Security Advice

2.1 General Security Advice

Caution!

Please do carefully read these instructions.

Keep this guide for future reference and consultation.

Any instructions and warnings attached to the device must be

followed.

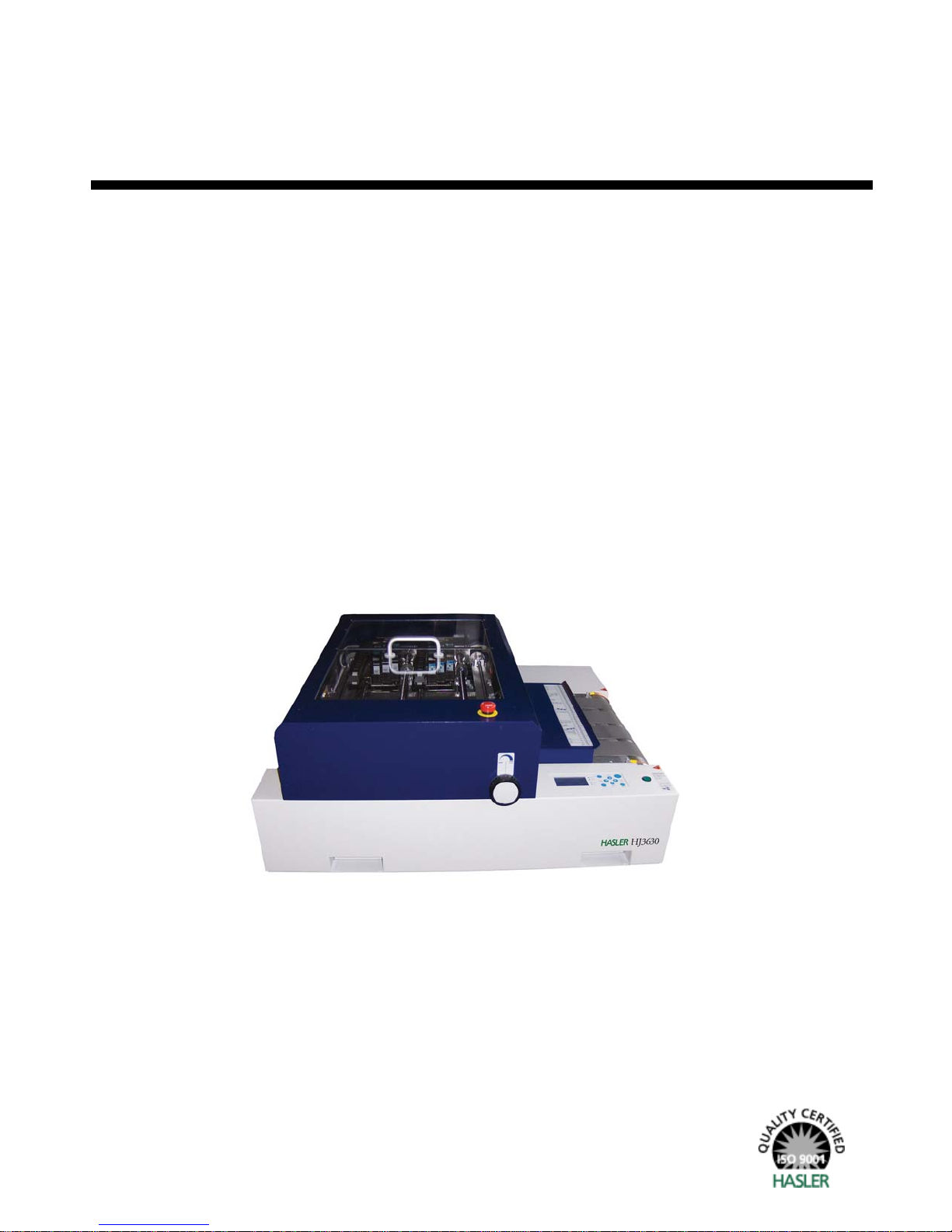

Setting-up

the printer When setting-up the printer, ensure safe and even

positioning. Tilting, inadvertent rolling or falling may cause

injuries.

The printer must be protected from humidity.

WARNING!

This is a device of class A. In living quarters it may cause

radio interference. In this case the operator can be claimed

to take appropriate measures.

Electric

danger Depending on country-specific performance, the Model 3630

digital printer may only be applied at voltages of either

230 V/50 Hz or 115 V/60 Hz.

The power plug may only be plugged into a shockproof

socket! The shockproof protection may not be overridden by

an extension without protective earth conductor. Any

interruption of the protective earth conductor inside or

outside the device is dangerous and not permissible.

The device is double-pole fused! After a fuse protection

failure or deficiency, electric components inside the printer

may continue to be energised.

When connecting to the electricity network, follow the

electrical specifications on the type plate.

Check the voltage setting at the electricity input module of

the device.

Place all cables and supply lines in such a way so that no one

can stumble across them. Do not place any objects on the

supply lines.

If the device is not used over a longer period of time, it

should be disconnected from the electricity network. In doing

so, you make sure to prevent it from damage caused by

overvoltage.

Protect the printer from humidity. Penetration of moisture

into the device bears the danger of electric shock.

Never open the device. For reasons of electrical safety, it

may only be opened by authorised service personnel.

Operating

safety Never reach into the running machine!

There is danger of injuries caused by draw-in or squeezing at

rotating rollers. Moreover, keep long hair and clothes away