11

Art. Nr.: 5090033075 Rev.:03/2019-10-21

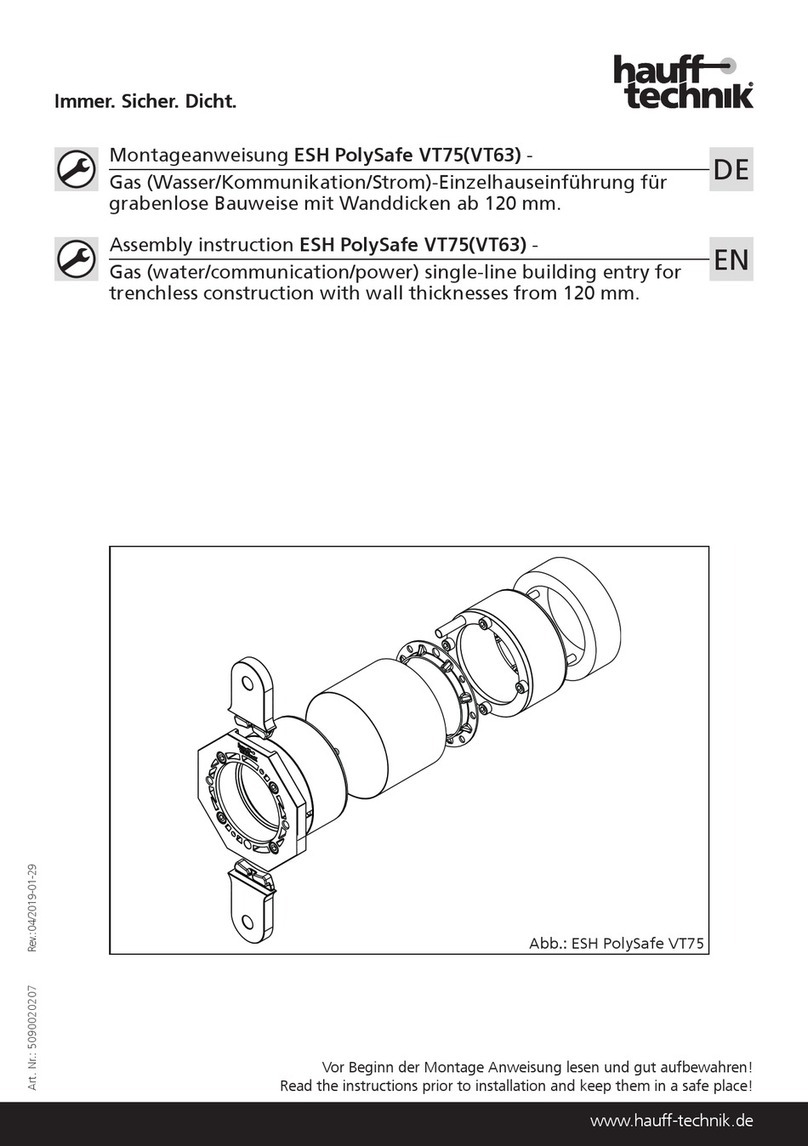

MSH PolySafe - Mehrspartenhauseinführung für

Gebäude mit Keller.

Zum Lieferumfang vom Modul 2 gehören:

