HBK U9C User manual

U9C

ENGLISH DEUTSCH FRANÇAIS ITALIANO

Mounting Instructions

Montageanleitung

Notice de montage

Istruzioni per il montaggio

Hottinger Brüel & Kjaer GmbH

Im Tiefen See 45

D-64293 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbkworld.com

Mat.: 7-0111.0012

DVS: A03815 03 YI0 02

06.2022

EHottinger Brüel & Kjaer GmbH

Subject to modifications.

All product descriptions are for general information

only. They are not to be understood as a guarantee of

quality or durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allge

meiner Form. Sie stellen keine Beschaffenheits- oder

Haltbarkeitsgarantie dar.

Sous réserve de modifications.

Les caractéristiques indiquées ne décrivent nos

produits que sous une forme générale. Elles

n'impliquent aucune garantie de qualité ou de

durabilité.

Con riserva di modifica.

Tutti i dati descrivono i nostri prodotti in forma

generica e non implicano alcuna garanzia di qualità o

di durata dei prodotti stessi.

U9C

ENGLISH DEUTSCH FRANÇAIS ITALIANO

Mounting Instructions

U9C

TABLE OF CONTENTS

2

TABLE OF CONTENTS

1 Safety instructions 4................................................

2 Markings used 7....................................................

2.1 The marking used in this document 7..................................

3 Scope of supply, accessories and variants 8............................

4 General application instructions 10....................................

5 Structure and mode of operation 11....................................

5.1 Transducer 11.......................................................

5.2 Strain gage covering agent 11.........................................

5.3 Inline amplifier 11....................................................

6 Conditions on site 12.................................................

6.1 Ambient temperature 12..............................................

6.2 Moisture and corrosion protection 12...................................

6.3 Deposits 12.........................................................

7 Mechanical installation 13............................................

7.1 Important precautions during installation 13..............................

7.2 General installation guidelines 13.......................................

7.3 Installing the U9C 14.................................................

7.3.1 Mounting with tension and compression bars 14..........................

7.3.2 Mounting with knuckle eyes 15.........................................

8 Electrical connection 20..............................................

8.1 Connection to measuring amplifier without permanently connected amplifier

module 20..........................................................

8.1.1 General information and connection 20..................................

8.1.2 Cable extension and cable shortening 20................................

8.1.3 EMC protection 21...................................................

8.1.4 TEDS transducer identification 21......................................

8.2 Electrical connection of measuring amplifier with amplifier module 22.......

8.2.1 General information 22...............................................

8.2.2 Connecting the device 23.............................................

8.2.3 Operating the inline amplifier/zeroing the measurement chain 23............

U9C

SAFETY INSTRUCTIONS

4

1 SAFETY INSTRUCTIONS

Intended use

The force transducers in the type series U9C are solely designed for measuring static and

dynamic tensile and compressive forces within the load limits specified by the technical

data for the respective maximum capacities. Any other use is not the intended use.

To ensure safe operation, it is essential to comply with the regulations in the mounting

instructions, the safety requirements listed below, and the data specified in the supplied

technical data sheets. It is also essential to observe the applicable legal and safety regu

lations for the relevant application.

Force transducers are not intended for use as safety components. Please also refer to

the “Additional safety precautions” section. Proper and safe operation of force transduc

ers requires proper transportation, correct storage, setup and mounting, and careful oper

ation.

Load-carrying capacity limits

The information in the technical data sheets must be observed when using the force

transducers. The respective specified maximum loads in particular must never be ex

ceeded. The following limits set out in the technical data sheets must not be exceeded:

SLimit forces

SLateral limit forces

SBending moment and torque

SBreaking forces

SPermissible dynamic loads

Stemperature limits

SElectrical load limits

Please note that when several force transducers are interconnected, the load/force distri

bution is not always uniform.

Use as machine elements

Force transducers can be used as machine elements. When used in this manner, note

that to favor greater sensitivity, force transducers were not designed with the safety fac

tors usual in mechanical engineering. Please refer to the “Load-carrying capacity limits”

section and the specifications.

Accident prevention

The prevailing accident prevention regulations must be taken into account, even though

the breaking force values in the destructive range are well in excess of the full scale

value.

