HBK C16M User manual

C16M

ENGLISH DEUTSCH ESPAÑOL

Mounting Instructions

Montageanleitung

Instrucciones de montaje

Hottinger Brüel & Kjaer GmbH

Im Tiefen See 45

D-64293 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbkworld.com

Mat.: 7-2001.0078

DVS: A01268 04 XS0 01

02.2022

EHottinger Brüel & Kjaer GmbH

Subject to modifications.

All product descriptions are for general information

only. They are not to be understood as a guarantee of

quality or durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allge

meiner Form. Sie stellen keine Beschaffenheits- oder

Haltbarkeitsgarantie dar.

Reservado el derecho a modificaciones.

Todos los datos describen nuestros productos de

manera general. No representan ninguna garantía de

calidad o de durabilidad.

C16M

ENGLISH DEUTSCH ESPAÑOL

Mounting Instructions

C16M

TABLE OF CONTENTS

2

TABLE OF CONTENTS

1 Safety instructions 3................................................

2 Markings used 5....................................................

2.1 The markings used in this document 5.................................

2.2 Symbols on the product 5............................................

3 General 6..........................................................

4 Mounting instructions 7.............................................

5 Mounting 8........................................................

6 Connection 9.......................................................

6.1 Parallel connection of several weighing modules 9.......................

6.2 Connections using the four‐wire technique 10............................

6.3 Cable extensions 10..................................................

7 Operation 11........................................................

8 Dimensions 12......................................................

8.1 Mounting example for weighing modules with stay rods 15.................

9 Specifications 16....................................................

10 Accessories, to be ordered separately 17...............................

10.1 Scope of delivery 17..................................................

3

C16M

SAFETY INSTRUCTIONS

1 SAFETY INSTRUCTIONS

In cases where a breakage would cause injury to persons or damage to equipment, the

user must take appropriate safety measures (such as fall protection, overload protection,

etc.). For safe and trouble‐free operation, weighing modules must not only be correctly

transported, stored, sited and installed but must also be carefully operated and main

tained.

It is essential to comply with the relevant accident prevention regulations. In particular

you should take into account the limit loads quoted in the specifications.

Use in accordance with the regulations

C16M... type weighing modules are conceived for weighing applications. Use for any

additional purpose shall be deemed to be not in accordance with the regulations.

In the interests of safety, the weighing modules should only be operated as described in

the Mounting Instructions. It is also essential to observe the appropriate legal and safety

regulations for the application concerned during use. The same applies to the use of

accessories.

The weighing modules are not safety elements within the meaning of its use as intended.

Proper and safe operation of this load cell requires proper transportation, correct

storage, assembly and mounting and careful operation and maintenance.

General dangers due to non‐observance of the safety instructions

The weighing modules correspond to the state of the art and are fail‐safe. The weighing

modules can give rise to residual dangers if they are inappropriately installed and

operated by untrained personnel.

Everyone involved with the installation, commissioning, maintenance or repair of a force

transducer must have read and understood the Mounting Instructions and in particular

the technical safety instructions.

Residual dangers

The scope of supply and performance of the weighing modules covers only a small area

of weighing technology. In addition, equipment planners, installers and operators should

plan, implement and respond to the safety engineering considerations of weighing

technology in such a way as to minimise residual dangers. Prevailing regulations must be

complied with at all times. There must be reference to the residual dangers connected

with weighing technology.

C16M

SAFETY INSTRUCTIONS

4

Environmental conditions

In the context of your application, please note that all materials which release chlorine

ions will attack all grades of stainless steel and their welding seams. In such cases the

operator must take appropriate safety measures.

With environmental conditions that cannot be clearly defined, HBK recommends to pro

vide the load cells and weighing modules with a protective coating which matches these

conditions (after mounting) in order to prevent the influence of aggressive media. Please

take into account the resistance of the cable material and the mounting parts.

Prohibition of own conversions and modifications

The weighing modules must not be modified from the design or safety engineering point

of view except with our express agreement. Any modification shall exclude all liability on

our part for any damage resulting therefrom.

Qualified personnel

These weighing modules are only to be installed by qualified personnel strictly in

accordance with the technical data and with the safety rules and regulations which

follow. It is also essential to observe the appropriate legal and safety regulations for the

application concerned. The same applies to the use of accessories.

Qualified personnel means persons entrusted with the installation, fitting, commissioning

and operation of the product who possess the appropriate qualifications for their

function.

