1

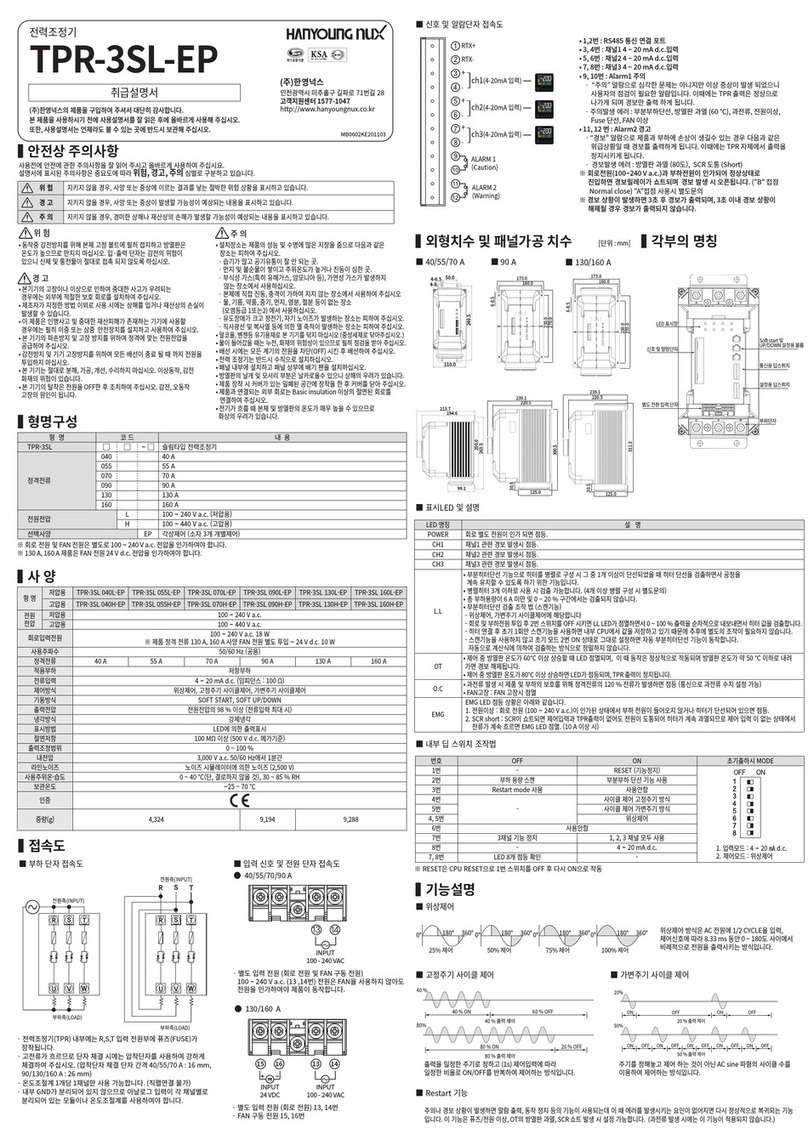

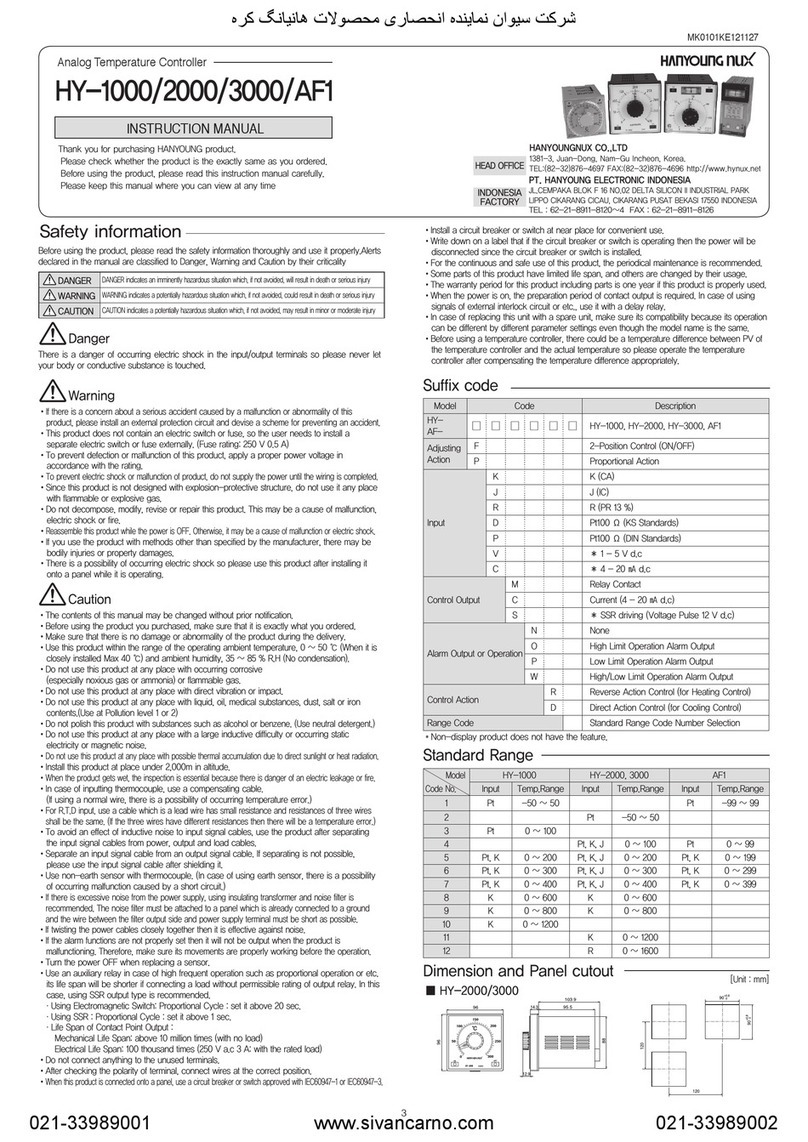

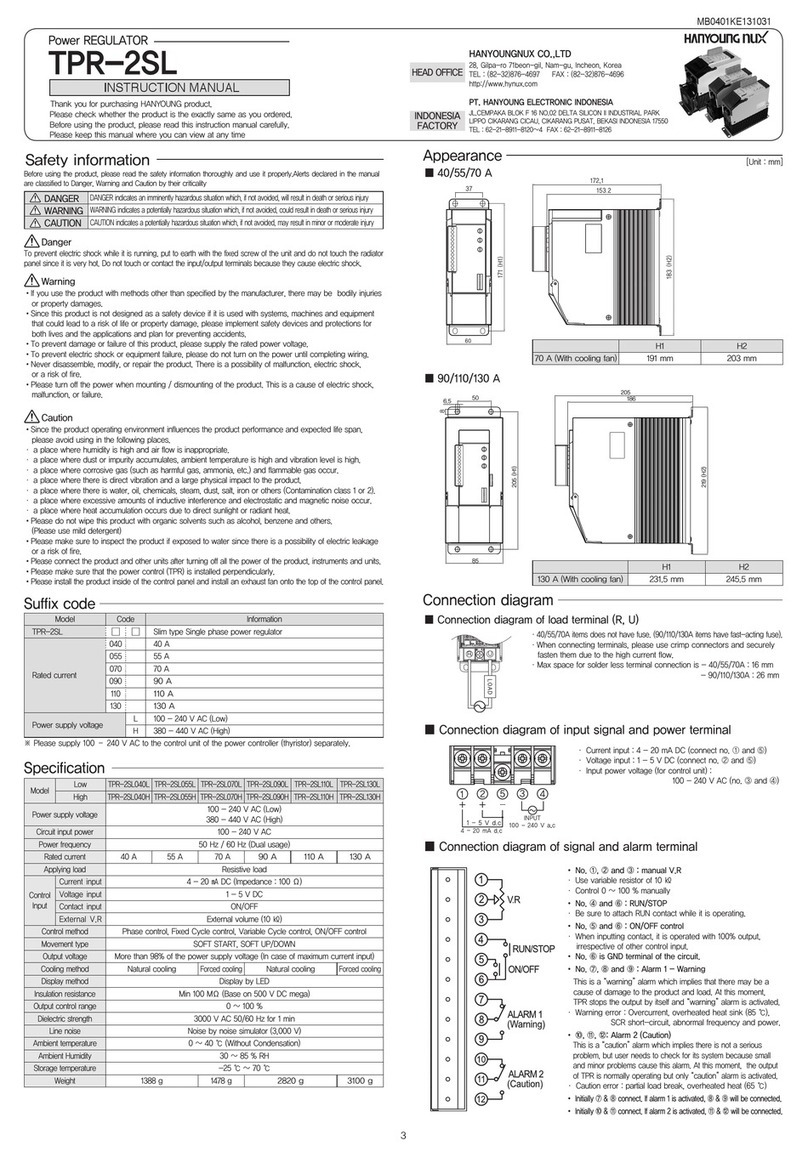

Suffix code

Model Code Information

TPR-3SL - Slim type 3-phase power regulator

Rated current

040 40 A

055 55 A

070 70 A

090 90 A

130 130 A

160 160 A

Power supply voltage L100 - 240 V a.c.

H100 - 440 V a.c.

Option EP Each phase control (3 device individual control)

※ The circuit power and fan power must be applied separately 100 - 240 V a.c.

※130 A, 160 A products are FAN power 24 V d.c. Voltage must be applied.