5

U9C

SAFETY INSTRUCTIONS

Additional safety precautions

Force transducers cannot (as passive transducers or as a measurement chain) imple

ment any (safety-relevant) cutoffs. This requires additional components and constructive

measures, for which the installer and operator of the plant is responsible.

In cases where a breakage or malfunction of the force transducer would cause injury to

persons or damage to equipment, the user must take appropriate additional safety pre

cautions that meet at least the applicable safety and accident prevention regulations (e.g.

automatic emergency shutdown, overload protection, catch straps or chains, or other fall

protection).

The electronic processor that processes the measurement signal should be designed so

that failure of the measurement signal cannot lead to secondary failures.

General dangers of failing to follow the safety instructions

Force transducers are state-of-the-art and failsafe. Transducers can give rise to residual

dangers if they are mounted, installed, used and operated inappropriately or by untrained

personnel. Every person involved with setting up, starting up, operating or repairing a

force transducer must have read and understood the mounting instructions and in partic

ular the technical safety instructions. The force transducers can be damaged or de

stroyed by non-designated use of the force transducer or by non-compliance with the

mounting and operating manual, these safety instructions or other applicable safety

regulations (safety and accident prevention regulations of the Employers' Liability Insur

ance Association) when using the force transducers. A force transducer can break, partic

ularly if it is overloaded. The breakage of a force transducer can cause damage to prop

erty or injury to persons in the vicinity of the force transducer.

If force transducers are not used as intended, or if the safety instructions or specifica

tions in the mounting and operating instructions are ignored, it is also possible that a

force transducer may fail or malfunction, with the result that persons may be injured or

property damaged (due to the loads acting on or being monitored by the force trans

ducer).

The scope of supply and performance of the transducer covers only a small area of force

measurement technology, as measurements with (resistive) strain gage sensors require

electronic amplification, and measurement chains require further signal processing.

Equipment planners, installers and operators should always plan, implement and respond

to the safety engineering considerations of force measurement technology in such a way

as to minimize residual dangers. Pertinent national and local regulations must be com

plied with.

Conversions and modifications

The design or safety engineering of the transducer must not be modified without our ex

press permission. Any modification shall exclude all liability on our part for any damage

resulting therefrom.

U9C

SAFETY INSTRUCTIONS

6

Maintenance

The force transducers of the U9C series are maintenance free.

Disposal

In accordance with national and local environmental protection and material recovery and

recycling regulations, old transducers that can no longer be used must be disposed of

separately and not with normal household garbage.

If you require more information about disposal, please contact your local authorities or

the dealer from whom you purchased the product.

Qualified personnel

Qualified personnel means persons entrusted with installing, mounting, starting up and

operating the product who possess the appropriate qualifications for their work.

This includes people who meet at least one of these three requirements:

SAs project personnel, you know and are familiar with the safety concepts of automa

tion technology.

SAs automation plant operating personnel, you have been instructed how to handle the

machinery. You are familiar with the operation of the equipment and technologies

described in this documentation.

SAs a commissioning or service engineer, you have successfully completed training on

the repair of automation plants. Moreover, you are authorized to start up, ground and

label circuits and equipment in accordance with safety engineering standards.

During use, compliance with the legal and safety requirements for the relevant applica

tion is also essential. The same applies to the use of accessories.

The force transducer may only be installed by qualified personnel, strictly in accordance

with the specifications and with the safety requirements and regulations.

7

U9C

MARKINGS USED

2 MARKINGS USED

2.1 The marking used in this document

Important instructions for your safety are specifically identified. It is essential to follow

these instructions in order to prevent accidents and damage to property.

Symbol Significance

WARNING This marking warns of a potentially dangerous situ

ation in which failure to comply with safety require

ments can result in death or serious physical injury.

CAUTION This marking warns of a potentially dangerous

situation in which failure to comply with safety

requirements can result in slight or moderate physical

injury.

Notice This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

Important This marking draws your attention to important in

formation about the product or about handling the

product.

Tip This marking indicates application tips or other

information that is useful to you.

Information This marking draws your attention to information

about the product or about handling the product.

Emphasis

See …

Italics are used to emphasize and highlight text and

identify references to sections, diagrams, or external

documents and files.