Accident prevention

Although the specified nominal capacity in the destructive range is several times the full

scale value, the relevant accident prevention regulations from the trade associations

must be taken into consideration.

5

C16M

MARKINGS USED

2 MARKINGS USED

2.1 The markings used in this document

Important instructions for your safety are specifically identified. It is essential to follow

these instructions in order to prevent accidents and damage to property.

Symbol Significance

CAUTION This marking warns of a potentially dangerous

situation in which failure to comply with safety

requirements can result in slight or moderate physical

injury.

Notice This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

Important This marking draws your attention to important in

formation about the product or about handling the

product.

Tip This marking indicates application tips or other

information that is useful to you.

Information This marking draws your attention to information

about the product or about handling the product.

Emphasis

See …

Italics are used to emphasize and highlight text and

identify references to sections, diagrams, or external

documents and files.

2.2 Symbols on the product

CE mark

The CE mark enables the manufacturer to guarantee that the

product complies with the requirements of the relevant EU direc

tives (the declaration of conformity is available at

http://www.hbm.com/HBMdoc

).

C16M

GENERAL

6

3 GENERAL

HBK supplies C16M... weighing modules for max. capacities 20 t up to 200 t. The tank

weigh modules are mainly designed for tank weighing applications and manufactured

completely from galvanized steel or stainless steel.

The tank weigh modules are fitted with integral transverse retention guides which can

absorb horizontal forces, such as occur for example with tanks used with stirring mecha

nisms or by wind forces. Optionally, a simple anti‐liftoff device may be installed by the

user.

The modules are formed from a lower module plate for fastening to the foundation

frame, the load cell with load transfer elements and the upper module plate for mounting

an the tank. A rocker pin is used for the load transfer which provides compensation for

horizontal offsets in the applied load (in direction perpendicular to transverse retention

guides as, for example, can arise through thermal strain). The weighing modules are pre‐

assembled and supplied with transport safety retainers.

7

C16M

MOUNTING INSTRUCTIONS

4 MOUNTING INSTRUCTIONS

Slt should be ensured that the mounting/siting surfaces are clean, flat and level. De

pending on the Installation circumstances, any levelling error can be compensated for

example by suitable wedges and compensating plates (permanently welded) or by the

grinding away the mounting surface. On no account must the module plates be

ground.

Notice

On no account must the module plates be ground.

SThe foundation/base frame must be sufficiently stiff so that no impermissible de

formations (e.g. deflections) occur on loading.

SIn order to keep the mounting as free of straining forces as possible, the fastening

holes on the base frame and the tank joint must be sufficiently in alignment. Same

means to the bore of the anti‐liftoff device.

SUniform loading on the support points should be provided where possible. Correct

adjustment of the height on the supporting points must be ensured (have compensat

ing shims ready). This is especially important for statically undefined supports.

C16M

MOUNTING

8

5 MOUNTING

Slt should be ensured when mounting the tank that, for example, no shock loads are

applied to the module when lowering it onto the supports. Even short‐term loads

which exceed the load cell limits can lead to damage.

SWith heavy tanks or unfavorable Installation conditions the use of mounting aids (aux

iliary supports, jack equipment) is recommended.

SThe mounting plate and upper module plate should be firmly fastened to the founda

tion, respectively the tank joint.

SThe weighing modules should be mounted such that they are free of transverse forces

in the initial state. This means that the mounted rocker pin load cell must be lined up

as near to the perpendicular as possible. This is the case when the foundation and

tank Joint are horizontal and the mounting holes on the foundation and the tank are

sufficiently aligned. As supplied, the transport locking plate is fitted such that this is

the case, thus allowing hole patterns to be checked easily.

SA anti‐liftoff device can be effected by screwing in a threaded rod of an appropriate

length and checking with a nut in the lower module plate. The threaded rod must have

a working clearance in a though hole of the vessel base. Two further nuts are to be

checked over a washer with approx. 2 mm working clearance relative to the vessel

base.

SAs protection against welding currents that can damage parts of the transducer, it is

recommended that the EEK4 Earthing Cable is used (included in the supply).

SWith statically undefined supports, non‐uniform loading of the modules occurs due to

flexibility as the Ioad is taken up or due to inadequate accuracy in the height adjust

ment. This non‐uniformity should be checked an the individual Ioad cells by applying

an excitation voltage and comparing the Output voltages. To prevent overloads, large

non‐uniformities should be compensated by inserting shims under those supports

which are least loaded.

