3 4

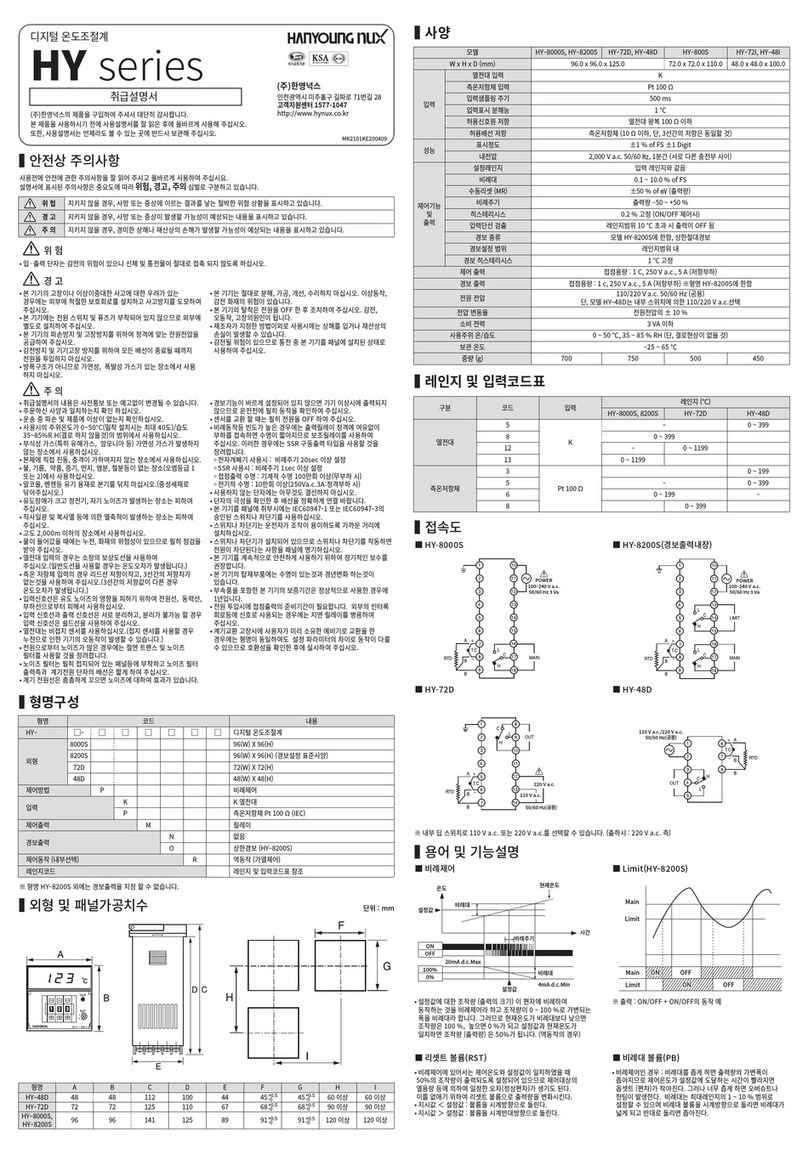

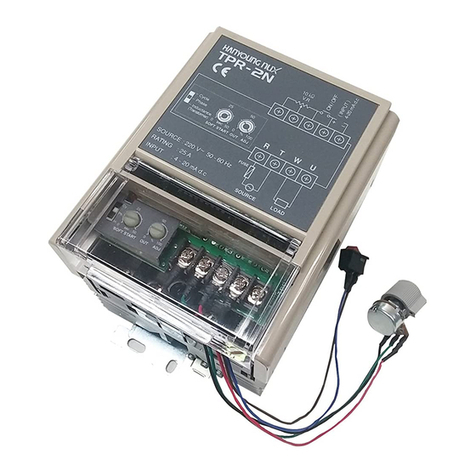

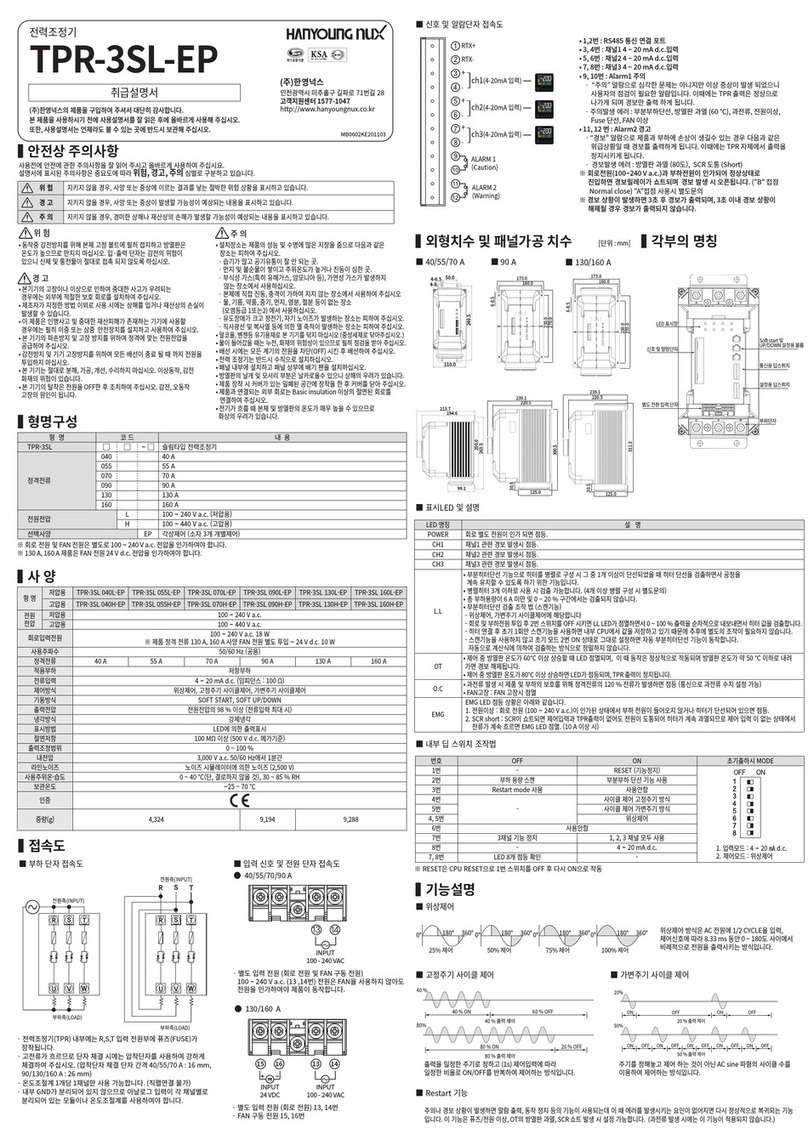

Part name and function

3 4125

++

-

TPR-3SL040L

Maxi mum rate d curren t : 40 A

10 0 -240 V

~

50 - 6 0 Hz 6 W

POWE R

2

1

3

4

5

6

7

8

9

10

1 1

12

V . R

R U N / S TO P

O N / O F F

A L A R M 1

(Warni ng)

A L A R M 2

(Caut ion)