U9C

SCOPE OF SUPPLY, ACCESSORIES AND VARIANTS

8

3 SCOPE OF SUPPLY, ACCESSORIES AND VARIANTS

Scope of supply

SU9C force transducer

SU9C mounting instructions

STest report

Accessories

Description Ordering number

KAB168-5, PUR connection cable with M12 8-pin socket, 5 m long,

free ends on opposite side. For connecting the amplifier module to

the downstream electronics

1-KAB168-5

KAB168-20, PUR connection cable with M12 8-pin socket, 20 m

long, free ends on opposite side. For connecting the amplifier mod

ule to the downstream electronics

1-KAB168-20

Thrust piece EDO9/20kN; suitable for nominal (rated) forces from

0.5 kN … 20 kN

1-EDO9/20kN

Thrust piece EDO9/50kN; suitable for nominal (rated) force 50 kN 1-EDO9/50kN

Equipment variants

All force transducers are available in different versions. The following options are avail

able:

1. Cable

The U9C is equipped with a cable 1.5m long in the standard version. You can also or

der the force transducer with the following cable lengths:

-3 m

-5 m

-6 m

-7 m

-12 m

2. Device plug/electrical connection

We can mount one of the following connectors on the U9C if requested:

-D-SUB connector, 15-pin: 15-pin connector for connection to numerous amplifier

systems, e.g. MGCplus, Scout, MP85, etc.

-D-SUB HD connector: A 15-pin plug for connection to appropriate amplifier systems,

e.g. the HBM QuantumX system

9

U9C

SCOPE OF SUPPLY, ACCESSORIES AND VARIANTS

-3106 PEMV connector (Greenline): For connection to appropriate amplifier sys

tems, e.g. MGCplus with AP03.

-Free ends: Transducer delivered without plugs.

-The force transducer can be ordered with a permanently connected amplifier elec

tronics module which converts the output signal of the force transducer into a 0 ...

10 V signal. This option is only available with 1.5 m and 3 m cable lengths.

-The force transducer can also be ordered with a permanently connected amplifier

electronics module which converts the output signal of the force transducer into a

4…20mA signal. This option is only available with 1.5 m and 3 m cable lengths.

3. TEDS

You can order the force transducer with transducer identification ("TEDS"). TEDS

(Transducer Electronic Data Sheet) allows you to store the transducer data (character

istic values) in a chip that can be read out by a connected measuring device (with an

appropriate amplifier). HBM records the TEDS data before delivery so that no parame

terization of the amplifier is necessary.

TEDS can only be fitted in the plug of the U9C, therefore it is not possible to equip the

"free cable ends" version with TEDS. The versions with permanently connected ampli

fier electronics cannot be connected with the TEDS option.

U9C

GENERAL APPLICATION INSTRUCTIONS

10

4 GENERAL APPLICATION INSTRUCTIONS

The force transducers are suitable for measuring tensile and compressive forces. They

provide highly accurate static and dynamic force measurements and must therefore be

handled very carefully. Particular care must be taken during transportation and installa

tion. Dropping and knocking the transducer may cause permanent damage.