1 Außen ansch mit Pro ldichtung

4 Gewindefurchende Schrauben 8x35

2 Abstandhalter

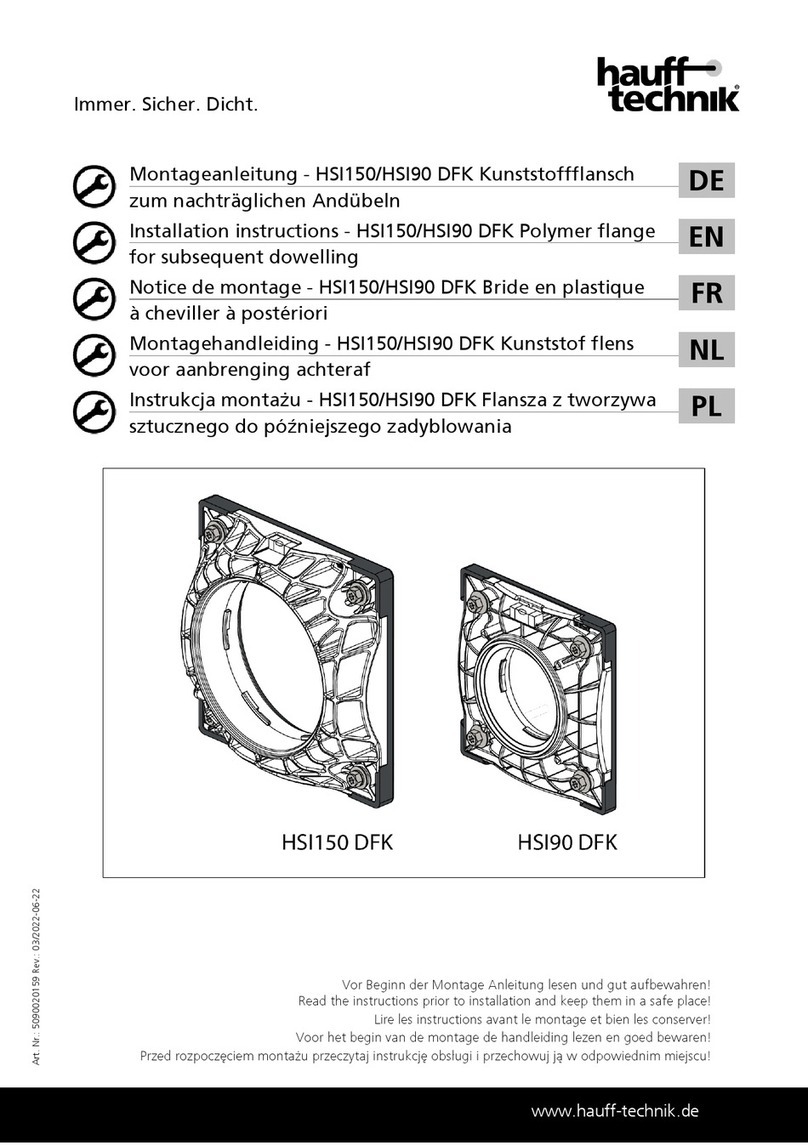

Zum Lieferumfang vom Modul 4 gehören:

1 Fest-/Los ansch zum Andübeln

4 Wand-Befestigungselemente SXR 10x80

Die Module 1, 1.2, 3, 6 und 6.2 werden ohne weiteren Lieferumfang geliefert.

Lagerung

HINWEIS!

Beschädigungen durch unsachgemäße Lagerung!

Bei unsachgemäßer Lagerung können Sachschäden in erheblicher Höhe entstehen.

• Mehrspartenhauseinführung MSH PolySafe, Manschettenstopfen und Universal-

Dichtelemente vor der Montage vor Beschädigungen, Feuchte und Verunreinigungen

schützen. Es dürfen nur unbeschädigte Teile montiert werden.

• Die Lagerung der Mehrspartenhauseinführung MSH PolySafe, Manschettenstop-

fen und Universal-Dichtelemente muss so erfolgen, dass sie zu keinen niederen

Temperaturen (<5° C) und höheren Temperaturen (>30° C) sowie keiner direkten

Sonneneinstrahlung ausgesetzt ist.

Entsorgung

Sofern keine Rücknahme- oder Entsorgungsvereinbarung getroffen wurde, zerleg-

te Bestandteile nach sachgerechter Demontage der Wiederverwertung zuführen:

• Metallreste nach den geltenden Umweltvorschriften entsorgen.

• Elastomere nach den geltenden Umweltvorschriften entsorgen.

• Kunststoffe nach den geltenden Umweltvorschriften entsorgen.

• Verpackungsmaterial nach den geltenden Umweltvorschriften entsorgen.

Safety instructions and informations

Target group

The installation may only be carried out by technical experts.

• Quali ed and trained individuals carrying out installation must have

• knowledge of general safety and accident prevention regulations as amended,

• knowledge of how to use safety equipment,

• knowledge of how to use hand tools and electric tools,

• knowledge of the relevant standards and guidelines for laying pipes/cables and

for back lling utility trenches, as amended,

• knowledge of the regulations and installation guidelines of the supply company

as amended,

• knowledge of the impermeable concrete directive and building waterproo ng

standards as amended.

• Expertise and training in installing PMBC systems.

General information and intended use

According to their intended use, our products have been designed exclusively for

installation in buildings made from state-of-the-art construction materials. We do

not accept liability for use deviating from or beyond this unless our express written

con rmation has been obtained in advance.

For warranty conditions, please see our current General Terms and Delivery Con-

ditions.

MSH PolySafe multiple-service building entry systems meet the requirements of

Annex B1 of Test Speci cation VP 601 dated January 2008 and are compatible

with gas building entries which likewise comply with Supplement B1 in terms of

design and construction.

