8

Wiring The Unit

Sultan Acoustic Wave Series

Sultan SMART Units

The Sultan SMART unit has wiring information printed inside the lid of the unit.

Screw Cap Version

Unscrew the lid to expose the terminals. It is

recommended you remove the terminal block from

the unit before wiring - to do this, insert a screw driver

into one of the middle terminals to lever the block out.

Pass the cables through the cable entry gland before

wiring in to the terminal block.

Ensure the terminal is open by screwing counter

clockwise with a flat head screwdriver. Place the

exposed wires into the open terminals and tighten

until firm. Insert the block back into the unit when

wiring is complete. Press firmly on the plug in terminal

block to ensure it is fully home.

If you are connecting HawkLink communications,

connect the blue wire to B and the white wire to A.

The black wire can be connected to the DC- terminal

next to B.

Tighten cable entry gland(s) and cover to ensure

sealing is effective.

IP68 Sealed Cable Version

Connect the free ends of the cable following the wire

colours as shown in the terminal diagrams.

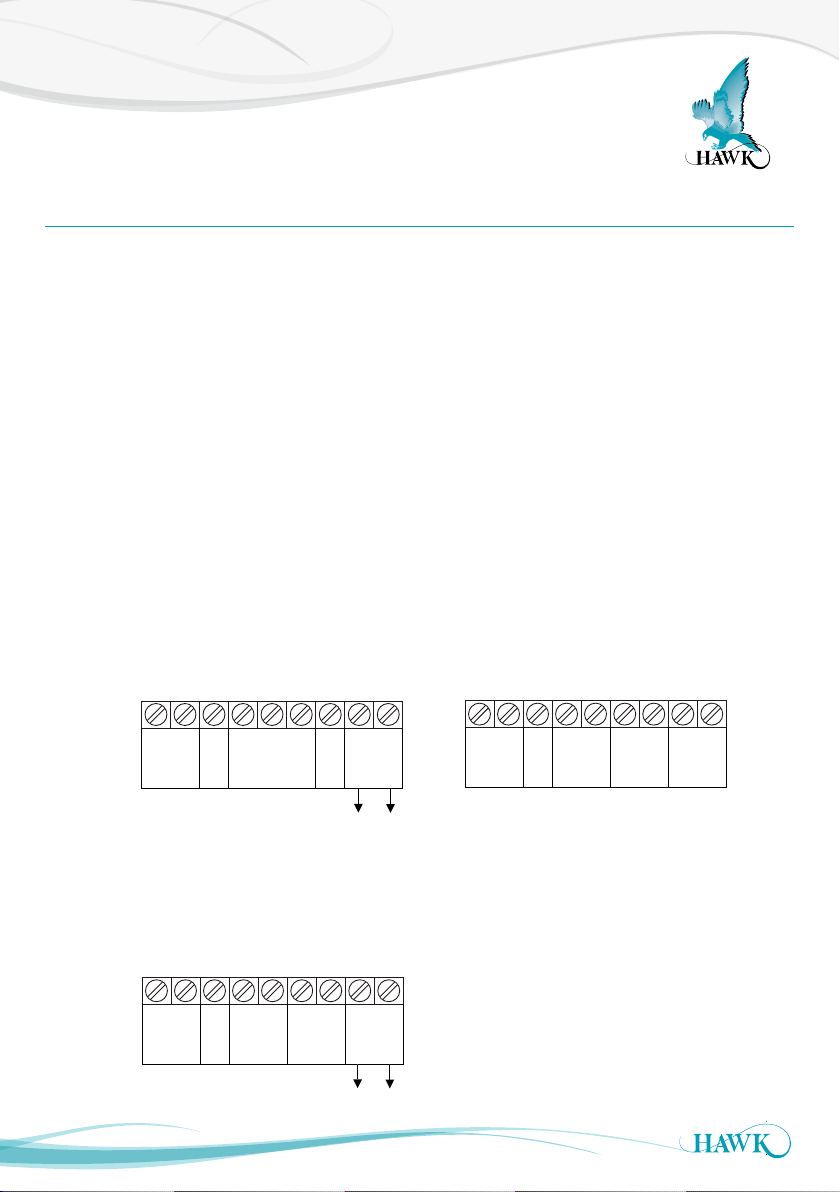

AWSTD AWSTC

AWSTA

COM

NO

Test in

A

B

-

+

-

+

BWN

ORG

PPL

WT

BLU

BLK

RD

GRN

YEL

RELAY COMMS DC-in 4-20mA

COM

NO

Test in

A

B

-

+

-

+

BWN

ORG

PPL

WT

BLU

BLK

RD

GRN

YEL

RELAY COMMS DC-in 4-20mA

Outputs

- 4-20mA

- Relay

- Modbus Multidrop

Outputs

- Relay

- Modbus Multidrop

Outputs

- 4-20mA

(2) Modbus

RELAY RS - 485

24 Vdc

4-20mA

current sinking

RELAY RS - 485

24 Vdc

(1) (1)

Sinking 4-20mA

from user device

(loop powered)

Notes:

(1) - No internal connection

(2) - Single Modbus connection PC to unit only

Multidrop connection not recommended

For cable only models (without

integrated junction box option),

please use colors shown to

denote wire functions.

For models with integrated

junction box option, remove

plug-in terminal blocks for easier

wiring.

COMMS DC-IN

A

B

12-30VDC

+

RS 485

AC-IN

N

L1

80-265VAC

RELAY 1

NC

COM

NO

RELAY 2

NC

COM

NO

COMMS

A

B

+

–

4-20mA

Is

1L

N

+

–

AC-In

Driving 4-20mA from

Sultan to user PLC

Modulating

4-20mA from

PLC input

–

Test In

COMMS

A

B

–

Test In

+

COM

N / O

COMMS

A

B

–

Test In

+

COM

N / O

RELAY

Sinking 4-20mA

from user device

+

–

4-20mA

DC in

DC in

PURPLE

WHITE

BLUE

BLACK

GREEN

YELLOW

BROWN

ORANGE

PURPLE

WHITE

BLUE

BLACK

RED

BROWN

ORANGE

PURPLE

WHITE

BLUE

BLACK

RED

GREEN

YELLOW

RELAY

AWSTA version AWSTC version

AWSTD version