HBK U3 User manual

U3

ENGLISH DEUTSCH FRANÇAIS

Mounting Instructions

Montageanleitung

Notice de montage

Hottinger Brüel & Kjaer GmbH

Im Tiefen See 45

D-64293 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbkworld.com

Mat.: 7-2001.2113

DVS: A02113 02 Y00 04

04.2022

EHottinger Brüel & Kjaer GmbH

Subject to modifications.

All product descriptions are for general information

only. They are not to be understood as a guarantee of

quality or durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allge

meiner Form. Sie stellen keine Beschaffenheits- oder

Haltbarkeitsgarantie dar.

Sous réserve de modifications.

Les caractéristiques indiquées ne décrivent nos

produits que sous une forme générale. Elles

n'impliquent aucune garantie de qualité ou de

durabilité.

U3

ENGLISH DEUTSCH FRANÇAIS

Mounting Instructions

U3

TABLE OF CONTENTS

2

TABLE OF CONTENTS

1 Safety instructions 3................................................

2 Markings used 5....................................................

2.1 The markings used in this document 5.................................

2.2 Symbols on the product 5............................................

3 Scope of supply 6...................................................

4 Application information 7............................................

5 Structure and mode of operation 8....................................

5.1 Measuring element 8................................................

5.2 Housing 8.........................................................

6 Conditions on site 9.................................................

6.1 Ambient temperature 9..............................................

6.2 Moisture 9.........................................................

6.3 Deposits 9.........................................................

7 Mechanical installation 10............................................

7.1 Important measures for installation 10..................................

7.2 General installation guidelines 10.......................................

7.3 Installation for tensile loading/compressive loading 11....................

7.3.1 Installation without adapter 11.........................................

7.3.2 Installation with adapter and knuckle eye 12.............................

7.3.3 Installation with two knuckle eyes 14....................................

8 Electrical connection 19..............................................

8.1 Instructions for cabling 19.............................................

9 Specifications (VDI/VDE2638) 21......................................

10 Dimensions 23......................................................

3

U3

SAFETY INSTRUCTIONS

1 SAFETY INSTRUCTIONS

Use in accordance with the regulations

Force transducers in the U3 range are designed for force measurements on test

benches/in press‐fit devices/test devices/pressing. Use for any additional purpose shall

be deemed to be not in accordance with the regulations.

In the interests of safety, the transducer should only be operated as described in the

Mounting Instructions. It is also essential to observe the appropriate legal and safety

regulations for the application concerned during use. The same applies to the use of

accessories.

The transducer is not a safety element within the meaning of its use as intended. Proper

and safe operation of this transducer requires proper transportation, correct storage,

assembly and mounting and careful operation and maintenance.

General dangers due to non‐observance of the safety instructions

The U3 force transducer corresponds to the state of the art and is fail‐safe.

The transducers can give rise to residual dangers if they are inappropriately installed and

operated by untrained personnel.

Everyone involved with the installation, commissioning, maintenance or repair of a force

transducer must have read and understood the Mounting Instructions and in particular

the technical safety instructions.

Residual dangers

The scope of supply and performance of the transducer covers only a small area of force

measurement technique. In addition, equipment planners, installers and operators should

plan, implement and respond to the safety engineering considerations of force measure

ment technique in such a way as to minimise residual dangers. Prevailing regulations

must be complied with at all times. There must be reference to the residual dangers con

nected with force measurement technique.

U3

SAFETY INSTRUCTIONS

4

Conversions and modifications

The transducer must not be modified from the design or safety engineering point of view

except with our express agreement. Any modification shall exclude all liability on our part

for any damage resulting therefrom. Mounting and removing the adapter in accordance

with Chapter 7 excluded.

Qualified personnel

This instrument is only to be installed by qualified personnel strictly in accordance with

the technical data and with the safety rules and regulations which follow. It is also

essential to observe the appropriate legal and safety regulations for the application

concerned. The same applies to the use of accessories.

Qualified personnel means persons entrusted with the installation, fitting, commissioning

and operation of the product who possess the appropriate qualifications for their func

tion.

Conditions on site

Protect the transducer from damp and weather influences such as rain, snow, etc.

Maintenance

The U3 force transducer is maintenance free. We recommend to calibrate the force

transducer at regular intervals.

Accident prevention

Although the specified nominal force in the destructive range is several times the full

scale value, the relevant accident prevention regulations from the trade associations

must be taken into consideration.

5

U3

MARKINGS USED

2 MARKINGS USED

2.1 The markings used in this document

Important instructions for your safety are specifically identified. It is essential to follow

these instructions in order to prevent accidents and damage to property.

Symbol Significance

WARNING This marking warns of a potentially dangerous situ

ation in which failure to comply with safety require

ments can result in death or serious physical injury.

CAUTION This marking warns of a potentially dangerous

situation in which failure to comply with safety

requirements can result in slight or moderate physical

injury.

Notice This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

Important

This marking draws your attention to important in

formation about the product or about handling the

product.

Tip

This marking indicates application tips or other

information that is useful to you.

Information

This marking draws your attention to information

about the product or about handling the product.

Emphasis

See …

Italics are used to emphasize and highlight text and

identify references to sections, diagrams, or external

documents and files.

2.2 Symbols on the product

Statutory marking requirements for waste disposal

National and local regulations regarding the protection of the

environment and recycling of raw materials require old equip

ment to be separated from regular domestic waste for disposal.

For more detailed information on disposal, please contact the

local authorities or the dealer from whom you purchased the

product.

U3

SCOPE OF SUPPLY

6

3 SCOPE OF SUPPLY

S1 U3 force transducer

S1 U3 Mounting Instructions

STest report

Accessories (not included in the scope of supply)

S'Complete adapter' for knuckle eye mounting:

0.5-10 kN Adapter with four M5x12 and four M5x16 screws

Order no. 2-9289.1956

20 kN Adapter with four M10x25 and four M10x30 screws

Order no. 2-9289.1957

50 kN Adapter with eight M10x25 and eight M10x30 screws

Order no. 2-9289.1958

100 kN Adapter with eight M10x25 and eight M10x30 screws each

Property class 12.9. galvanized Order no. 2-9289.2280

SKnuckle eye ZGUW for:

0.5-10 kN Order no. 1-U2A/1 t/ZGUW

20 kN Order no. 1-U2A/2 t/ZGUW

50 kN Order no. 1-U2A/5 t/ZGUW

100 kN Order no. 1-Z4/100 kN/ZGUW

7

U3

APPLICATION INFORMATION

4 APPLICATION INFORMATION

Force transducers of the U3 type series are suitable for measuring tensile and

compressive forces. They measure static and dynamic forces extremely accurately and

therefore require careful handling. You must take particular care when transporting and

installing the devices. If you knock or drop the transducers, this could permanently

damage them.

