HBK PMX User manual

PMX

ENGLISH DEUTSCH

Quick Start Guide

Kurzanleitung

Hottinger Brüel & Kjaer GmbH

Im Tiefen See 45

D-64293 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbkworld.com

Mat.: 7-2001.3259

DVS: A03259 05 X00 02

04.2023

EHottinger Brüel & Kjaer GmbH

Subject to modifications.

All product descriptions are for general information

only. They are not to be understood as a guarantee of

quality or durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allge

meiner Form. Sie stellen keine Beschaffenheits- oder

Haltbarkeitsgarantie dar.

PMX

ENGLISH DEUTSCH

Quick Start Guide

PMX

TABLE OF CONTENTS

2

TABLE OF CONTENTS

1 Safety instructions 3................................................

2 Purpose of the manual 3.............................................

3 Symbols on the device 4.............................................

4 Mounting/Dismounting/Replacing 5...................................

4.1 Assembly tools and tightening torques 5...............................

4.2 Support rail mounting 6..............................................

4.3 Mounting the wall bracket 9..........................................

4.4 Installing cable fastening plates (optional) 11............................

5 Quick start 12.......................................................

5.1 Preparing the measurement system 12..................................

5.1.1 Connecting transducers 12............................................

5.1.2 Connecting the power supply 15........................................

5.1.3 Connecting to a PC 15................................................

5.1.4 Configuring the PMX 17...............................................

5.2 Typical operating sequence (measurement example) 18...................

5.3 Firmware update 23..................................................

3

PMX

SAFETY INSTRUCTIONS

1 SAFETY INSTRUCTIONS

Important

Please follow the safety instructions in the PMX Operating Manual and in the separate

"Safety Instructions" document (enclosed with the device).

2 PURPOSE OF THE MANUAL

This Quick Start Guide sets out the key points when mounting a PMX device and connect

ing it to a PC, making it easy for you to start gathering measurement results with your

PMX.

It also provides a concrete example of setup with commonly used transducer types.

Important

This Quick Start Guide does not replace the detailed PMX Operating Manual.

The information provided in this Quick Start Guide is expanded on in greater detail in:

Sthe Operating Manual for the PMX Measuring Amplifier System

Sthe PMX web server online Help

PMX

SYMBOLS ON THE DEVICE

4

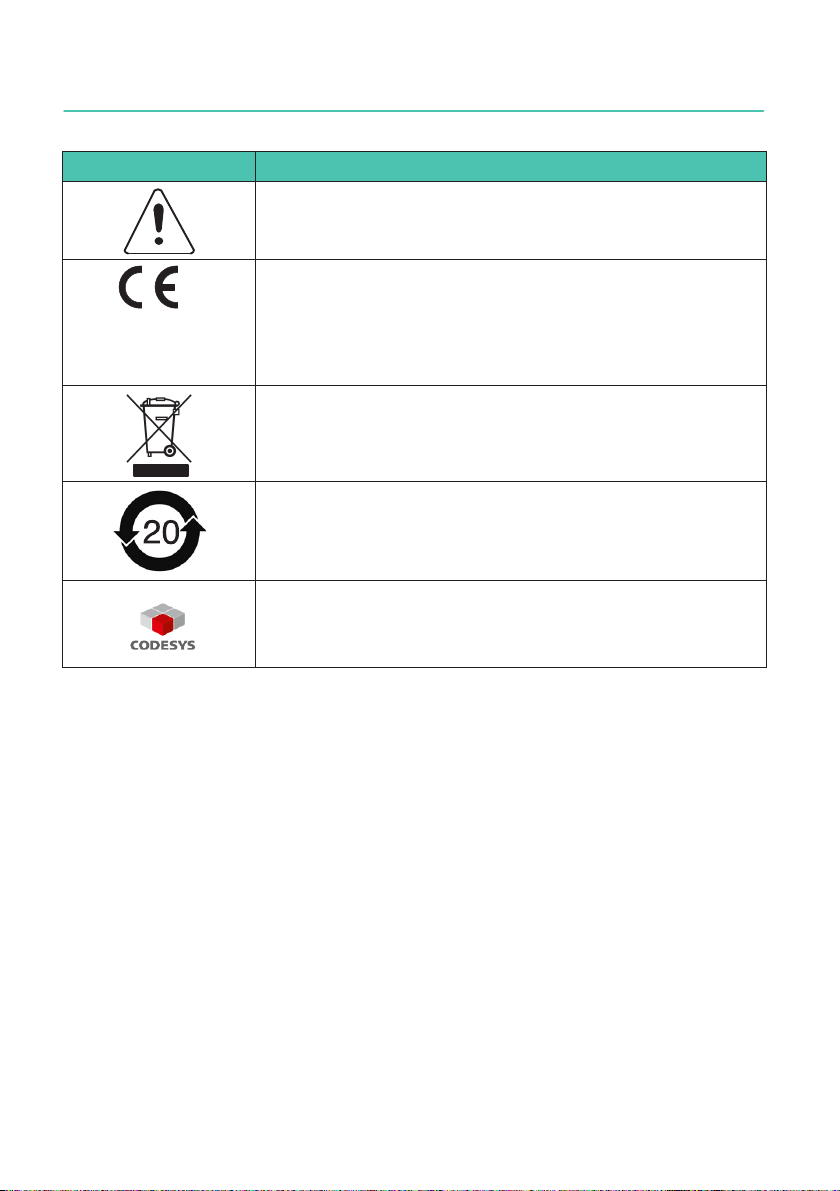

3 SYMBOLS ON THE DEVICE

Symbol Meaning

The supply voltage must be between 10 and 30VDC.

Read and follow the instructions given in the operating

manual.

CE mark

With the CE mark, the manufacturer guarantees that the prod

uct complies with the requirements of the relevant EC direc

tives (the Declaration of Conformity can be found on the HBM

website HBM www.hbm.com under HBMdoc).