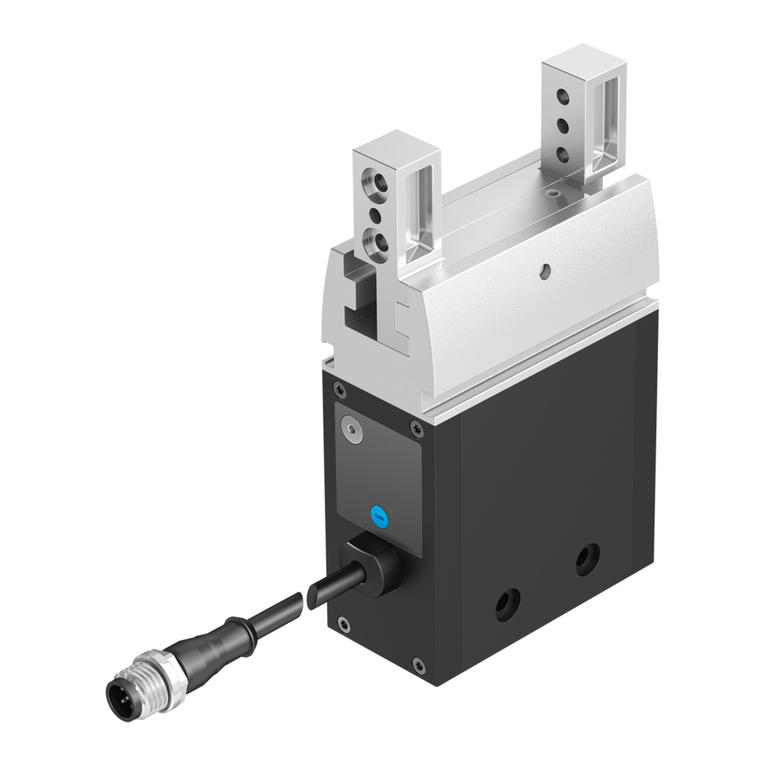

The U9C series force transducers have two external threads into which the forces to be

measured must be applied.

The Specifications section 10 on page 29 lists the permissible limits for mechanical, ther

mal and electrical loading. It is essential to observe these limits when planning the mea

suring set-up, during installation and, ultimately, during operation.

11

U9C

STRUCTURE AND MODE OF OPERATION

5 STRUCTURE AND MODE OF OPERATION

5.1 Transducer

The measuring body is a steel loaded member on which strain gages (SG) are installed.

The influence of a force deforms the measuring body, so there is deformation in places

where the strain gages are installed. The SG are attached so that two are stretched and

two are compressed when a force is applied. The strain gages are wired to form a Wheat

stone bridge circuit. They change their ohmic resistance in proportion to their change in

length and so unbalance the Wheatstone bridge. If there is an excitation voltage, the cir

cuit produces an output signal proportional to the change in resistance and thus also pro

portional to the applied force. The strain gage arrangement is chosen to compensate, as

much as possible, for parasitic forces and moments (e.g. lateral forces and eccentricity

influences), as well as the effects of temperature.

5.2 Strain gage covering agent

To protect the SG, the force transducers have thin cover plates that are welded on the

bottom and, in versions with a nominal (rated) force of up to 200 N, on the top.This

method offers very good protection against environmental conditions so that the U9C

reaches the protection class IP67. In order to retain the protective effect, these plates

must not be removed or damaged in any way.

