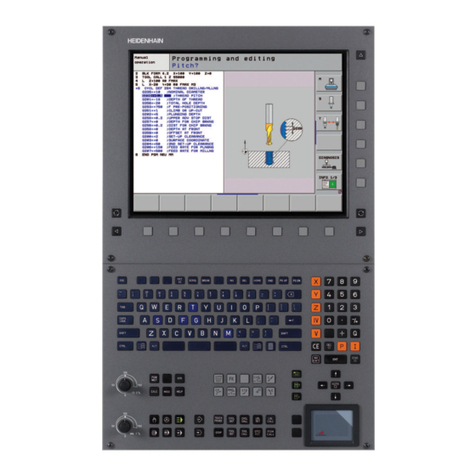

Fundamentals | Software and features

10 HEIDENHAIN | MANUALplus 620 | User's Manual | 12/2017

Software and features

This manual describes functions that are available in the control

with NC software number 548431-05.

The programming of smart.Turn and DIN PLUS are not included in

this manual. These functions are described in the User's Manual

for smart.Turn and DIN PLUS Programming (ID 685556-xx). Please

contact HEIDENHAIN if you need this user's manual.

The machine manufacturer adapts the usable features of the

control to his machine by setting the machine parameters. Some

of the functions described in this manual may not be among the

features possible on your machine tool.

Control functions that may not be available on your machine

include:

Positioning of spindle (M19) and driven tool

Machining with the C or Y axis

Machining with the B axis

In order to find out about the specific support for your machine,

please contact the machine manufacturer.

Many machine manufacturers and HEIDENHAIN offer programming

courses. We recommend these courses as an effective way of

improving your programming skill and sharing information and ideas

with other users of the control.

HEIDENHAIN also offers the DataPilot MP 620 or DataPilot CP 640

software for PCs, which is designed for use with the respective

control. The DataPilot is suitable for both shop-floor programming

as well as off-location program creation and testing. It is also

ideal for training purposes. The DataPilot can be run on PCs with

WINDOWS operating systems.

Intended place of operation

The control complies with the limits for a Class A device in

accordance with the specifications in EN 55022, and is intended for

use primarily in industrially-zoned areas.

Legal information

This product uses open-source software. Further information is

available on the control under:

Organization mode of operation

LICENSE INFO soft key