HBK RTN/M2 User manual

RTN/M2

RTN/M2LAR, RTN/M2LA, RTN/M2LBR, RTN/M2LB

ENGLISH DEUTSCH FRANÇAIS ESPAÑOL

Mounting Instructions

Montageanleitung

Notice de montage

Instrucciones de montaje

Hottinger Brüel & Kjaer GmbH

Im Tiefen See 45

D-64293 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbkworld.com

Mat.: 7-2001.1088

DVS: A01867 02 YS0 03

05.2022

EHottinger Brüel & Kjaer GmbH

Subject to modifications.

All product descriptions are for general information

only. They are not to be understood as a guarantee of

quality or durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allge

meiner Form. Sie stellen keine Beschaffenheits- oder

Haltbarkeitsgarantie dar.

Sous réserve de modifications.

Les caractéristiques indiquées ne décrivent nos

produits que sous une forme générale. Elles

n'impliquent aucune garantie de qualité ou de

durabilité.

Reservado el derecho a modificaciones.

Todos los datos describen nuestros productos de

manera general. No representan ninguna garantía de

calidad o de durabilidad.

RTN/M2

RTN/M2LAR, RTN/M2LA, RTN/M2LBR, RTN/M2LB

ENGLISH DEUTSCH FRANÇAIS ESPAÑOL

Mounting Instructions

RTN/M2

TABLE OF CONTENTS

2

TABLE OF CONTENTS

1 Safety instructions 3................................................

2 Markings used 5....................................................

2.1 The markings used in this document 5.................................

3 General 6..........................................................

4 Mounting preparation 8.............................................

5 Mounting 12........................................................

6 Dimensions 15......................................................

7 Specifications RTN/M2L... weighing modules 21.........................

3

RTN/M2

SAFETY INSTRUCTIONS

1 SAFETY INSTRUCTIONS

In cases where a breakage would cause injury to persons or damage to equipment, the

user must take appropriate safety measures (such as fall protection, overload protection,

etc.).

It is essential to comply with the relevant accident prevention regulations. In particular

you should take into account the limit loads quoted in the specifications.

Use in accordance with the regulations

The weighing modules have been designed for weighing applications. Use for any

additional purpose shall be deemed to be not in accordance with the regulations.

In the interests of safety, the weighing modules should only be operated as described in

the Mounting Instructions. It is also essential to observe the appropriate legal and safety

regulations for the application concerned during use. The same applies to the use of

accessories.

The weighing modules are not safety elements within the meaning of its use as intended.

Proper and safe operation of this weighing module requires proper transportation,

correct storage, assembly and mounting and careful operation and maintenance.

General dangers due to non‐observance of the safety instructions

The weighing modules correspond to the state of the art and are fail‐safe. The weighing

modules can give rise to residual dangers if they are inappropriately installed and

operated by untrained personnel.

Everyone involved with the installation, commissioning, maintenance or repair of a

weighing module must have read and understood the Mounting Instructions and in

particular the technical safety instructions.

Residual dangers

The scope of supply and performance of the weighing modules covers only a small area

of weighing technology. In addition, equipment planners, installers and operators should

plan, implement and respond to the safety engineering considerations of weighing

technology in such a way as to minimise residual dangers. Prevailing regulations must be

complied with at all times. There must be reference to the residual dangers connected

with weighing technology.

Environmental conditions

In the context of your application, please note that all materials which release chlorine

ions will attack all grades of stainless steel and their welding seams. In such cases the

operator must take appropriate safety measures.

RTN/M2

SAFETY INSTRUCTIONS

4

With environmental conditions that cannot be clearly defined, HBK recommends to

provide the load cells and weighing modules with a protective coating which matches

these conditions (after mounting) in order to prevent the influence of aggressive media.

Please take into account the resistance of the cable material and the mounting parts.

Prohibition of own conversions and modifications

The weighing modules must not be modified from the design or safety engineering point

of view except with our express agreement. Any modification shall exclude all liability on

our part for any damage resulting therefrom.

Qualified personnel

These weighing modules are only to be installed by qualified personnel strictly in

accordance with the specifications and with the safety rules and regulations which

follow. It is also essential to observe the appropriate legal and safety regulations for the

application concerned. The same applies to the use of accessories.

Qualified personnel means persons entrusted with the installation, fitting, commissioning

and operation of the product who possess the appropriate qualifications for their

function.

Accident prevention

Although the specified brealing load is several times the full scale value, the relevant

accident prevention regulations from the trade associations must be taken into

consideration.