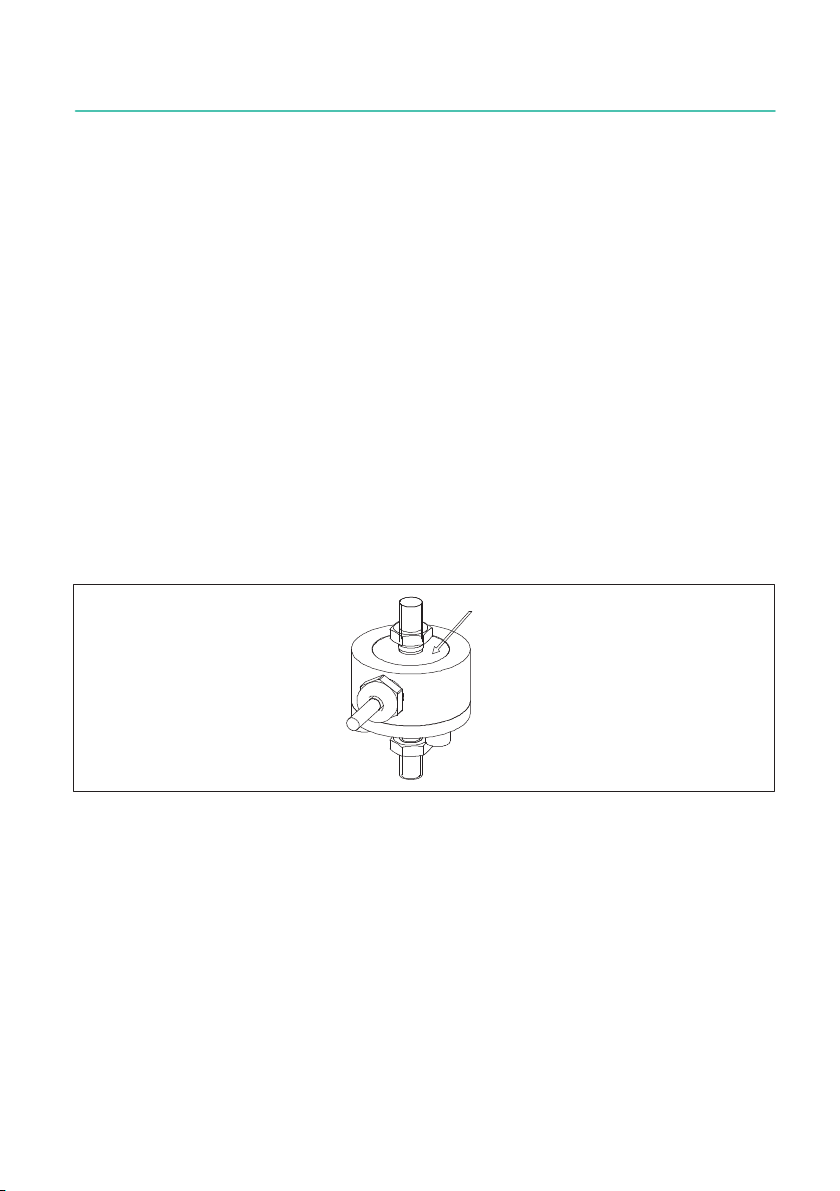

Fig. 5.1 The thin plate on the top side must not be damaged in the variants with

nominal (rated) forces 50N, 100N and 200N; the same applies for the plate on

the bottom of all force transducers.

5.3 Inline amplifier

The sensors can optionally be ordered with an inline amplifier. This amplifier module sup

plies the bridge circuit of the sensors with a suitable supply voltage, and converts the

small output signal of the force transducers with low noise into a 0 ... 10 V voltage signal

(VA1) or a 4 ... 20 mA current signal (VA2). The delivery is then carried out as a measure

ment chain, and the test record describes the correlation between the force input quantity

and the output signal in V or mA.

U9C

CONDITIONS ON SITE

12

6 CONDITIONS ON SITE

U9C series force transducers are made of rustless materials. It is nevertheless important

to protect the transducers from weather conditions such as rain, snow, ice and salt water.

6.1 Ambient temperature

The effects of temperature on the zero signal and on sensitivity are compensated.

To obtain optimum measurement results, comply with the nominal (rated) temperature

range. The compensation of the temperature effect on the zero point is implemented with

great care, but temperature gradients can still have a negative effect on the stability of

zero. Constant or very slowly changing temperatures are therefore best. A radiation

shield and all-round thermal insulation produce noticeable improvements. However, they

must not be allowed to set up a force shunt, i.e. slight movement of the force transducer

must not be prevented.

6.2 Moisture and corrosion protection

The force transducers are hermetically encapsulated and are therefore very insensitive to

moisture. The transducers achieve protection class IP67.

Despite the careful encapsulation, it makes sense to protect the transducers against per

manent exposure to moisture.

The force transducer must be protected against chemicals that could attack the steel.

With stainless steel force transducers, note that acids and all materials which release

ions will in general also attack stainless steels and their welded seams. Should there be

any corrosion, this could cause the force transducer to fail. In this case, appropriate pro

tective measures must be provided.

The housing of the inline amplifiers is made of aluminum and, like the sensor, meets the

requirements of IP67 protection. We recommend protecting the amplifier housing from

sustained weather effects.

6.3 Deposits

Dust, dirt and other foreign matter must not be allowed to accumulate sufficiently to di

vert some of the measuring force around the force transducer, thus invalidating the mea

sured value. (Force shunt). Also remember to lay the connection cable so that no force

shunts are produced at the lower nominal (rated) forces (<1 kN).

13

U9C

MECHANICAL INSTALLATION

7 MECHANICAL INSTALLATION

7.1 Important precautions during installation

SHandle the transducer with care.

SEnsure that the force application parts mounted on the sensor are designed to with

stand the forces to be measured.

SWelding currents must not be allowed to flow over the transducer. If there is a risk

that this might happen, you must use a suitable low-ohm connection to electrically

bypass the transducer. HBM offers the highly flexible EEK ground cable in various

lengths for this purpose, which can be screwed on above and below the transducer.

SMake sure that the transducer is not overloaded.

The cable fastening side of the transducer should always be connected directly with the

rigid customer-side force transfer area. Ensure that the cable is laid so that, where possi

ble, no force shunt is caused by the cable.

WARNING

There is a danger of the transducer breaking if it is overloaded. This can cause danger for

the operating personnel of the system in which the transducer is installed, as well as for

people in the vicinity.

