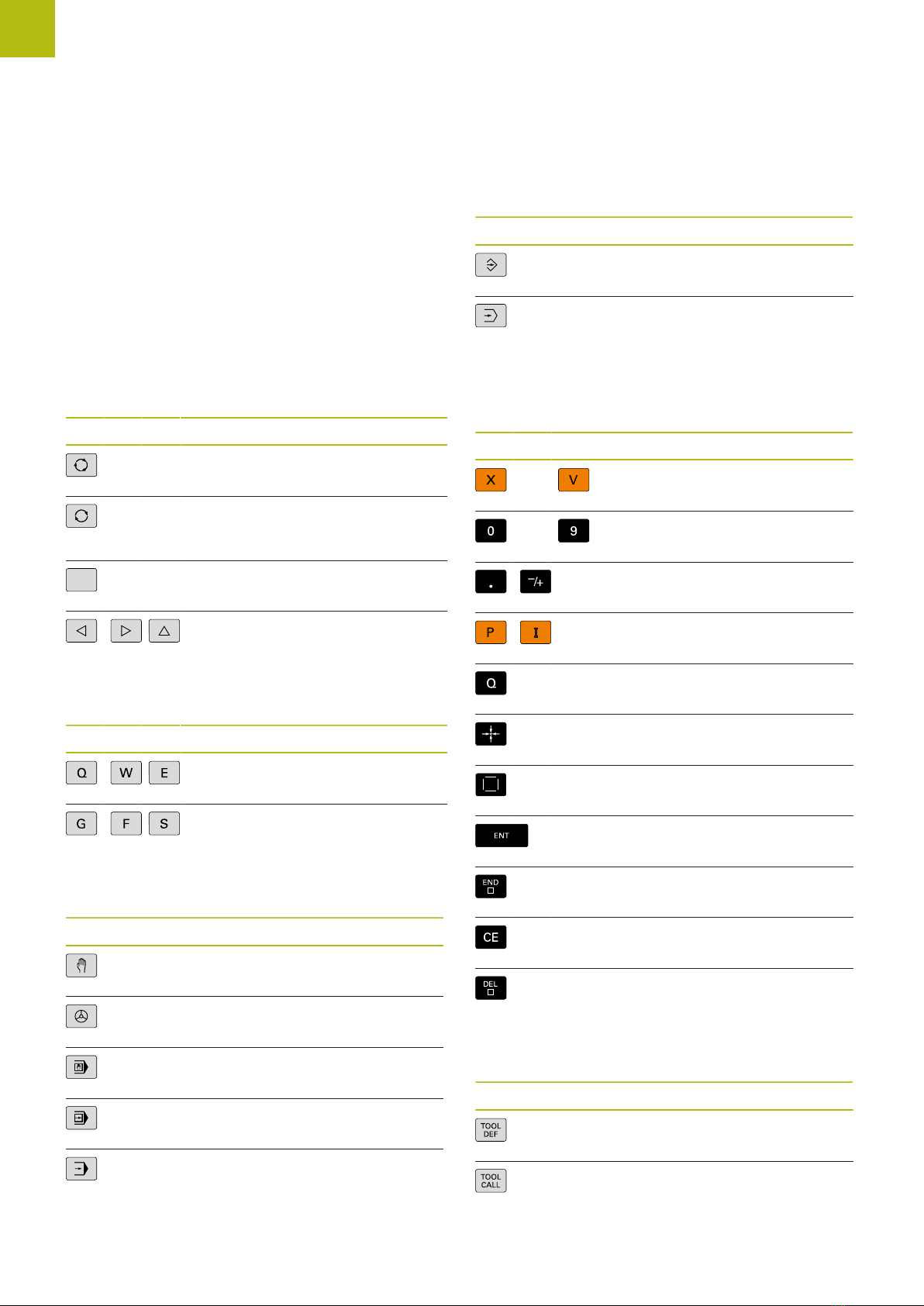

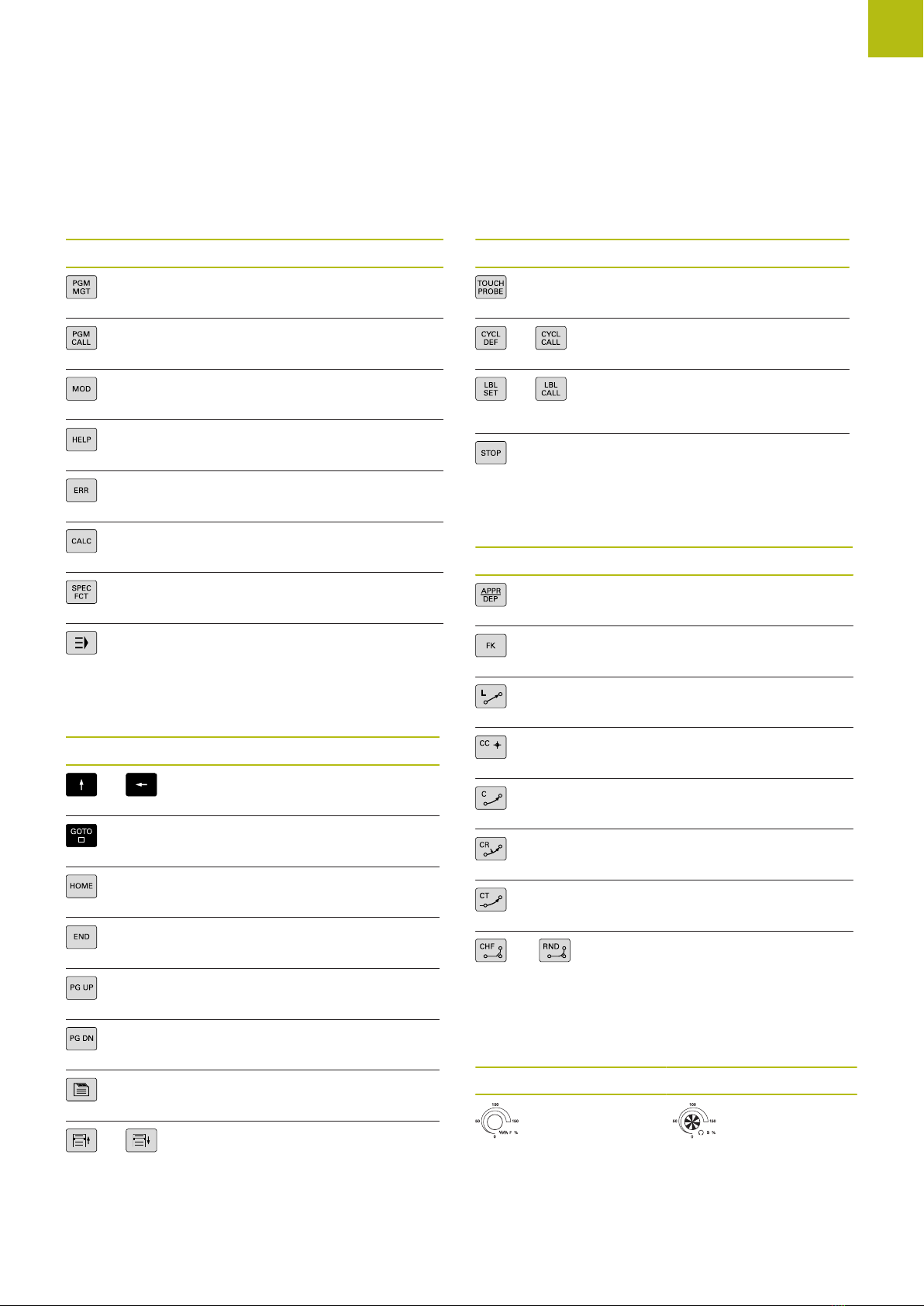

Fundamentals | Control model, software and features

10 HEIDENHAIN | TNC 640 | ISO Programming User's Manual | 10/2017

CAD Import (option 42)

CAD import Support for DXF, STEP and IGES

Adoption of contours and point patterns

Simple and convenient specification of presets

Selecting graphical features of contour sections from conversational

programs

Adaptive Feed Control – AFC (option 45)

Adaptive Feed Control Milling:

Recording the actual spindle power by means of a teach-in cut

Defining the limits of automatic feed rate control

Fully automatic feed control during program run

Turning (option 50):

Cutting force monitoring during machining

KinematicsOpt (option 48)

Optimizing the machine kinematics Backup/restore active kinematics

Test active kinematics

Optimize active kinematics

Mill-Turning (option 50)

Milling and turning modes Functions:

Switching between Milling/Turning mode of operation

Constant surface speed

Tool-tip radius compensation

Turning cycles

Cycle 880: Gear hobbing (option 50 and option 131)

KinematicsComp (option 52)

Three-dimensional compensation

Export license required

Compensation of position and component errors

3D-ToolComp (option 92)

3-D tool radius compensation

depending on the tool’s contact

angle

Export license required

Compensate the deviation of the tool radius depending on the tool’s

contact angle

Compensation values in a separate compensation value table

Prerequisite: Working with surface normal vectors (LN blocks)

Extended Tool Management (option 93)

Extended tool management Python-based

Advanced Spindle Interpolation (option 96)

Interpolating spindle Interpolation turning:

Cycle 291: Interpolation turning, coupling

Cycle 292: Interpolation turning, contour finishing