SThe optional cable with an outer braided wire covering for the configurable K-Z16A3

with option 20R, is intended for use when there is increased mechanical stress (e.g.

damage caused by gnawing rodents). If this cable is used, the outer braided wire has

to be connected to potential equalization at least once, to avoid accidental energiza

tion. This outer braided wire is not used to shield the load cell. The inner braid of the

load cell cable is used for shielding.

9

C16M

CONNECTION

6 CONNECTION

Strain‐gauge based Ioad cells can be connected to:

Scarrier frequency or

SDC‐measuring amplifiers.

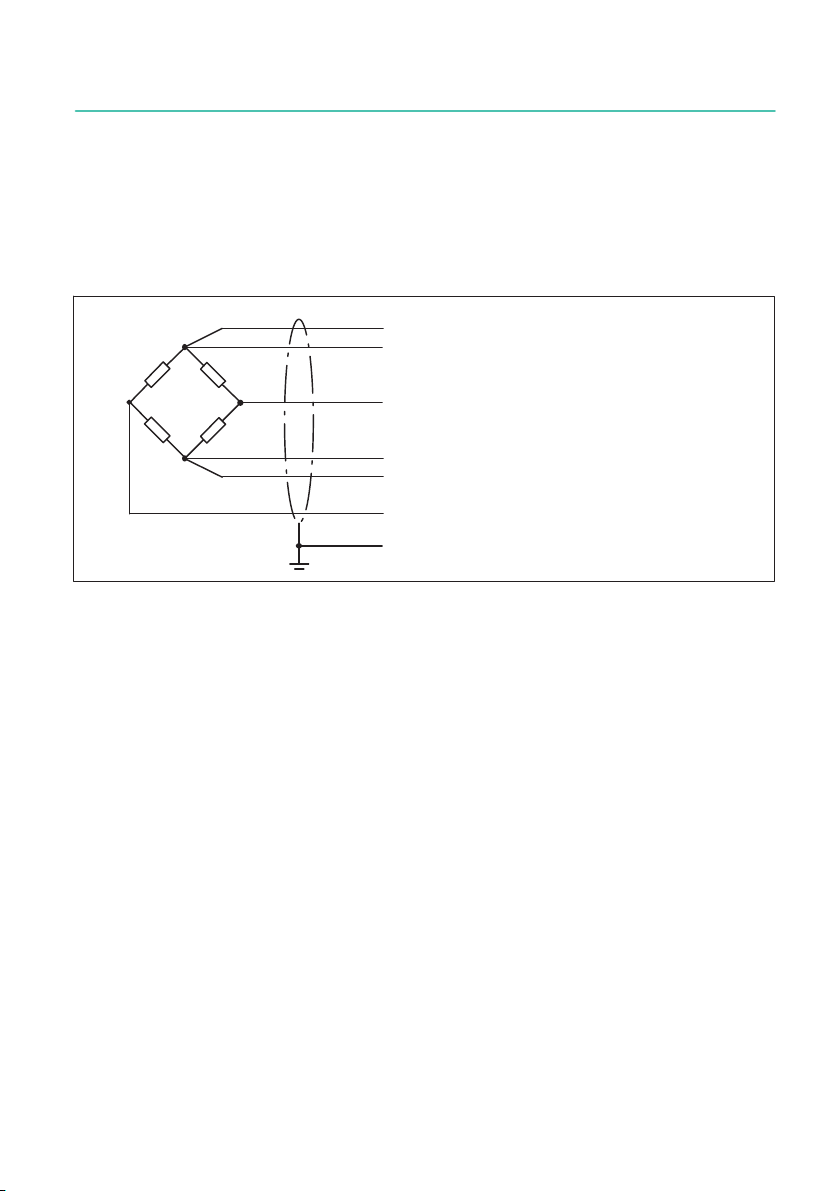

The transducer connection is implemented using the six‐wire technique. The connection

assignment can be taken from the following illustration.