4 - 2 0 mA

1 - 5 V

Rate d voltag e: 1 00V

-

240 V

~

PO W E R FI R E SOF TO.C

L. LO T 1SCR FUS E

O . C

SOF T

POW E R

22

11

33

44

55

O N

O F F

66

77

88

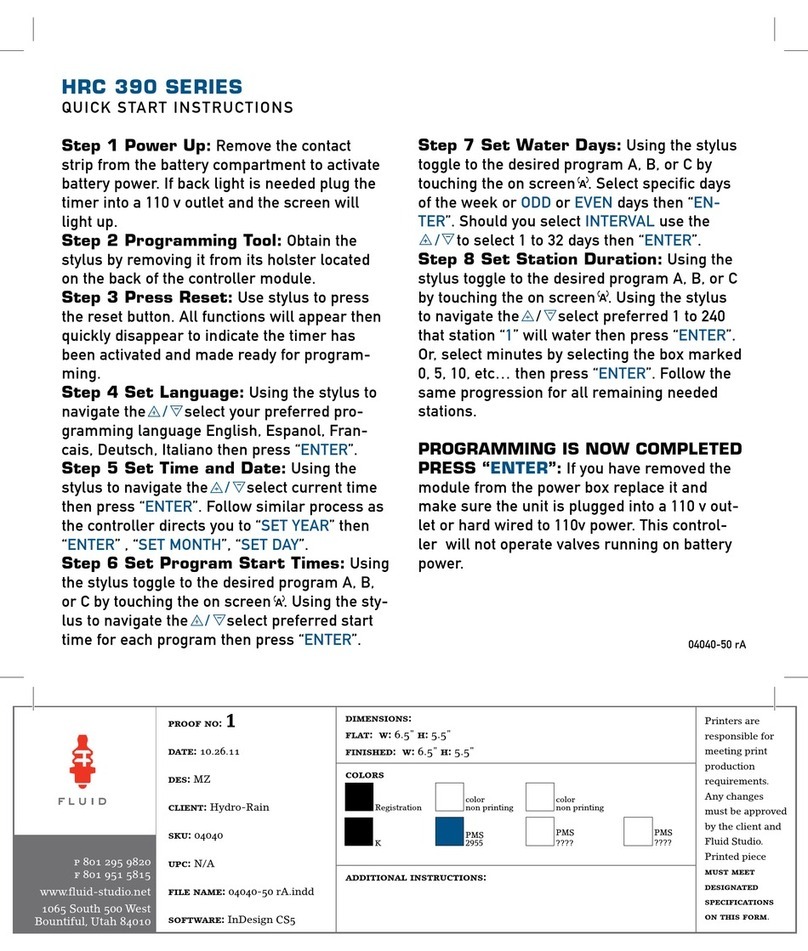

Signal and

alarm terminals

LED display Overcurrent

setting volume

Soft start or

UP/DOWN setting volume

Output limit volume

Internal dip switch

Input signal and

power terminal (control unit)