Implement appropriate safety measures to avoid overloads (also see the Specifications

section 10 on page 29) or to protect against resulting dangers.

7.2 General installation guidelines

The forces to be measured must act on the transducer as accurately as possible in the

direction of measurement. Torques, bending moments resulting from lateral force, eccen

tric loading and the lateral forces themselves, may produce measurement errors and de

stroy the transducer if limit values are exceeded.

Eccentric loads can lead to a bending moment load. The bending moment can be calcu

lated by multiplying the applied force by the eccentricity:

Mb= F*e

U9C

MECHANICAL INSTALLATION

14

Fnom Force in direction of measurement, centric

application

Fex Force in direction of measurement, but

applied outside center of force transducer

e Eccentricity, distance between center of

force transducer and an eccentrically applied

force Fex

FQForce applied vertically to direction of

measurement (lateral force)

MbBending moment

MdTorque

Fnom Fex

FQ

Mb

Md

e

Fig. 7.1 Parasitic forces and moments

Notice

During installation and when operating the transducer, please be aware of the maximum

parasitic forces/lateral forces (caused by skewed application), bending moments (caused

by eccentric force introduction) and torques, see Specifications section 10, and the maxi

mum permissible load-carrying capacity of any (customer side) force application parts that

may be used.

Also note the maximum load-carrying capacity of the fittings, tension/compression bars,

bolts and knuckle eyes that are used.

7.3 Installing the U9C

7.3.1 Mounting with tension and compression bars

In this mounting variant, the transducer is mounted on a construction element by means

of tension/compression bars, and can measure tensile and compressive forces. Alternat

ing loads are also correctly recorded if the transducer is mounted without axial play. For

dynamic alternating loads, the upper and lower threaded connectors must be pre-

stressed to above the maximum force to be measured and then locked in place.

15

U9C

MECHANICAL INSTALLATION

1. Installationand locking with initial stress (for dynamic loading):

-Unscrew the locknut and screw on the threaded connector.

-Pre-stress the transducer to 110% operating load in tensile direction. The trans

ducer itself can be used to measure this force

-Hand-tighten the locknut.

-Relieve the load on the transducer.

Notice

If the torque for locking is shunted through the transducer, ensure that the maximum

torque is not exceeded. See specifications.

2. Mounting with locking

Screw on the load application parts and lock with a torque according to the table below.

Notice

As the initial stress also depends on the friction between the locknut and thread, the initial

stress cannot be precisely set correctly with this method. When using the force transducer

under high alternating loads, we therefore recommend installation using method 1 (instal

lation and locking with initial stress).

Nominal (rated) force range Torque

[Nm]