5

RTN/M2

MARKINGS USED

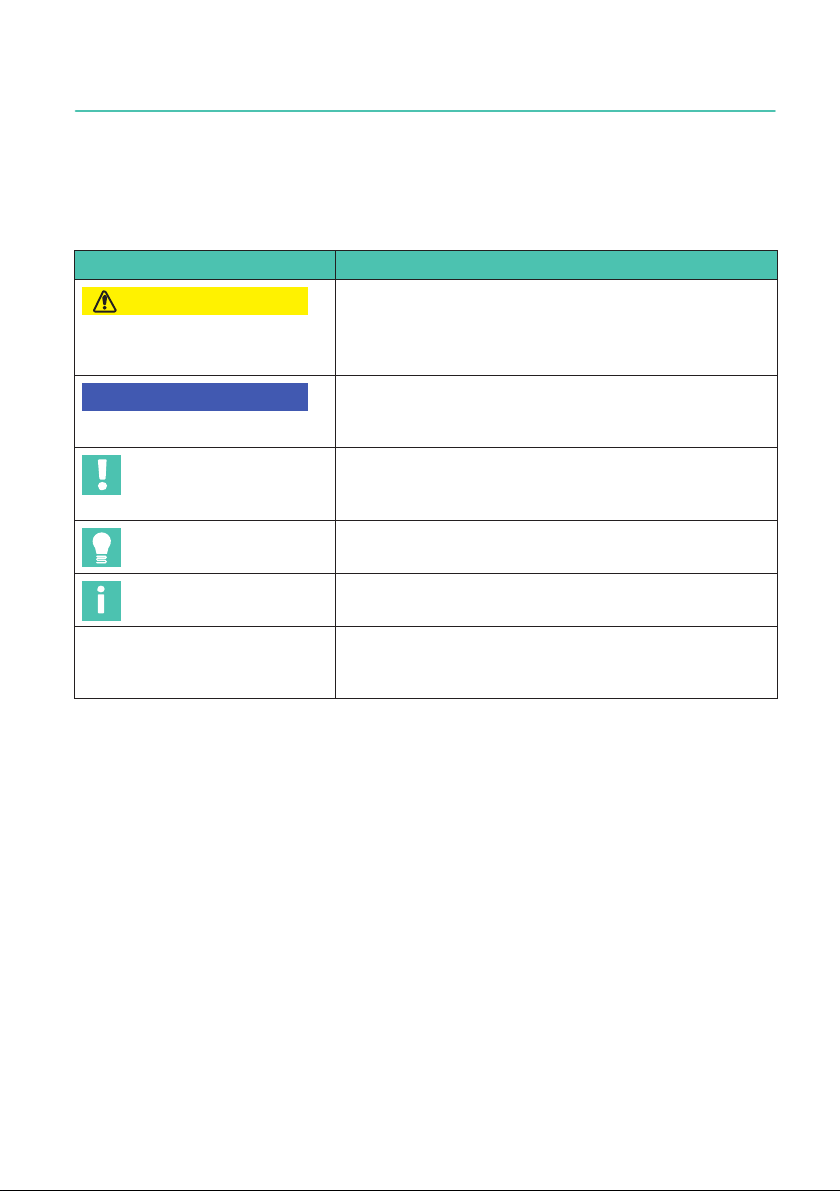

2 MARKINGS USED

2.1 The markings used in this document

Important instructions for your safety are specifically identified. It is essential to follow

these instructions in order to prevent accidents and damage to property.

Symbol Significance

CAUTION This marking warns of a potentially dangerous

situation in which failure to comply with safety

requirements can result in slight or moderate physical

injury.

Notice This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

Important This marking draws your attention to important in

formation about the product or about handling the

product.

Tip This marking indicates application tips or other

information that is useful to you.

Information This marking draws your attention to information

about the product or about handling the product.

Emphasis

See …

Italics are used to emphasize and highlight text and

identify references to sections, diagrams, or external

documents and files.

RTN/M2

GENERAL

6

3 GENERAL

HBK offers the RTN/M2(L)... weighing module for RTN load cells with max. capacities of

1 t ... 33 t. The ”L” in the type designation signifies that the module has been fitted with a

stay rod. “A” signifies rubber‐metal bearing, “B” stands for pendulum bearing.

Product types RTN/M2LA...

Order number Max. capacity

for load cell

Material Version

1-RTN/M2LAR2.2T 1 t ... 2.2 t stainless steel WITH stay rod

1-RTN/M2AR2.2T WITHOUT stay rod

1-RTN/M2LAR4.7T 4.7 t stainless steel WITH stay rod

1-RTN/M2AR4.7T WITHOUT stay rod

1-RTN/M2LAR22T 10 t ... 22 t stainless steel WITH stay rod

1-RTN/M2AR22T WITHOUT stay rod

1-RTN/M2LA33T 33 t galvanized WITH stay rod

1-RTN/M2A33T WITHOUT stay rod

Product types RTN/M2LB...