The housing provides an elaborate seal to protect the sensitive strain gauge applications

and it is essential that this is preserved. You must be particularly careful with the base of

the housing, as this is extremely thin.

The limits for the permissible mechanical thermal and electrical stresses are stated in the

Specifications. It is essential that these are taken into consideration in planning the

measuring set‐up, during installation and finally, during operation.

U3

STRUCTURE AND MODE OF OPERATION

8

5 STRUCTURE AND MODE OF OPERATION

5.1 Measuring element

The measuring element is a measuring spring made from stainless steel, to which strain

gauges (S/G) are applied. The S/Gs are arranged so that four of them can be strained

and the other four compressed when the transducer reacts to a force.

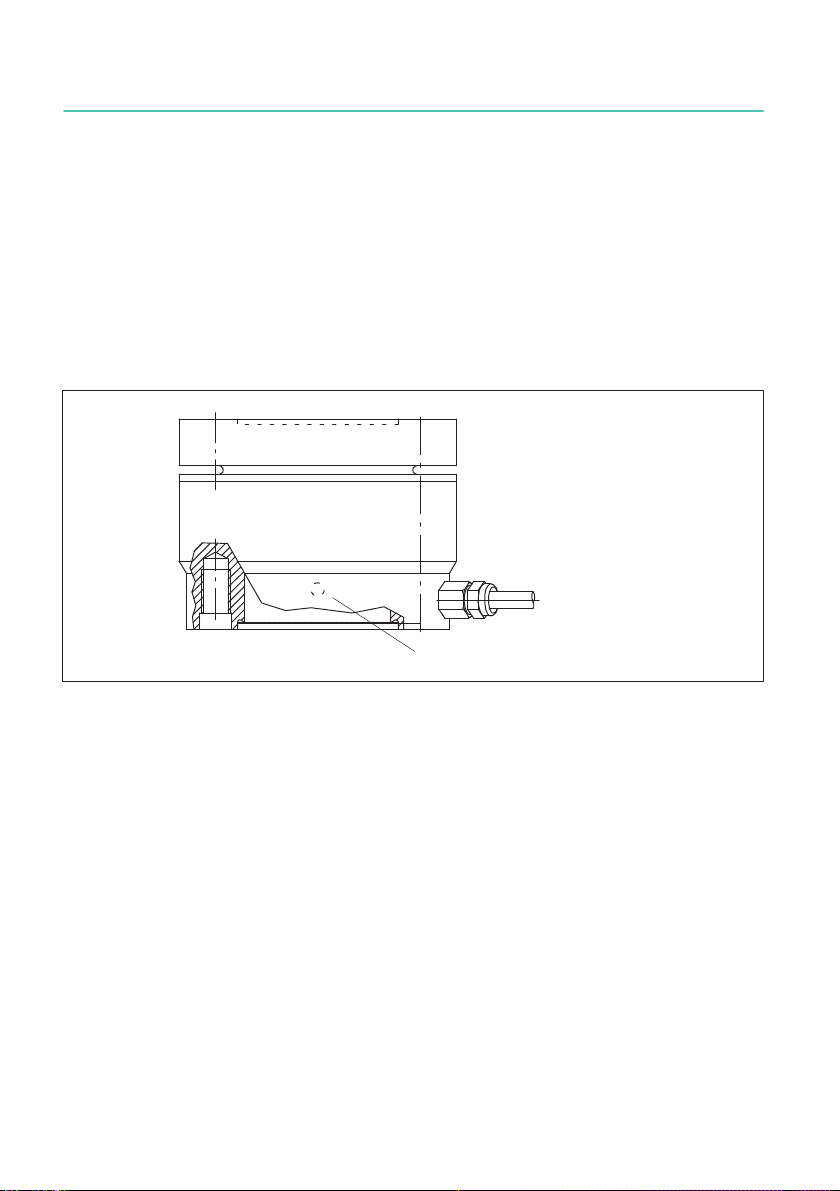

5.2 Housing

The housing with the integrated measuring spring is completed underneath by an

attached base. This base is extremely thin and must not be loaded centrally (see Page

11). It should be protected against mechanical damage.