Specification

Model

Low TPR-3SL

040L-EP TPR-3SL

055L-EP TPR-3SL

070L-EP TPR-3SL

090L-EP TPR-3SL

130L-EP TPR-3SL

160L-EP

High TPR-3SL

040H-EP TPR-3SL

055H-EP TPR-3SL

070H-EP TPR-3SL

090H-EP TPR-3SL

130H-EP TPR-3SL

160H-EP

Power supply

voltage

Low 100 - 240 V a.c.

High 100 - 440 V a.c.

Circuit input power

100 - 240 V a.c. 18 W

Power frequency

50/60 Hz (Dual usage)

Rated current 40 A 55 A 70 A 90 A 130 A 160 A

Applying load Resistive load

Current input 4 - 20 mA d.c. (Impedance : 100 Ω)

Control method

Phase control, Fixed Cycle control, Variable Cycle control, ON/OFF control

Movement type

SOFT START, SOFT UP/DOWN

Output voltage

More than 98 % of the power supply voltage (In case of maximum current input)

Cooling method

Forced cooling

Display method

Display by LED

Insulation resistance

Min 100 MΩ (Base on 500 V d.c. mega)

Output control range

0 ~ 100 %

Dielectric strength

3000 V a.c. 50/60 Hz for 1 min

Line noise

Noise by noise simulator (2,500 V)

Ambient temperature

0 ~ 40 ℃ (Without Condensation)