Order number Max. capacity

for load cell

Material Version

1-RTN/M2LBR4.7T/2 1 t ... 4.7 t stainless steel WITH stay rod

1-RTN/M2BR4.7T/2 WITHOUT stay rod

1-RTN/M2LBR22T 10 t ... 22 t stainless steel WITH stay rod

1-RTN/M2BR22T WITHOUT stay rod

1-RTN/M2LB33T 33 t galvanized WITH stay rod

1-RTN/M2B33T WITHOUT stay rod

7

RTN/M2

GENERAL

The weighing modules have been primarily designed for use in tank weighing. As a rule,

the weighing modules are equipped with adjustable limit stops that limit horizontal move

ments, for example by wind forces or in mixer operation. In addition, the modules are

provided with a anti‐liftoff device which prevents the tank from lifting off. However, en

sure that the specified data (see chapter 7 on page 21) are not exceeded.

The modules comprise a lower module plate for mounting on the basic construction

(foundations), a load cell dummy with load introduction elements and the upper module

plate for tank mounting. For load introduction into the load cell, a rubber‐metal bearing

(with RTN/M2LA) or a pendulum bearing (with RTN/M2LB)is used which allows for

horizontal shifting of the load applied. The weighing modules are completely fitted with a

load cell dummy that can be loaded, with a ground cable, and a securing device for

transport.

RTN/M2

MOUNTING PREPARATION

8

4 MOUNTING PREPARATION

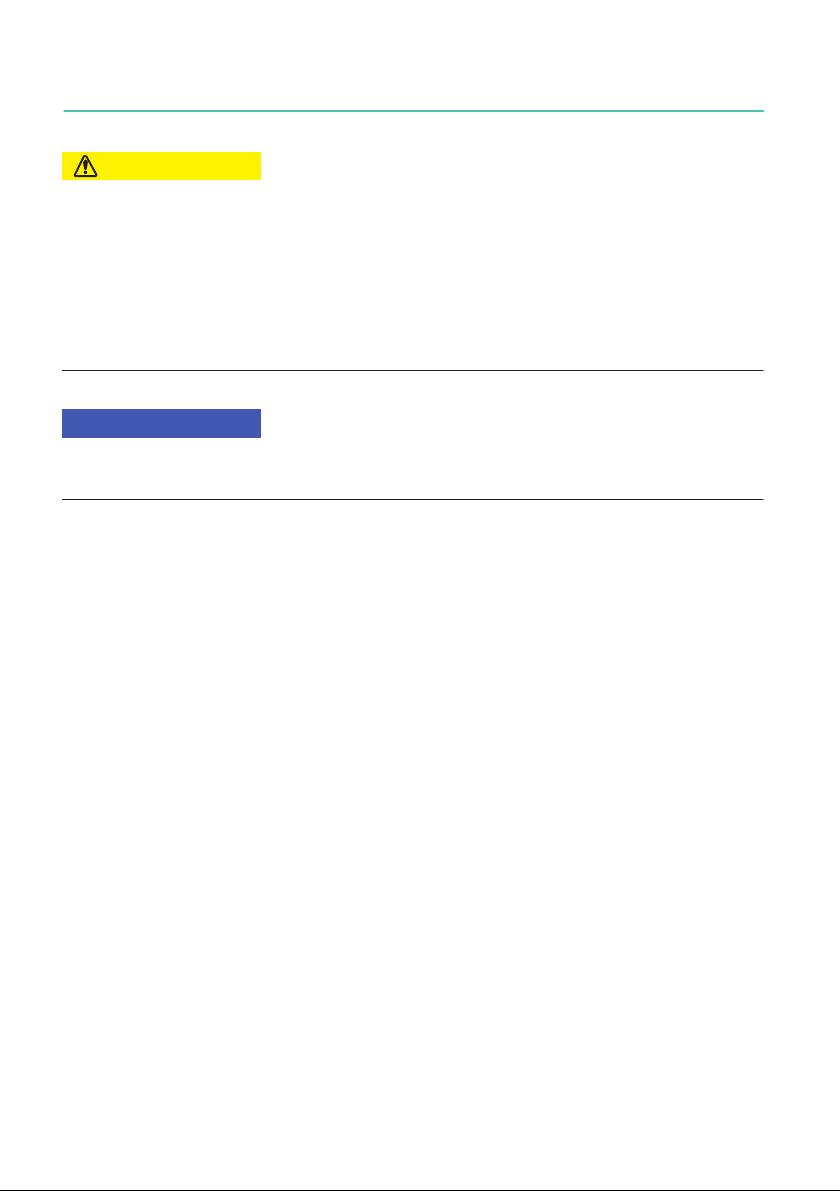

CAUTION

The weighing modules are delivered completely assembled, however, without a load cell.