Load terminal

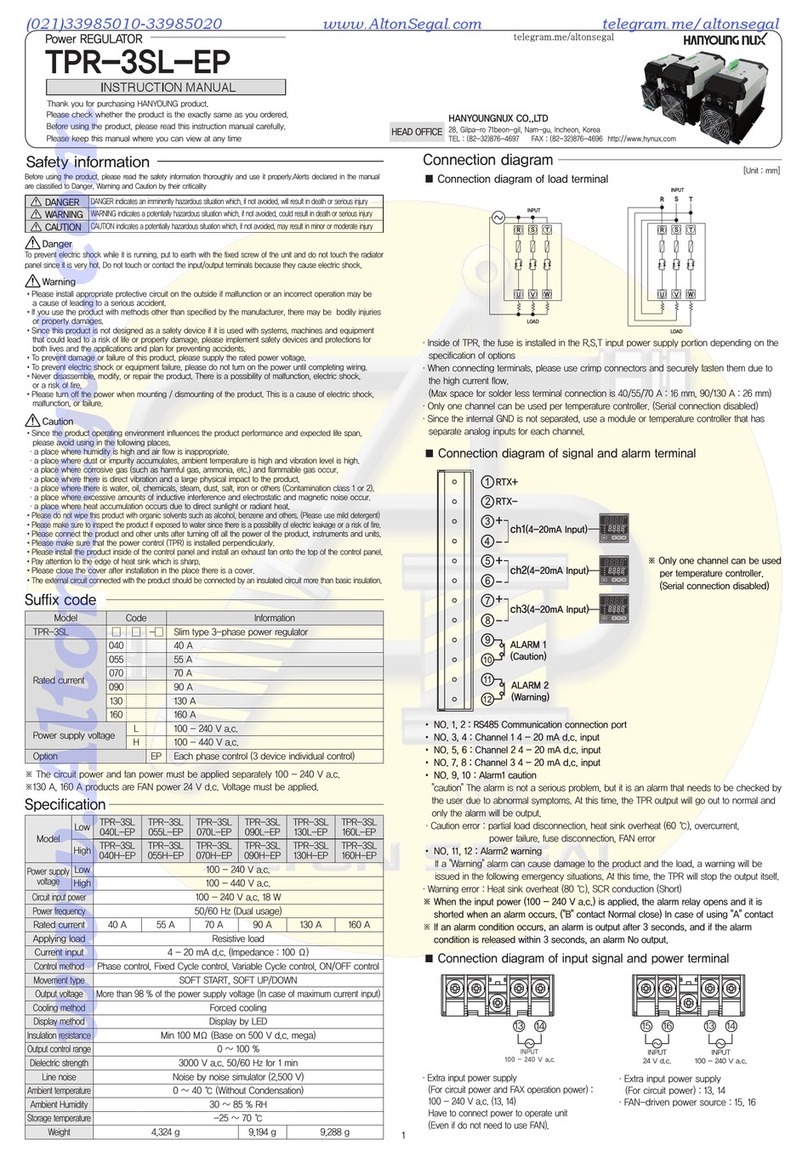

▒ LED indicator and explanation

▒ Internal dip switch operation

Number ON OFF Initial setup mode

No. 1 RESET (Functioning stops) -

1. Input mode 4 - 20 ㎃ DC

2. Control Mode: Phase control

3. Extra : Restart is in use,

I n n e r o f V R i s i n u s e

No. 2 Inner Power VR is in use External VR is in use

No. 3 Not Using

Use of Restart mode is in use

No. 4 Cycle Control fixed cycle way

-No. 5 Cycle Control variable cycle way

No. 4, 5 Phase control

No. 6 Not Using

No. 7 1 - 5 V DC

-

No. 8 External of V.R is only in use

No. 7, 8 4 - 20 mA DC

Function description

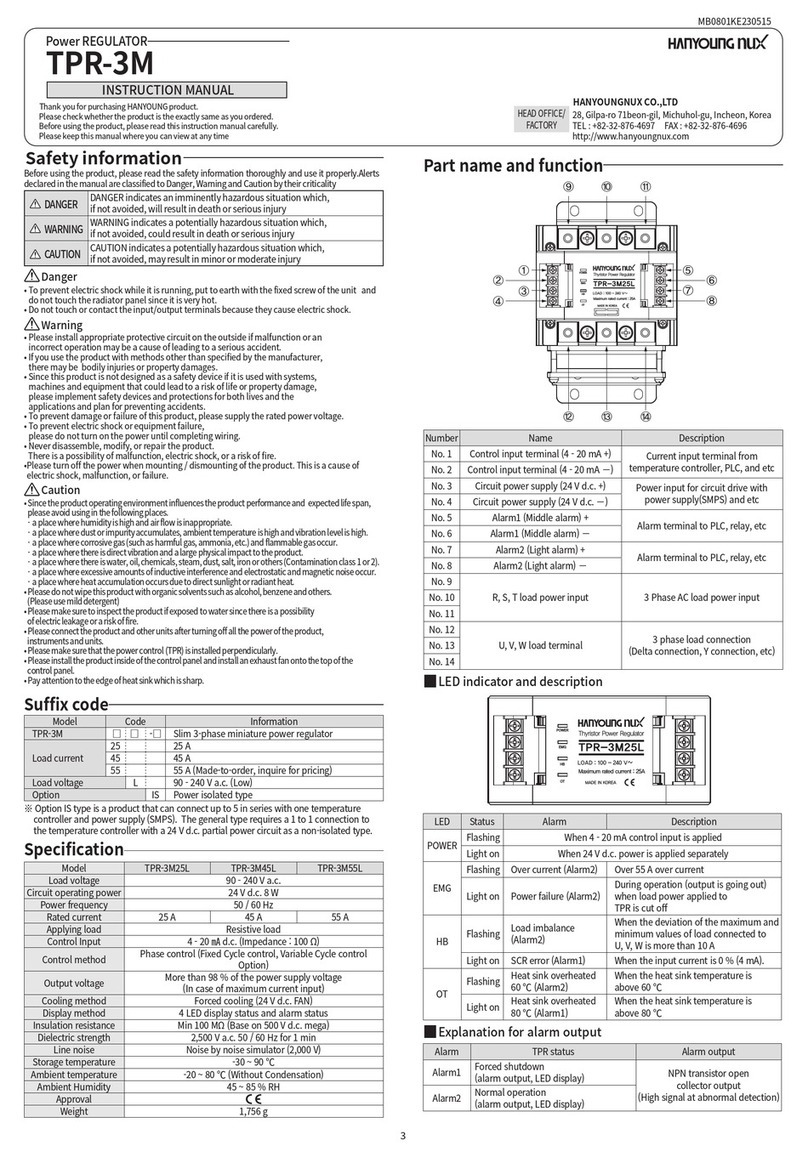

▒ Phase control

Phase control is to control the AC power supply applied to the load proportionally according to the control

input signal as changing phase angle (0 ~ 180 degree) in a each half cycle, 8.33 ms.

50%

ON

50 % Output control

OFFON OFFON OFFON OFFON OFF

20%

ON OFF

20 % Output control

ON OFF

80%

80 % ON20 % OFF

80 % Output control

40 %

40 % ON80 % OFF

40 % Output control

25 % Contr o l

Output

Contact

signal

50 % Contr o l75 % Contr o l100 % Contr o l

▒ Fixed cycle control

As setting the constant cycle of the

output, (1 sec), fixed cycle control is

to control the AC power supply

repeatedly with a constant rate of

ON/OFF according to the control

input.

▒ ON/OFF control

▒ Restart function

▒ V.R Explanation

If ON/OFF contact is ON, then the output is 100 %. ON/OFF always operates near zero point.

When a warning or caution alarm occurs, TPR gives alarm 1 or 2 or stop the output. This function is used

to return to normal operation mode when factors caused errors are eliminated.

This function is able to set up when Fuse/Power Supply is in disorder, Heat sink over heat, SCR Short is

occurred. (When Overcurrent is occurred, this function is not working)

