OPTIONS (NOT FOR RETROFIT)

❑Stainless Steel Bo y, Base, an Si es

❑Pressure Re ucing Valves (Brass or Iron)

❑6"-7" (152-178 mm) A justable Stainless Steel Legs (4)

❑Floor Mounting Har ware

❑Security Package

ITEM#

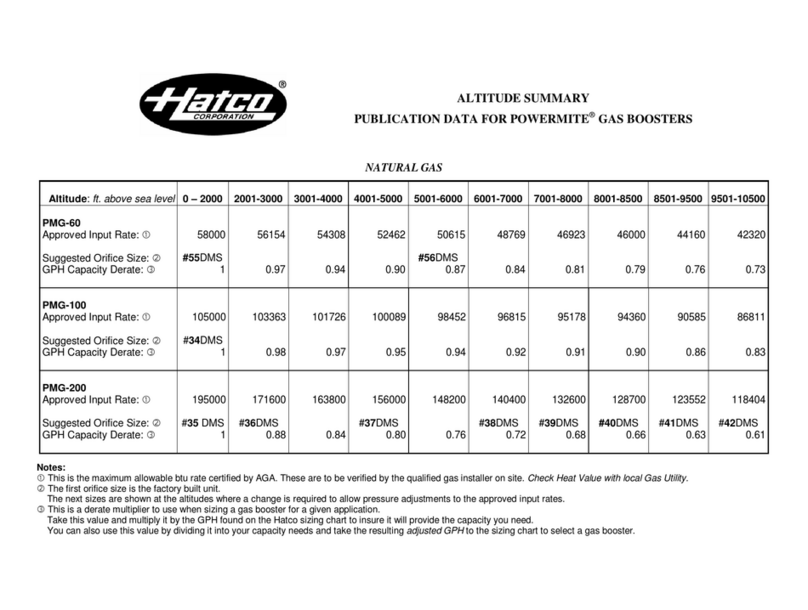

PMG-60 Input 58,000 BTUs/Hour.

Output – 46,000 = 13.4kW

PMG-100 Input 105,000 BTUs/Hour.

Output – 84,800 = 24.8kW

PMG-200 Input 195,000 BTUs/Hour.

Output – 156,000 = 45.7kW

SPECIFICATIONS

Capacity

Mo el PMG-60 & optional PMGH-60 Hoo

245⁄8"

(625 mm)

185⁄8"

(473 mm)

203⁄8"(518 mm)

Alternate

TPRV on back

TPRV

241⁄2"(622 mm)

6" (152 mm)

4" (102 mm) diameter flue adapter

FRONT VIEW RIGHT SIDE VIEW

243⁄8"(619 mm)

67⁄8"

(175 mm)

Electrical

POWERMITE®

GAS BOOSTER WATER HEATERS

Models PMG-60, PMG-100, PMG-200

Mo els PMG-100 & PMG-200

25"

(635 mm)

271⁄2"(699 mm) PMG-100

36" (914 mm) PMG-200

203⁄4"(527 mm)

6" (152 mm)

REAR VIEW

RIGHT SIDE VIEW

Water

Outlet

Water

Inlet

Gas

Inlet

Alternate

Flue

Location

TPRV

4" (102 mm)

Vent Adapter

Water Outlet

Water Inlet

Gas Inlet

DIMENSIONS

PMG-60: 203/8"W x 241/2"D x 245/8"H* (518 x 622 x 625 mm).

PMG-100: 271/2"W x 203/4"D x 31"H* (699 x 527 x 787 mm).

PMG-200: 36"W x 203/4"D x 31"H* (914 x 527 x 787 mm).

PMGH-60 Hoo : 243/8"W x 133/8"D+x 67/8"H•(619 x 340 x 175 mm).

* Height inclu es 6" (152 mm) legs.

+A4" (102 mm) for flue a apter.

•A s 4" (102 mm) to wi th an 57/8"(149 mm) to height of PMG-60.

PRODUCT SPECS

Gas Booster Water Heater

The Gas Booster Water Heater to supply the final 180°F (82°C)

rinse for the ishwasher shall be a Hatco Powermite®Mo el ...., as

manufacture for commercial use by the Hatco Corporation,

Milwaukee, WI 53234 U.S.A.