Instead of the load cell, a dummy has been assembled into the weighing module, which is

capable of taking up the specified loads. Before the weighing module is mounted under

neath the tank, vessel or silo, check whether dummy replacement through the load cell will

still be possible even if the tank is placed on the weighing module. In order to effect the

replacement, a suitable lifting device is necessary that is capable of lifting the tank by at

least 10 mm. Pipe connections mounted on the tank or the feed‐in or discharge systems

have to be vertically movable or separable.

Notice

If this is not the case, the dummy must be replaced by an appropriate RTN load cell already

before the weighing module is mounted.

General mounting preparations

SEnsure that the assembly/siting areas provided are clean, level and horizontally

aligned. Any askew positions can be compensated for, depending on the assembly

situation, for example by appropriate wedges and compensation plates (weld in posi

tion) or by grinding down the assembly area. However, module plates must not be

ground down under any circumstances.

SThe foundations / basic construction and the connection of the superstructure must

be sufficiently rigid in order to avoid deformations (e.g. deflections) under load.

SIn order to provide for fitting and assembly free from any constraining forces, the

mounting bores on the basic construction and the tank connection must be suffi

ciently aligned.

SAn even loading on the bearing points is to be sought. To this end, in particular for

statically indefinite bearings, ensure that the height level setting at the bearing points

is correct (provide spacer plates, 5 x 1 mm included in scope of delivery).

SUndo transport protection device and stops, fit height adjustment plates (dependent

on maximum capacity, see Dimensions).

9

RTN/M2

MOUNTING PREPARATION

Notice

How to use the enclosed grease tube

Before fitting the load cell, the enclosed grease must be applied to the upper thrust piece

and to the underside of the pendulum bearing (with RTN...B) in order to minimize friction

between the inside surface of the thrust piece and the load introduction element of the

RTN load cell or pendulum bearing.

Use of the spacer plates provided

The scope of delivery of the module includes 2 x 5 spacer plates. They are used for the

vertical adjustment of the module. Five plates max. are to be fitted underneath the upper

module plate, and five plates max. between the base and the cross bracket of the

anti‐liftoff device

Important

Ensure that all screws are fitted with U‐washers.

