6 Art. Nr.: 5090032031 Rev.: 02/2023-07-13

•1 O-Ring

•1 bzw. 3 bzw. 7 Thermoschrumpfmuffen bzw. Kaltschrumpfmuffen (gemäß

Anzahl der Durchgänge)

•1 Zentrierband L = ca. 430 mm (bei HSI150 D1x80 und HSI150 D3x58)

Zum Lieferumfang des Systemdeckels HSI150 D110 GSM (HSI150 D125 GSM) ge-

hören:

•1 Systemdeckel HSI150 D110 GSM bzw. HSI150 D125 GSM

•1 Spannmutter

•1 Gleitring

•1 O-Ring

Lagerung

Beschädigung durch unsachgemäße Lagerung!

Bei unsachgemäßer Lagerung können Sachschäden in erheblicher Höhe ent-

stehen.

•Systemdeckel vor der Montage vor Beschädigungen, Feuchte und Verunreini-

gungen schützen. Es dürfen nur unbeschädigte Teile montiert werden.

•Die Lagerung des Systemdeckels muss so erfolgen, dass dieser keinen zu niede-

ren Temperaturen (<5 °C) und höheren Temperaturen (>30 °C) sowie keiner di-

rekten Sonneneinstrahlung ausgesetzt ist.

Entsorgung

Sofern keine Rücknahme- oder Entsorgungsvereinbarung getroffen wurde, zer-

legte Bestandteile nach sachgerechter Demontage der Wiederverwertung zufüh-

ren:

•Metallische Materialreste nach den geltenden Umweltvorschriften verschrotten.

•Elastomere nach den geltenden Umweltvorschriften entsorgen.

•Kunststoffe nach den geltenden Umweltvorschriften entsorgen.

•Verpackungsmaterial nach den geltenden Umweltvorschriften entsorgen.

EN Safety Instructions and Information

Target Group

The installation may only be carried out by technical experts.

Qualified and trained individuals carrying out installation must have

•knowledge of general safety and accident prevention regulations as amended,

•knowledge of how to use safety equipment,

•knowledge of how to use hand tools and electric tools,

•knowledge of the relevant standards and guidelines for laying pipes/cables and

for backfilling utility trenches as amended,

•knowledge of the regulations and installation guidelines of the supply company

as amended,

•knowledge of the waterproof concrete directive and building waterproofing

standards as amended.

General information and intended use

In line with their intended use, our products have been developed solely for instal-

lation in buildings made of state-of-the-art materials. Insofar as no express written

confirmation has been provided by us, we do not accept any liability for any other

purposes or purposes going beyond the above.

For warranty conditions, please see our current General Terms and Delivery Condi-

tions. We explicitly draw your attention to the fact that no warranty whatsoever

applies for any subsequent damage occurring as a result of failure to follow the

installation instructions or if our products are used incorrectly or combined with

third-party products.

