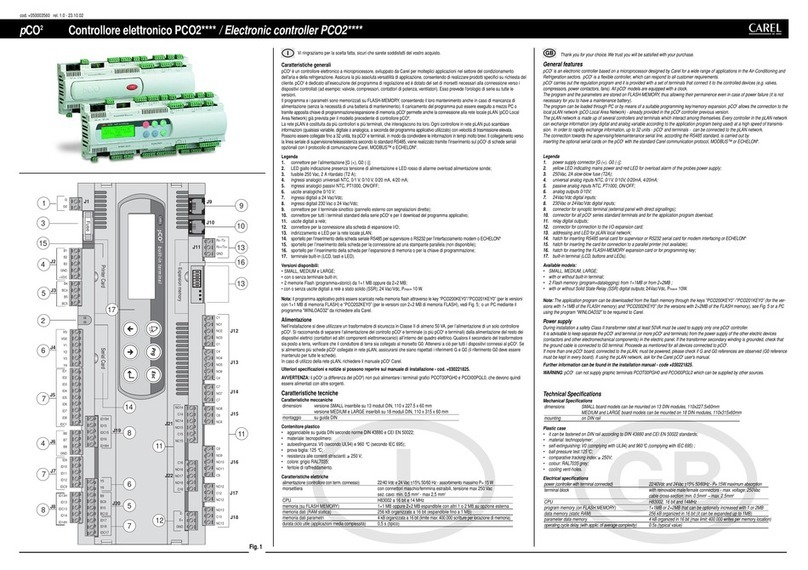

Setting key and volume

•Mode displaying 7 segment LED : Mode of each list will be displayed when setting the parameter

•Set value displaying 7 segment LED : Display the set value when setting the parameter Also,

it displays the measured value which selected in the displaying mode during operation.

Name of each button Explanation

Mode button Enter into the manual mode and save the data

Incremental button Increase the set value

Decrement button Decrease the set value

Selecting button

Manual operation/auto operation selectable by pressing it for 2 sec

When performing manual operation, it varies an output amount by

pressing increment/decrement key disregarding the input signal

Press it for 2 sec again then it will save the setting and return to the

auto operation mode

Reset button System temporarily stops when alarm occurs.

Pressing this button will restore the setting

Over current

compensating volume

Compensate the current indicated value displayed in the displaying

unit (default setting: positioned in the middle)

※Applied only when performing phase control

▒ FND type (TPRF-3N)

Parameter composition

Actuating key

Name

Default value

Information

Key lock level selection

OFF : Lock cancel

LOC 1 : Lock all

LOC2 : Auto mode lock

Input type selection

4 - 20 (㎃), 1 - 5 (V), 0 - 10 (V)

VOL : Set by the manual volume (10 KΩ)

ON/OFF : ON/OFF control by the external contact input

※ Input specification with dot in present, the output

limitation by the external volume setting is applied.

Operation mode selection

PA-r : resistive load (phase control)

Mot : inductive load (phase control)

※ output amount limited to 50 %

Output limitation setting

Set the output limitation value

(set range : 0 ~ 100 %)

Elevation setting

Input signal compensation about output amount

(set range : -100 ~ 100)

Soft start setting

Set the reaching time from when supplying in the power or

starting operation to the time when reaching the output amount

corresponding to the input signal (set range: 1 ~ 250 sec)

Soft up and

soft down setting

During controlling, it sets the time to reach the output

amount corresponding to the critical variation of input signal

(set range : 0 ~ 50 sec)

Over current alarm setting

Over current protective alarm value setting

(set range : 0 ~ 100 A)

Over heating alarm setting

Over temperature alarm value of heat sink setting

(set range : 0 ~ 100 ℃)

Load break alarm setting

When the load current is above the set value, alarm output

will become ON if the load current is less than 1 A.

(Set range : 0 ~ 100 A)

Output limitation

function selection

: Slope setting function selection

: Output limitation setting function selection

Display mode selection

INP selection : input signal percentage display

OUT selection : output voltage percentage display

CUR selection : load current display(A)

HST selection : heat sink temperature display(℃)

Communication device

number setting

Set the communication address (set range : 0 ~ 255)

Communication speed

setting

Set the communication speed (set range : 24 ~ 1 Mbps)

Cautious) selecting the operation mode as phase control inductive load will limit the output amount to 50 %.