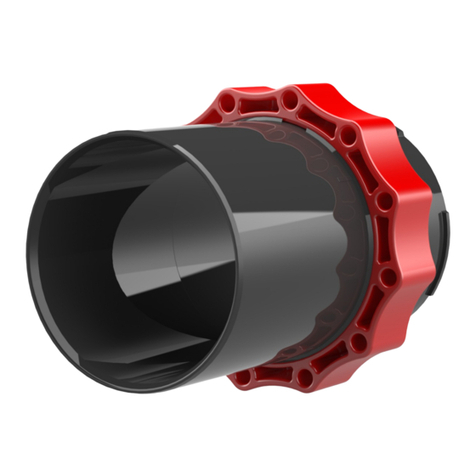

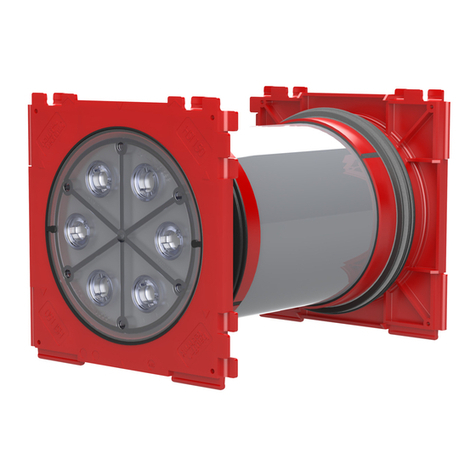

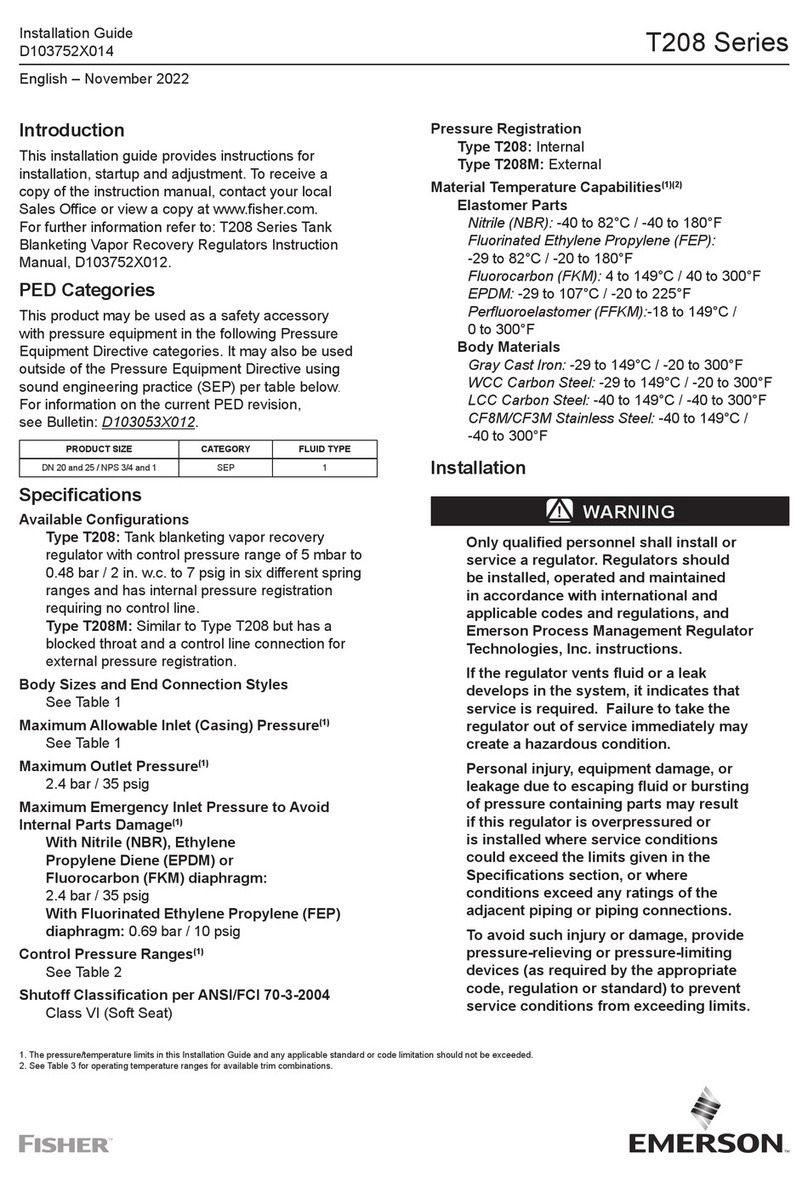

Gastight and watertight multiple-service building entry systems MSH PolySafe for

gas, water, electricity and telecommunications for installation of core drill holes or

wall sleeves. Basic variant 1 with internal sealing in 30 mm sealing width and basic

variant 2 with internal sealing 60 mm in sealing width for buildings with a base-

ment. The external sealing can be freely selected by means of the module system

used, depending on the wall type or building sealing und im Standard (Modul 1)

für WU-Beton geeignet.