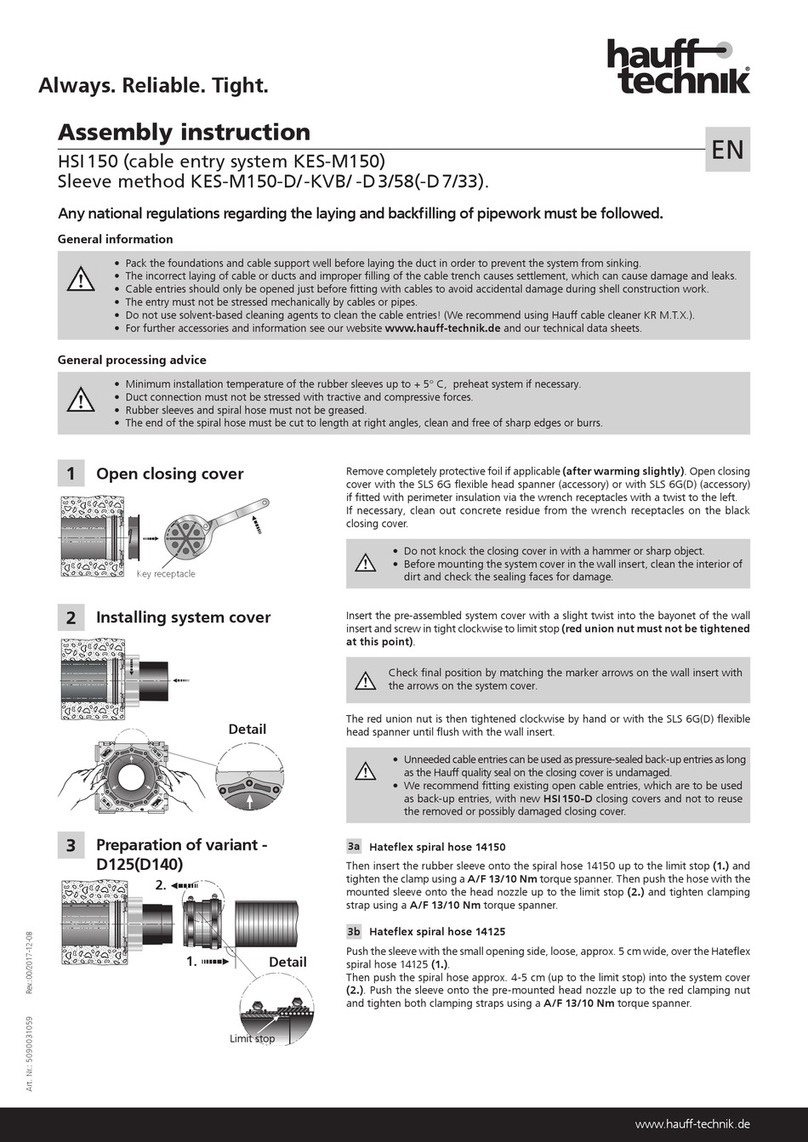

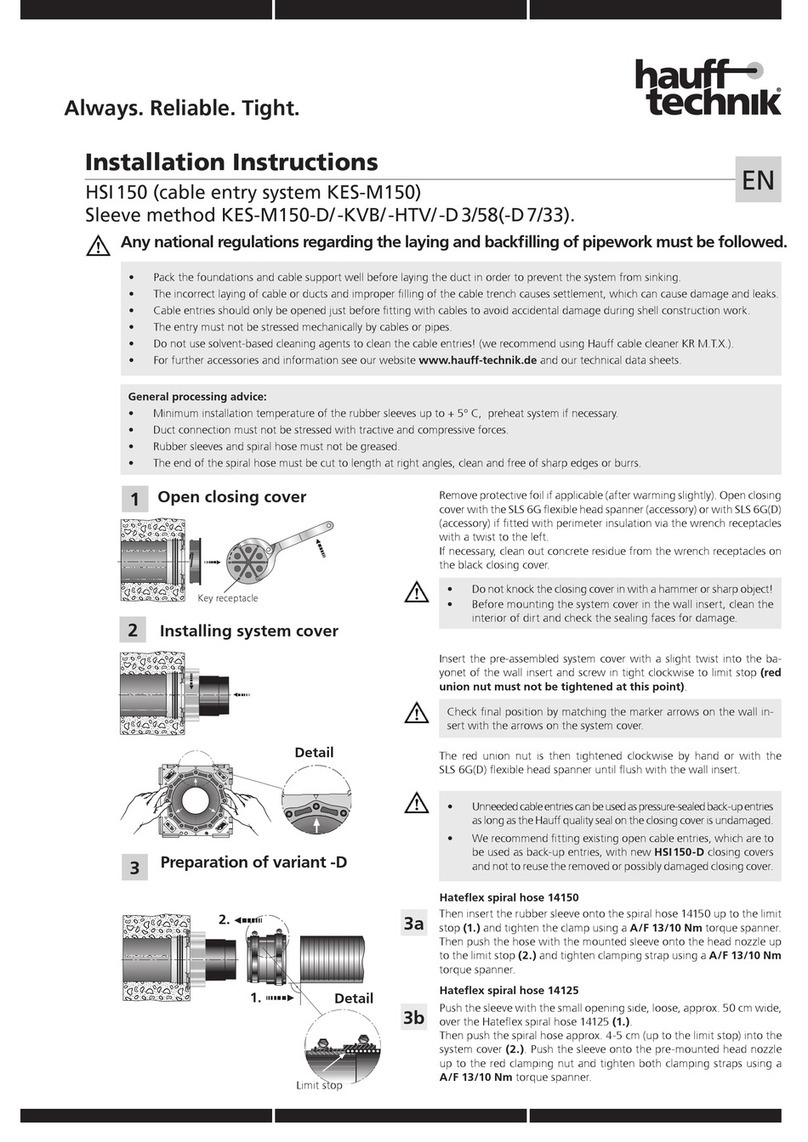

System covers HSI150 D... are tested by

FHRK according to current test guide-

lines and bear the seal "FHRK Quality".