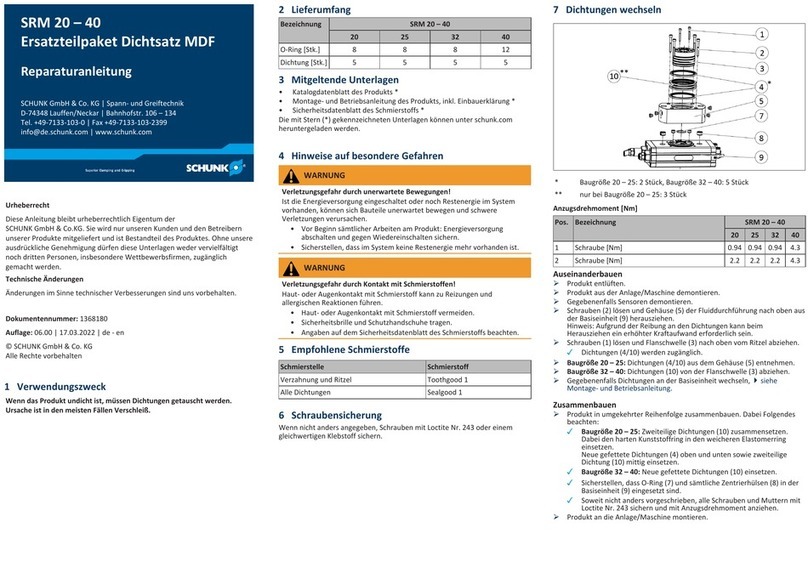

wh (white)

bk (black)

gy (grey)

Shield connected with housing

gr (green)

rd (red)

ye (yellow)

Excitation line (-)

Sensor line

Signal line (+)

bu (blue)

Sensor line

Signal line (-)

Excitation line (+)

Fig. 6.1 Wiring code (6‐wire‐technique)

Electrical and magnetic fields often induce interference voltages in the measurement

circuit.

Therefore:

SUse screened low‐capacitance measurement cables only (HBK cables satisfy this cri

terion).

SDo not route the measuring cable parallel to power and control lines. If this is not pos

sible, protect the measurement cable, e.g. with steel conduit.

SAvoid the stray fields of transformers, motors and conductors.

6.1 Parallel connection of several weighing modules

Transducers can be wired in parallel by joining the transducer cable core ends of the

same color. In this case HBK program offers the junction boxes VKK... and for use in Ex

areas the junction box VKK...EX. The output signal of these junction boxes is the an aver

age of the single output signals.

C16M

CONNECTION

10

CAUTION

Overloading in a single load cell can no longer be detected from the output signal.

6.2 Connections using the four‐wire technique

With connections to amplifiers using the four‐wire technique the cores BU (blue) and GN

(green) should be connected together, as should BK (black) and GR (grey). Please take in

account that this causes deviations to the sensitivity and the temperature coefficient of

sensitivity that this causes.

6.3 Cable extensions

Cable extensions must be screened and of low capacitance. We recommend the use of

HBK cables which satisfy these requirements. With cable extensions it should be ensured

that a proper connection is provided with low contact resistances and good insulation.

When using the six‐wire technique, the effects of resistance changes in the extension

cable are compensated. If you extend the cable with the four-wire technique, the sensitiv

ity deviation can be rectified by adjustment. Temperature effects though are only com

pensated with the operation using the six-wire technique.

The load cell connecting cable should be routed so that any condensed water or damp

ness forming on the cable can drip off. lt must not be led to the load cell. In addition, it

must be ensured that no dampness can penetrate the open end of the cable.

11

C16M

OPERATION

7 OPERATION

STransverse forces during operation, which do not act in the direction of the guide arm,

should be avoided.

SThe play on the transverse guide arm should be checked regularly and adjusted if nec

essary.

SThe play in the tank removal lock should be set to 2 mm.

SThe weighing modules without tank removal lock should not be completely relieved of

the Ioad (the load transfer elements lift off).

