3

T10FM

A0894-5.2 en HBM

Contents Page

Contents

Safety instructions 5..............................................

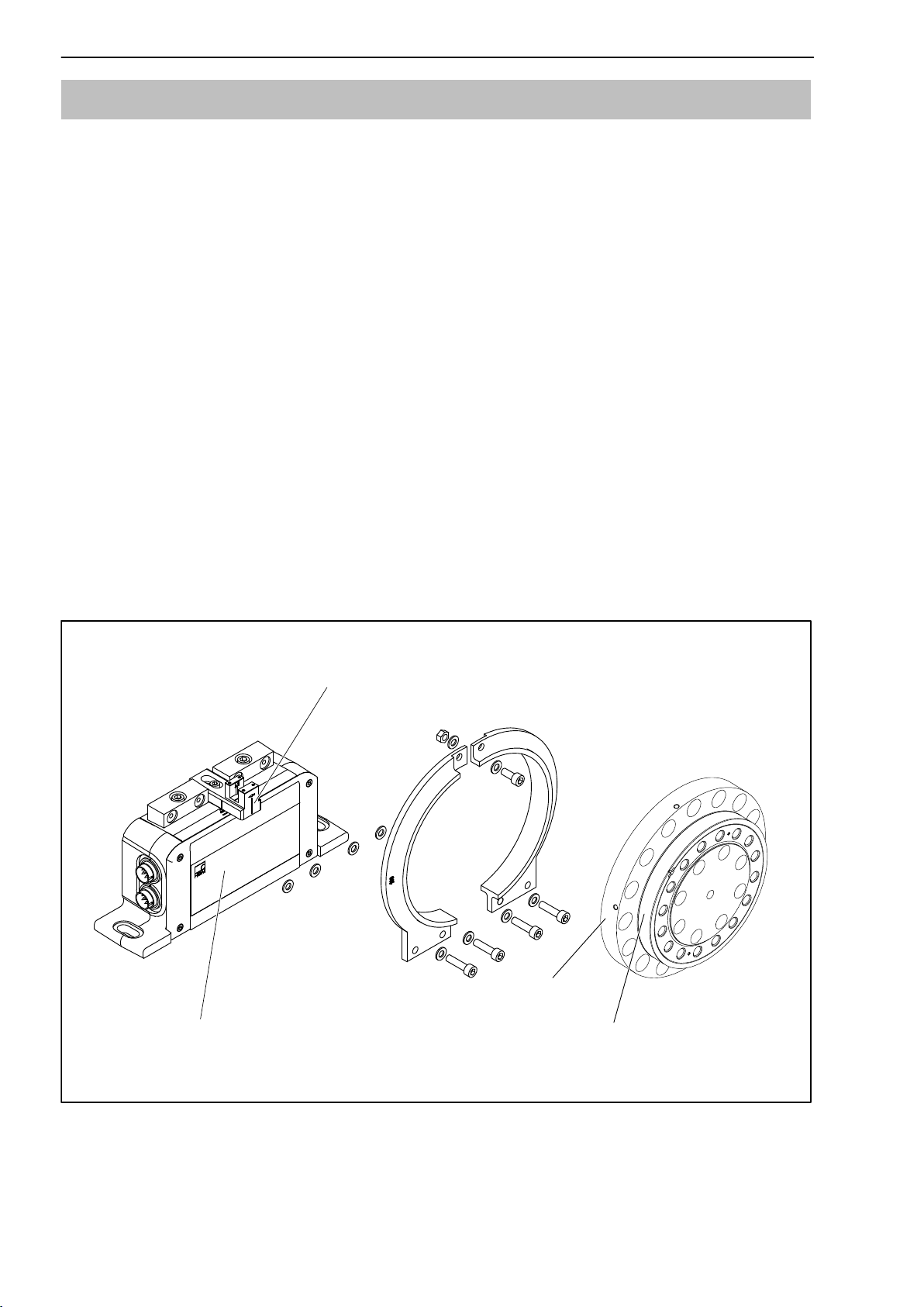

1 Scope of supply 9.............................................

2 Application 9..................................................

3 Structure and mode of operation 10..............................

4 Mechanical installation 11.......................................

4.1 Conditions on site 12........................................

4.2 Installation orientation 12....................................

4.3 Installation options 12.......................................

4.3.1 Installation without dismantling the antenna ring 13.......

4.3.2 Installation with subsequent stator mounting 14...........

4.4 Preparing for the rotor mounting 15...........................

4.5 Mounting the rotor 17.......................................

4.6 Installing the stator 20.......................................

4.7 Installing the clamp fixture 22................................

4.8 Fitting the slotted disc (speed measuring system) 24............

4.9 Aligning the stator (speed measuring system) 25................

5 Electrical connection 27.........................................

5.1 General information 27......................................

5.2 Shielding design 27.........................................

5.3 Connector pin assignment 28................................

5.4 Supply voltage 30..........................................

6 Calibration signal 31............................................

7 Settings 32.....................................................

7.1 Torque output signal 32......................................

7.2 Setting up the zero point 33..................................

7.3 Functional testing 34........................................

7.3.1 Power transmission 34................................

7.3.2 Aligning the speed module 34..........................

7.4 Setting the pulse count 35...................................

7.5 Vibration suppression (hysteresis) 36..........................

7.6 Form of speed output signal 36...............................

7.7 Type of speed output signal 38...............................

8 Loading capacity 39.............................................

8.1 Measuring dynamic torque 39................................