RTN/M2

MOUNTING PREPARATION

10

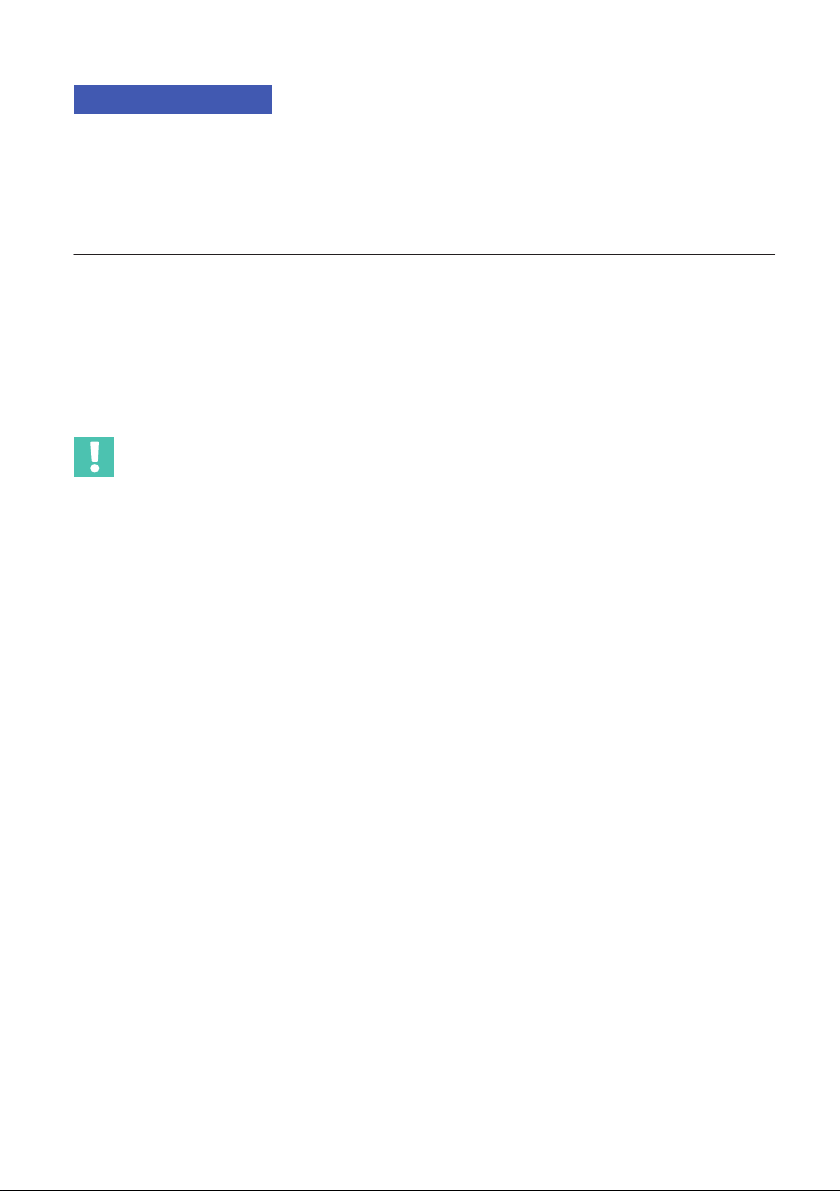

5 plates max. for

height adjustment

5 plates max. for height adjustment

Upper module plate

Centering disc

(only up to 4.7 t

max. capacity)

Lateral stops

Cross‐bracket

(Anti‐liftoff device)

Air gap: 1 mm

Mounting base

(only up to 4.7 t

max. capacity)

Bearing

Dummy

Fig. 4.1 Fitting of the spacer plates with 4.7 t version

11

RTN/M2

MOUNTING PREPARATION

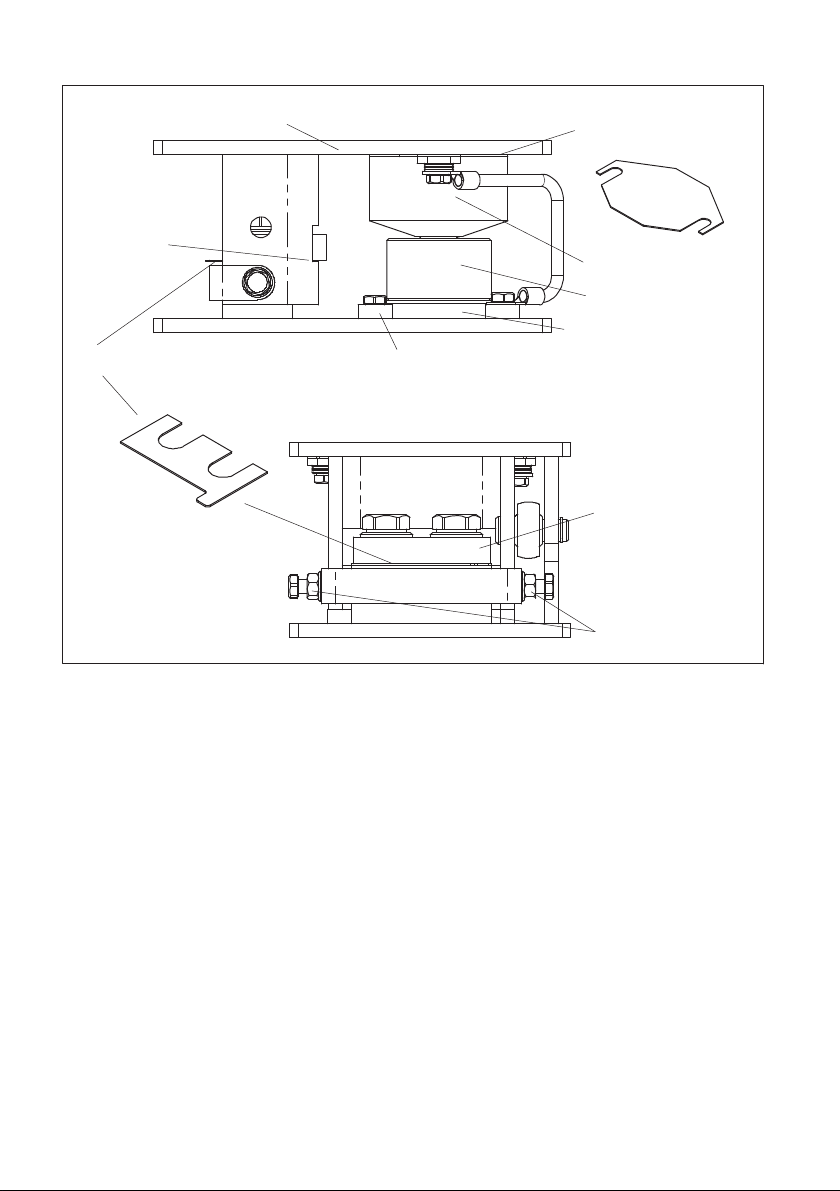

5 plates max. for

height adjustment

5 plates max. for height adjustment

Upper module plate

Lateral stops

Cross‐bracket

(Anti‐liftoff device)

Air gap: 1 mm

Bearing

Dummy

Fig. 4.2 Fitting of the spacer plates with 10 t ... 33 t version

RTN/M2

MOUNTING

12

5 MOUNTING

SWhen fitting the tank, vessel or silo, ensure that e.g. when lowering it onto the bearing

points no shock loads act upon the module. Even short term loads that exceed the

load cell limit values can result in damage to the load cell.