Statutory waste disposal mark

Statutory marking of compliance with emission limits in

electronic equipment supplied to China

CODESYS is a software platform for programmable logic

controllers. The license for CODESYS is already implemented

in WG001 basic housings.

5

PMX

MOUNTING/DISMOUNTING/REPLACING

4 MOUNTING/DISMOUNTING/REPLACING

4.1 Assembly tools and tightening torques

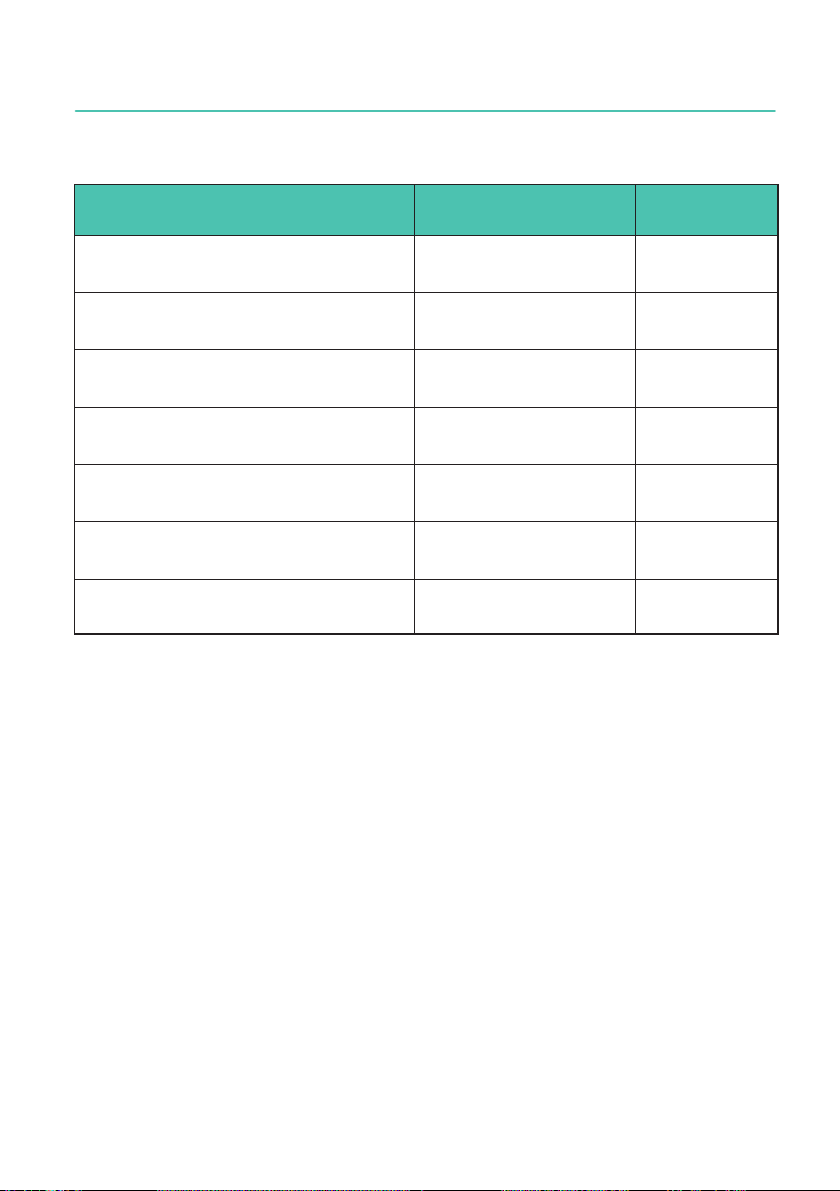

Mounting Required tool Tightening

torque

Fastening the rail clip to the support rail

M 5 hexagon socket screw

Hexagon socket wrench

a.f. 2.5 1.0 … 1.2Nm

Fastening the DIN rail clip to the housing

M 5 hexagon socket screw

Hexagon socket wrench

a.f. 3 3Nm

Fastening the plug-in card

Torx screws M2.5

Torx screwdriver

TX8 0.5 … 0.6Nm

Fastening the wall mount kit

M 4 hexagon socket screw

Hexagon socket wrench

a.f. 3 1.5 … 2Nm

Fastening the side panels

M3 Torx screws

Torx screwdriver

TX10 0.8 … 1Nm

Grounding screw on the PMX

M4 Torx screws

Torx screwdriver

TX20 1.5 … 2Nm

Cable fastening plates

M4 hexagon socket screw

Hexagon socket wrench

a.f. 3 1.5 … 2Nm

PMX

MOUNTING/DISMOUNTING/REPLACING

6

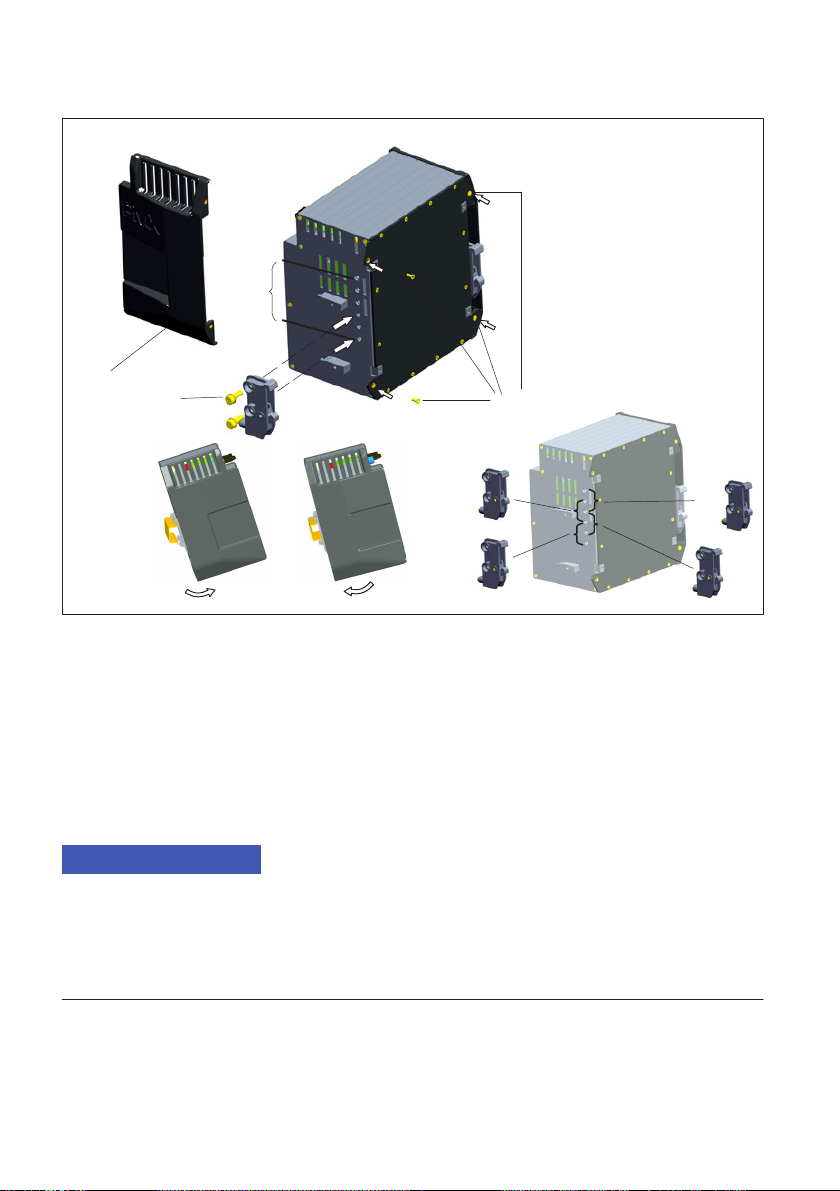

4.2 Support rail mounting