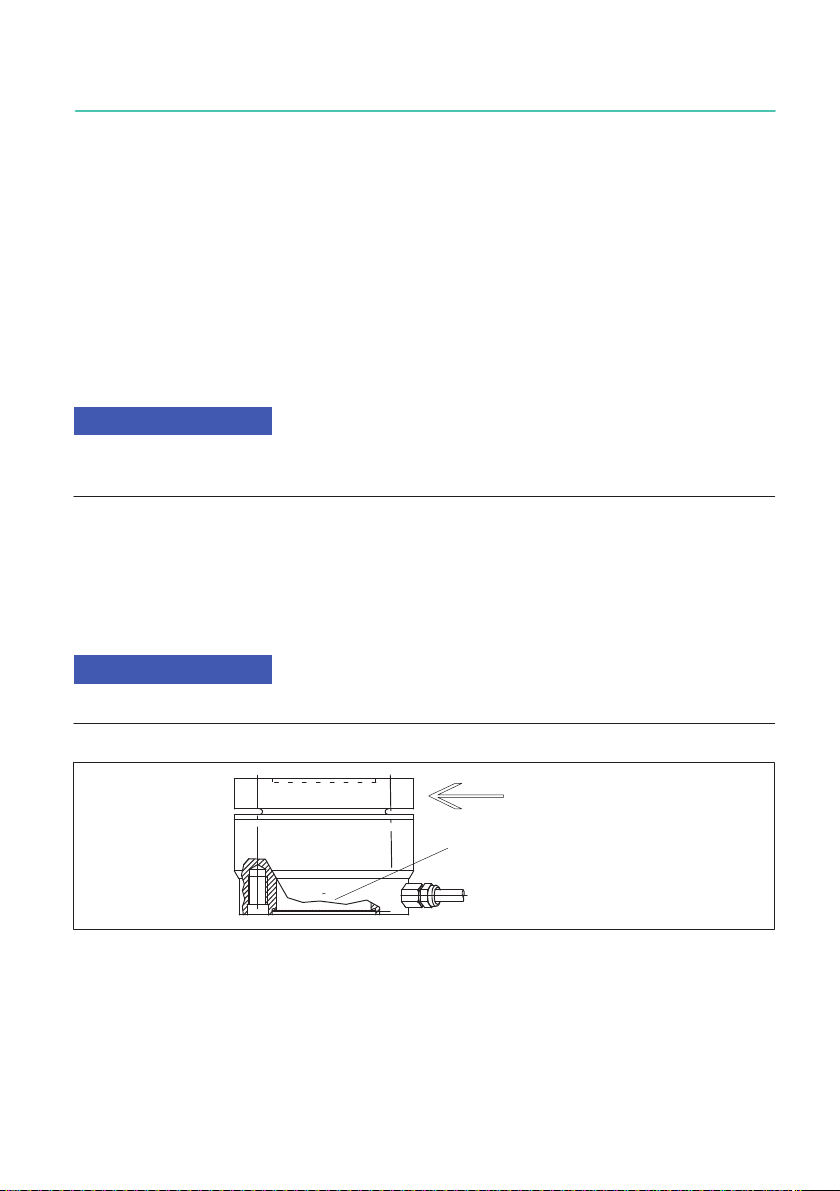

Pressure compensation hole

Fig. 5.1 Position of housing base

9

U3

CONDITIONS ON SITE

6 CONDITIONS ON SITE

6.1 Ambient temperature

The effects of temperature on the zero signal and on the sensitivity are compensated. To

achieve optimal measurement results the nominal temperature range must be main

tained. Temperature‐induced measurement errors are caused by heating (e.g. radiant

heat) or cooling on one side. A radiation barrier and all‐round thermal insulation will pro

duce a marked improvement, but should not form a force shunt.

6.2 Moisture

Extreme humidity or a tropical climate should be avoided if this means that the classified

limit values are exceeded (degree of protection IP65 under DIN EN 60529).

Notice

Moisture must not be allowed to penetrate the free end of the connection cable or get into

the pressure compensation hole.

6.3 Deposits

Dust, dirt and other foreign bodies must not be allowed to accumulate such that they

divert part of the measured force onto the housing and so falsify the measured value

(force shunt).

Notice

Foreign bodies must not be allowed to clog the gap beneath the flange surface.

Pressure compensation hole

U3

MECHANICAL INSTALLATION

10

7 MECHANICAL INSTALLATION

7.1 Important measures for installation

SHandle the transducer with care.

SDo not overload the transducer.

SWelding currents must not be allowed to flow over the transducer. If there is a risk

that this might happen, you must use a suitable low‐ohm connection to electrically

bypass the transducer. HBM, forexample, provides the highly flexible EEK ground

cable, which can be screwed on, both above and below the transducer.

WARNING

If there is a risk of breakage through overload on the transducer and thus a risk to persons,

additional safety measures are to be taken.

7.2 General installation guidelines

The direction of measurement in which the forces work should be as much towards the

transducer as possible. Torsion and bending moments, eccentric loading and transverse

forces may result in measurement errors and if the limit values are exceeded, could

destroy the transducer. The U3 has a centering aid for centric force application. Refer to

the drawing in section 10 "Dimensions", page 23.

The transducer can take up 100 % (80 % at 50 kN, 50 % at 100 kN) of its nominal force as

transverse force by reference to a force introduction point on the force‐introduction

surface (see diagram Fig. 7.1), without losing its mechanical competence.