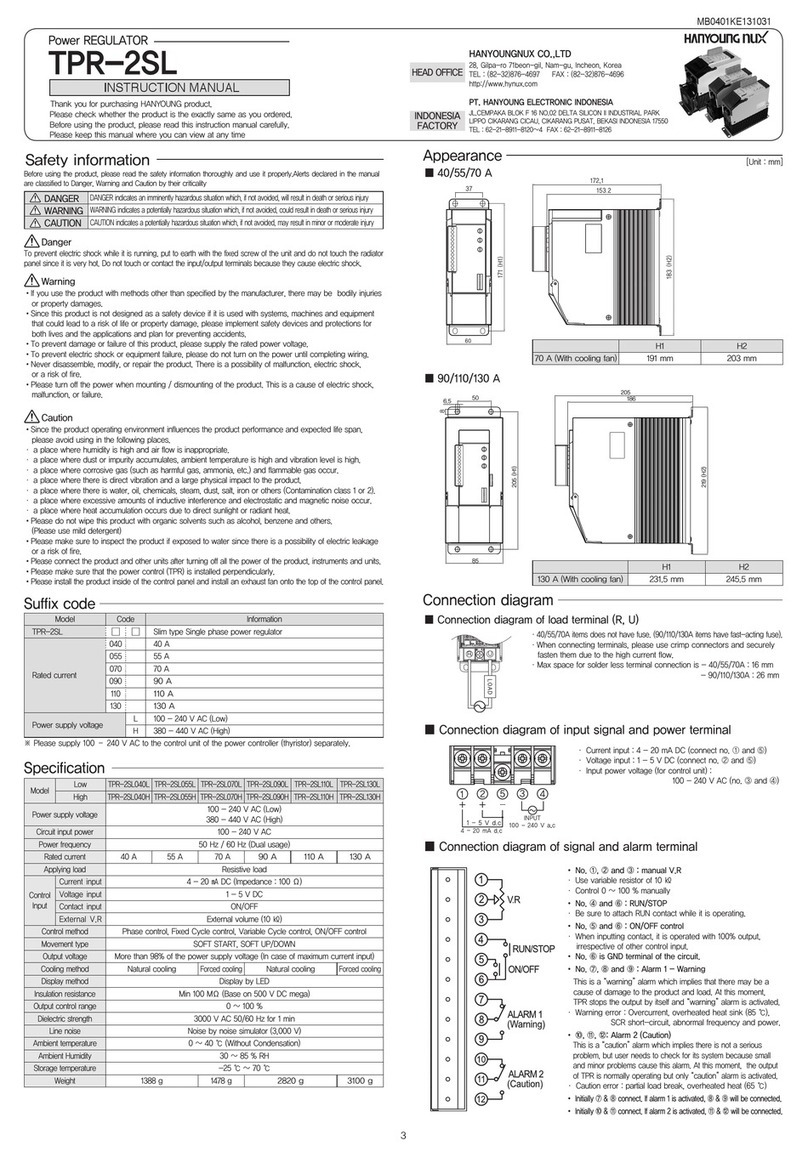

1. O.C (overcurrent setting function)

When overcurrent occurs, protection function for TPR and load (Only for phase control)

• V.R gradation for overcurrent setting position.

•Depending on load type and VR error, overcurrent

setting position can be different.

•

The overcurrent setting can be different depending on the

types of load or VR tolerance. In order to set an accurate

position of the overcurrent setting, adjust the control signal

that TPR can have the current that needs to be alarmed.

Turn the O.C VR until the O.C indicator is ON. The position of the O.C VR is the overcurrent setting value.

•If OC V.R turning to the right of the maximum, overcurrent function does not work.

2. SOFT

This volume is to set time for Soft start or Soft up/down. (only applicable to phase control, ON/OFF control)

- Soft start : Protection functions against big load of start current (inrush current). It increases output softly.

When control input is applied and power is on, Soft start operates when rung signal is applied.

In case of maximum VR, it set 50 second. (Example : 20 mA : 50 sec, 12 mA : 25 sec)

- Soft up / down : When run signal and power are applied and if control input is applied, it will operate. It

case of maximum VR, it set 10 second.

- If VR turn up to the right, the function does not work. And if VR turn right, time will be reduced.

3. POWER (output limit function)

This function is to limit the output regardless of

the control input amount. Even though the control

input is 100 %, the output will decrease as turning

POWER volume counterclockwise.

•Even though the control input signal is

ON, the output is 100 % when ON/OFF

control is used.

50%

ON

50 % Output control

OFFON OFFON OFFON OFFON OFF

20%

ON OFF

20 % Output control

ON OFF

80%

80 % ON20 % OFF

80 % Output control

40 %

40 % ON80 % OFF

40 % Output control

25 % Contr o l

Output

Contact

signal

50 % Contr o l75 % Contr o l100 % Contr o l

Output

current

Time

Time

Input

signal

output voltage(%)

VR setting value (%)

Control input (%)

100

80

60

40

20

0

100

80

60

40

20

0

20 40 60 80 100

1. Please install it perpendicularly. If the product is installed vertically in

unavoidable circumstances, please use 50 % of rated current.

