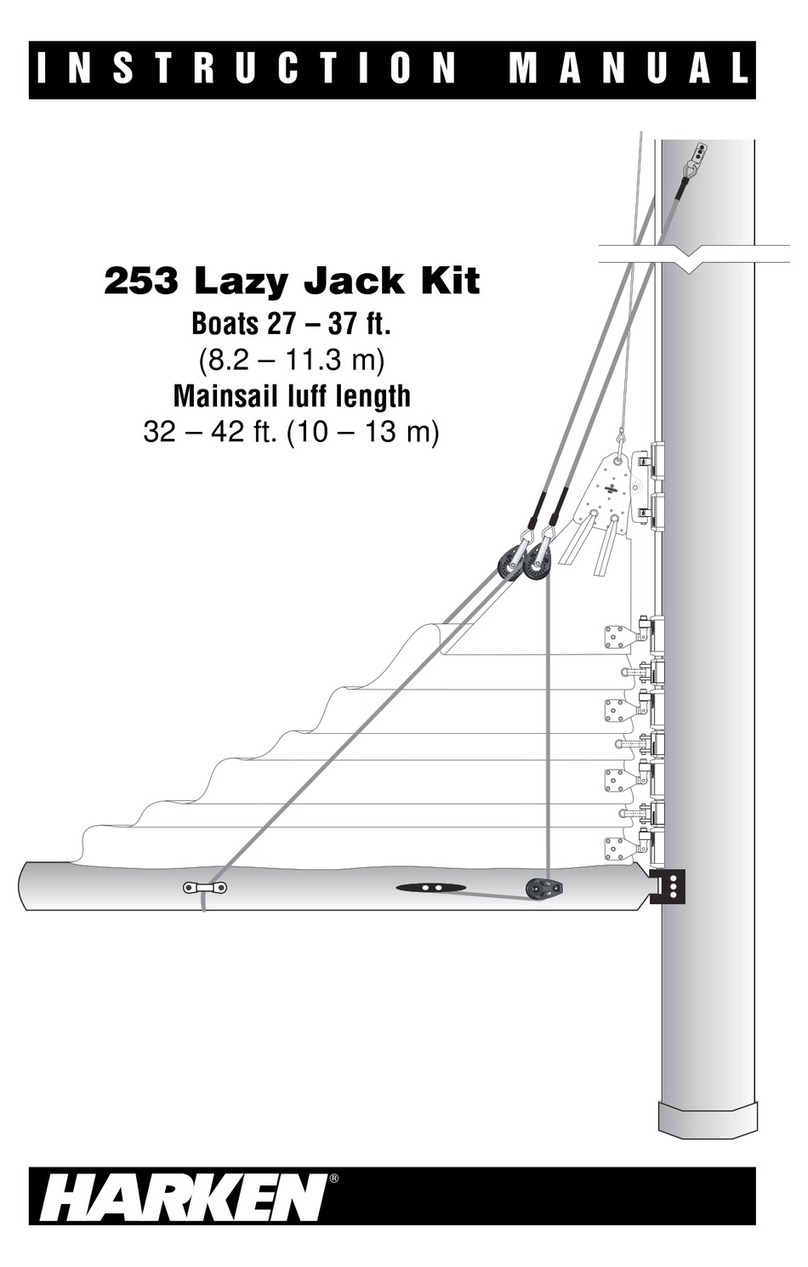

Harken V 3355 User manual

Other Harken Boating Equipment manuals

Harken

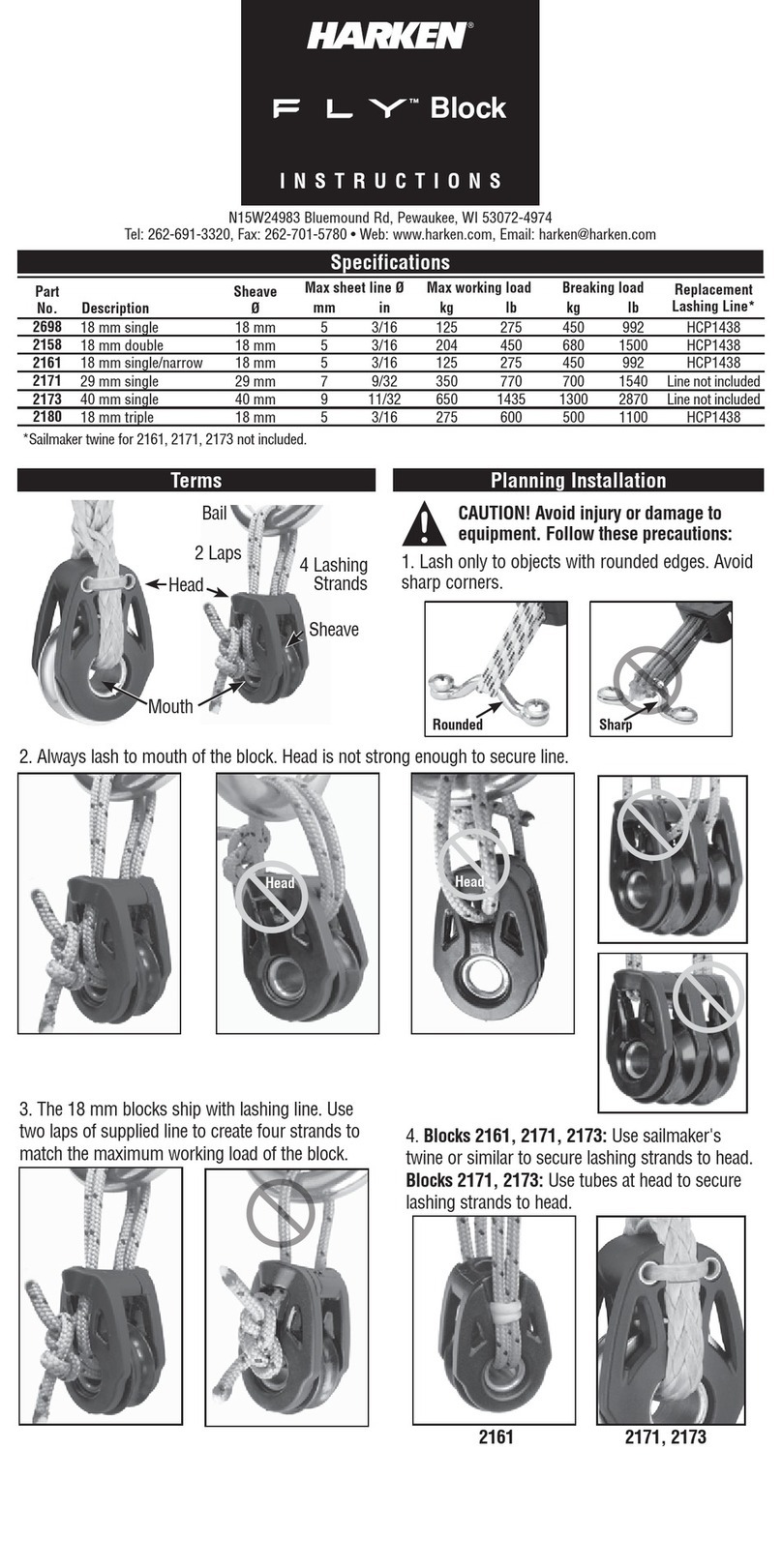

Harken FLY Series User manual

Harken

Harken FlatWinder 250 Manual

Harken

Harken MKIII 00AL User manual

Harken

Harken 3813 User manual

Harken

Harken 252 User manual

Harken

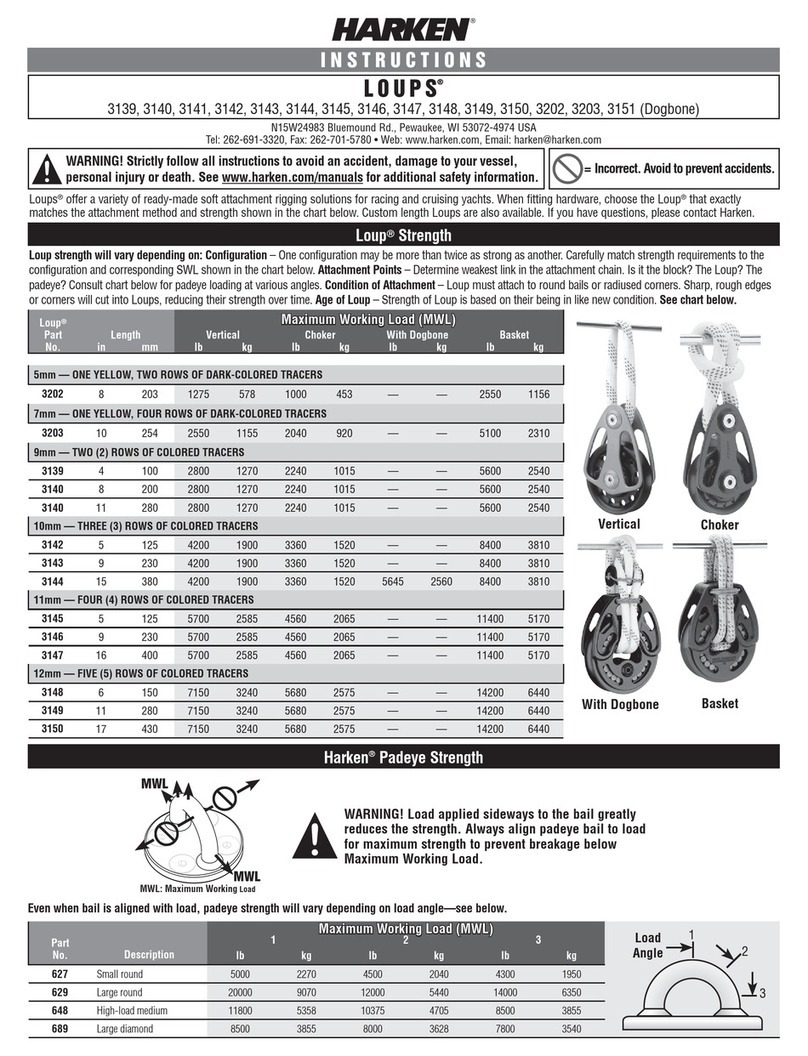

Harken LOUP S 3139 User manual

Harken

Harken Vang-Master VM-1 User manual

Harken