SFor heavy containers or unfavourable fitting conditions, the use of appropriate fitting

aids (auxiliary supports, lifting devices) is required.

SLower module plate and upper module plate are to be firmly connected with the

foundations or tank connection.

SThe weighing modules must be assembled such that, in their original state, they are

free from lateral forces. The pendulum bearing version requires the fitted pendulum

bearing to be aligned exactly vertically, if possible. This is the case, if foundations and

tank connection are horizontal and the mounting bores on the basic construction and

the container connection are sufficiently aligned. Slotted holes in the module plates

facilitate alignment.

SFor protection against welding currents which may destroy the electronic components

of the transducer the fitted EEK4 ground cable is provided.

SEspecially in the case of a statically indefinite bearing uneven loading of the modules

can occur due to an insufficiently precise height adjustment. This unevenness is to be

checked on the individual load cells by applying an excitation voltage and comparing

the output voltages. In order to avoid any overloads, major unevenness is to be

compensated by inserting spacer plates on the bearings with the lowest loads.

Mounting of the load cell

In order to assemble the load cell into the weighing module the pre‐fitted dummy needs

to be removed.

Mounting of load cells up to a max. capacity of 4.7 t: see Fig. 4.1

SRemove the anti‐liftoff device by undoing the 2 hexagonal screws

SLoosen the lateral stops

SUse a suitable lifting device to lift the respective tank base by approx. 10 mm

SUndo the centering discs

SRemove the dummy with the mounting base of the RTN by lifting lightly and withdraw

ing to one side (for pendulum bearing version, with pendulum bearing)

SRemove mounting from dummy and fit to load cell; tightening torque of the 4 screws:

4 N⋅m

SSecure and position load cell with mounting base by means of centering discs on the

lower module plate. Apply the enclosed grease to the load introduction parts of the

load cell.

13

RTN/M2

MOUNTING

SWith the pendulum bearing version, position the pendulum bearing on the load cell.

Also apply grease.

SSlowly lower the tank while making sure that the load buttons engage with the corre

sponding seats without suffering damage.

SVertical module alignment by inserting or removing the five 1‐mm‐thick spacer plates

underneath the upper module plate.

SMount and adjust the anti‐liftoff device by inserting plates underneath such that an air

gap of about 1 mm results (see Fig. 4.1) with the tank empty.

SFirst adjust and then lock the horizontal stops. The U‐shaped bracket accounts for the

stiffness of the stops and has to be fastened with the stop screws. Please refer to the

Specifications in chapter 7 for the maximum permissible horizontal shifts (distance

from the stops). The stay rods already have been adjusted at the factory to ensure

that the load introduction parts are aligned with the load cell in the rod direction.

Should a readjustment prove necessary, the rod end bearings subsequently have to be

carefully locked.

Mounting of load cells with a max. capacity of 10 t, 15 t, 22 t and 33 t: see Fig. 4.2

SRemove the anti‐liftoff device by undoing the 2 hexagonal screws

SUse a suitable lifting device to lift the respective tank base by approx. 10 mm

SRemove the load cell dummy without the mounting base with thrust piece by lifting

lightly and withdrawing to one side (for pendulum bearing version, with pendulum

bearing)

SInsert the load cell with the thrust piece and, if necessary, the pendulum support, apply

the enclosed grease to the load introduction parts.

SSlowly lower the tank. The thrust piece above the load cell must center in the center

ing flange of the upper module plate without suffering damage.

SVertically align the module by inserting or removing the five 1‐mm‐thick spacer plates

above the thrust piece of the load cell (see Fig. 4.2)

SMount and adjust the anti‐liftoff device by inserting spacer plates underneath such

that an air gap of about 1 mm results with the tank empty.

SFirst adjust and then lock the horizontal stops. The U‐shaped bracket accounts for the

stiffness of the stops and has to be fastened with the stop screws. Please refer to the

Specifications in Chapter 7 for the maximum permissible horizontal shifts (distance

from the stops). The stay rods already have been adjusted at the factory to ensure

that the load introduction parts are aligned with the load cell in the rod direction.