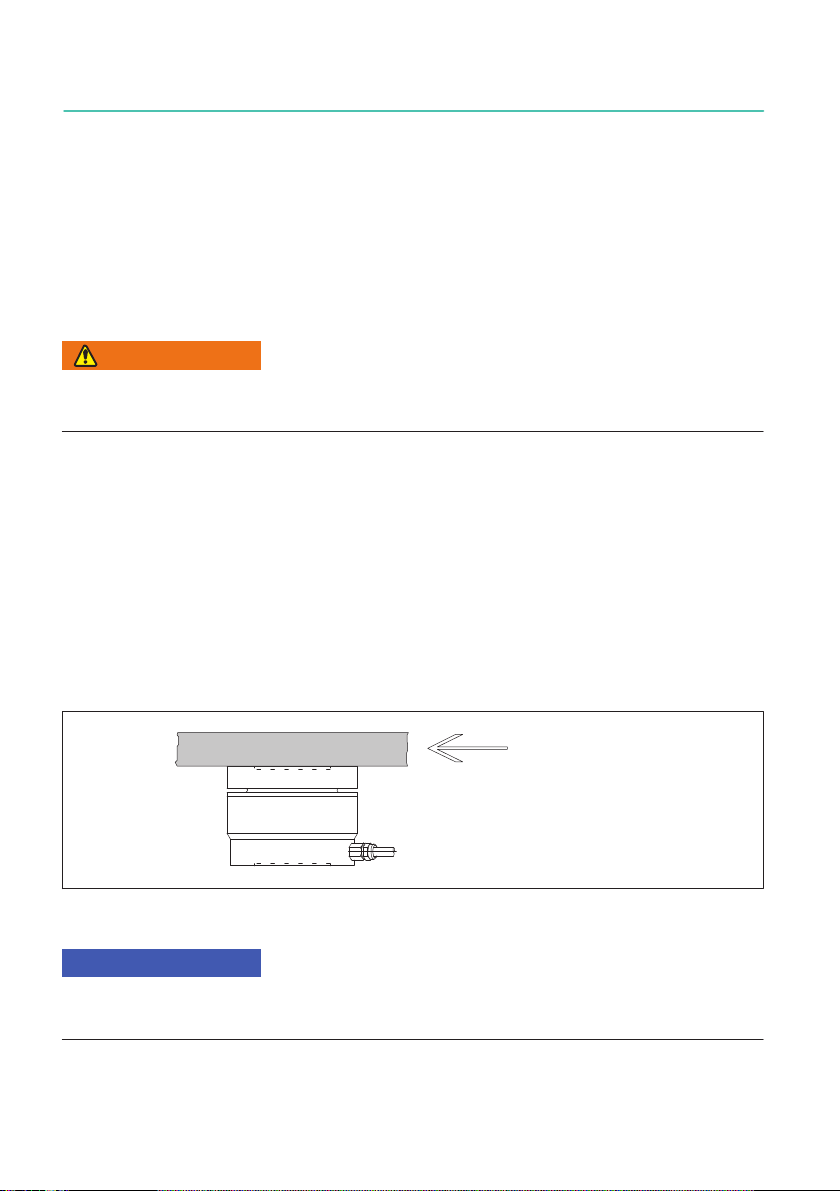

Transverse force

Fig. 7.1 Transverse force introduction

Notice

In the case of transducers of nominal forces 20 kN, 50 kN and 100 kN, the base area is not

flat.

11

U3

MECHANICAL INSTALLATION

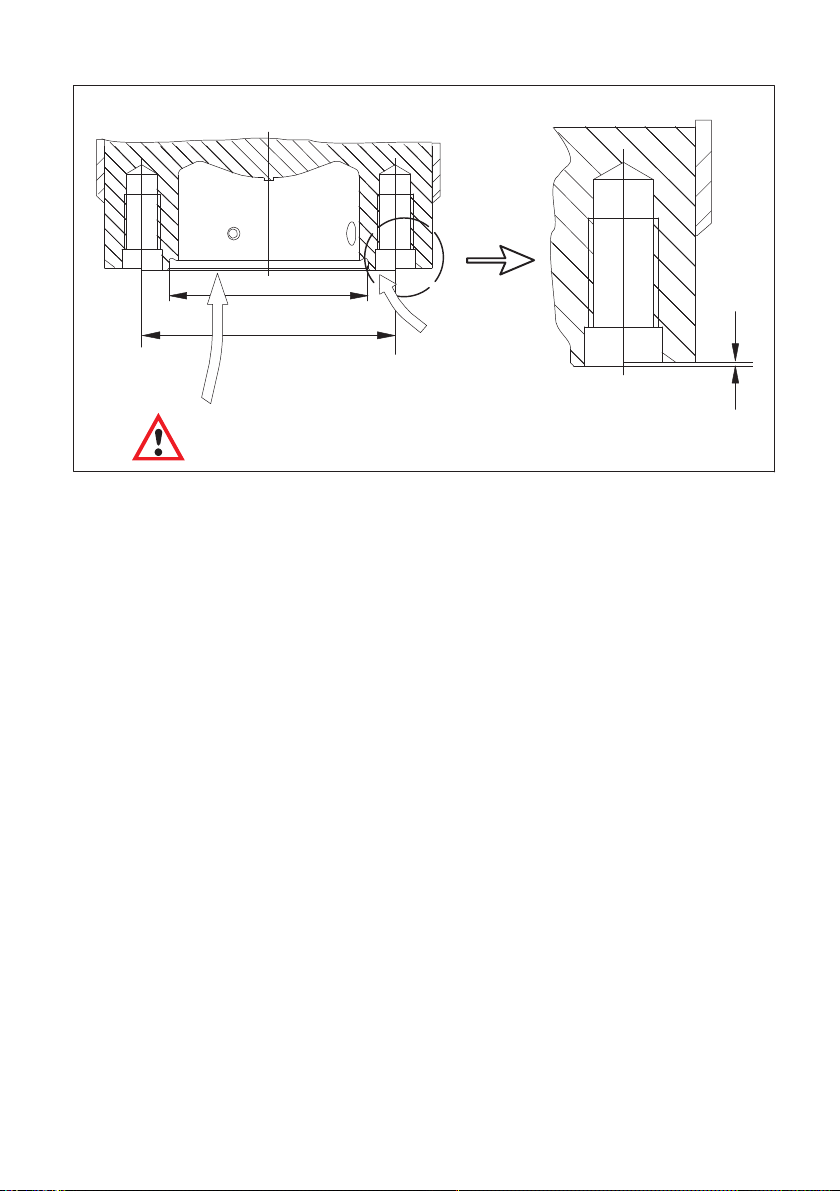

55H8

∅70"0.1 Force must only

be introduced here

0.5

Do not load centrally here.

Center the U3 over diameter 55H8.

Nominal force 20 kN, 50 kN and 100 kN

Fig. 7.2 Base of the U3

7.3 Installation for tensile loading/compressive loading

7.3.1 Installation without adapter

The transducer is screwed directly (by flange or base) on to an existing structural

element (e.g. profile, cover, plate). This type of installation enables the transducers to

measure axial forces in the tensile force and compressive force directions. Alternating

loads can also be recorded perfectly. The transducer must be installed without axial play

for this. For dynamic sustained loading, the top and bottom threaded connectors must be

prestressed by lock nuts to above the maximum load.