MSH PolySafe is suitable for application areas such as standing seepage water,

pressurised water, Class 1 waterproof concrete, DIN 18533 W2.1-E and DIN 18533

W2.2-E.

Safety

This section provides an overview of all the main safety aspects for optimum pro-

tection of personnel and a safe installation process. If there is a failure to observe

the instructions and safety information set out here, this may result in signi cant

hazards.

This section provides an overview of all the main safety aspects for optimum protec-

tion of personnel and a safe installation process.

If there is a failure to observe the instructions and safety information set out here,

this may result in signi cant hazards.

Multiple-service building entry systems MSH PolySafe installation must comply with

the relevant professional association regulations, VDE provisions, national safety

and accident prevention regulations as well as company regulations (work and

procedural instructions).

The tter must wear the relevant protective clothing.

Only intact components may be installed.

The tter must wear the relevant protective clothing.

Only intact components may be installed.

The following warnings, tips and recommendations are to be

observed prior to installation of the MSH PolySafe:

observed prior to installation of the MSH PolySafe:

WARNING!

Risk of injury in the event of improper installation!

Improper installation can result in signi cant bodily harm and property damage.

• The nationally applicable laying and lling regulations for pipes and cables are

to be observed at all times.

• Seal the underground and cable substructure well prior to laying pipes/cables so

that the latter cannot subside.

• The DIN norms and directives referred to here are valid in Germany only. In all

other countries, the national norms and directives are to be observed as amended.

• The relevant country speci c standards and regulations are to be observed when

carrying out concreting work. This applies especially to concrete construction

elements according to EN206-1 which are impermeable to water, element con-

struction and work involving self-sealing concrete.

NOTE!

No sealing due to incorrect installation!

• Wall sleeves are to be used for all wall types except for concrete and waterproof

concrete!

• A clean, smooth contact surface is required for MSH PolySafe GV1. Any existing

breaks must be reworked.

• The connection to the interior installation may not exert any force on the gas

building entry.

• All four sealing elements must be installed, even if only some of the media

channels are to be used.

• If no gas tting is to be installed for the time being, a blind sealing element PolySafe

D0 (Art. no.: 1560000510) must be tted.

• The installation of a gas tting may only be carried out by the appropriate energy

supplier or by a specialist commissioned by him. For this the mounting instructions

"PolySafe Twist and Rip Protection DN25/32/40 Schuck" or "PolySafe Twist and

Rip Protection DN25 RMA" is to be considered.

• Deformed or damaged corrugated cable conduits are not suitable for sealing.

These must be cut off or replaced.

• Consult the supplier before feeding through the media lines

• With element and triple walls it is necessary to install Module 6 or 6.2.

• In the event of load case "pressurised water" (standing water up to 3 m) according

to DIN 18533 W2.1-E, the use of Module 2 is stipulated. In the event of load case

"pressing water (standing water over 3 m) according to DIN 18533 W2.2-E, the

use of Module 4 is stipulated.

• For xed and loose ange constructions (W2.2, load case: pressing water), the following

spacing measurements and installation guidelines apply according to DIN 18533:

Outer edge of ange to other installation or parts attached by dowel: 300 mm.

Outer edge of ange to building edges, building recesses or wall connections: 300 mm.

Outer edge of ange to expansion joints: 500 mm.

• The current building waterproo ng standard DIN 18533 for underground structural

components is to be observed.

• The tightening torque (see Table 1) is to be adapted to the type of sealing in

question (see DIN 18533, Part 1). The instructions of the sealing sheet manufac-

turer are to be observed.

• Due to the different construction types and wall structures, the sealing sys-

tem of a multi-line building entry has to be adapted to the circumstances

on site in individual cases. In order to avoid complaints in such special cas-

es, send us a sketch or drawing of the wall structure if necessary. This ad-

ditional effort is definitely worthwhile in order to avoid later complaints!

Make use of our technical advisory service if need be!

• Substructure sealing systems (FBV) are not included in standard sealing ty-

pes ("black tank") and are not covered by DIN 18195 or DIN 18533.

Here, FBV systems are used solely in connection with waterproof concrete.

For this reason, substructure sealing technology (also known as "yellow tank", "white

tank plus" etc.) may not be planned and applied according to this sealing standard!

• No cleaning agents containing solvent may be used to clean the standard press

seal. We recommend using cable cleaner KR M.T.X.

• For details of other accessories and further information, see www.hauff-tech-

nik.de and the technical speci cation sheets.

Personnel requirements

Qualifi cations

WARNING!

Risk of injury in case of inadequate qualifi cation!

Improper handling can result in signi cant bodily harm and damage to property.

Installation may only be carried out by quali ed and trained individuals who have

read and understood these instructions.

Skilled experts

EN