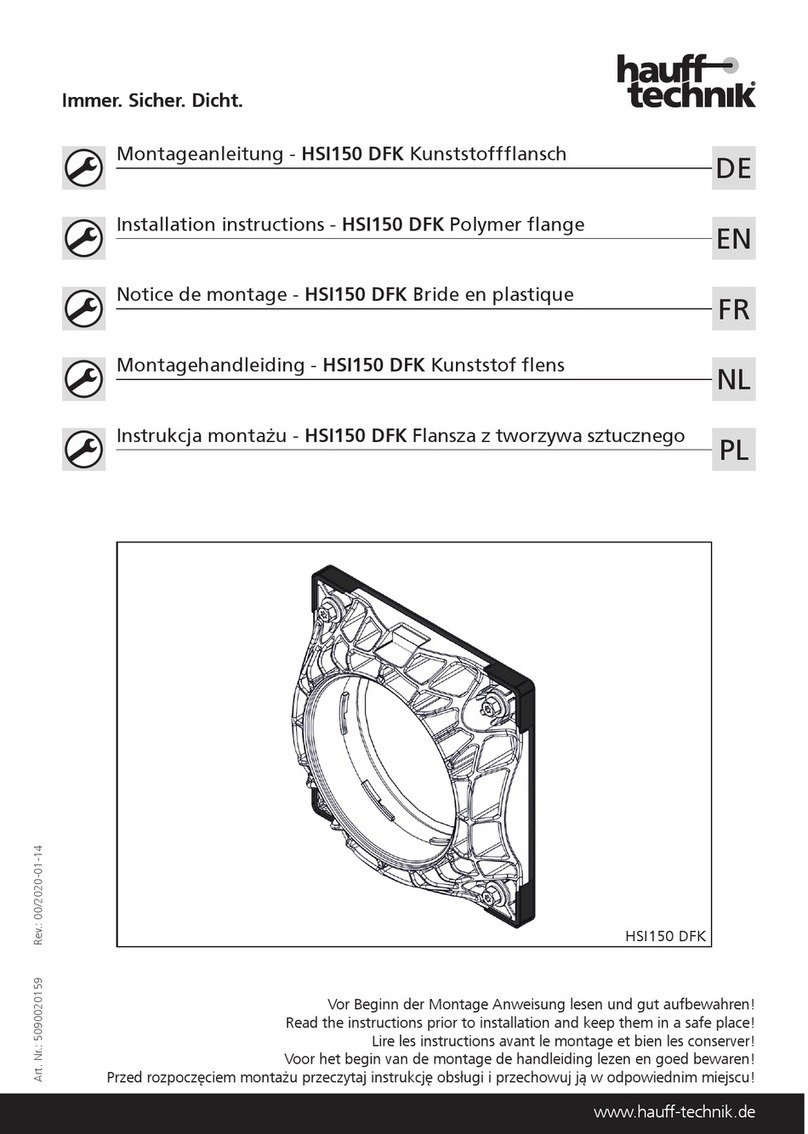

The System covers HSI150 D... are designed for use in HSI150 wall inserts and pol-

ymer flanges and for entry of up to 7 cables (pipes) with an outer diameter of 12 -

120 mm. The thermal sleeves support a wide area of application. They are shrunk

onto the cables by means of the application of heat from the system cover socket.

The cold shrink sleeves also support a wide area of application. They are shrunk

onto the cables by the system cover socket without tools. Empty system cover

sockets can be sealed with blind plugs.

Safety

This section provides an overview of all the main safety aspects for optimum pro-

tection of personnel and a safe installation process.

A failure to observe the instructions and safety information set out here may re-

sult in significant hazards.

During installation of the System cover it is imperative to observe the relevant pro-

fessional association rules, the VDE provisions, the relevant national safety and ac-

cident prevention regulations and your company’s guidelines (work and procedure

instructions).

The fitter must wear the relevant protective clothing.

Only intact components may be installed.