1

2

3

4

Hexagon

socket screw

a.f. 3 mm

75 mm

3

B

A

C

D

Fig. 4.1 Mounting on a support rail

1. Loosen the four rear panel screws (Torx Tx10) (1).

2. Push the side panels forward (2).

3. Screw on the support rail mounting (3) (about 5Nm). Four positions (Ato D) are op

tionally possible (two positions for 7.5 mm rail).

4. Screw the side panels (2) back on.

5. Attach the PMX to the support rail (4).

Notice

Device damage by dropping the PMX due to difficulty of attaching/detaching the PMX.

HBM recommends using a DIN support rail (DIN EN 60715) with a height of 15 mm. When

using a smaller support rail (7.5 mm high), it should be packed, to make it easy to attach/

detach the PMX.

The 7.5 mm support rail can only be used in the top two positions (A and B).

7

PMX

MOUNTING/DISMOUNTING/REPLACING

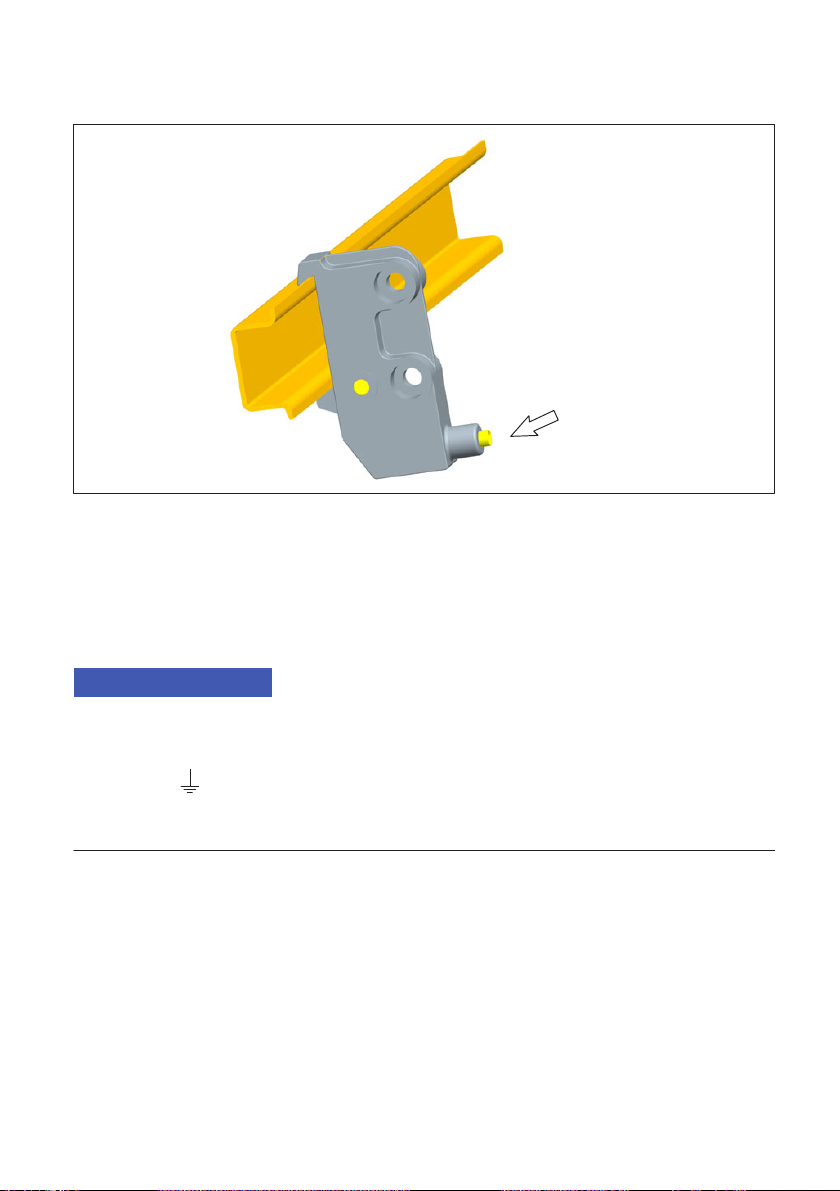

Fastening the support rail mounting (rail clip) to the support rail

Hexagon socket

screw

a.f. 2.5 mm

Fig. 4.2 Fastening the rail clip

On delivery, the self-locking (2.5 mm) hexagon socket screws are unscrewed as far as

the stop.

uClamp on the support rail mounting (rail clip).

uHand-tighten the self-locking hexagon socket screw.

