36000353 Iss 03

Figure 2 – Wall Mounting of Ceramic Heaters

NOTE: IT IS NOT RECOMMENDED TO SWIVEL THE BODY

MORE THATN 800FROM THE VERTICAL

Figure 3 – Minimum Clearances to Adjacent Wall and Ceilings

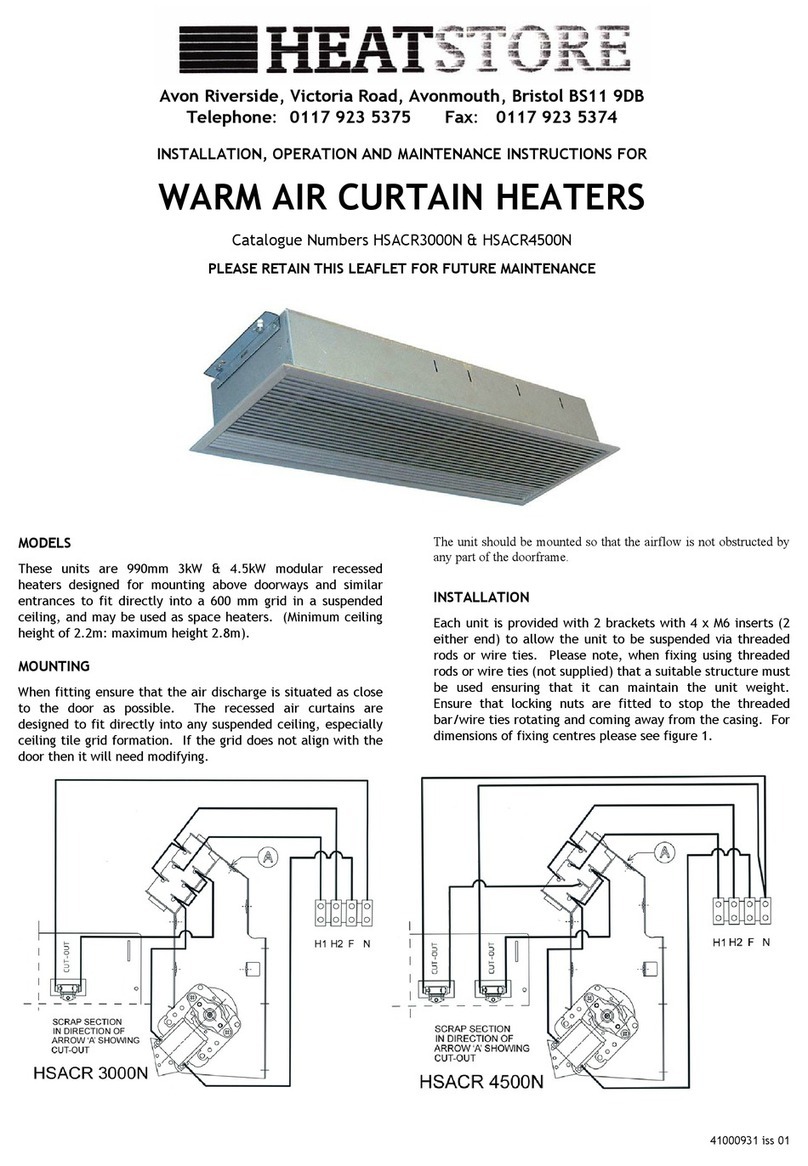

5. ASSEMBLY

Unpack the heater, remove all outer packaging. Although the

appliance’s construction is robust, care should be taken when

assembling the yoke and when securing onto the haning bracket the

yoke/heater assembly.

For all units, assemble the yoke onto the heater body, tightening the

clamp bolts finger tight.

Secure the hanging bracket to the wall with suitable fixings. Ensure

the position of this bracket will allow suitable clearances between the

heater, when fitted, and adjacent walls, ceilings or objects. See Fig 3.

Mount the yoke/heater assembly to the hanging bracket using the bolt,

washer and nut provided.

Finally adjust the direction of the heater to irradiate the desired area

and tighten up all clamping nuts and bolts.

6. ELECTRICAL CONNECTIONS

WARNING: Ensure that the electrical supply is isolated and made

safe before making any electrical connections.