C16M

DIMENSIONS

12

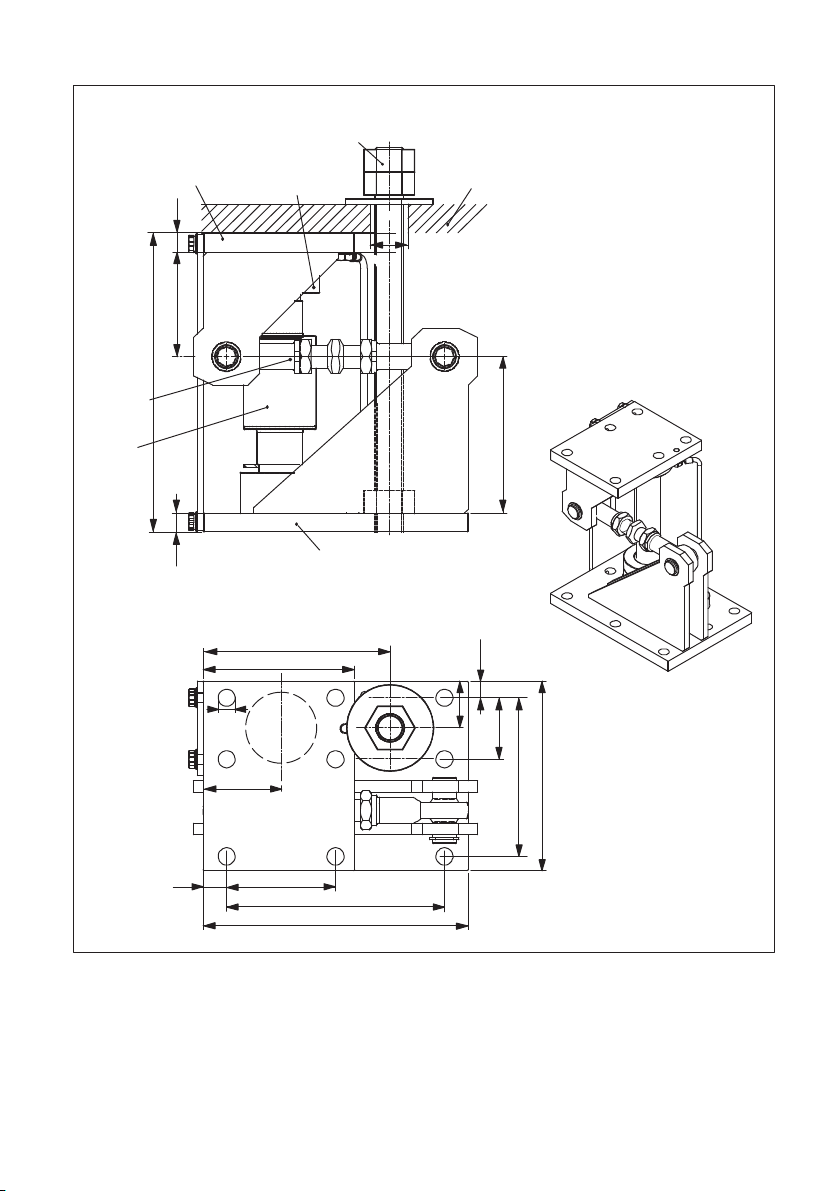

8 DIMENSIONS

222.5

130

15

15

Tank foot

Accessory

1‐ZAC16/MSL(R)40T

Lower module plate

Thrust piece

Upper module plate

Stay rod

C16A/...

∅28

Top view, drawing without tank foot

* Threat for alternative mounting of the anti‐liftoff device (accessory)

C16/M1LB20 t ... 40 t

Drawing without anti‐liftoff

device

280

160

230

115

25

32.5

65 17.5

167.5

200

18

196

88

M20*

Dimensions in mm

(1 mm = 0.03937 inches)

13

C16M

DIMENSIONS

Top view, drawing without tank foot

C16/M1LB60 t

50

197.5

82.5

Ø18

25 115

230

160

17.5

65

167.5

200

280

Stay

rod

Lower module plate

∅40

C16A...

110

315

Upper module plate Thrust piece

Accessory

1‐ZAC16/MSL60T

Tank foot

20

20

165

Dimensions in mm

(1 mm = 0.03937 inches)

C16M

DIMENSIONS

14

C16/M1LB100 t + 200 t

110

165

400

35165

60280

Accessory

1‐ZAC16/MSL100T

Upper module plate

Thrust piece

Tank foot

Stay rod

35 230

330

300

150

Ø22

Top view, drawing without foot tank

Ø50

Lower module plate

100 30

30

380

C16A...