Notice

Device damage caused by electromagnetic irradiation of external devices. Faulty measure

ments due to electromagnetic irradiation from other devices.

To ensure sufficient grounding of the PMX, the support rail must be connected to func

tional ground .

Both the support rail and the PMX must be free of paint and dirt at the mounting location.

uConnect the PMX housing to ground via the grounding screw.

PMX

MOUNTING/DISMOUNTING/REPLACING

8

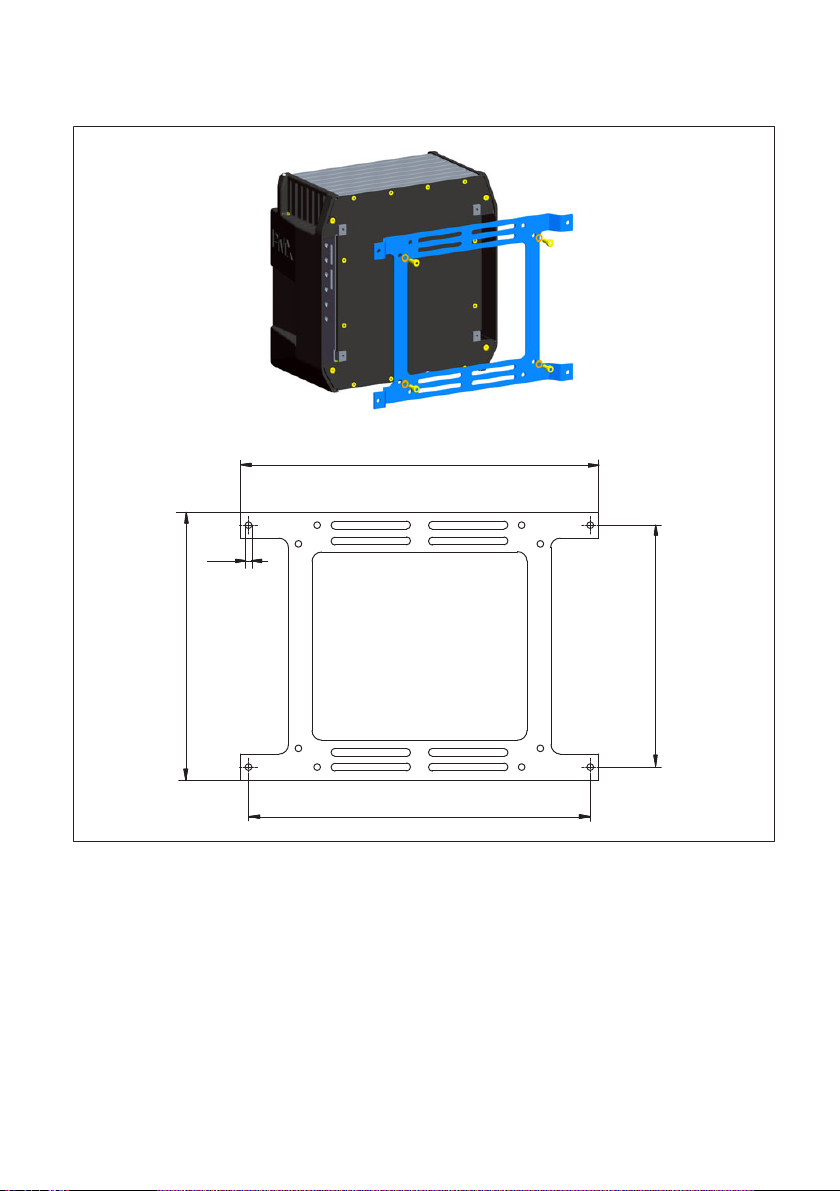

Dimensions and mounting instructions

200

141

200

122

variable

141*)

min. 25***)

133.5**)

*) Height of support rail 15 mm

**) Height of support rail 7.5 mm

***) Min. dimension: Plug plus sensor cable

NOTE:

To ensure sufficient ventilation/cooling, a 2 cm gap must be maintained above and below

neighboring devices. Dimensions in mm.

Fig. 4.3 Dimensions

9

PMX

MOUNTING/DISMOUNTING/REPLACING

4.3 Mounting the wall bracket

1

225

215

152

4.3

168.5

Dimensions in mm

Fig. 4.4 Mounting on a wall

1. Attach the wall bracket to the back of the PMX by the supplied M4 screws (1).

PMX

MOUNTING/DISMOUNTING/REPLACING

10

Screw

M4

Screw

M4

Screw

M4

Screw

M4

Grounding screw

(Torx TX20)

Fig. 4.5 Wall-mounting

2. Screw the complete unit to the wall. The hole diameter is 4 mm.

Notice

Device damage caused by electromagnetic irradiation of external devices. Faulty measure

ments due to electromagnetic irradiation from other devices.

The housing must also be connected to functional ground when wall-mounted .

uConnect the PMX housing to ground via the grounding screw.

11

PMX

MOUNTING/DISMOUNTING/REPLACING

4.4 Installing cable fastening plates (optional)

Fig. 4.6 PMX with cable holder

To ensure that cables running from and to the PMX are fastened securely and reliably, an

optional plate can be secured to the top and bottom of the PMX mainframe to fasten the

cables using two M4 hexagon socket screws for each plate.

Holes in the plate can be used to fasten the cables using cable ties.