Harken 32 mm Big Boat User manual

Harken

Harken 2698 User manual

Harken

Harken 418 User manual

Harken

Harken 944 User manual

Harken

Harken 2608 User manual

Harken

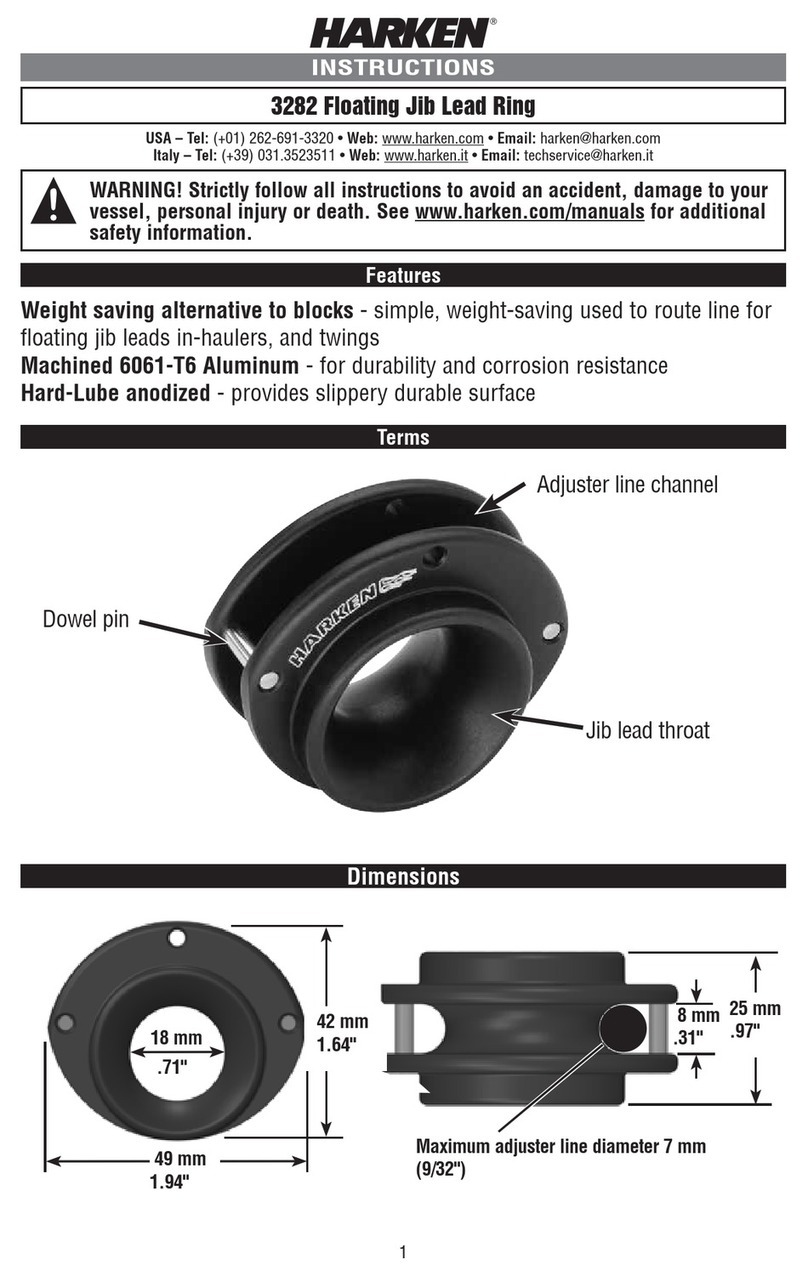

Harken 3282 User manual

Harken

Harken 3168 Assembly instructions

Harken

Harken Performa 20.2 PTP Manual

Harken

Harken MKIV User manual

Harken

Harken Unit 1 ESP User manual

Harken

Harken T2701B User manual

Harken

Harken 254 User manual

Harken

Harken 207 Assembly instructions

Popular Boating Equipment manuals by other brands

Dowco

Dowco V322 CC - 2019 installation instructions

Humphree

Humphree HCS-5 installation manual

Vetus

Vetus BOW4512D Operation manual and installation instructions

Dock Doctors

Dock Doctors SLIDING BOARDING STEP Assembly instructions

Mastervolt

Mastervolt Mass Combi 12/2000-100 Quick installation

Zattini Group

Zattini Group bamar BOXTRON E14S Use and maintenance instruction manual