WARNING: The Ceramic heater must be connected to a known

good earth. The terminal block earth terminal is clearly marked with

the standard earth symbol.

WARNING: The 3 and 4.5 kW appliances are supplied with a

1m length of silicone SIHF high temperature cable. If this cable

is replaced, then cable of the same specification MUST be used.

WARNING: When the unit is mounted ensure that the cable

entry point is in the lowest position; this will assist in keeping the

terminals and cable cool.

The heaters should be connected to a 240 Volt single phase supply.

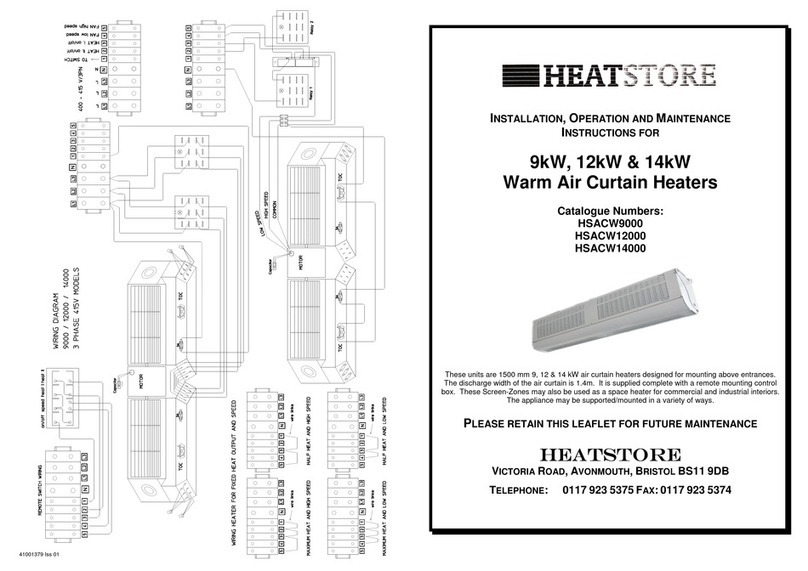

Fig 4 – Circuit Diagrams of Ceramic Heaters

Access to the mains supply terminal block can be obtained by

removing the entry plate at the rear of the heater, the plate being

secured by two screws. The terminal block is fitted to this plate.

The plate is connected to the heater body via an earthing cable.

Ensure that the cables are tightly connected in the terminal block;

ensure that the cables are secure in the cable gland and that the

cables are tight against the entry plate. Ensure that the cables do

not contact the rear of the reflector.

The installation should comply with the requirements of the IEE

wiring regulations and the heaters should be connected to a suitable

isolating switch.

7 CONTROL

In control systems, heaters may be switched on and off, using

suitable contractors, linked to the time switches or thermostats.

Temperature control using either air thermostats or black bulb

thermometers is possible, but the characteristics of radiant heating

make it difficult to achieve comfort control without very careful

choice of the thermostat and its position. Details of suitable circuits

and advice on the correct siting may be obtained from Claudgen.

8. MAINTENANCE

WARNING: Before opening the heater to carry out any

maintenance, ensure that the mains supply is switched off and made

safe. Also ensure that the unit has cooled and is not too hot to

handle.

Because of the high heat output and the open nature of the

construction, there is a substantial convected airflow through the

unit. Any dust in the atmosphere will also be carried up through the

heater and, in due course, deposits of dust may build up within the

unit. It is essential that such deposits are removed at regular

intervals, otherwise they could become a fire hazard. To maintain

the efficiency of the unit, the reflector should be cleaned regularly.

Before cleaning ensure the appliance is switched OFF and has cooled

down. Cleaning the reflector should require no more than a damp

cloth. Avoid using any abrasive cleaners. It should not be necessary

to remove the ceramic emitters during cleaning; carefully wipe

around them.

9. SPARES

HSCEH7115N

HSC1500CE – Spare Emitter (1.5 kW) suits: HSCEH7230N

HSCEH7345N

In the interest of progress the Company reserves the right to vary

specification from time to time without notice. The material listed is

offered subject to the Company’s General Conditions of Sale, a copy

of which may be obtained on request