200

250

158

23 28

25

15°

2

122

Dimensions in mm

PMX

QUICK START

12

5 QUICK START

5.1 Preparing the measurement system

5.1.1 Connecting transducers

All PMX plug-in cards (PX401, PX455, PX460, PX878) are supplied as standard with easy-

fit push-in plug terminals. But you can also obtain screw-type terminals from Phoenix

Contact (www.phoenixcontact.com

).

The clamping area is 0.2mm2(AWG24) to 1.5mm2(AWG16). If you need to connect

multiple wires to one terminal, adapt the wire cross-sections accordingly. Use 10mm

wire end ferrules (without plastic collars) to connect the wires to the terminals wherever

possible.

Notice

The plug terminals are not interchangeable ex factory. Depending on the sensor type, plug

connection errors can damage the plug-in card.

Use the supplied coding pins to prevent interchanging.

The plug terminals can be protected by coding pins against interchanging. To do this,

insert a coding pin fully into one of the slots in the device sockets and snap it off from the

holder - see Fig. 5.1. Use a different slot for each plug terminal and transducer type. You

can also use more than one coding pin for one plug terminal.

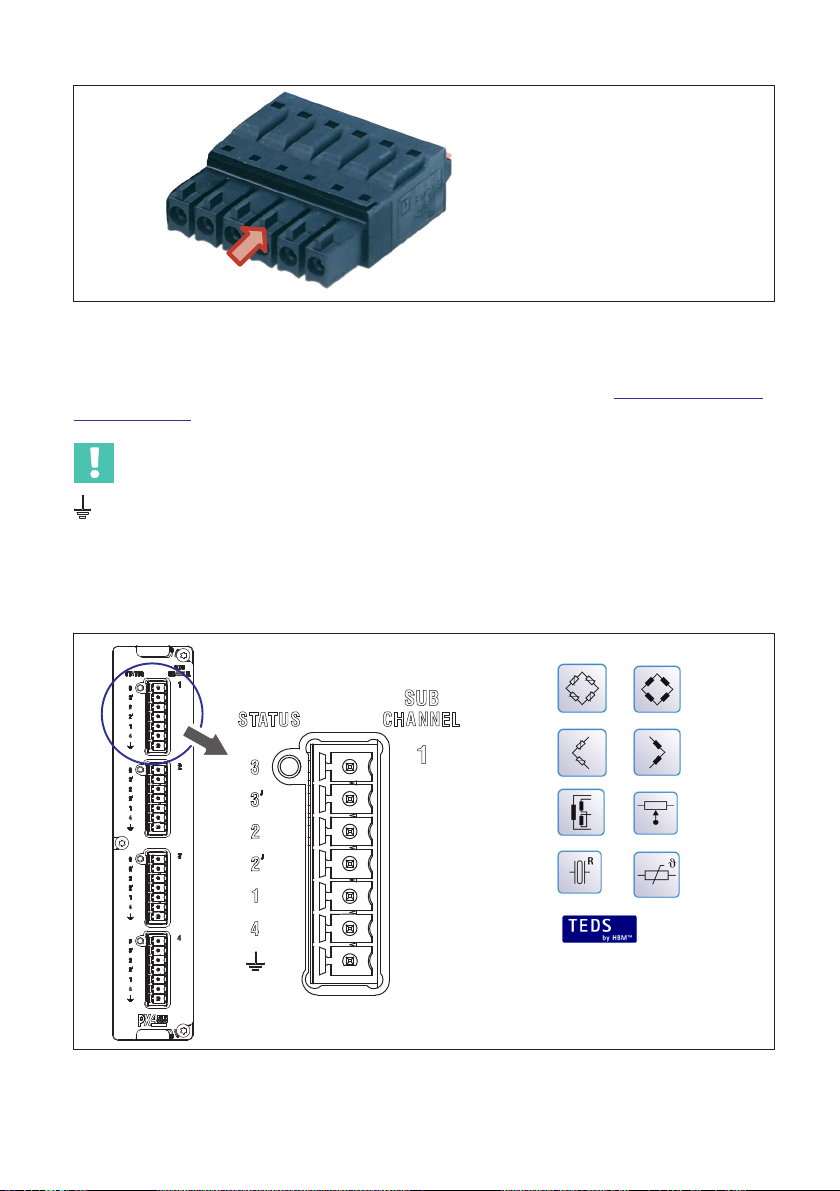

Fig. 5.1 Coding pin 90% inserted

Remove the lug on the corresponding plug terminal connector, using a knife for example

(Fig. 5.2).

13

PMX

QUICK START

Fig. 5.2 Lug (arrow) on a plug terminal (zoomed view)

Attach the shield of the transducer cable to the ground connection provided on the PMX's

multipoint connector, in accordance with HBM Greenline information https://www.hbm.

com/Greenline.

Important

The ground terminal on the PMX is not a protective ground (connection optional).

The measurement system features automatic current limitation for each device card and

for the PMX basic device.

Connect your transducers to the measurement cards (plug terminals).

