8P3MBP BlueLine

A1710-3.3 enHBM

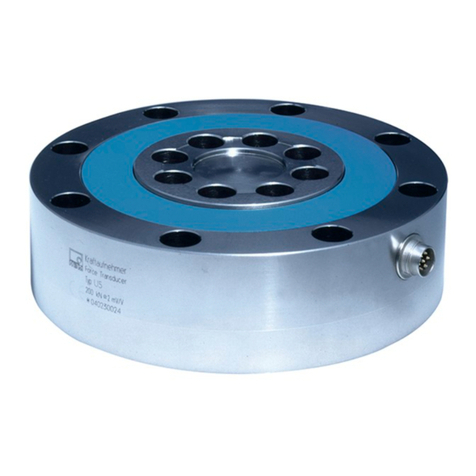

2 Construction and operating mode

BlueLine series pressure transducers (5000 bar, 10,000 bar, 15,000 bar) have

been designed to measure static and dynamic pressures of fluids.

The development of the P3MB BlueLine was based on HBM’s years of expe-

rience in high pressure technology.

Since 1970, devices in accordance with the P3M principle have been working

successfully with a nominal (rated) measuring range up to 3600 bar.

A large number of devices have proved themselves in dynamic applications.

We are now adding to this type series in the high-pressure direction with the

nominal (rated) measuring range 5000 bar and also adding devices with a

range of 10,000 bar and 15,000 bar

The P3MB BlueLine is suitable for dynamic applications:

•The measuring body is made of field-tested, ductile steel

•P3MB measuring bodies for higher pressures with their threaded connector

are made of a single piece of rolled steel – there is no weld or any other

sort of sealing or jointing point.

•The size of the chosen output signal is big enough to enable measured

value adjustments to be made without too much extra work. On the other

hand, the choice of output signal – or the stresses and strains - should be

small enough for dynamic loading to be possible (without the premature

signs of material fatigue).

•Any fluid or gas (vapour) that does not attack these steels is a suitable

measurement medium. The pressure transducer and its threaded connector

are strengthened for the purpose of the pressure connector and can be

installed anywhere. In particular cases there are specific instructions in

Chapter 3 ”Mounting” which must be followed!

The stated properties are protected by FEM calculations and dynamic loading

tests.

The stated measuring body design, chosen for all devices of the P3MB type

series of measuring ranges 500 bar and above, enables the P3MB to meet a

higher safety standard.

Years of reliable use under dynamic load and in rough operating conditions

provide practical proof that the P3MB has a safe and robust design.

Strain gages (S.G.) are attached directly above the measurement hole. They

are coupled to a Wheatstone bridge and to protect them from harsh ambient

conditions, are located in a hermetically sealed reference chamber. This is

made of stainless steel. In this way, the reliability and precision of the trans-

ducers is assured, even if operating conditions are persistently rough.