U3

MECHANICAL INSTALLATION

12

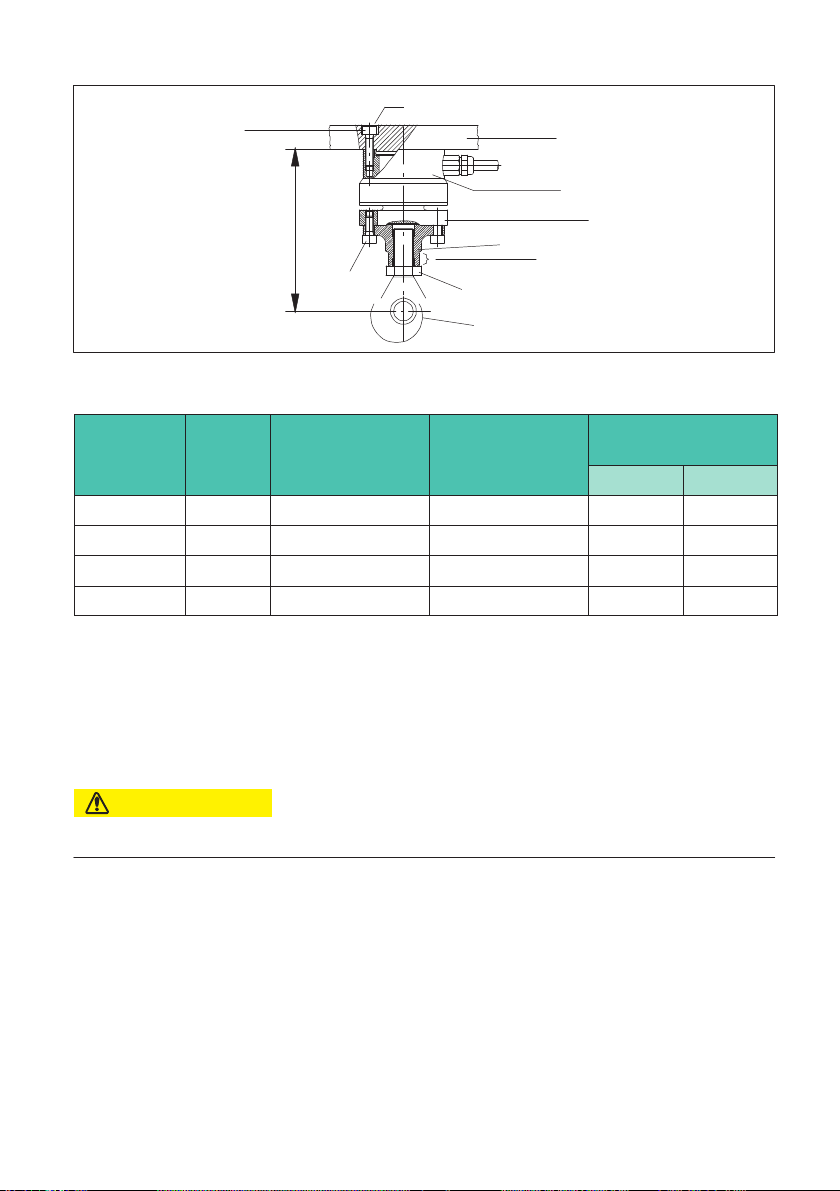

drawing offset

by 45° or 22.5°

MA

MA

provided by customer

provided by customer

Flange

base

Fig. 7.3 Installation for compressive loading

Nominal force (kN) Starting torque MA(NVm) Thread1)

0.5 - 10 54 x M5

20 40 4 x M10

50 40 8 x M10

100 94 8 x M10 2)

1) Take note of the thread depth (see Dimensions, Page 23)

2) 12.9 DIN912 galvanized

HBM supplies knuckle eyes as mounting accessories for transducers of the U3 type

series. Knuckle eyes are suitable for use during quasi‐static loading (10 Hz alternating

loads). In the case of dynamic loading at a higher frequency, you should use flexible

tension bars. Knuckle eyes prevent the introduction of torsional moments and when 2

knuckle eyes are used, stop bending moments and transverse and angular loading being

introduced in the transducers.

7.3.2 Installation with adapter and knuckle eye

If the transducer is to be tensile force loaded, it can be mounted with an adapter (HBM

accessory) and a knuckle eye. There is a center hole (34H8 mm or 55H8 mm, effective

depth approx. 1 mm) on both sides of the transducer.