2. When multiple products are closely installed, please install them with

keeping a distance of more than a width of 5 cm and a length of

10 cm as shown in the picture.

3. In order to not block the air flow, please install the wiring duct less

than the half of the heat sink height.

4. Please consider whether the air flow is good enough when installing

the product. If the ambient temperature is as low as possible in the

inside then the life span of the product is increasing as the durability

and reliability of the product are improving. The operating ambient

temperature is 0 ℃ ~ 40 ℃. Please refer to the following graph.

However, if the ambient temperature is higher than 40 ℃, the

maximum load current is decreasing like the below.

5. When wiring, please use crimp connectors to high current flows terminal. If the contact surface of the

connectors and terminals are poor, it may lead to a fire since the wires and terminal gets overheated

6. Before applying power, this model need more than the third class grounding to prevent electric shock.

This model does not have separate grounding terminal so we suggest using grounding terminal and

bracket together when install this model to a panel.

Installation

Airflow

Perpendicular installation

▒ Variable cycle control

Without setting a constant cycle,

variable cycle control is to control

AC power supply with using the

number of cycle.

50%

ON

50 % Output control

OFFON OFFON OFFON OFFON OFF

20%

ON OFF

20 % Output control

ON OFF

80%

80 % ON20 % OFF

80 % Output control

40 %

40 % ON80 % OFF

40 % Output control

25 % Contr o l

Output

Contact

signal

50 % Contr o l75 % Contr o l100 % Contr o l

50%

ON

50 % Output control

OFFON OFFON OFFON OFFON OFF

20%

ON OFF

20 % Output control

ON OFF

80%

80 % ON20 % OFF

80 % Output control

40 %

40 % ON80 % OFF

40 % Output control

25 % Contr o l

Output

Contact

signal

50 % Contr o l75 % Contr o l100 % Contr o l

60 ㎜ min

100 ㎜ min

30 ㎜ min

Air flow

Wiring duct

Wiring duct

Air in

Air out (FAN)

50 ㎜ min

LED indicator

name

Description

POWER POWER indicator is ON when the power is being supplied to the control unit

FIRE Fire indicator is ON proportionally to the control input. It lights longer if the output amount is

large and it is continuously ON if it outputs 100 % continuously.

SOFT

To use Soft start, Soft up/down function, turn Soft VR clockwise and SOFT indicator will be ON.

O.C

If the current flows higher than set value of O.C volume when there is overcurrent then O.C indicator

is ON, the TPR stops the output to protect the product and the load and alarm 1 is activated.

L.L

When Load disconnected : In a situation where output is over 10 %, if load current is not

founded, alarm rings.

When Load Unbalanced : In a situation where output is over 10 %, if the load unbalance

between phases is over 4 A, the alarm rings

O.T When Heat sink temperature rise over 85 ℃’, it light up. Alarm 2 output will be out but TPR

operates without stop. And when temperature go down under 75 ℃, alarm will be off.

FUSE

When inner fuse is disconnected, When load power is not connected, In a situation where

circuit power supply (100 - 240 V AC) is connected, if any one phase of load power supply is

not working or inner part of FUSE is disconnected, alarm output ALARM1 rings.

SCR When inner part of SCR is short, the heater will keep overheating. So current flows to any

one-phase without control input, the light up.

TPR-3SL040/055/070 TPR-3SL090/130/160

O.C

17 A

37 A

58 A

O.C

23 A

51A

82

▒ Connection diagram of input signal and power terminal

· Current input : 4 - 20 mA DC (connect no. ① and ⑤)

· Voltage input : 1 - 5 V DC (connect no. ② and ⑤)

· Extra input power supply

(For circuit power and FAX operation power) :

100 - 240 V AC (3, 4) Have to connect power to

operate unit (Even if do not need to use FAN).