Zero-wire TEDS

PMX

QUICK START

14

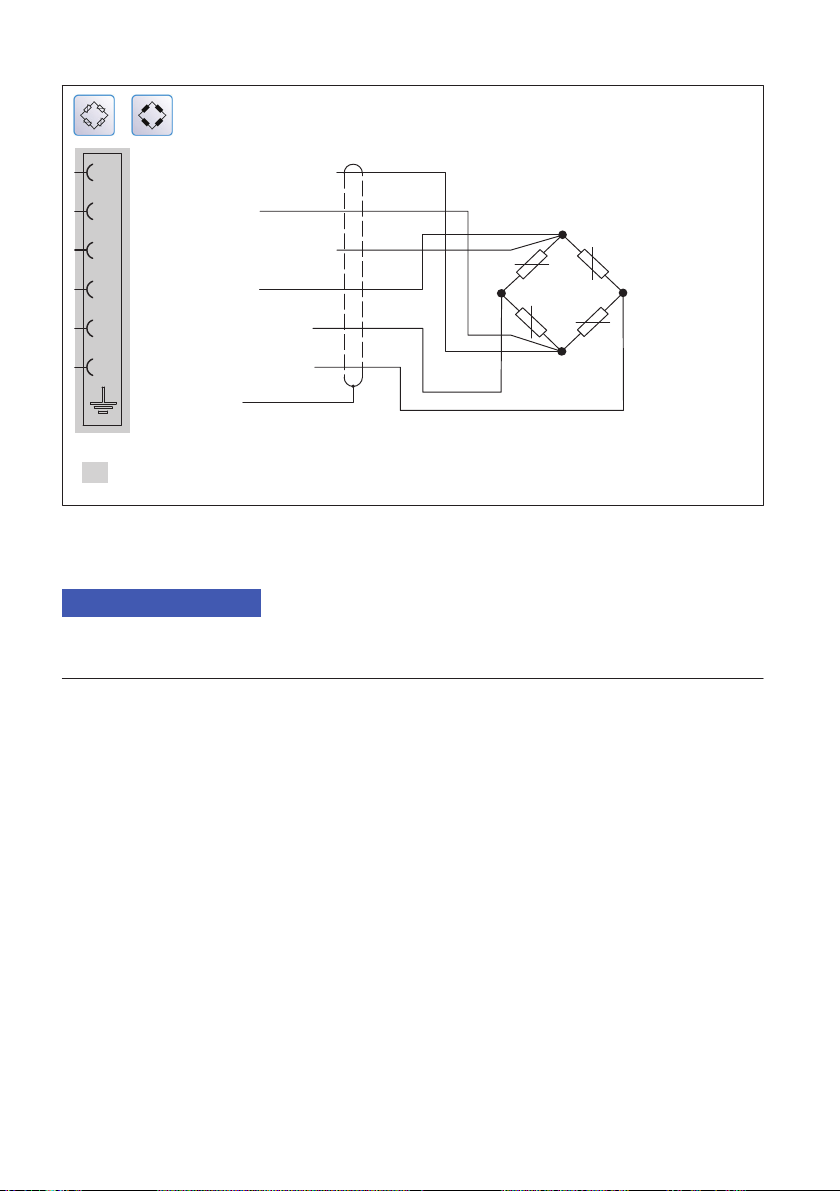

Measurement signal +

Sense lead *

Bridge excitation voltage +

Sense lead +

Bridge excitation voltage *

Cable shield

Measurement signal *3

2

14

rd

wh

gr

bk

gn

bl

1

2'

3

3'

2

4

Cable color codes for HBM transducer cables:

wh= white; bk= black; bl= blue; rd= red; gn= green; gy= gray

Transducer connection

plug terminal

Fig. 5.3 PX455 pin assignment in 6-wire circuit, based on the example of a force

transducer

Notice

The transducers can also be connected if you have previously connected the voltage

supply.

15

PMX

QUICK START

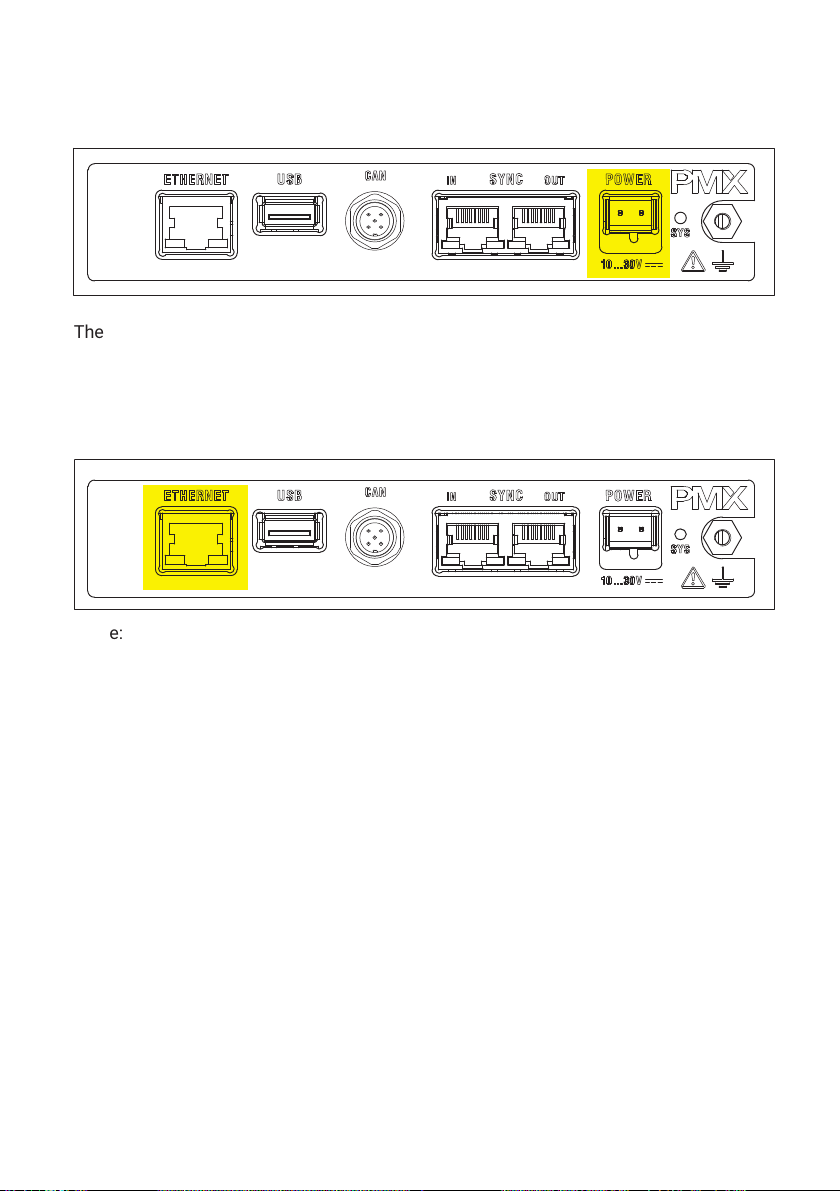

5.1.2 Connecting the power supply

The power supply must be at least 15W.