13

U3

MECHANICAL INSTALLATION

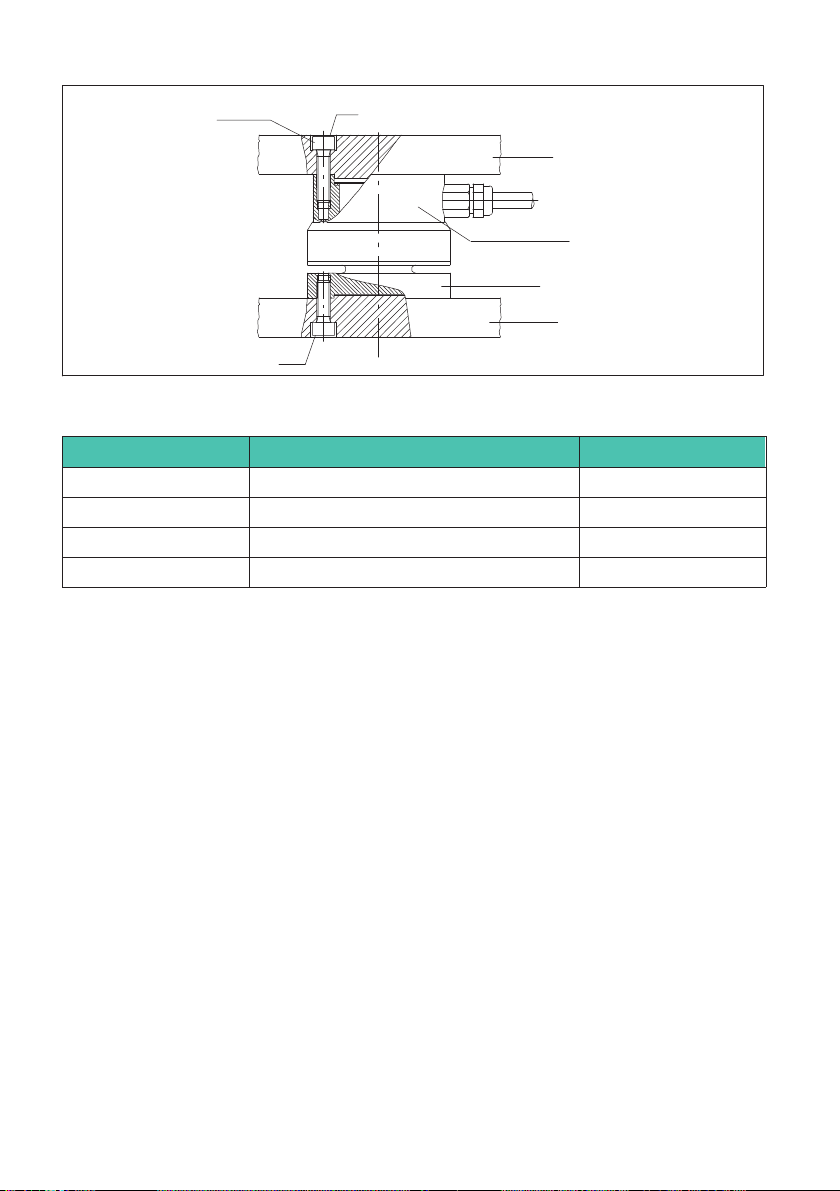

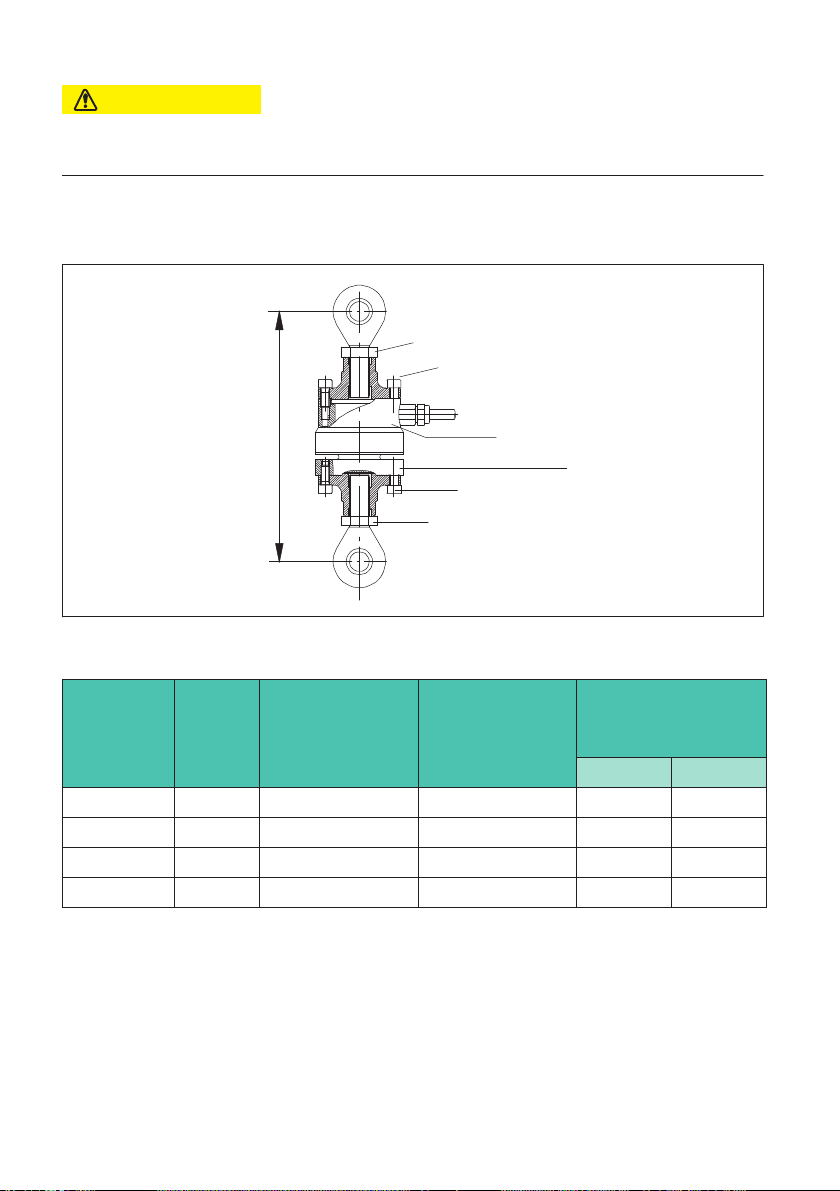

H

drawing offset

by 45° or 22.5°

M2 (MA)

provided by customer

lock nut, MB

ZGUW/1 - 5T/100 kN

M1 (MA)

adapter

flat

base

flange

Fig. 7.4 Installation for tensile loading

Nominal

force (kN)

HMax

(mm)

Starting torque

MA(NVm)

Starting torque

MB(NVm)

Screws for adapter

mounting

M1 M2

0.5 - 10 108 5 60 M5x12 M5

20 170 40 300 M10x25 M10

50 180 40 500 M10x25 M10

100 187 94 1000 M10x25 M10

Attaching the knuckle eye

SScrew the correct adapter (dependent on nominal force!) to the U3 (please note screw

length, screw quality A2-70, at 100 kN. 12.9 DIN912, galvanized)

STurn the lock nut back as far as the eye

SScrew the knuckle eye into the adapter as far as the stop

CAUTION

Do not apply force to the transducer flange.

SUnscrew knuckle eye 1 to 2 turns and align

SLoad eye with nominal load

STighten lock nut (MB, lock using the flat of the adapter)

U3

MECHANICAL INSTALLATION

14

CAUTION

When locking with the lock nut, under no circumstances let the torque be transmitted

through the transducer.

7.3.3 Installation with two knuckle eyes

H

M2 (MA)

MB

MB

M1 (MA)

base

flange

Fig. 7.5 Installation for tensile loading with two knuckle eyes

Nominal

force (kN)

H (mm) Starting torque

MA(NVm)

Starting torque

MB(NVm)

Screws for adapter

mounting

M1 M2

0.5 - 10 153 5 60 M5x12 M5x16

20 232 40 300 M10x25 M10x30

50 256 40 500 M10x25 M10x30

100 300 94 1000 M10x25 M10x30

Attaching the knuckle eye

SScrew the correct adapter (dependent on nominal force!) to the U3 (please note screw

length)

STurn the lock nut back as far as the eye

SScrew the knuckle eye into the adapter as far as the stop

15

U3

MECHANICAL INSTALLATION

CAUTION

Do not apply force to the transducer flange.

SUnscrew knuckle eye 1 to 2 turns and align

SLoad eye with nominal load

STighten lock nut (MB, lock using the flat of the adapter)

CAUTION

When locking with the lock nut, under no circumstances let the torque be transmitted

through the transducer.

Notes on mounting with two knuckle eyes

1. Shaft diameter

When using a sensor with knuckle eyes mounted on one or both sides, make sure that the

shaft is the right size.

You will find the diameters of the knuckle eyes and shafts and their recommended

tolerances in the table below.