▒ Inductance input (DIP S/W 3 : OFF)

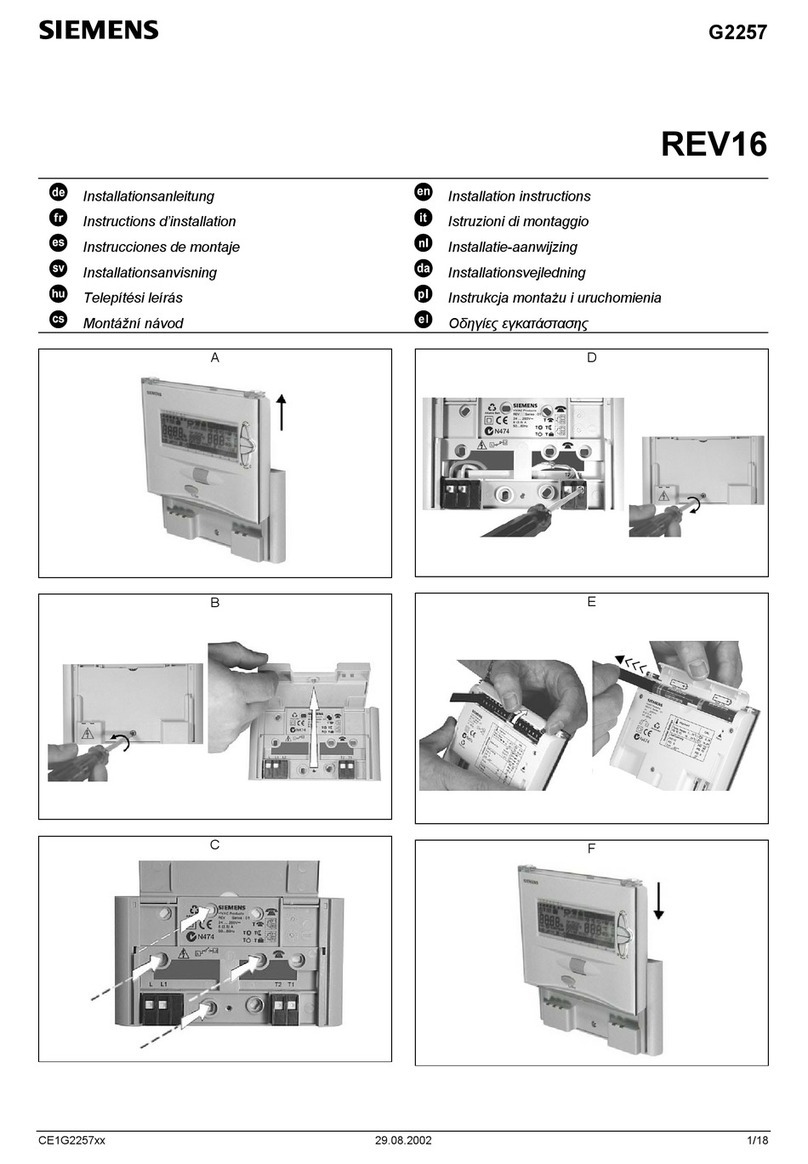

FND display

① LED display

② Setting key

and volume

③ Mode displaying

7 segment LED

④ Set value displaying 7 segment LED

•

Front Toggle Switch and reset key

Switch Information

Select whether users will use the external manual controlling volume which connected to the terminal

or the internal output limitation (PW.MAX)

•REMOTE : Selected when using the external volume connected to the terminal

•LOCAL : Selected when using the output limitation (PW.MAX) setting internal volume

Select whether users will use the control output (4-20 mA) of controller as input signal or not (use

volume)

•AUTO : Selected when using the control output (4-20 ㎃) of controller as input signal

•HAND : Not using the input signal (4-20㎃) (select the setting by volume)

Select the control action as RUN state or STOP state

•RUN : Selected when it is in the general control state

•STOP : Selected when stopping the control action temporarily (output OFF)

When using the RUN/STOP which operates by the external contact input (D.I), please select the

internal RUN/STOP toggle switch as STOP side

Control state becomes the hold state temporarily when alarm output is ON. Pressing the Reset key

after solving the problem will restore the setting.

•

Example of toggle switch selection

Switch selection Information

REMOTE - LOCAL Use external volume, ignore internal volume, use input signal

REMOTE - HAND Use external volume, ignore internal volume, ignore input signal

(output variation by the external volume)

LOCAL - AUTO Ignore external volume, use internal volume, use input signal

LOCAL - HAND Ignore external volume, use internal volume, ignore input signal

(output variation by the external volume)

FND display

① LED display

② Setting key

and volume

③ Mode displaying

7 segment LED

④ Set value displaying 7 segment LED

② Deep switch

⑧ MODE key

⑦ UP KEY

⑥ DOWN KEY

④ RESET KEY

⑨ SIGNAL Terminal

① Input terminal

② Setting screen displaying unit

⑩ Load terminal

load terminal

SIGNAL Terminal

input terminal

setting screen

displaying unit

③ Over current compensating volume

⑤ Selection key

① LED indicator

③ internal volume

④ toggle switch

and reset key

•

LED display

Number LED name Explanation

①FI L.ON when output becomes ON and becomes L.ON proportional to an output amount

②PR L.ON when selecting resistive load

③PL L.ON when selecting inductive load

④S.F L.ON when operating the soft start

⑤A.L L.ON with over current, heat sink temperature alarm operation

⑥O.C L.ON when value exceeds the over current set value

⑦A.O L.ON when performing the auto-operation