ÑÑ

ÑÑ

The PMX boots, and then displays its system status. The system LED must light up green.

This process takes a few seconds.

5.1.3 Connecting to a PC

Connect the PMX to a PC via the Ethernet socket.

ÑÑ

Cable: Standard Ethernet cable (Cat5)

The PMX is set to DHCP (automatic address assignment) at the factory. Set your PC to

DHCP as well. The IP addresses will then be set automatically. This process takes sev

eral tens of seconds.

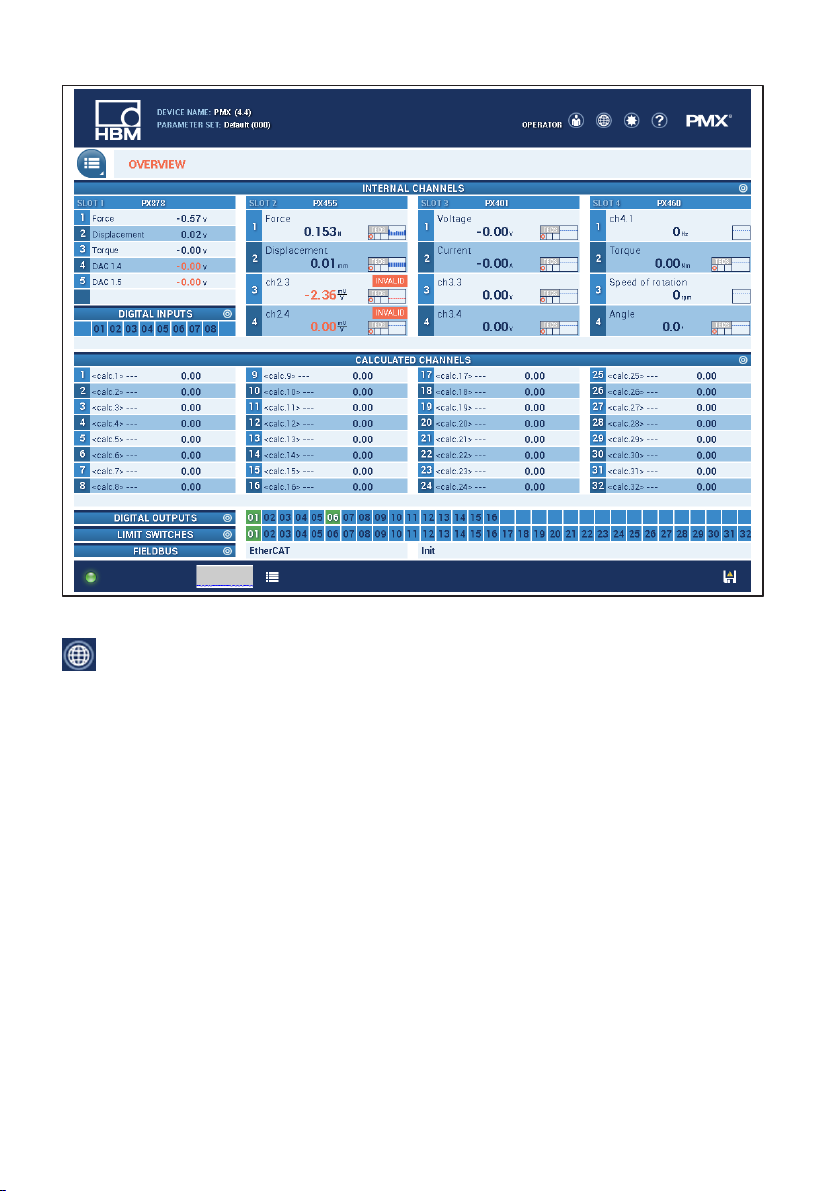

Call the PMX web server by entering "PMX/" in the address bar of your browser.

The PMX web server appears, showing the start screen (overview).

PMX

QUICK START

16

The PMX system is now ready for measurement, and you can see live measured values.

uClick on the globe icon to switch to another PMX web server language.