Knuckle eyes Nominal

diameter

Hole fitting

size

Recommended shaft

fitting size

1-U2A/1t/ZGUW 12

H7 g6

1-U2A/2t/ZGUW 20

1-U2A/5t/ZGUW 25

1-Z4/100kN/ZGUW 30

Tab. 7.1 Recommended fitting sizes/tolerances for shaft and hole

U3

MECHANICAL INSTALLATION

16

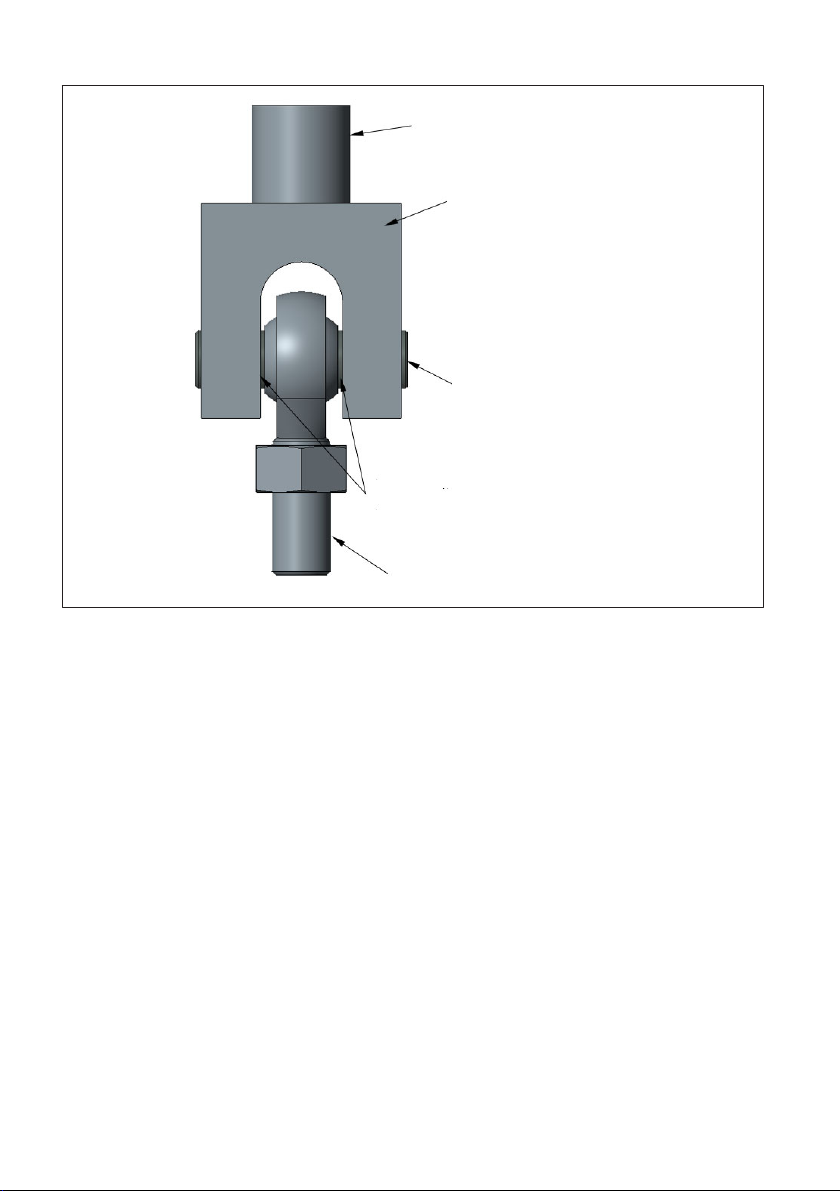

Customer's construction

Customer's shaft holder

Shaft

Play based on recommended fitting

size, see Tab. 7.1, page 15

Threaded connector for mounting

on force transducers

Fig. 7.6 Example diagram of installation with knuckle eye

CAUTION

If a shaft with an overly small diameter is used, the bearing of the knuckle eye will be

subjected to linear load. This subjects the inner bearing shell to excessive load, which can

lead to damage and, if forces are high, can cause the knuckle eye bearing to break.

Select the shaft as recommended in the mounting instructions.

2. Distance between knuckle eye and shaft bearing

The shaft support must allow for suitable play between the knuckle eye and the shaft

bearing.

17

U3

MECHANICAL INSTALLATION

CAUTION

If there is too much distance between the knuckle eye and the shaft bearing, this generates

bending moments in the shaft, causing it to deform.

This deformation puts strain on points of the edges of the inner bearing shell, which can

cause the knuckle eye or shaft to suffer damage or break.

Select the play as recommended in the mounting instructions.

To determine the play between the knuckle eye and the shaft bearing, you can apply the

following rule of thumb:

Shaft diameter Play between knuckle eye and bearing

≤30mm 1/10 of the nominal diameter

Tab. 7.2 Rule of thumb for determining play between knuckle eye and shaft bearing

Based on this, recommendations for the play between the knuckle eye and shaft bearing

are as follows:

Knuckle eye Play between knuckle eye and shaft bearing

1-U2A/1t/ZGUW 1.2mm

1-U2A/2t/ZGUW 2mm

1-U2A/5t/ZGUW 2.5mm

1-Z4/100kN/ZGUW 3mm

Tab. 7.3 Recommendations for play between knuckle eye and shaft bearing

U3

MECHANICAL INSTALLATION

18

Customer's construction

Customer's shaft holder

Recommended play,

see Tab. 7.3, page 17

Threaded connector for mounting

on force transducers

Shaft

Fig. 7.7 Example diagram of installation with knuckle eye

3. Shaft surface quality and hardness

The recommended surface roughness is ≤10 μm.

The shaft must have a minimum hardness of 50 HRC.