420

350 Dimensions in mm

(1 mm = 0.03937 inches)

15

C16M

DIMENSIONS

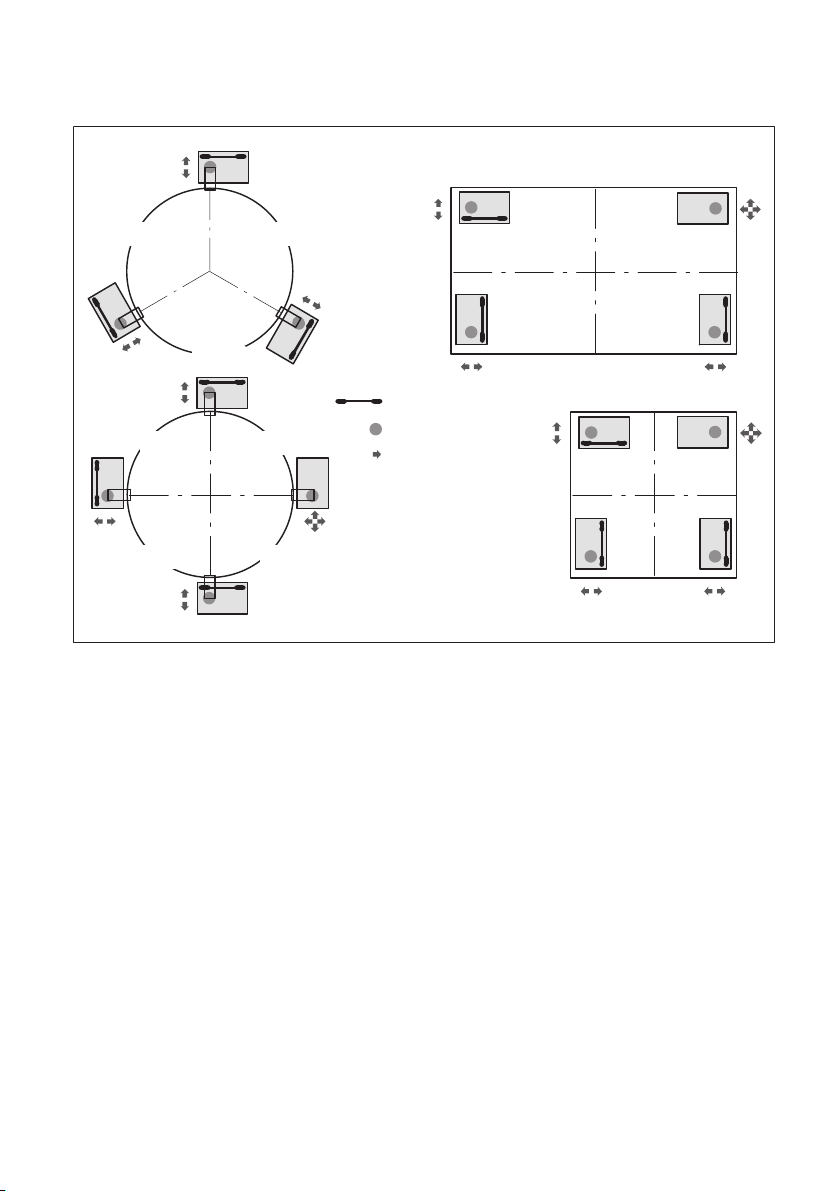

8.1 Mounting example for weighing modules with stay rods

Stay rod

Load introduction

Degree of freedom

120°120°

120°

90°90°

90°90°

Attention:

The represented bearing ar

rangements consider only

weighing‐technical criteria.

The carrying and stability

must be examined and guar

anteed in each case by the

operator.