Ambient Humidity

30 ~ 85 % RH

Storage temperature

-25 ~ 70 ℃

Weight

4,324 g 9,194 g 9,288 g

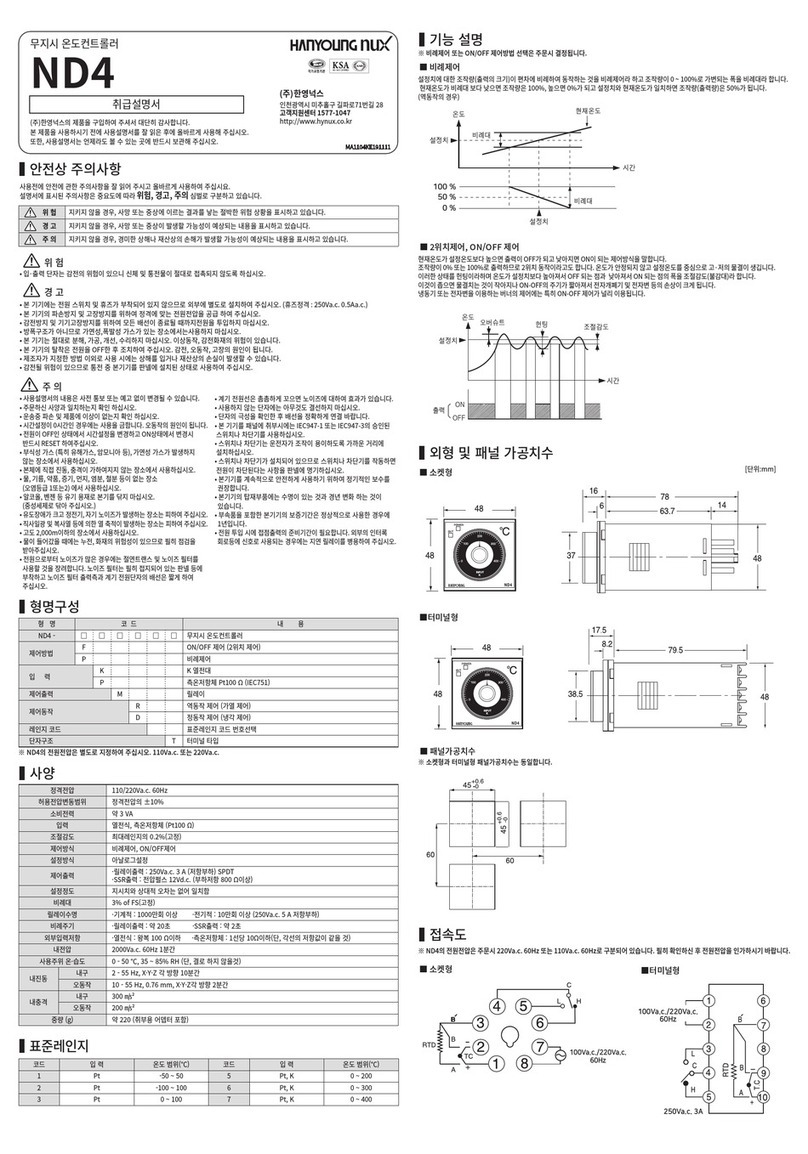

[Unit : mm]

Connection diagram

█ Connection diagram of load terminal

INPUT

LOAD

INPUT

LOAD

· Inside of TPR, the fuse is installed in the R,S,T input power supply portion depending on the

specification of options

· When connecting terminals, please use crimp connectors and securely fasten them due to

the high current flow.

(Max space for solder less terminal connection is 40/55/70 A : 16 mm, 90/130 A : 26 mm)

· Only one channel can be used per temperature controller. (Serial connection disabled)

· Since the internal GND is not separated, use a module or temperature controller that has

separate analog inputs for each channel.

█ Connection diagram of input signal and power terminal

· Extra input power supply

(For circuit power and FAX operation power) :

100 - 240 V a.c. (13, 14)

Have to connect power to operate unit

(Even if do not need to use FAN).

· Extra input power supply

(For circuit power) : 13, 14

· FAN-driven power source : 15, 16

15 16 13 14

INPUT

24 V d.c.

INPUT

100 - 240 V a.c.

15 16 13 14

INPUT

24 V d.c.

INPUT

100 - 240 V a.c.

telegram.me/altonsegal

※ Only one channel can be used

per temperature controller.

(Serial connection disabled)