50 N - 1 kN 8

2 kN - 20 kN 40

50 kN 200

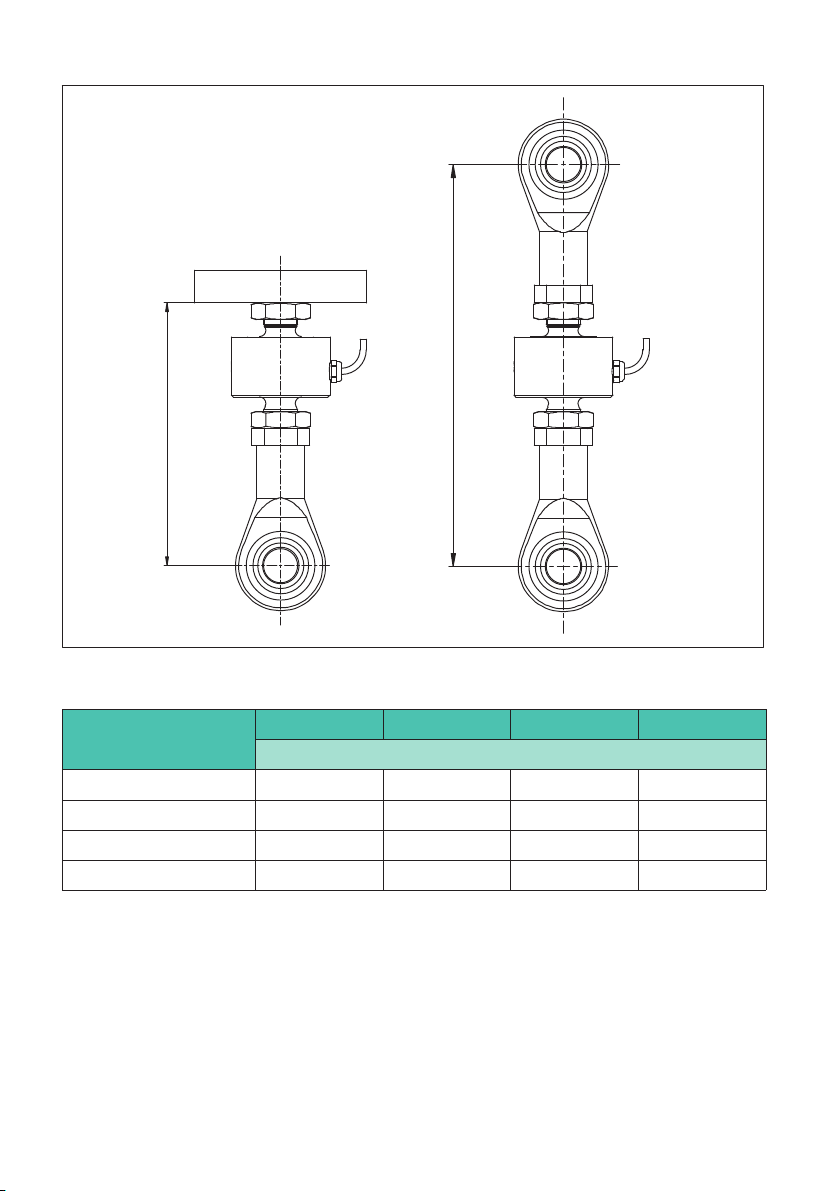

7.3.2 Mounting with knuckle eyes

Knuckle eyes prevent the application of torsional moments and, where two knuckle eyes

are used, bending moments, together with lateral and oblique loads. They are particularly

suitable for static and quasi-static measurements. We recommend tension/compression

bars that are pliable for dynamic alternating loads.

Mounting with knuckle eyes is implemented in the same manner for loads a mounting

with tension/compression bars. Knuckle eyes without locking can be used for static and

quasi-static applications.

U9C

MECHANICAL INSTALLATION

16

b

a

Fig. 7.2 U9C dimensions when using one or two knuckle eyes.

Nominal (rated) force amin amax bmin bmax

mm

50 … 20 N 55 59 82 86

0.5 … 1 kN 56 61 83 88

2 … 20 kN 79 82 122 125

50 kN 116 116 180 180

Tab. 7.1 Mounting dimensions of the U9C when using knuckle eyes

Notes on mounting with knuckle eyes

1. Shaft diameter

When using a sensor with knuckle eyes mounted on one or both sides, make sure that the

shaft is the right size.

17

U9C

MECHANICAL INSTALLATION

You will find the diameters of the knuckle eyes and shafts and their recommended

tolerances in the table below.

Knuckle eyes Nominal

diameter

Hole fitting

size

Recommended shaft

fitting size

1-Z8/100kg/ZGW 5

H7 g6

1-U9/20kg/ZGWR 10

1-U9a/50kg/ZGW 16

Tab. 7.2 Recommended fitting sizes/tolerances for shaft and hole

Customer’s construction

Customer’s shaft holder

Shaft

Play based on recommended fitting

size, see Tab. 7.2, page 17

Threaded connector for mount

ing on force transducers

Fig. 7.3 Example diagram of installation with knuckle eye

CAUTION

If a shaft with an overly small diameter is used, the bearing of the knuckle eye will be sub

jected to linear load. This subjects the inner bearing shell to excessive load, which can lead

to damage and, if forces are high, can cause the knuckle eye bearing to break.

Select the shaft as recommended in the mounting instructions.

U9C

MECHANICAL INSTALLATION

18

2. Distance between knuckle eye and shaft bearing

The shaft support must allow for suitable play between the knuckle eye and the shaft

bearing.

CAUTION

If there is too much distance between the knuckle eye and the shaft bearing, this generates

bending moments in the shaft, causing it to deform.

This deformations put strain on points of the edges of the inner bearing shell, which can

cause the knuckle eye or shaft to suffer damage or break.

Select the play as recommended in the mounting instructions.