Should a readjustment prove necessary, the rod end bearings subsequently have to be

carefully locked.

RTN/M2

MOUNTING

14

Notes for adjustment of the horizontal stops

Horizontal movability is ensured by the rubber‐metal or pendulum bearing. The horizontal

stops should be adjusted in compliance with the maximum permissible horizontal shift

(see chapter 7 on page 21).

Notice

Precautions during operation:

SDeposits such as dirt or corrosion particles from the tank can falsify measurement

results.

SThe limits for movability and loading capacity specified in the Specifications must not

be exceeded.

SHorizontal shifts that exceed the maximum permissible value and do not act in the

direction of the stay rod are to be avoided by aligning the other modules appropriately,

or to be taken up by other stops or devices.

SThe movement tolerance of the stay rod should be checked regularly and readjusted,

if necessary.

15

RTN/M2

DIMENSIONS

6 DIMENSIONS

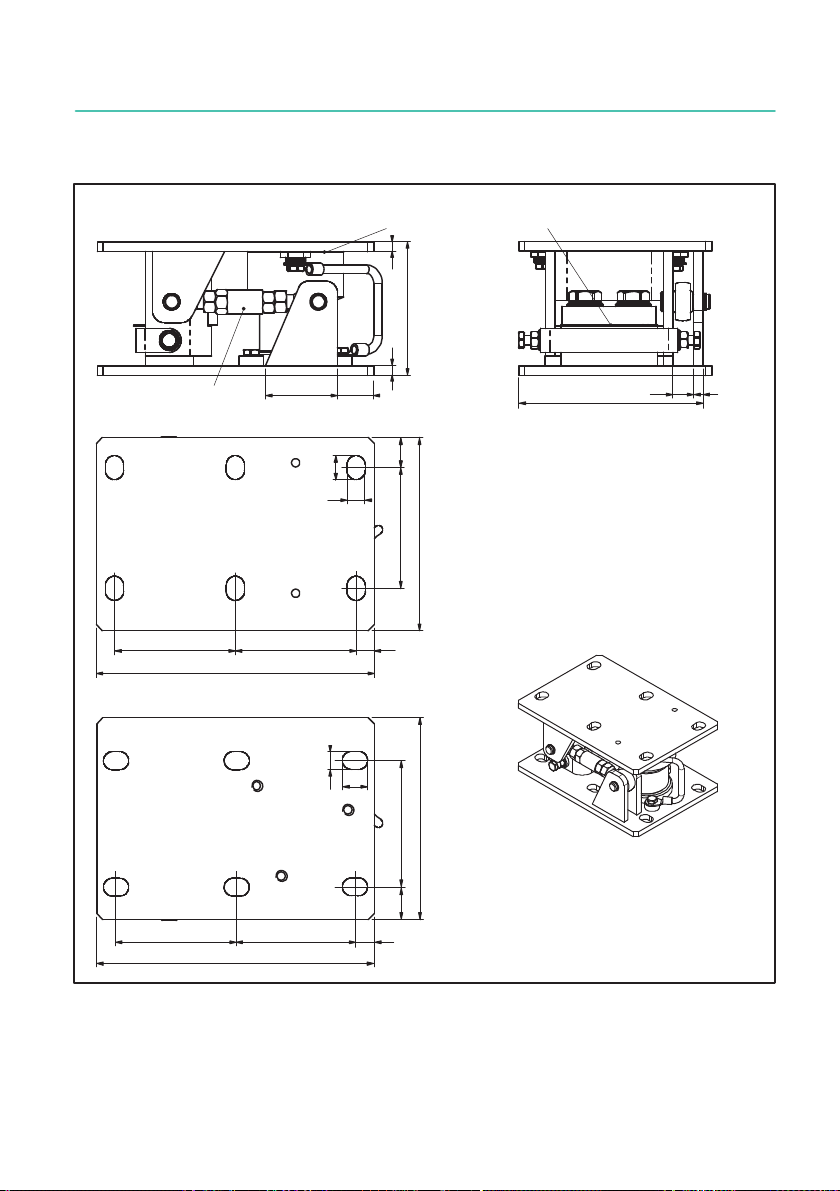

RTN/M2LA - Version with rubber‐metal bearing

60

8

111

8

30 8

153 17

only version with

stay rod

max. 5 spacer plates

(110 - 115 by

spacer plates)

230

100

100100

160

25

15

View from above

20

15

View from below

230

100

100100

160

25

15

15

20

Max. capacity 1 t ... 4,7 t

Perspective view

Dimensions in mm

(1mm = 0.03937 inches)