With 24/7 service (U.S an Cana a only), the booster shall have

the capacity to heat ....gph (lph) from 110°F to 180°F (43°C to

82°C) an it shall be rate at ....btu, 120 volts, single phase. The

stainless steel tank shall be esigne for a working pressure of 150

psi (1034 kPa) an hy rostatically teste at 300 psi (2069 kPa).

The heater shall be complete with all internal plumbing, inclu ing

3

⁄

4

" NPT pipe an fittings from inlet an outlet. All controls shall

be built-in, an carry safety approval in accor ance with

ANSI 21.10.3. Sanitary approval shall be in accor ance with

NSF Stan ar 5. Proper surface mounting circuit breaker or fuse

isconnect switch shall be provi e by electrical contractor.

The gas fire heating system shall be controlle by close

tolerance immersion thermostats. The booster shall be protecte

with high temperature limit switch (ECO) an low water cut-off.

The heater shall consist of stainless steel front, top, an stainless

steel a justable legs or stainless steel front an silver-gray

hammertone si es an back with stan ar 6" (152 mm) legs.

The heater shall inclu e a temperature/pressure relief valve,

high-temperature limit, pressure re ucing valve with bypass,

in icating temperature/pressure gauge, shock absorber, an

blen e phosphate water treatment system.

PMG-60 120 VAC, 210 watt, 1.75 amps.

PMGH-60 120 VAC, 18 watt, 0.15 amps.

PMG-100/200 120 VAC, 360 watt, 3.00 amps.

PMG-60 Gas – 1⁄2" NPT, Water – 3⁄4" NPT,

Electric – 120 VAC, 15 amp.

PMG-100/200 Gas – 3⁄4" NPT, Water – 3⁄4" NPT,

Electric – 120 VAC, 15 amp.

All Mo els Natural or Propane Gas

Fuel

Electrical

PMG-60 Direct – combustion air enters

bottom, flue gasses exit si es at

top of unit.

PMG-100/200 Direct – combustion air enters bottom,

flue gasses exit right si e or back

at top of unit. 4" (102 mm) flue roun .

ACCESSORIES

❑Exhaust Hoo PMGH-60 (For PMG-60 only)

❑High Altitu e Orifice Kit

All Mo els 150 PSI max. Relief valve set at

150 PSI, 210°F (99°C)

^Before installing any metho of venting you shoul contact the local co e

authority or your gas supplier to make sure that the final installation will be

acceptable to the authorities who have juris iction.

The proper metho of venting a power vente gas appliance is too

complicate to cover in this specification sheet an is explaine in etail

in the National Fuel Gas Co e. Before installing the venting system, the

person or agency making the installation must be familiar an experience

with the gui elines of the National Fuel Gas Co e.

ALL INSTALLATIONS MUST BE MADE BY A QUALIFIED

INSTALLER IN ACCORDANCE WITH THE NATIONAL

FUEL GAS CODE OR LOCAL CODES.

Water Column

Gas Type Minimum Maximum

Natural 5.0" (127 mm) 10.5" (267 mm)

Propane/LP 11.0" (279 mm) 13.0" (330 mm)

Gas Inlet Pressure

Water Column At Pressure Tap

Gas Type High Burn

Natural 3.5" ( 89 mm)

Propane/LP 10.0" (254 mm)

Operating Pressure Specifications at Manifol

PMGH-60 4" (102 mm) iameter vent pipe a apter

PMG-100/200 Force raft system with 4" (102 mm)

iameter vent pipe a apter.

PMG-60 130 lbs. (59 kg) ry.

PMG-100 180 lbs. (82 kg) ry.

PMG-200 215 lbs. (98 kg) ry.

Shipping Weight

31"

(787 mm)

271⁄2"(699 mm) PMG-100

Water Outlet

Electrical

Electrical

Water Inlet

Gas Inlet

36" (914 mm) PMG-200

203⁄4"(527 mm)

251⁄4"

(641 mm)

6" (152 mm)

FRONT VIEW

LEFT SIDE VIEW

Water

Outlet

Water

Inlet

Gas

Inlet

Alternate TPRV

Location

Operating Water Pressure

Fluing

Connections

HATCO CORPORATION P.O. Box 340500 Milwaukee, WI 53234-0500 U.S.A. • (800) 558-0607 • (414) 671-6350

Fax (800) 543-7521 • Int’l. Fax (414) 671-3976 • www.hatcocorp.com • E-mail: equipsales@hatcocorp.com

Vent^

Form No. PMG Spec Sheet

Printe in U.S.A.

January 2007