To determine the play between the knuckle eye and the shaft bearing, you can apply the

following rule of thumb:

Shaft diameter Play between knuckle eye and bearing

<30 mm 1/10 of the nominal diameter

Tab. 7.3 Play between knuckle eye and shaft bearing

Based on this, recommendations for the play between the knuckle eye and shaft bearing

are as follows:

Knuckle eye Play between knuckle eye and shaft bearing

1-Z8/100kg/ZGW 0.5mm

1-U9/20kg/ZGWR 1mm

1-U9a/50kg/ZGW 1.6mm

Tab. 7.4 Recommendations for play between knuckle eye and shaft bearing

Table of contents

Languages:

Other HBK Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Peter electronic

Peter electronic VersiSafe Speed 27810 Series Assembly instructions

HISAKA

HISAKA UX-005A manual

Group Dynamics

Group Dynamics 2300 Technical manual

SAMES KREMLIN

SAMES KREMLIN REGULEX 5 CC Installation and safety instructions

Numa

Numa Patriot 120 Care & maintenance instructions

Vixen Horns

Vixen Horns VXO8330/4901B installation guide

Datcon

Datcon DT1102 M (PS) operating instructions

Microcanner

Microcanner MC FLEX Operating instructions manual

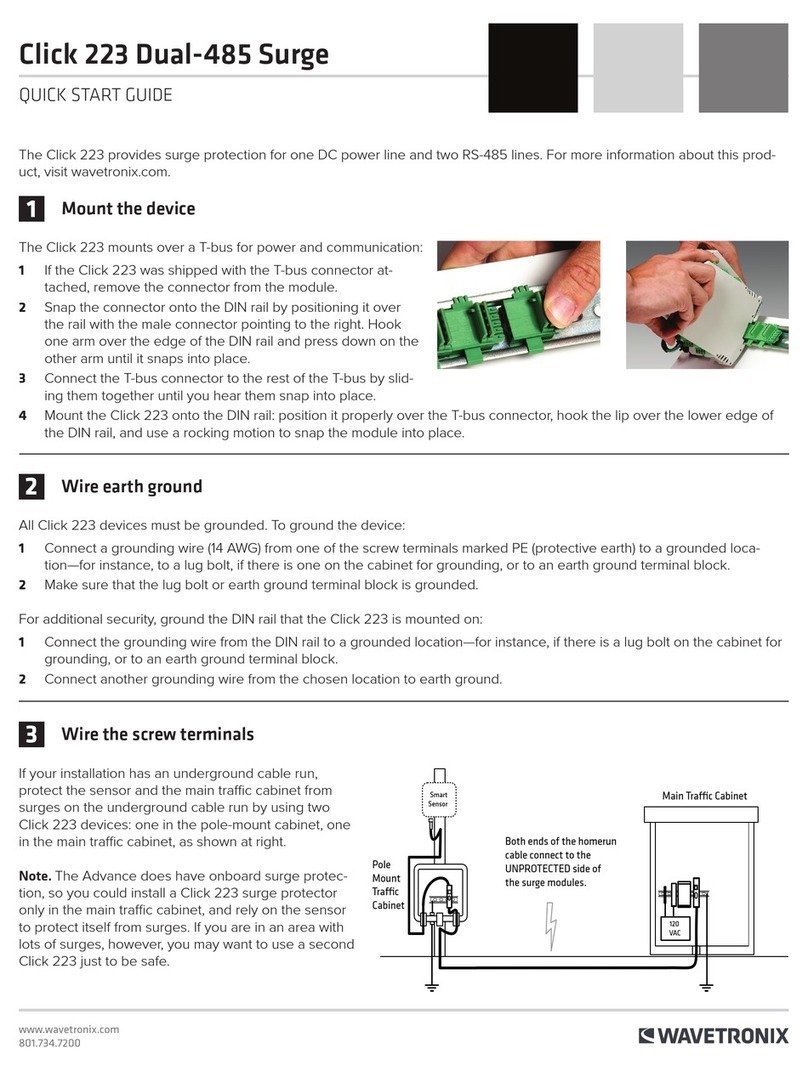

Wavetronix

Wavetronix Click 223 quick start guide

KTR-Group

KTR-Group BoWex M Series Operating & assembly instructions

Fein

Fein AGSZ18-280 BL instruction manual

Moeller

Moeller DILM32-XTE Series installation instructions