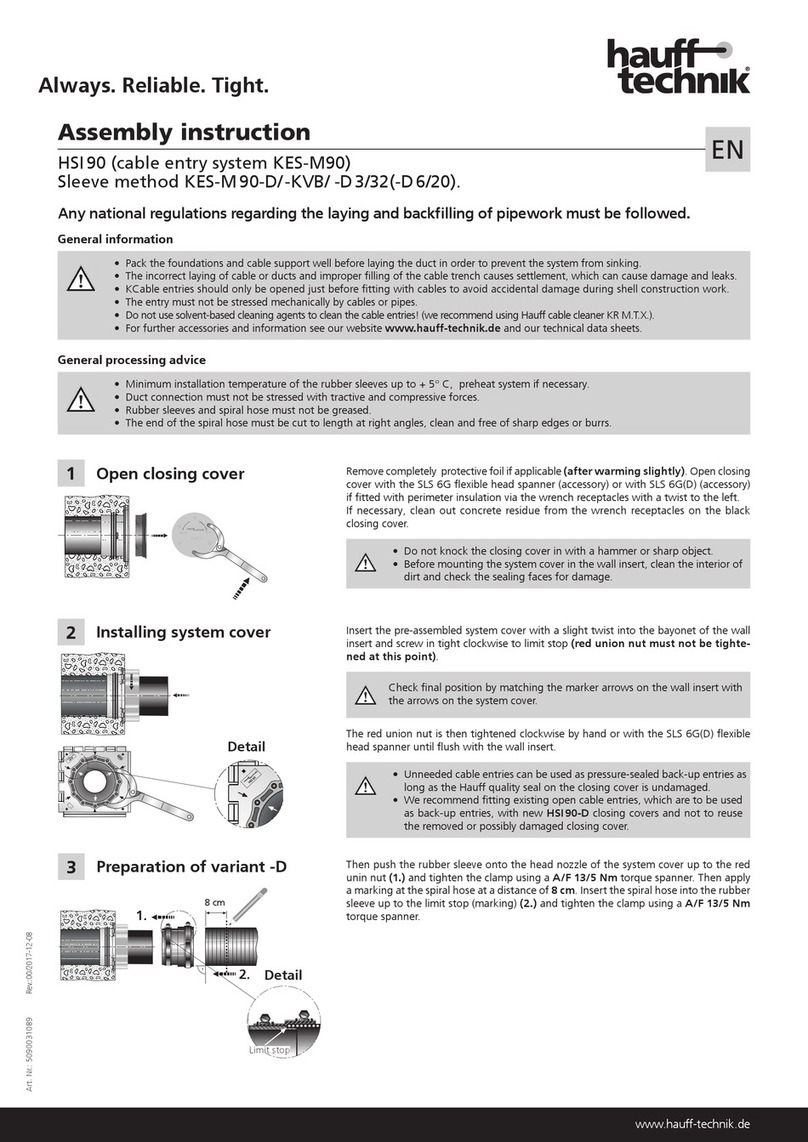

The following instructions are to be observed prior to installa-

tion of the System cover HSI150 D...:

Risk of injury in the event of improper installation!

Improper installation can result in significant bodily harm and property dam-

age.

•Observe the nationally applicable laying and filling regulations for pipes and ca-

bles.

•Seal the underground and cable substructure well prior to laying pipes or cables

so that the latter cannot subside.

No sealing due to incorrect installation!

Improper installation can result in damage.

•The incorrect laying of cables or ducts and improper filling of the cable trench

causes settlement, which can lead to damage and leaks.

•Only open cable entries just before fitting with cables to avoid accidental dam-

age during foundation works.

•Do not knock the blind cover in with a hammer or sharp object!

•The System cover should not be supposed to mechanical load through cables or

pipes.

•Any System covers that are not required may be used as pressure-tight back-up

entries if there is an undamaged Hauff quality seal on the closing cover.

•Open System covers, which are used as back-up entries or closing cover which

have been opened accidentally, should be fitted with new HSI 150 DT/DTS re-

spectively HSI90 D blind covers.

•Do not reuse uninstalled or damaged closing covers.

•When tapping in the safety cover (second sealing cover), the bayonet mounting

and the seal seat for the O-ring of the seal packing must not be damaged.

•If installed correctly, the marking arrows on the system cover should match up

with the arrows on the square frame of the packing piece.

•After laying the cables or pipes they must be permanently fixed. In general, ca-

bles and pipes should be fed into the cover socket centrally and must not rest

on the socket after the shrink-fit procedure.

•Apply a constantly moving flame all around for even warming (with the flame

adjusted to a soft yellow) during the shrinking process so as to avoid any local

overheating.

•The shrink-fit process will slow down at temperatures below 5 °C.

•Installation according to the cold shrink-fit method is carried out from outside

the building.

•If there is any evidence of damage on the cable coating, you can attach hot-

melt tape such as "Hauff Hatetherm" to the cable before carrying out the

shrink-fit procedure.

•For establishing a pipeline alignment free of damage, suitable slide-on double

sleeves have to be used.

•There must not be any continuous longitudinal grooves on the cables in the

sealing area (if necessary, move the cable slightly forwards or backwards until

any longitudinal grooves are no longer visible).

•Reducing the diameter of protective pipe connections (DN110/125) in the

HSI150 system restricts the sealing technology of thick cables.

•Before mounting a system cover in the wall insert, clean the interior of any dirt

and check the sealing surfaces for any damage.

•No cleaning agents containing solvent may be used for cleaning the System

cover. We recommend using the KRMTX cable cleaner.

•For details of other accessories and further information, see www.hauff-tech-

nik.de and the technical data sheets as well as the safety data sheet.

Personnel requirements

Qualifications

Risk of injury in case of inadequate qualification!

Improper handling can result in significant bodily harm and property dam-

age.

•Installation may only be carried out by qualified and trained individuals who

have read and understood these instructions.

Skilled experts

Based on their specialist training, skills, experience and familiarity with the rele-

vant provisions, standards and regulations, skilled experts are able to carry out the

work assigned, independently identifying and avoiding potential hazards.

Transport, packaging, scope of delivery and storage

Safety instructions in connection with transport

Damage in the event of improper transport!

Significant damage can occur in the event of improper transport.

•When unloading packaging items on delivery and in the course of in-house

transport, proceed with care and observe the symbols on the packaging.