RTN/M2

DIMENSIONS

16

RTN/M2LA - Version with rubber‐metal bearing

1022

65

148

10

10 151

255

max. 5 spacer plates

only version with stay rod

(150 - 155 by

spacer plates)

Max. capacity 10 t ... 22 t

Perspective view

310

140130

140

18

200

View from above

20

25

View from below

310

140130

140

200

25

20

18

20

20 Dimensions in mm

(1mm = 0.03937 inches)

17

RTN/M2

DIMENSIONS

RTN/M2LA - Version with rubber‐metal bearing

View from above

View from below

Max. capacity 33 t

Perspective view

85

188

12 12

193

290

max. 5 spacer plates

only version with stay rod

1226

(192 - 197 by

spacer plates)

420

200155

200

280

35

420

200155

200

280

35

22

26

26

22

35

35 Dimensions in mm

(1mm = 0.03937 inches)

RTN/M2

DIMENSIONS

18

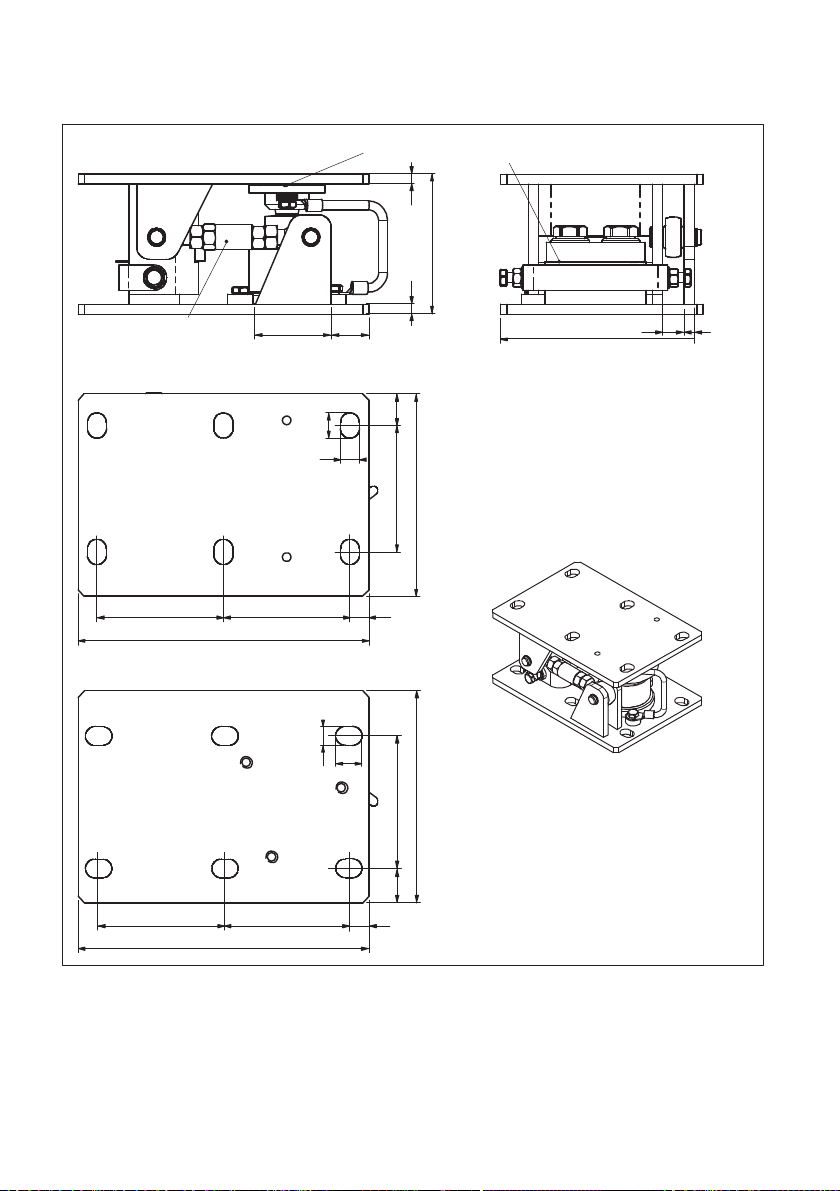

RTN/M2LB - Version with pendulum bearing

max. 5 spacer plates

only version with

stay rod

8

153 17

230

100

100100

160

25

15

View from above

20

15

View from below

230

100

100100

160

25

15

15

20

Max. capacity 1 t ... 4.7 t

Perspective view

60

111

30

(110 - 115 by

spacer plates)

88

Dimensions in mm

(1mm = 0.03937 inches)

This manual suits for next models

4

Table of contents

Languages:

Other HBK Industrial Equipment manuals