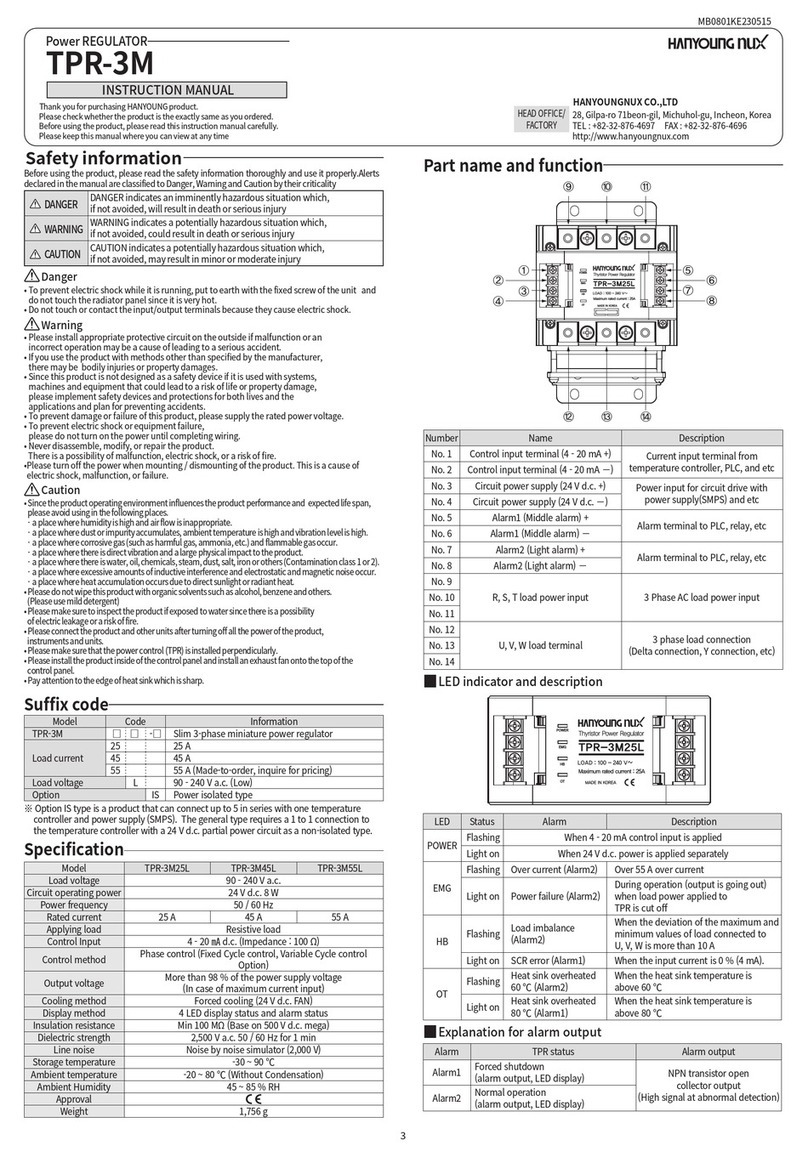

█ Connection diagram of signal and alarm terminal

• NO. 1, 2 : RS485 Communication connection port

• NO. 3, 4 : Channel 1 4 - 20 mA d.c. input

• NO. 5, 6 : Channel 2 4 - 20 mA d.c. input

• NO. 7, 8 : Channel 3 4 - 20 mA d.c. input

• NO. 9, 10 : Alarm1 caution

"caution" The alarm is not a serious problem, but it is an alarm that needs to be checked by

the user due to abnormal symptoms. At this time, the TPR output will go out to normal and

only the alarm will be output.

· Caution error : partial load disconnection, heat sink overheat (60 ℃), overcurrent,

power failure, fuse disconnection, FAN error

• NO. 11, 12 : Alarm2 warning

If a "Warning" alarm can cause damage to the product and the load, a warning will be

issued in the following emergency situations. At this time, the TPR will stop the output itself.

· Warning error : Heat sink overheat (80 ℃), SCR conduction (Short)

※ When the input power (100 - 240 V a.c.) is applied, the alarm relay opens and it is

shorted when an alarm occurs. ("B" contact Normal close) In case of using "A" contact

※ If an alarm condition occurs, an alarm is output after 3 seconds, and if the alarm

condition is released within 3 seconds, an alarm No output.

ALARM 1

(Caution)

ALARM 2

(Warning)

RTX+

RTX-

+ch1(4-20mA Input)

ch2(4-20mA Input)

ch3(4-20mA Input)

-

+

-

+

-

Power REGULATOR

TPR-3SL-EP

Thank you for purchasing HANYOUNG product.

Please check whether the product is the exactly same as you ordered.

Before using the product, please read this instruction manual carefully.

Please keep this manual where you can view at any time

28, Gilpa-ro 71beon-gil, Nam-gu, Incheon, Korea

TEL : (82-32)876-4697 FAX : (82-32)876-4696 http://www.hynux.com

HANYOUNGNUX CO.,LTD

HEAD OFFICE

INSTRUCTION MANUAL

•Please install appropriate protective circuit on the outside if malfunction or an incorrect operation may be

a cause of leading to a serious accident.

•If you use the product with methods other than specified by the manufacturer, there may be bodily injuries

or property damages.

•Since this product is not designed as a safety device if it is used with systems, machines and equipment

that could lead to a risk of life or property damage, please implement safety devices and protections for

both lives and the applications and plan for preventing accidents.

•To prevent damage or failure of this product, please supply the rated power voltage.

•To prevent electric shock or equipment failure, please do not turn on the power until completing wiring.

•Never disassemble, modify, or repair the product. There is a possibility of malfunction, electric shock,

or a risk of fire.

•Please turn off the power when mounting / dismounting of the product. This is a cause of electric shock,

malfunction, or failure.