Table of contents

Languages:

Other HBK Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ASTEC

ASTEC JCI LS Series Operation and Service Manual and Parts Book

Bomar

Bomar Extend Series operating instructions

R&M

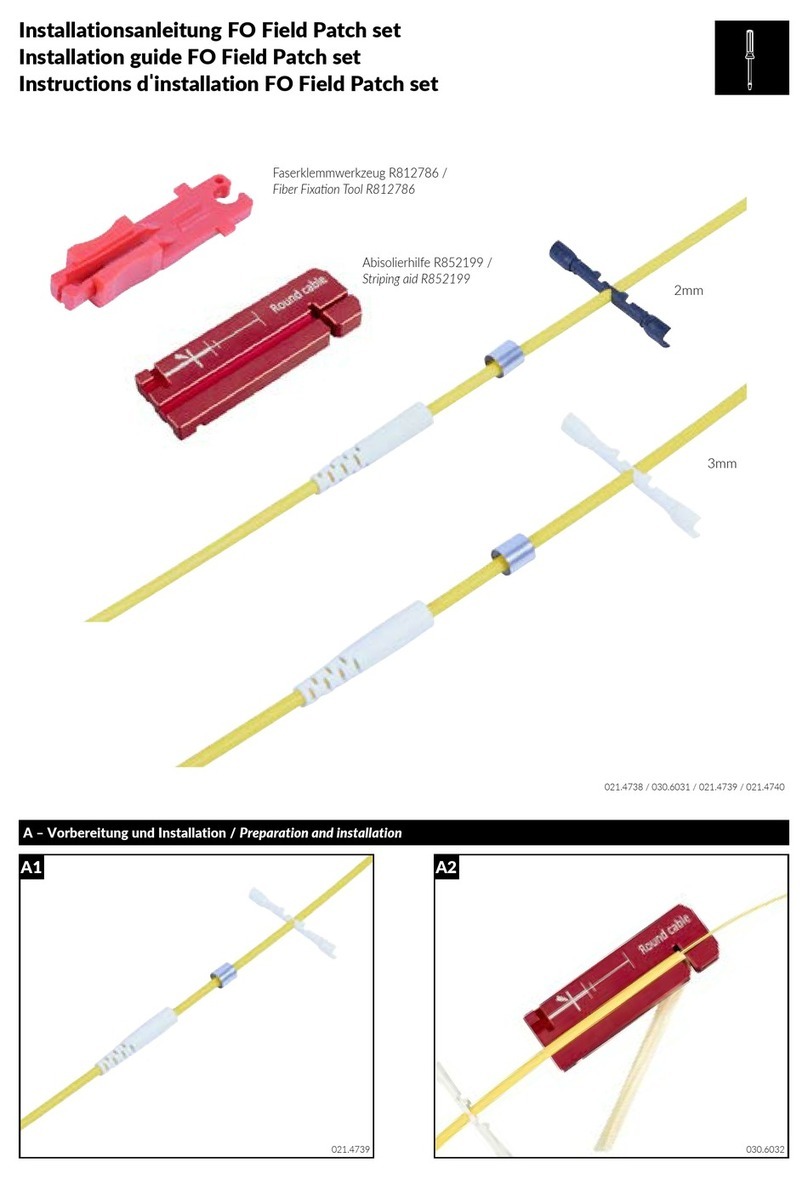

R&M FO Field Patch set installation guide

schmersal

schmersal MZM 100 AS operating instructions

PCB Piezotronics

PCB Piezotronics ICP 320C15 Installation and operating manual

Toro

Toro 110-5076 installation instructions

WALTERSCHEID

WALTERSCHEID FK96 Repair instructions

FLO-DYNAMICS

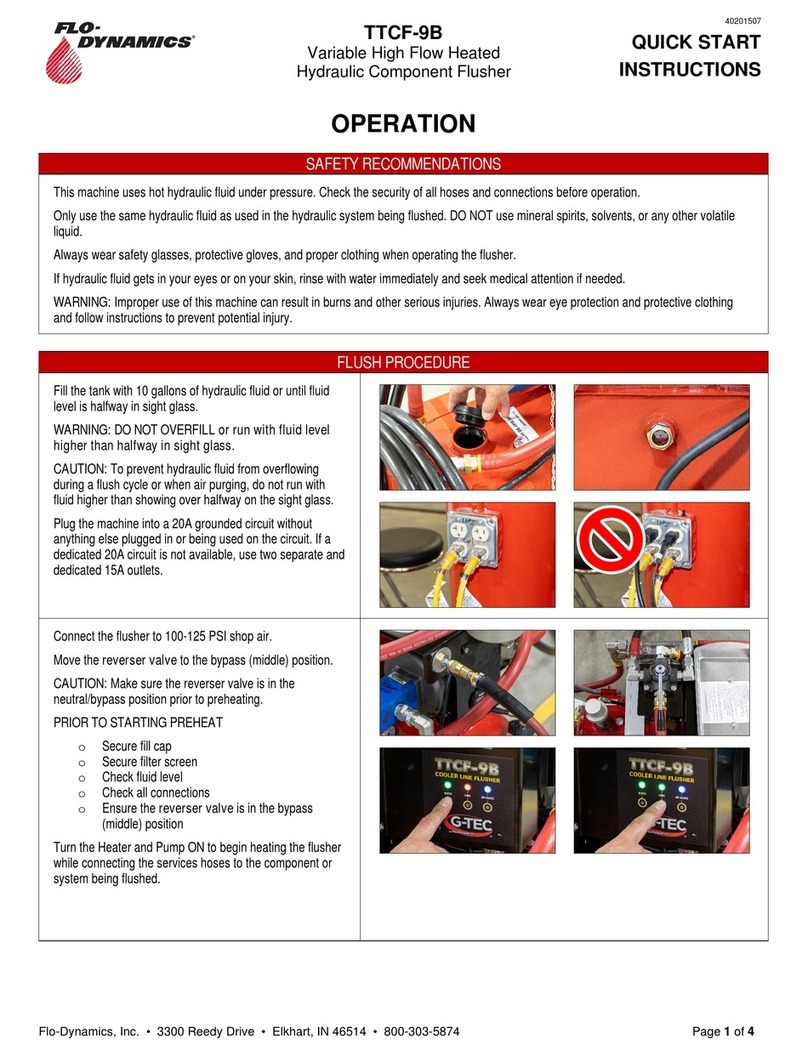

FLO-DYNAMICS TTCF-9B Quick start instructions

Aerotech

Aerotech HexGen HEX500-350HL Hardware manual

TriangleTube

TriangleTube MAXI-FLO MF 350 PT Series Installation and maintenance manual

Pronomic

Pronomic Squeeze&Turn 19472 user manual

MIYAWAKI

MIYAWAKI AG11 user manual