C16M

SPECIFICATIONS

16

9 SPECIFICATIONS

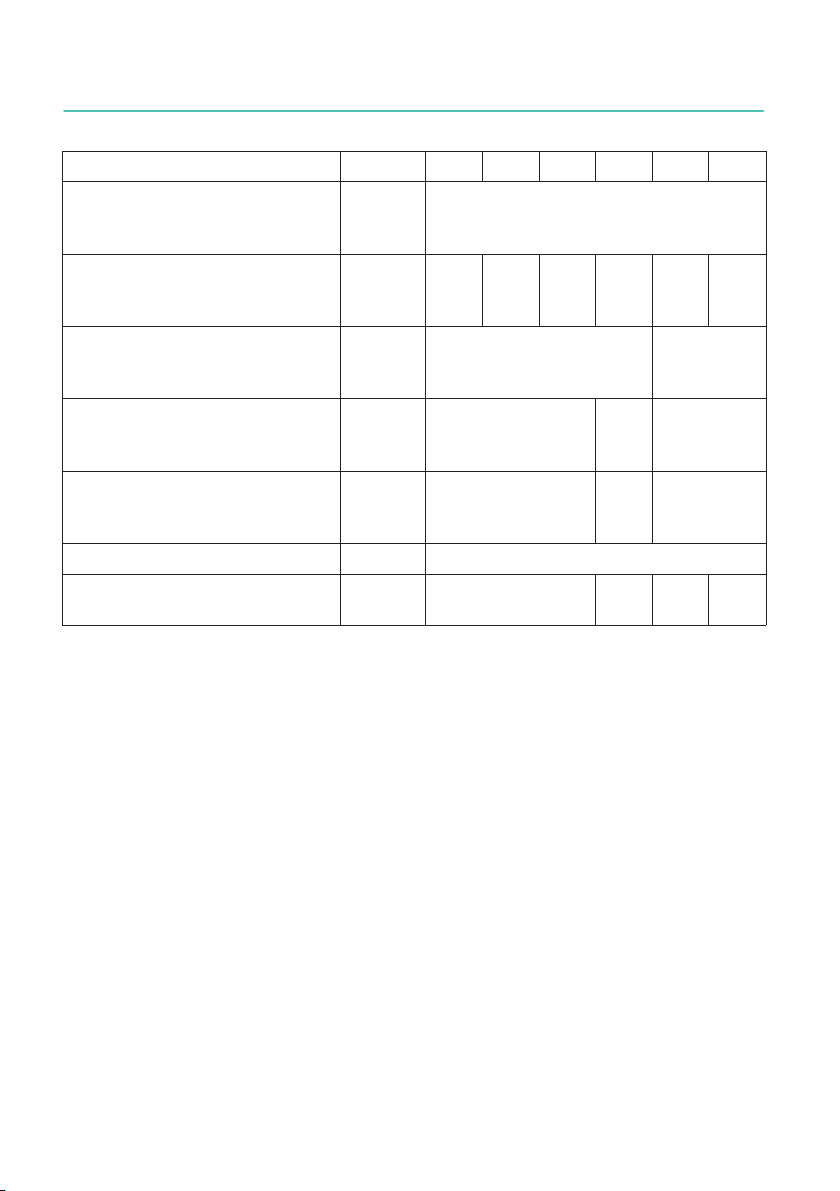

Maximum capacity t 20 30 40 60 100 200

Limit load % of

max.

capacity

150

Restoring force, at 1 mm side

offset vertically to the stay rod

direction

% of

applied

load

0.49 0.76 0.94 0.52 0.48 0.81

Maximum permissible side off

set transverse to the stay rod

axis

mm ±4.0 ±5.0

Maximum permissible

horizontal force in the stay rod

direction

kN 50 100 150

Max. permissible lifting force

when a anti‐liftoff device is

used1)

kN 80 120 240

Material stainless steel or galvanized

Weight, approx. (depending on

the version, incl. load cells)

kg 20 55 105 107

1) An anti‐liftoff device, for example a threaded rod (please see accessories), can be mounted in the

assigned threaded hole.

17

C16M

ACCESSORIES

10 ACCESSORIES, TO BE ORDERED SEPARATELY

Each for two weighing modules (see Dimensions):

1-ZAC16/MSL40T, for C16/MSL20 t...40 t, consists of:

1 piece threaded rod M20x10001), galvanized

6 pieces hexagonal nut M20 DIN 934, galvanized

2 pieces washer DIN 9021, ∅21 mm, galvanized

1-ZAC16/MSLR40T, for C16/MSLR20 t...40 t, consists of:

1 piece threaded rod M20x10001), stainless steel

6 pieces hexagonal nut M20 DIN 934, stainless steel

2 pieces washer DIN 9021, ∅21 mm, stainless steel

1-ZAC16/MSL60T, for C16/MSL60 t, consists of:

1 piece threaded rod M30x10001), galvanized

6 pieces hexagonal nut M30 DIN 934, galvanized

2 pieces washer DIN 9021, ∅31 mm, galvanized

1-ZAC16/MSL100T, for C16/MSL100 t + 200 t, consists of:

4 pieces threaded rod M30x10001), galvanized

12 pieces hexagonal nut M30 DIN 934, galvanized

4 pieces washer DIN 9021, ∅31 mm, galvanized

Further accessory

Fixed bearings with the same installation height as the weighing module are e.g. very

helpful as a dummy for installations. Please find further information in a separate data

sheet.

10.1 Scope of delivery

Weighing module complete mounted with stay rod, thrust pieces, ground wire and load

cell.

1) The threaded rods have to be adapted to the corresponding installation conditions on the customer

side.

C16M

ACCESSORIES

18

Table of contents

Languages:

Other HBK Industrial Equipment manuals