17

PMX

QUICK START

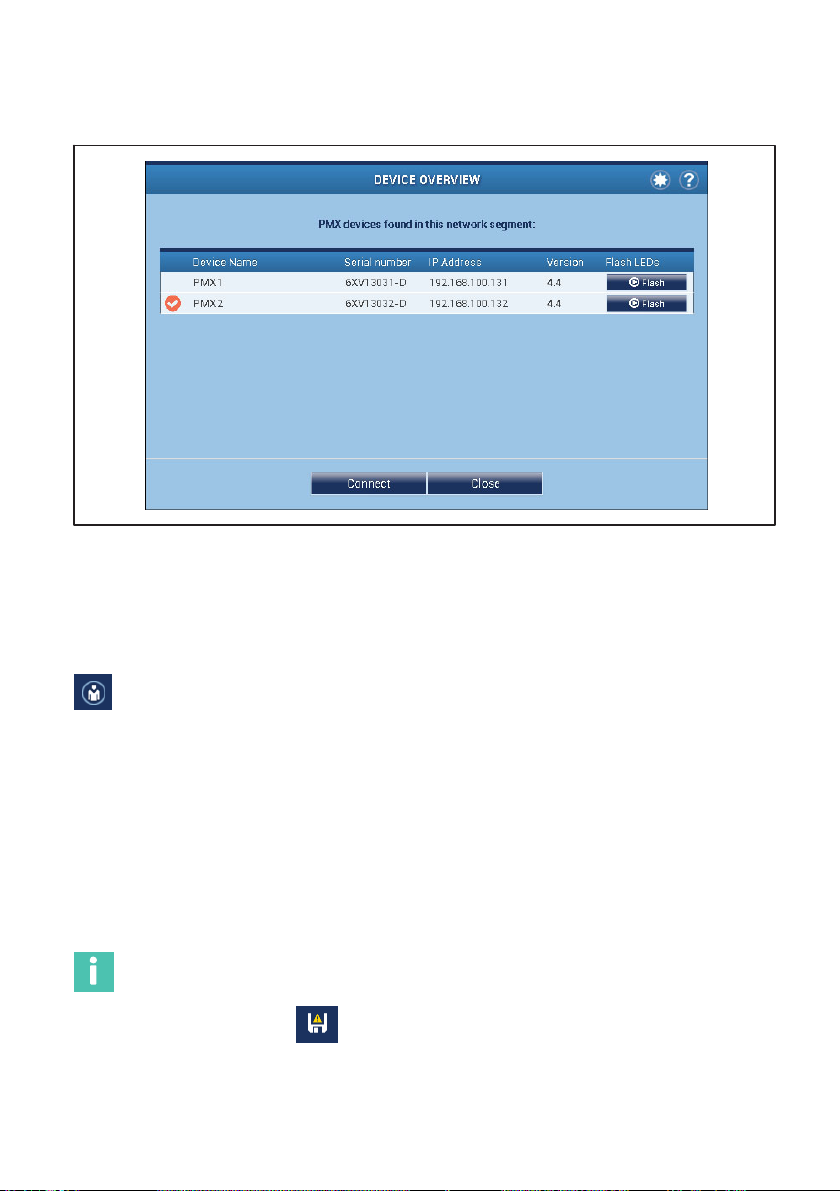

If there are multiple PMX devices in the network, this selection box will appear before the

overview:

uCheck the desired PMX.

uConfirm with Connect.

The flash function allows the device to be identified by flashing all the device LEDs.

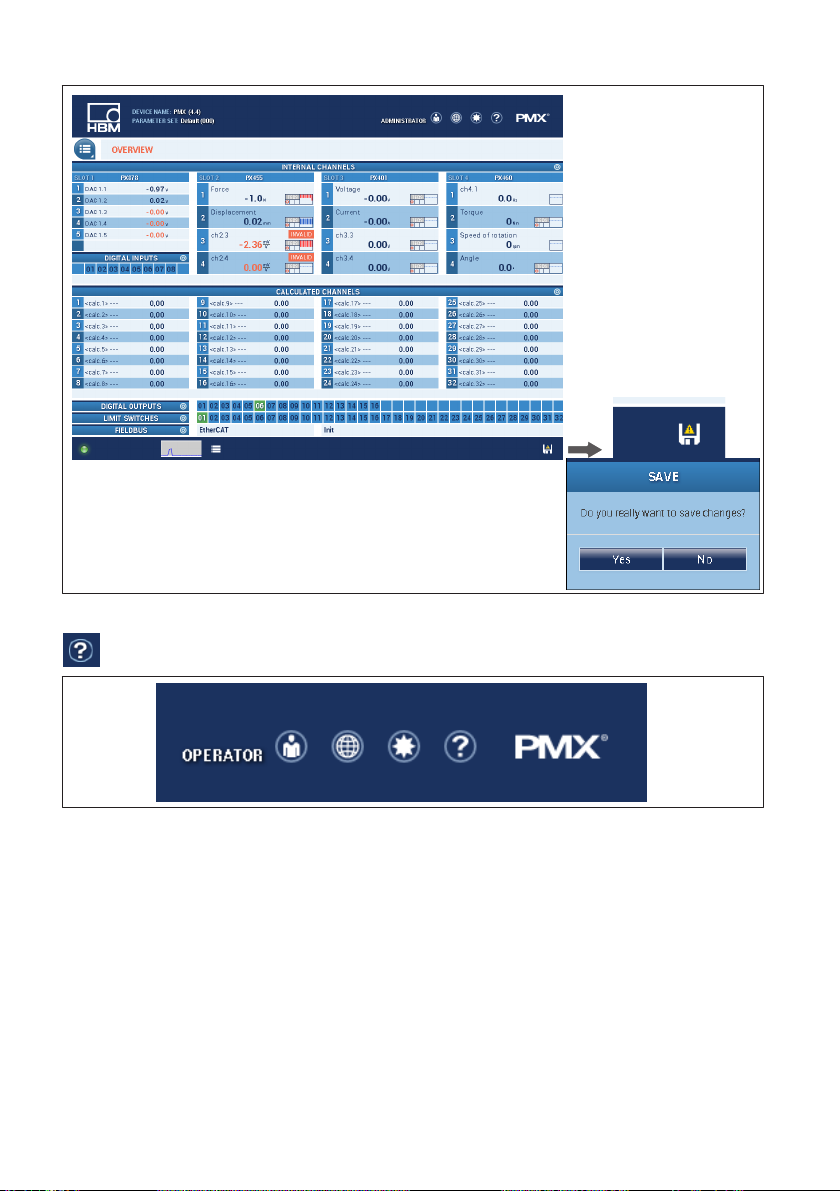

5.1.4 Configuring the PMX

uClick on the user icon to go to the Maintenance or Administrator level. Depend

ing on authorization, you can make the following settings:

-Assign sensors

-Assign units

-Set filters

-Monitor maximum and minimum values

-Monitor limit values (Thresholds)

-Set up virtual (calculated) channels

-Configure digital and analog inputs/outputs

-Create and administer parameter sets

Information

Click on the floppy disk icon to save changed settings power failsafe to the device.

PMX

QUICK START

18

Confirmation prompt

uTo get additional help, click on the Help icon.

The web server help opens with information relevant to the displayed page.

5.2 Typical operating sequence (measurement example)

The easiest way to configure the PMX measuring amplifier and its measurement chan

nels is via the PMX web browser. The sensors, Ethernet cable and voltage supply must be

properly connected.

The overview shows the PMX with all its measurement cards and signals, as well as all

device information.

Other manuals for PMX

1

Table of contents

Languages:

Other HBK Industrial Equipment manuals