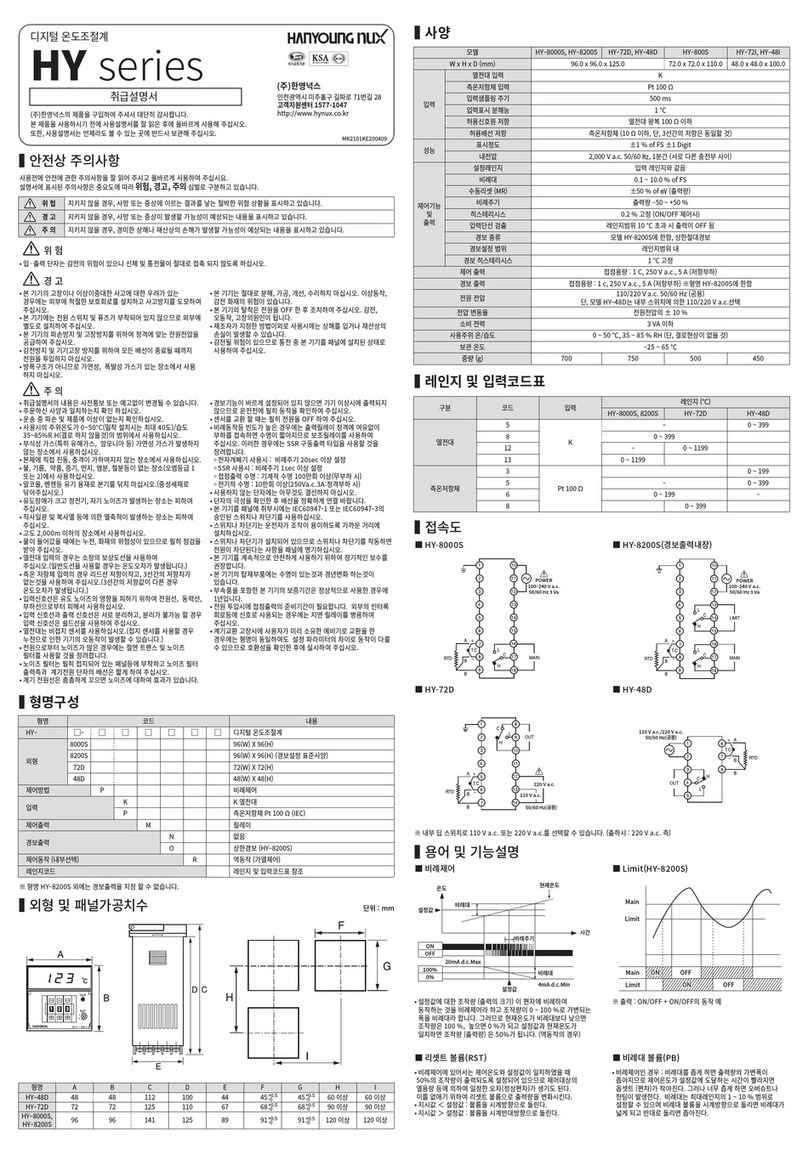

Warning

Safety information

Before using the product, please read the safety information thoroughly and use it properly.Alerts declared in the manual

are classified to Danger, Warning and Caution by their criticality

DANGER

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury

To prevent electric shock while it is running, put to earth with the fixed screw of the unit and do not touch the radiator

panel since it is very hot. Do not touch or contact the input/output terminals because they cause electric shock.

Danger

•Since the product operating environment influences the product performance and expected life span,

please avoid using in the following places.

· a place where humidity is high and air flow is inappropriate.

· a place where dust or impurity accumulates, ambient temperature is high and vibration level is high.

· a place where corrosive gas (such as harmful gas, ammonia, etc.) and flammable gas occur.

· a place where there is direct vibration and a large physical impact to the product.

· a place where there is water, oil, chemicals, steam, dust, salt, iron or others (Contamination class 1 or 2).

· a place where excessive amounts of inductive interference and electrostatic and magnetic noise occur.

· a place where heat accumulation occurs due to direct sunlight or radiant heat.

•

Please do not wipe this product with organic solvents such as alcohol, benzene and others. (Please use mild detergent)

•

Please make sure to inspect the product if exposed to water since there is a possibility of electric leakage or a risk of fire.

•

Please connect the product and other units after turning off all the power of the product, instruments and units.

•Please make sure that the power control (TPR) is installed perpendicularly.

•

Please install the product inside of the control panel and install an exhaust fan onto the top of the control panel.

•Pay attention to the edge of heat sink which is sharp.

•Please close the cover after installation in the place there is a cover.

•

The external circuit connected with the product should be connected by an insulated circuit more than basic insulation.

Caution